Blog by Steve Laug

The grain on this Parker is absolutely stunning. The sandblast follows the cross grain around the bowl with a deep, craggy blast. The shape is a classic poker or Cherrywood. It is stamped on underside of the shank with the brand name Parker over Super in a Diamond over Briarbark over Made in London England. Next to the shank/stem union it’s stamped with the shape no. 809 and a circled 4 designating the bowl size. There is a Diamond P on top of the stem. The finish is in decent shape with a medium to dark brown stain. When I received the pipe it had a thick cake in the bowl and the lava had overflowed onto the rim filling in the grooves of the sandblast. It is hard to tell if there was rim damage as it is so caked and encrusted on the rim. The stem had calcification from a softee bit on the first inch from the button forward. There were deep tooth marks on top & bottom side of the stem near the button. The following four pictures show the general condition of the pipe when I brought it to my work table.

The next photo shows the rim top and the thickness of the cake. The cake was very hard and it would take some serious work to remove it from the bowl. It also looked to me like there was rim edge and bowl damage on the front left side. Once I had reamed it I would know for sure. (Just a side note – this is where I really appreciate my brother’s clean up work. I really like working on pre-cleaned pipes.)

The next photo shows the rim top and the thickness of the cake. The cake was very hard and it would take some serious work to remove it from the bowl. It also looked to me like there was rim edge and bowl damage on the front left side. Once I had reamed it I would know for sure. (Just a side note – this is where I really appreciate my brother’s clean up work. I really like working on pre-cleaned pipes.) The cake was very hard. I have found that on some of these older pipes the tobacco must have been significantly different as the cake is like concrete whereas on the newer tobaccos it is never this hard. Could it be just the fact that the pipe has been sitting for a long time? I reamed it with the PipNet reamer starting with the smallest cutting head and working my way up to the third head. I used the Savinelli Fitsall Pipe Knife to work on the cake as well. It took a lot of time to get the pipe cleaned out. I probably spent over 45 minutes just reaming this bowl. The second photo below shows the bowl at the end of the 45 minutes of work. Still work to do on it as you can see the remnants of the cake on the walls. I used the Savinelli Fitsall to clean it up further.

The cake was very hard. I have found that on some of these older pipes the tobacco must have been significantly different as the cake is like concrete whereas on the newer tobaccos it is never this hard. Could it be just the fact that the pipe has been sitting for a long time? I reamed it with the PipNet reamer starting with the smallest cutting head and working my way up to the third head. I used the Savinelli Fitsall Pipe Knife to work on the cake as well. It took a lot of time to get the pipe cleaned out. I probably spent over 45 minutes just reaming this bowl. The second photo below shows the bowl at the end of the 45 minutes of work. Still work to do on it as you can see the remnants of the cake on the walls. I used the Savinelli Fitsall to clean it up further. I picked at the lava on the rim with a dental pick to loosen the rock hard buildup and a brass bristle brush to clean off the debris once I had it loosened. The photo below shows the cleaned out bowl and the cleaned rim. Notice the damage to the front left inner edge of the rim.

I picked at the lava on the rim with a dental pick to loosen the rock hard buildup and a brass bristle brush to clean off the debris once I had it loosened. The photo below shows the cleaned out bowl and the cleaned rim. Notice the damage to the front left inner edge of the rim. With the bowl cleaned and reamed I turned my attention to the internals. I scrubbed out the mortise and the airway in the shank and the stem with pipe cleaners, cotton swabs and alcohol. It took some coaxing with the swabs and cleaners to finally get the internals free of buildup and debris.

With the bowl cleaned and reamed I turned my attention to the internals. I scrubbed out the mortise and the airway in the shank and the stem with pipe cleaners, cotton swabs and alcohol. It took some coaxing with the swabs and cleaners to finally get the internals free of buildup and debris. The stem had a thick calcified buildup on the first inch from the button forward on both sides. This too was rock hard. I sanded the calcification off the surface of the vulcanite. Doing so revealed the tooth dents on the surface of the both sides of the stem near the button.

The stem had a thick calcified buildup on the first inch from the button forward on both sides. This too was rock hard. I sanded the calcification off the surface of the vulcanite. Doing so revealed the tooth dents on the surface of the both sides of the stem near the button. I “painted” the stem with a Bic lighter flame to raise the tooth dents as much as possible. While they came up significantly some of the edges were sharp and the dents would rise no more. I wiped the stem down with some alcohol to clean out the dents and filled them in with black super glue. I set the stem aside so that the repairs would cure and headed off to work.

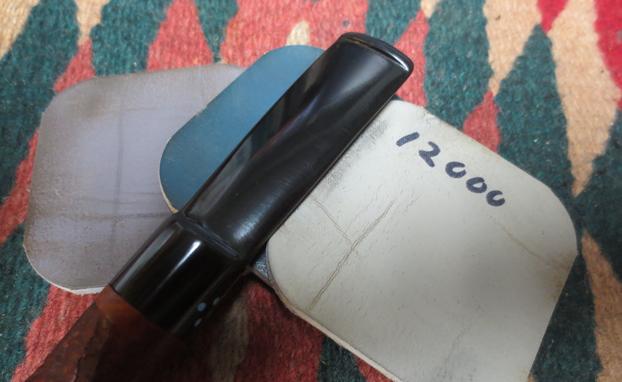

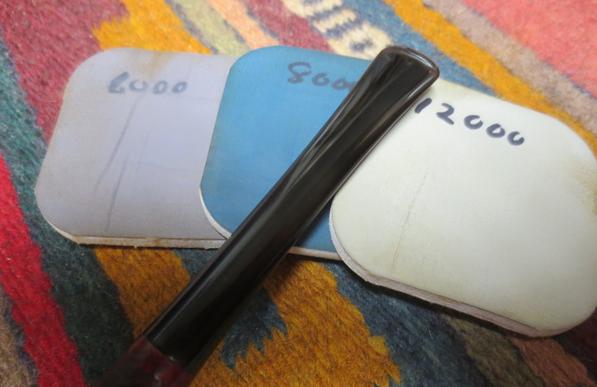

I “painted” the stem with a Bic lighter flame to raise the tooth dents as much as possible. While they came up significantly some of the edges were sharp and the dents would rise no more. I wiped the stem down with some alcohol to clean out the dents and filled them in with black super glue. I set the stem aside so that the repairs would cure and headed off to work. When I returned in the evening the patches had cured. I sanded the repairs with 220 grit sandpaper and sharpened the 90 degree angle of the button with needle files. I sanded the stem surface some more to remove the oxidation.

When I returned in the evening the patches had cured. I sanded the repairs with 220 grit sandpaper and sharpened the 90 degree angle of the button with needle files. I sanded the stem surface some more to remove the oxidation. I decided to take a bit of time and work on the bowl so I set the stem aside for a while. I touched up the worn spots on the rim and on the shank end with a dark brown stain pen. The colour was a perfect match to the rest of the bowl and it blended in very well.

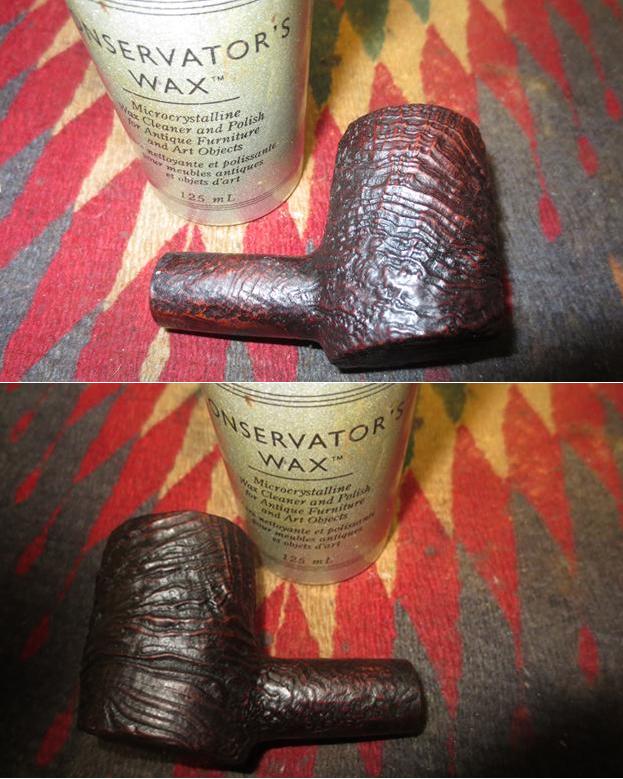

I decided to take a bit of time and work on the bowl so I set the stem aside for a while. I touched up the worn spots on the rim and on the shank end with a dark brown stain pen. The colour was a perfect match to the rest of the bowl and it blended in very well.  I waxed the briar with Conservator’s Wax. It is a soft rub on past that work well with sandblast and rusticated finishes. I buff it with a shoe brush and I am able to polish even the deep grooves in the grain so that no wax sits in those and hardens, dulling the finish. I lightly buffed the bowl with a soft microfibre cloth to raise the shine. The photos below show the bowl at this point in the process.

I waxed the briar with Conservator’s Wax. It is a soft rub on past that work well with sandblast and rusticated finishes. I buff it with a shoe brush and I am able to polish even the deep grooves in the grain so that no wax sits in those and hardens, dulling the finish. I lightly buffed the bowl with a soft microfibre cloth to raise the shine. The photos below show the bowl at this point in the process.

I decided to polish the stem using a different method than my normal routine. I sanded it with 1500-2400 grit micromesh sanding pads to remove the scratching in the vulcanite. I use a product that I have used before called Before & After Pipe Stem Deoxidizer to work over the remaining oxidation. I repeated the process until the vulcanite was clean. I polished it with the Before & After Pipe Polish in both Fine and Extra Fine grits. I rubbed the stem down with a soft cotton pad to remove the polishing compound and buffed it with Blue Diamond on the buffing wheel. I rubbed it down with a coat of Obsidian Oil and set it aside to dry.

I decided to polish the stem using a different method than my normal routine. I sanded it with 1500-2400 grit micromesh sanding pads to remove the scratching in the vulcanite. I use a product that I have used before called Before & After Pipe Stem Deoxidizer to work over the remaining oxidation. I repeated the process until the vulcanite was clean. I polished it with the Before & After Pipe Polish in both Fine and Extra Fine grits. I rubbed the stem down with a soft cotton pad to remove the polishing compound and buffed it with Blue Diamond on the buffing wheel. I rubbed it down with a coat of Obsidian Oil and set it aside to dry. I used an artist’s fine bristle brush and white acrylic paint to fill in the Parker Diamond P stamp on the stem. I wiped it down afterwards and lightly buffed it with Blue Diamond to remove the excess paint.

I used an artist’s fine bristle brush and white acrylic paint to fill in the Parker Diamond P stamp on the stem. I wiped it down afterwards and lightly buffed it with Blue Diamond to remove the excess paint. I buffed the pipe and stem with Blue Diamond on the buffing wheel – with a light touch on the bowl. The finish shows up beautifully, the sandblasted ring grain standing out front. It is one of those rugged blasts that are a tactile wonder as it heats up during a smoke. I gave the bowl another coat of Conservator’s Wax and the stem multiple coats of carnauba followed by a buff with a clean buffing pad. I hand buffed the bowl with a shoe brush and then with a microfibre cloth to deepen the shine. The finished pipe is shown in the photos below. The dimensions of the pipe are Length: 6 inches, Height: 2 inches, Outer diameter of the bowl: 1 1/2 inches, Chamber diameter: 7/8 inches. The contrast of the dark brown and a medium brown that shines through give the finish a rich patina. The bowl has been cleaned and the entire pipe is ready to smoke. The stem is in great shape. The tooth marks have been removed though there is slight scratching on the vulcanite. It is a beautiful pipe, just a little big for my liking or I would hang on to it. I will be putting it on the rebornpipes store soon. If you are interested in adding it to your collection email me at slaug@uniserve.com or send me a message on Facebook. Thanks for looking.

I buffed the pipe and stem with Blue Diamond on the buffing wheel – with a light touch on the bowl. The finish shows up beautifully, the sandblasted ring grain standing out front. It is one of those rugged blasts that are a tactile wonder as it heats up during a smoke. I gave the bowl another coat of Conservator’s Wax and the stem multiple coats of carnauba followed by a buff with a clean buffing pad. I hand buffed the bowl with a shoe brush and then with a microfibre cloth to deepen the shine. The finished pipe is shown in the photos below. The dimensions of the pipe are Length: 6 inches, Height: 2 inches, Outer diameter of the bowl: 1 1/2 inches, Chamber diameter: 7/8 inches. The contrast of the dark brown and a medium brown that shines through give the finish a rich patina. The bowl has been cleaned and the entire pipe is ready to smoke. The stem is in great shape. The tooth marks have been removed though there is slight scratching on the vulcanite. It is a beautiful pipe, just a little big for my liking or I would hang on to it. I will be putting it on the rebornpipes store soon. If you are interested in adding it to your collection email me at slaug@uniserve.com or send me a message on Facebook. Thanks for looking.