Blog by Steve Laug

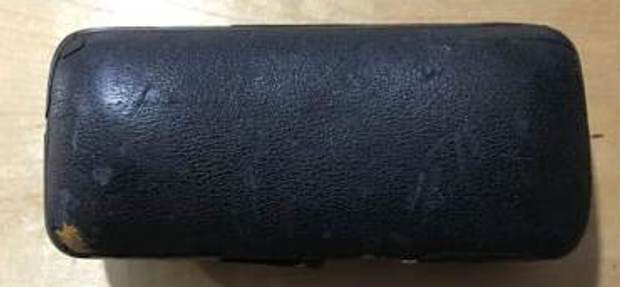

The next pipe on the table is a House of Robertson Rusticated Dublin with a tapered, vulcanite Bite Through stem. The rustication on the briar is very tactile and deep. There are grooves around the bowl and shank and those have been deeply rusticated. The pipe is stamped on the left side of the diamond shank and reads House of [over] Robertson. It really is a beautiful pipe and the rustic finish works very well with the diamond twin bore saddle stem. The fellow who sent it to me is a previous customer and in his box were two pipes with a snapped tenon – the Radice (which I have repaired already) and this House of Robertson. This one was quite dirty with a thick cake in the bowl and overflowing onto the rim top. There was some burn damage on the inner edge of the rim around the bowl and the pipe was dull and dusty. The tenon had snapped off cleanly at the shank end with no damage to the briar. The stem had tooth marks on both the top and underside ahead of the button and was also dirty. I took some photos of the pipe before I started my work on it.

I took a close up photo of the rim top to show the condition of the bowl and inner edge. You can see the damage on the inner edge of the rim. It will become more evident once the bowl has been reamed and cleaned. The photos of the stem show the tooth marks and chatter on both sides near the button.

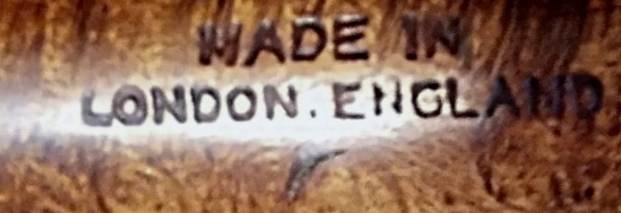

I took a close up photo of the rim top to show the condition of the bowl and inner edge. You can see the damage on the inner edge of the rim. It will become more evident once the bowl has been reamed and cleaned. The photos of the stem show the tooth marks and chatter on both sides near the button. I took photos of the stamping on the left side of the diamond shank to capture how the classic House of Robertson signature looked.

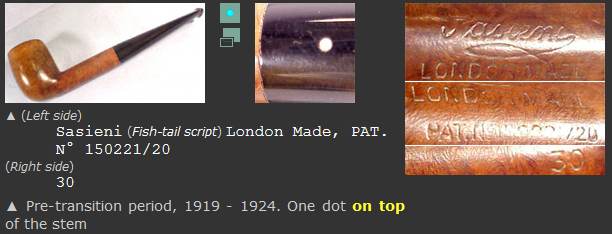

I took photos of the stamping on the left side of the diamond shank to capture how the classic House of Robertson signature looked. House of Robertson pipes were made by Thayne Robertson in Boise, Idaho. He did some beautiful work and all had the etched stamp on them. I have worked on many of these pipes over the years and done the research on the brand previously. Here is a link to one of the pipes where I have included background information (https://rebornpipes.wordpress.com/wp-admin/post.php?post=60954&action=edit&classic-editor).

House of Robertson pipes were made by Thayne Robertson in Boise, Idaho. He did some beautiful work and all had the etched stamp on them. I have worked on many of these pipes over the years and done the research on the brand previously. Here is a link to one of the pipes where I have included background information (https://rebornpipes.wordpress.com/wp-admin/post.php?post=60954&action=edit&classic-editor).

“House of Robertson” was in business for many years, but alas, closed their doors in 1999. They were located in Boise, Idaho. They are noted for making rather large and interesting pipes. Thayne Robertson was a Master Mason, AF & AM, and started the shop about 1947 and his son Jon started working there in 1970 when he finished college, along with Thayne’s daughter. Thayne and his son started making the big pipes at that time, and made them together until 1987 when Thayne passed away. Jon kept the store and his sister moved on to other things. The House of Robertson appears to have closed around 1999. https://pipedia.org/wiki/Robertson

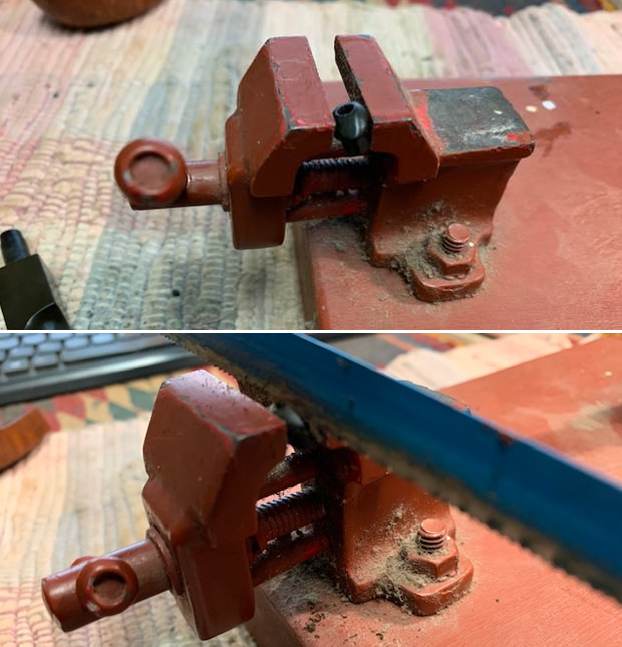

I began my work on this pipe by pulling the broken tenon from the shank. I generally use a dry wall screw and twist it into the airway of the broken tenon and wiggle it free. This one was stuck. I put it in the freezer while I had lunch and afterward it came out quite easily. I went through my replacement tenons and found one that would work on this stem.

I sanded the broken end of the tenon remaining on the stem with a sanding drum on my Dremel. I also sanded the diameter of the new tenon at the same time to get a good fit in the shank. I took photos of the tenon in the shank at this point to show the fit.

I sanded the broken end of the tenon remaining on the stem with a sanding drum on my Dremel. I also sanded the diameter of the new tenon at the same time to get a good fit in the shank. I took photos of the tenon in the shank at this point to show the fit.

I drilled out the airway on the stem with successively larger drill bits to accommodate the tenon. The last bit was ¼ inch which is perfect for the tenon.

I drilled out the airway on the stem with successively larger drill bits to accommodate the tenon. The last bit was ¼ inch which is perfect for the tenon.

I slipped the stem over the tenon and took photos of the pipe at this point. It looks very good.

I slipped the stem over the tenon and took photos of the pipe at this point. It looks very good.

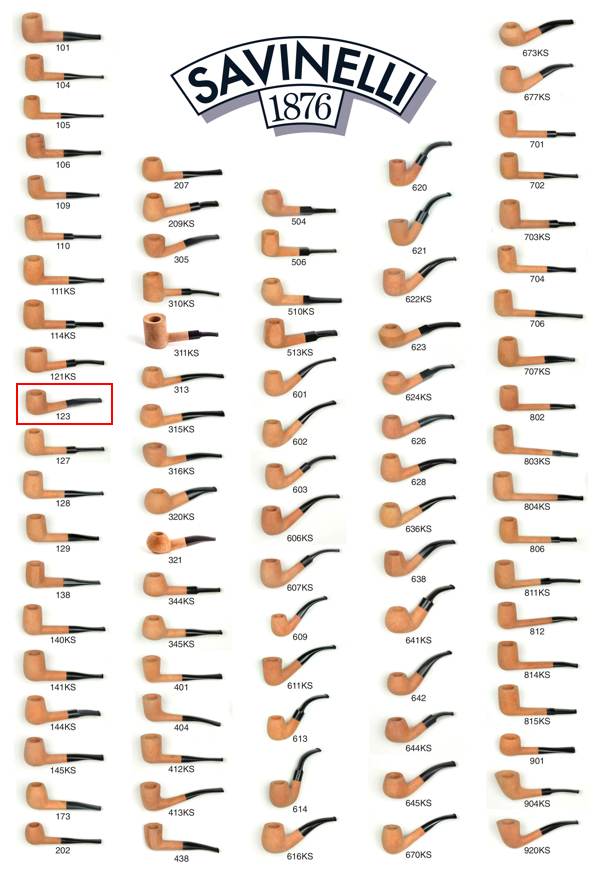

With that done I turned my attention to the bowl. I reamed it with a PipNet reamer and took the cake back to briar. I cleaned up the remnants with a Savinelli Fitsall pipe knife. I sanded the bowl walls with a piece of dowel wrapped with 220 grit sandpaper.

With that done I turned my attention to the bowl. I reamed it with a PipNet reamer and took the cake back to briar. I cleaned up the remnants with a Savinelli Fitsall pipe knife. I sanded the bowl walls with a piece of dowel wrapped with 220 grit sandpaper.

I cleaned up the rim top with a brass bristle wire brush to remove the lava in the sandblast and a bit of the burn damage on the inner edge of the bowl.

I cleaned up the rim top with a brass bristle wire brush to remove the lava in the sandblast and a bit of the burn damage on the inner edge of the bowl. I cleaned out the internals on the stem and shank with pipe cleaners, cotton swabs and alcohol until they were clean.

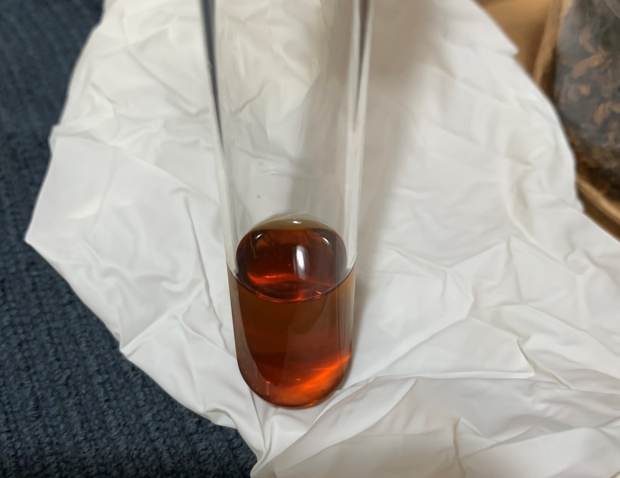

I cleaned out the internals on the stem and shank with pipe cleaners, cotton swabs and alcohol until they were clean. I rubbed down the bowl with Before & After Restoration Balm to clean, enliven and protect the briar. I worked it into the blast with a horsehair shoe brush. I let it sit and do its magic for 10 minutes and then buffed it off with a soft cloth.

I rubbed down the bowl with Before & After Restoration Balm to clean, enliven and protect the briar. I worked it into the blast with a horsehair shoe brush. I let it sit and do its magic for 10 minutes and then buffed it off with a soft cloth.

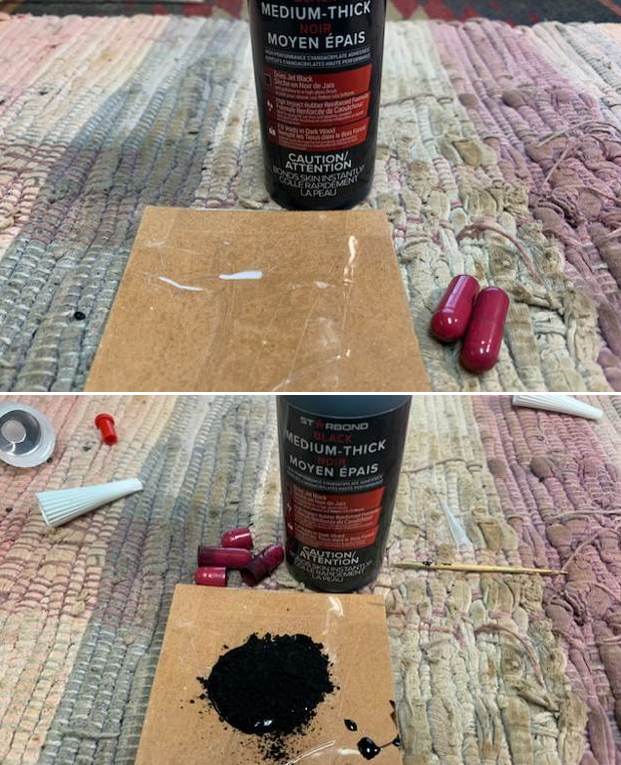

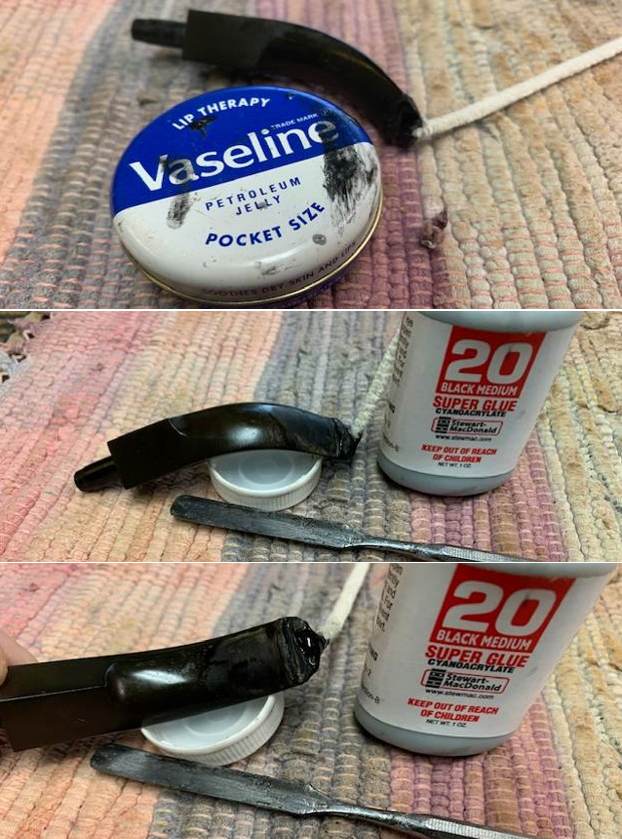

I set the bowl aside and turned my attention to the vulcanite stem. I glued the new tenon in the shank with black super glue. While it cured, I “painted” the surface of the vulcanite stem with the flame of a lighter to lift the tooth chatter and marks. Many of them lifted significantly with the heat. Those that remained I filled in with black super glue and set the stem aside to cure.

I set the bowl aside and turned my attention to the vulcanite stem. I glued the new tenon in the shank with black super glue. While it cured, I “painted” the surface of the vulcanite stem with the flame of a lighter to lift the tooth chatter and marks. Many of them lifted significantly with the heat. Those that remained I filled in with black super glue and set the stem aside to cure.

Once it had cured I flattened out the repairs with a small flat file. I sanded them with 220 grit sandpaper to further flatten them out and blend them into the surrounding area. I started polishing the stem with 400 grit wet dry sandpaper.

Once it had cured I flattened out the repairs with a small flat file. I sanded them with 220 grit sandpaper to further flatten them out and blend them into the surrounding area. I started polishing the stem with 400 grit wet dry sandpaper.

I polished the vulcanite bite through stem with micromesh sanding pads – dry sanding with 1500-12000 grit pads. I wiped the stem down after each pad with Obsidian Oil. I finished the polishing with Before & After Stem Polishes – both Fine and Extra Fine. I wiped the stem down with a cloth impregnated with Obsidian Oil to protect and give the deep shine to the stem.

I polished the vulcanite bite through stem with micromesh sanding pads – dry sanding with 1500-12000 grit pads. I wiped the stem down after each pad with Obsidian Oil. I finished the polishing with Before & After Stem Polishes – both Fine and Extra Fine. I wiped the stem down with a cloth impregnated with Obsidian Oil to protect and give the deep shine to the stem.

I was happy to be finished with this beautiful House of Robertson Rusticated Diamond Shank Dublin. The vulcanite stem fit well and looked good with the rich finish of the rusticated bowl and shank. I lightly buffed the pipe with Blue Diamond on the buffing wheel and gave the bowl and shank multiple coats of Conservator’s Wax. I buffed it with a clean buffing wheel to raise the shine. I hand buffed it with a microfiber cloth to deepen the shine. The House of Robertson’s Dublin is a great looking pipe that has an amazing looking rustication. The dimensions of the pipe are Length: 5 ½ inches, Height: 2 inches, Outer Diameter of the bowl: 1 ½ inches, Diameter of the chamber: ¾ of and inch. The weight of the pipe is 42 grams/1.48 ounces. I will be packing it up to send back to my friend in Idaho along with the first pipe – the Radice Silk Cut Billiard. Thanks for reading the blog.

I was happy to be finished with this beautiful House of Robertson Rusticated Diamond Shank Dublin. The vulcanite stem fit well and looked good with the rich finish of the rusticated bowl and shank. I lightly buffed the pipe with Blue Diamond on the buffing wheel and gave the bowl and shank multiple coats of Conservator’s Wax. I buffed it with a clean buffing wheel to raise the shine. I hand buffed it with a microfiber cloth to deepen the shine. The House of Robertson’s Dublin is a great looking pipe that has an amazing looking rustication. The dimensions of the pipe are Length: 5 ½ inches, Height: 2 inches, Outer Diameter of the bowl: 1 ½ inches, Diameter of the chamber: ¾ of and inch. The weight of the pipe is 42 grams/1.48 ounces. I will be packing it up to send back to my friend in Idaho along with the first pipe – the Radice Silk Cut Billiard. Thanks for reading the blog.