by Kenneth Lieblich

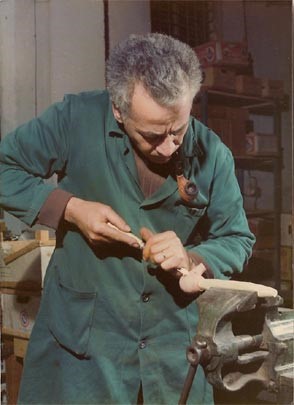

This pipe has a bit of a story to it. Every once in a while, I pull out a pipe from my late grandfather and clean it up. The pipe today is a charming hexagonal panelled billiard, with a square shank, and a straight square stem. I do not know where my grandfather acquired it (or under what circumstances), so I asked my father but he didn’t know either. It doesn’t really seem like the sort of pipe he would have selected, so I wonder if it was given to him. After my grandfather died, his pipes ended up wrapped in newspaper, in a cardboard box, in a basement – as so many grandfather’s pipes do. In this case, it was the basement of my parents’ home. About fifteen years ago, my parents had a small flood and this box (along with several others) got wet and stayed wet for a long time. This had ramifications…

The pipe’s markings on the left side of the shank read Gold Star [over] Diplomat. On the right side, they read London England [over] 9486. Also, on the stem, there is a star enclosing the letters GS.

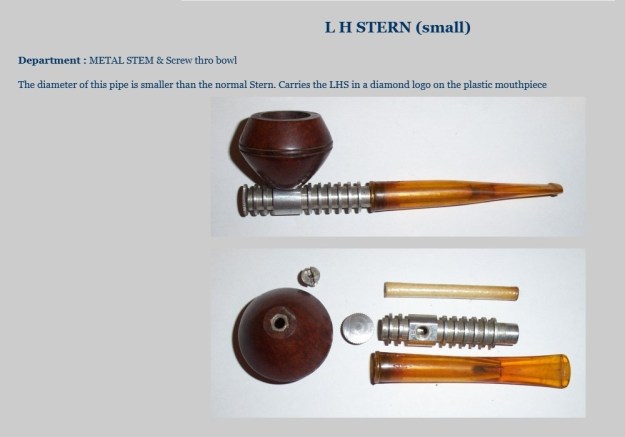

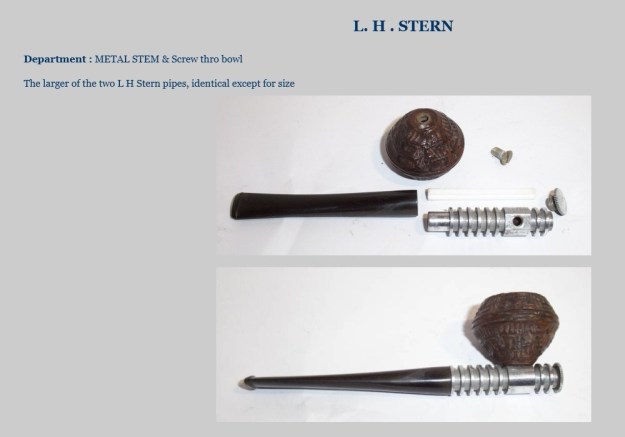

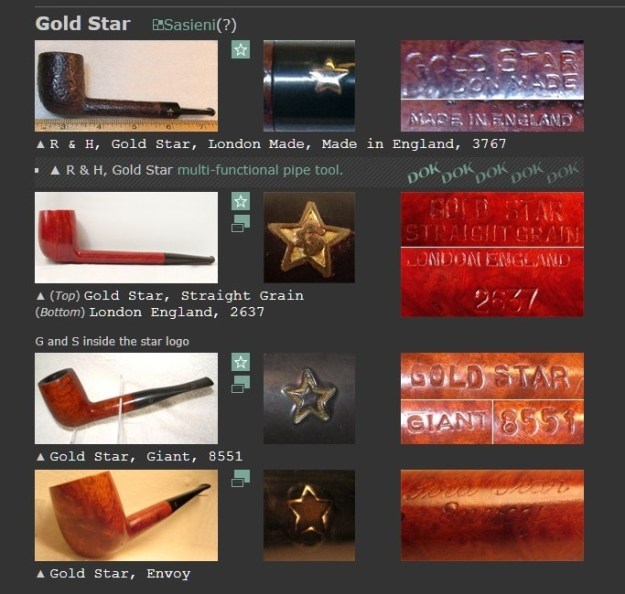

The pipe’s markings on the left side of the shank read Gold Star [over] Diplomat. On the right side, they read London England [over] 9486. Also, on the stem, there is a star enclosing the letters GS. Very little information turned up about the brand, Gold Star. Nothing from Pipedia. Over at Pipephil, they had the following:

Very little information turned up about the brand, Gold Star. Nothing from Pipedia. Over at Pipephil, they had the following: This suggested to me that the pipe was a Sasieni sub-brand. Crucially, however, Pipephil also included this line:

This suggested to me that the pipe was a Sasieni sub-brand. Crucially, however, Pipephil also included this line:

The pipes temporarily gathered under the “Gold Star” label obviously aren’t from the same maker.

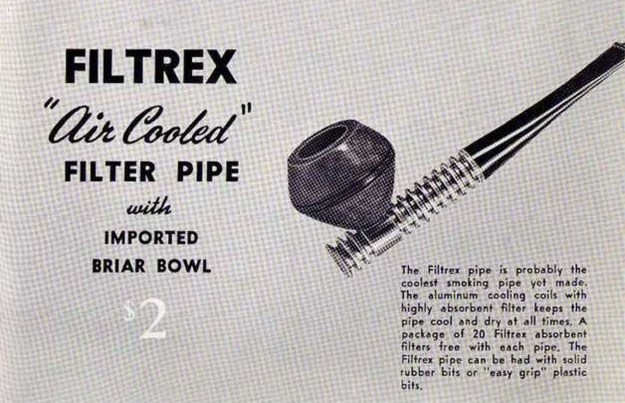

This was important to me, because the shape number, 9486, didn’t seem to correspond to anything that Sasieni made. So, I did some sleuthing and figured out that, in fact, the name Gold Star was also produced by GBD. This did fit, and I found some examples of GBD 9486 online, including this one (among others) from Iwan Ries’ website: Clearly, my grandfather’s pipe was one of these and I can confirm that both Sasieni and GBD (at least) made the Gold Star name. I am pleased to say that this post has added that small tidbit to the collective knowledge of pipe making in the twentieth century.

Clearly, my grandfather’s pipe was one of these and I can confirm that both Sasieni and GBD (at least) made the Gold Star name. I am pleased to say that this post has added that small tidbit to the collective knowledge of pipe making in the twentieth century.

Anyway, on to the pipe – and this poor pipe had some issues. Sitting in moist newspaper for as long as it did had some very negative effects. I don’t remember the crack on the shank being there in the past and I wonder if the water induced stresses in the wood that caused the crack. There were other small fissures in the bowl, I don’t think they were flood-related. Another problem related to the water was the colour of the wood – any staining this pipe had was long gone. Finally, as I was examining the pipe, I didn’t realize it in the moment, but the yellow stem would prove to be the biggest problem of them all. The effect of water on vulcanite stems is well known, but stems don’t normally sit in water for an extended period of time. Aside from the above, the stummel had the following problems: lava on the rim, charring to the rim, some cake in the bowl, and a few substantial fills. Meanwhile, the stem had its own set of problems (besides its colour): tooth marks and scratches, and a filthy stinger.

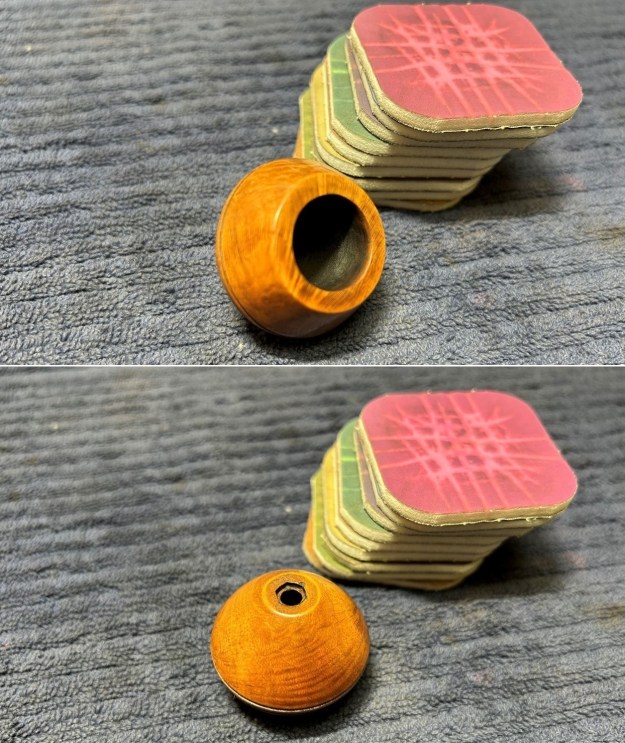

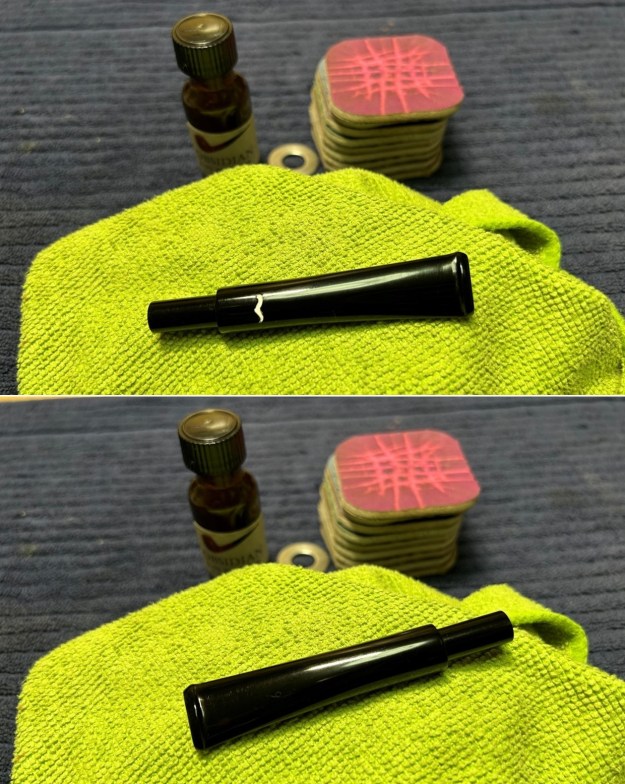

The stinger was first on my list. It went for a soak in some lemon-infused isopropyl alcohol. I let it set for several hours and then cleaned it off and it looked much improved. I then finished it with some 0000-grit steel wool and moved on.

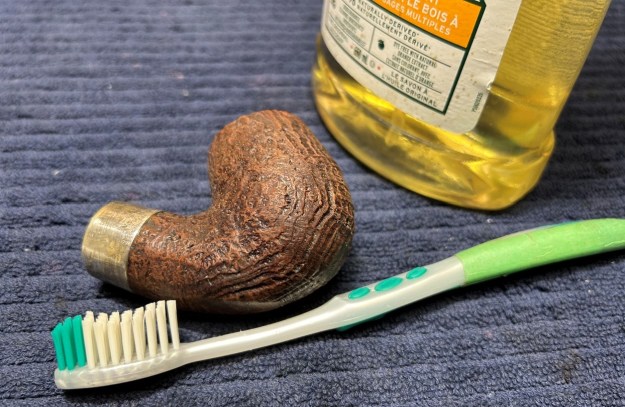

The stinger was first on my list. It went for a soak in some lemon-infused isopropyl alcohol. I let it set for several hours and then cleaned it off and it looked much improved. I then finished it with some 0000-grit steel wool and moved on. I wiped down the outside of the stem with oil soap on some cotton pads. That did next to nothing. I took my BIC lighter and painted the stem with its flame. This helped a bit, but not much. Then, I cleaned out the insides with pipe cleaners and isopropyl alcohol.

I wiped down the outside of the stem with oil soap on some cotton pads. That did next to nothing. I took my BIC lighter and painted the stem with its flame. This helped a bit, but not much. Then, I cleaned out the insides with pipe cleaners and isopropyl alcohol. Now it was time to remove the horrific yellow on the stem. I used some cream cleanser on the outside to remove the oxidation. I scrubbed and scrubbed and scrubbed. Then, the stem went for an overnight soak in the Pipe Stem Oxidation Remover. The following day, I cleaned the de-oxidizing mess off with alcohol, pipe cleaners, et cetera. I scrubbed again with cream cleanser on some cotton pads to remove the leftover oxidation. This worked only so well. I put the stem down, thought about it for a while, and decided to repeat that entire procedure: scrub with cream cleanser, soak overnight, and scrub with cream cleanser. This made the stem so much better than before, but still not great. Steve reminded me of an additional technique to try: soaking in Oxyclean. Again, this helped a bit, but it was just not going to be enough. This stem was definitely improved, but would always show the signs of its time in the water.

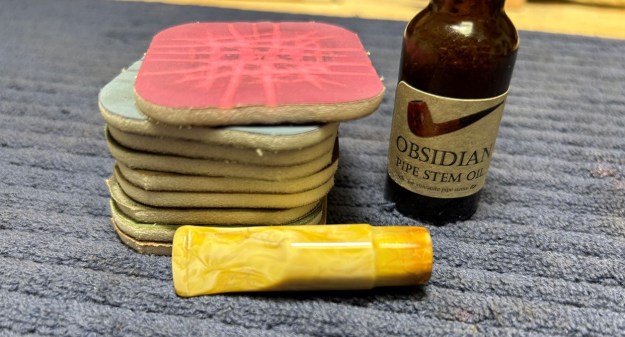

Now it was time to remove the horrific yellow on the stem. I used some cream cleanser on the outside to remove the oxidation. I scrubbed and scrubbed and scrubbed. Then, the stem went for an overnight soak in the Pipe Stem Oxidation Remover. The following day, I cleaned the de-oxidizing mess off with alcohol, pipe cleaners, et cetera. I scrubbed again with cream cleanser on some cotton pads to remove the leftover oxidation. This worked only so well. I put the stem down, thought about it for a while, and decided to repeat that entire procedure: scrub with cream cleanser, soak overnight, and scrub with cream cleanser. This made the stem so much better than before, but still not great. Steve reminded me of an additional technique to try: soaking in Oxyclean. Again, this helped a bit, but it was just not going to be enough. This stem was definitely improved, but would always show the signs of its time in the water. I then used all nine Micromesh pads (1,500 through 12,000 grit) on the stem to make it look as good as possible. I also used Obsidian Pipe Stem Oil in between each pad scrubbing.

I then used all nine Micromesh pads (1,500 through 12,000 grit) on the stem to make it look as good as possible. I also used Obsidian Pipe Stem Oil in between each pad scrubbing. On to the stummel. I used the KleenReem to remove the built-up cake, and followed that with 220-grit sandpaper to remove as much as I could. I wanted to take the bowl down to bare briar to ensure there were no hidden flaws in the walls of the bowl. Fortunately, there were none. I then proceeded to clean out the insides of the shank with cotton swabs, pipe cleaners, and isopropyl alcohol. There was quite a bit of filth inside this stummel – it took many pipe cleaners et cetera to clean it out.

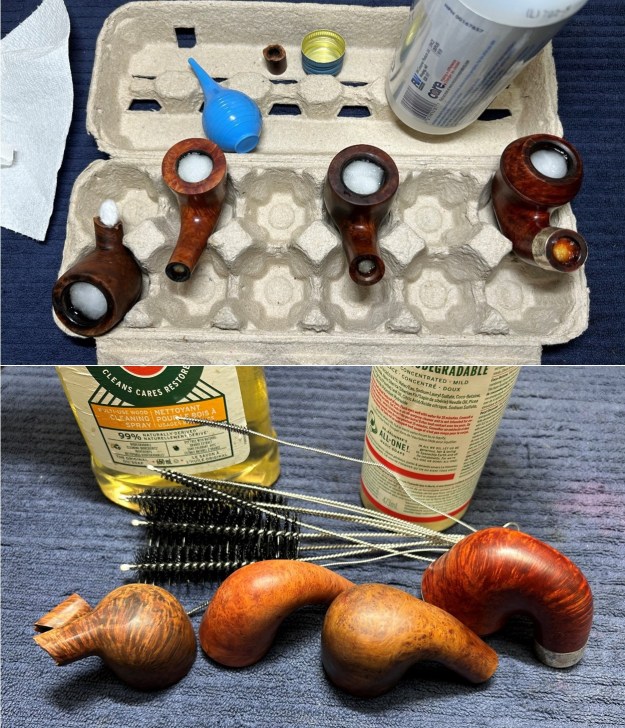

On to the stummel. I used the KleenReem to remove the built-up cake, and followed that with 220-grit sandpaper to remove as much as I could. I wanted to take the bowl down to bare briar to ensure there were no hidden flaws in the walls of the bowl. Fortunately, there were none. I then proceeded to clean out the insides of the shank with cotton swabs, pipe cleaners, and isopropyl alcohol. There was quite a bit of filth inside this stummel – it took many pipe cleaners et cetera to clean it out. I decided that a de-ghosting session would be a good idea. I thrust cotton balls into the bowl and the shank and saturated them with 99% isopropyl alcohol. I let the stummel sit overnight. This caused the oils, tars and smells to leach out into the cotton. I followed that up by cleaning the insides with some Castile soap and tube brushes. I then moved on to cleaning the outside of the stummel with oil soap and some cotton pads. That removed any remaining dirt. The bowl was nice and clean after this.

I decided that a de-ghosting session would be a good idea. I thrust cotton balls into the bowl and the shank and saturated them with 99% isopropyl alcohol. I let the stummel sit overnight. This caused the oils, tars and smells to leach out into the cotton. I followed that up by cleaning the insides with some Castile soap and tube brushes. I then moved on to cleaning the outside of the stummel with oil soap and some cotton pads. That removed any remaining dirt. The bowl was nice and clean after this.

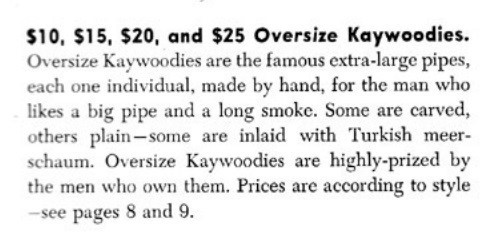

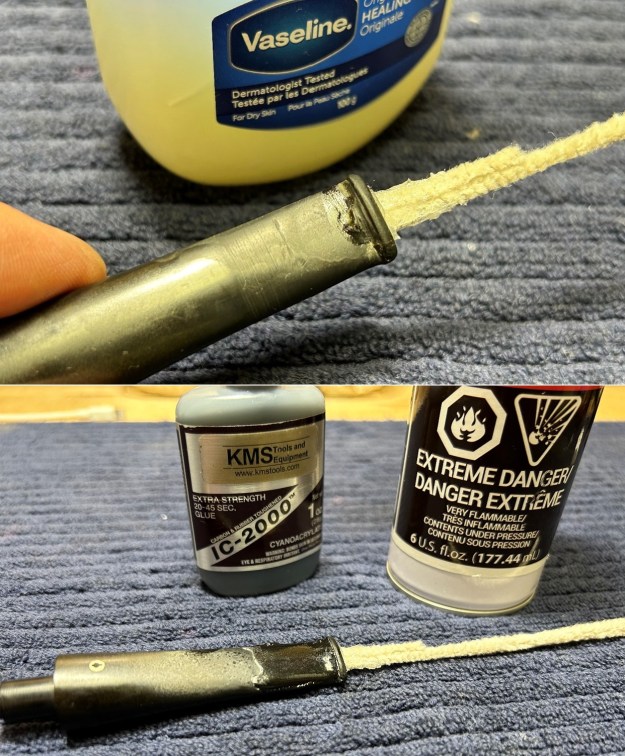

Having completed that, I was able to address the crack on the shank and the nicks on the bowl. This took some careful work. I filled the crack and the tiny divots with cyanoacrylate adhesive then let them cure.

Having completed that, I was able to address the crack on the shank and the nicks on the bowl. This took some careful work. I filled the crack and the tiny divots with cyanoacrylate adhesive then let them cure.

Now, with the nicks and crack filled, it was time to sand down the stummel. I used all nine Micromesh pads (1,500 through 12,000 grit) to sand everything smooth. Much improved.

Now, with the nicks and crack filled, it was time to sand down the stummel. I used all nine Micromesh pads (1,500 through 12,000 grit) to sand everything smooth. Much improved.

I felt that this pipe really needed a bit of colour – it had lost it during the flood. However, I only wanted a light stain. So I made a very dilute mixture of leather dye and alcohol. This didn’t really work well, so, instead, I simply put a drop (literally) at a time on my dauber and gently coated the wood with theat. I flamed it with my Bic lighter and let it sit overnight. Upon the morrow, I used isopropyl alcohol to wipe down the pipe and remove excess stain. I am very happy with the results.

I felt that this pipe really needed a bit of colour – it had lost it during the flood. However, I only wanted a light stain. So I made a very dilute mixture of leather dye and alcohol. This didn’t really work well, so, instead, I simply put a drop (literally) at a time on my dauber and gently coated the wood with theat. I flamed it with my Bic lighter and let it sit overnight. Upon the morrow, I used isopropyl alcohol to wipe down the pipe and remove excess stain. I am very happy with the results. After that, a light application of Before & After Restoration Balm brought out the best in the stummel’s grain. What a difference that made! Then it was off for a trip to the buffer. A dose of White Diamond and a few coats of carnauba wax were just what this pipe needed. The lovely shine made the wood look great.

After that, a light application of Before & After Restoration Balm brought out the best in the stummel’s grain. What a difference that made! Then it was off for a trip to the buffer. A dose of White Diamond and a few coats of carnauba wax were just what this pipe needed. The lovely shine made the wood look great.

This Gold Star Diplomat 9486 panelled billiard has an elegant feel to it. It took a lot of work – and the results were not exactly what I had hoped for – but I am proud of it and the final product is (hopefully) worthy of my beloved grandfather’s memory. Obviously, this is one pipe that I am keeping for myself and adding to my collection. I hope you enjoyed reading the story of this pipe as much I as I did restoring it. The approximate dimensions of the pipe are as follows: length 5⅛ in. (130 mm); height 1½ in. (39 mm); bowl diameter 1¼ in. (32 mm); chamber diameter ¾ in. (19 mm). The weight of the pipe is 1 oz. (31 g). If you are interested in more of my work, please follow me here on Steve’s website or email me directly at kenneth@knightsofthepipe.com. Thank you very much for reading and, as always, I welcome and encourage your comments.

This Gold Star Diplomat 9486 panelled billiard has an elegant feel to it. It took a lot of work – and the results were not exactly what I had hoped for – but I am proud of it and the final product is (hopefully) worthy of my beloved grandfather’s memory. Obviously, this is one pipe that I am keeping for myself and adding to my collection. I hope you enjoyed reading the story of this pipe as much I as I did restoring it. The approximate dimensions of the pipe are as follows: length 5⅛ in. (130 mm); height 1½ in. (39 mm); bowl diameter 1¼ in. (32 mm); chamber diameter ¾ in. (19 mm). The weight of the pipe is 1 oz. (31 g). If you are interested in more of my work, please follow me here on Steve’s website or email me directly at kenneth@knightsofthepipe.com. Thank you very much for reading and, as always, I welcome and encourage your comments.