Blog by Steve Laug

Last week I received an email from a fellow named Stanley who had gotten my info from the local Pipe and Cigar shop. He wrote that he had a trio of Comoy’s pipes that needed to be worked on. Two of them were Grand Slam Pipes and one was a Tradition. We connected via email and he said he would drop them off this week for me to work on. I am including part of his email so you have a sense of what I would be working on. I am also including the two photos that he attached to the email for me to see.

Hey Steve,

I had recently the chance to talk to a very kind and excellent gentleman over at City Cigar, I unfortunately was never able to get his name. However I mentioned I was looking for some replacement stems and he gave me your info…

…The pipes in question are attached in photos, I’ve never done any sort of pipe restoration in my life but I have attempted to take the cake down with a pocket knife. If you’d do it, would you be able to do a ream/clean on the three, as well as deal with the stems?

If possible, I’d prefer to save the original stems by repairing them, but it seems to me that most people remedy this problem with a replacement stem. Whatever you think is best I will go with.

If you think that I’d be better off without the stinger insert in the shape 64, then would you be able to remove it? I’m afraid I’d break the stem if I tried haha.

The 484b also seems to have a crack starting near the “Comoy’s Grand Slam” part of the shank, where it meets the stem. Is it possible to deal with this?

That is all! Please let me know what you think!

Thanks! Stanley

Last night Stanley stopped by and dropped off the three pipes. I took photos of pipes as there were when I opened the bag they were in. All three pipes were very dirty but the reaming had been started as noted in his email. The stems all had bite throughs on the underside. The bottom pipe in the photo below is a Grand Slam Pipe shape 64 Billiard. The stem has a 3 part C on the left side. The middle pipe is a Tradition 3591 Prince with 8 flattened panels on the bowl near the top. The stem also has a bite through and a missing divot. It also has a 3 part C on the left side. The top pipe in the photo is also Grand Slam Pipe 484B with a replacement stem that also has a bite through. The shank is also cracked on the left side.

Last night Stanley stopped by and dropped off the three pipes. I took photos of pipes as there were when I opened the bag they were in. All three pipes were very dirty but the reaming had been started as noted in his email. The stems all had bite throughs on the underside. The bottom pipe in the photo below is a Grand Slam Pipe shape 64 Billiard. The stem has a 3 part C on the left side. The middle pipe is a Tradition 3591 Prince with 8 flattened panels on the bowl near the top. The stem also has a bite through and a missing divot. It also has a 3 part C on the left side. The top pipe in the photo is also Grand Slam Pipe 484B with a replacement stem that also has a bite through. The shank is also cracked on the left side. I decided to work on the Grand Slam Pipe 64 Billiard. It is a beautifully grained Comoy’s Billiard that really is a pipe of Pipe Smoking History. The stamping is the significant marker that points this out for me. It is stamped on the left side of the shank and reads COMOY’S [over] Grand Slam [over] Pipe. On the right side it has the shape number 64 next to the bowl/shank junction and that is followed by a Comoy’s COM stamp that reads Made in London in a circle [over] England. On the underside there was a *6 stamped at the stem/shank junction. The finish had a lot of grime ground into the smooth finish on the bowl and some darkening around the sides of the bowl. The bowl had been scraped but there was still a moderately heavy cake. There was an overflow of thick lava on the top of the rim and on the inner bevel of the bowl. It was hard to know what the rim top and inner edge of the bowl looked like under the grime. The stem was lightly oxidized and there was a large bite through on the underside. There was a three part inlaid C on the left of the taper stem. When the pipe arrived it had a Softee Bit over the damaged stem. The pipe had promise but it was very dirty. I took photos of the pipe before he started his cleanup work.

I decided to work on the Grand Slam Pipe 64 Billiard. It is a beautifully grained Comoy’s Billiard that really is a pipe of Pipe Smoking History. The stamping is the significant marker that points this out for me. It is stamped on the left side of the shank and reads COMOY’S [over] Grand Slam [over] Pipe. On the right side it has the shape number 64 next to the bowl/shank junction and that is followed by a Comoy’s COM stamp that reads Made in London in a circle [over] England. On the underside there was a *6 stamped at the stem/shank junction. The finish had a lot of grime ground into the smooth finish on the bowl and some darkening around the sides of the bowl. The bowl had been scraped but there was still a moderately heavy cake. There was an overflow of thick lava on the top of the rim and on the inner bevel of the bowl. It was hard to know what the rim top and inner edge of the bowl looked like under the grime. The stem was lightly oxidized and there was a large bite through on the underside. There was a three part inlaid C on the left of the taper stem. When the pipe arrived it had a Softee Bit over the damaged stem. The pipe had promise but it was very dirty. I took photos of the pipe before he started his cleanup work.

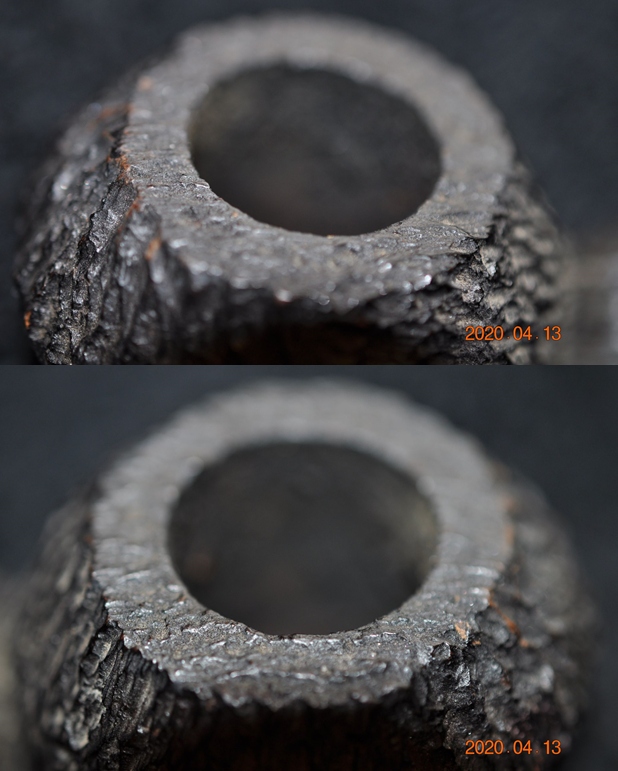

I took photos of the rim top and bowl to give a clear picture of the thickness of the cake and the overflow of lava on the rim top. It is hard to know if there is damage to the inner edge of the bowl because of the lava coat. I also took photos of the top and underside of the stem to show the condition of the stem surface and the bite through on the underside.

I took photos of the rim top and bowl to give a clear picture of the thickness of the cake and the overflow of lava on the rim top. It is hard to know if there is damage to the inner edge of the bowl because of the lava coat. I also took photos of the top and underside of the stem to show the condition of the stem surface and the bite through on the underside. I took photos of the stamping on both sides and underside of the shank. They read as noted above. I also included a photo of the 3 part C logo on the left side of the taper stem.

I took photos of the stamping on both sides and underside of the shank. They read as noted above. I also included a photo of the 3 part C logo on the left side of the taper stem.  I removed the stem and took a photo of the pipe to give a sense of the whole. It is a well shaped billiard. Once the stem was off I noted that tenon had a Comoy’s Grand Slam metallic stinger threaded in the stem. It was missing the cap on the end that held the leather washer in place the apparatus was damaged and I would not be able to fit a new cap on the end. I would remove it from the tenon so that I could clean the stem and do the repairs.

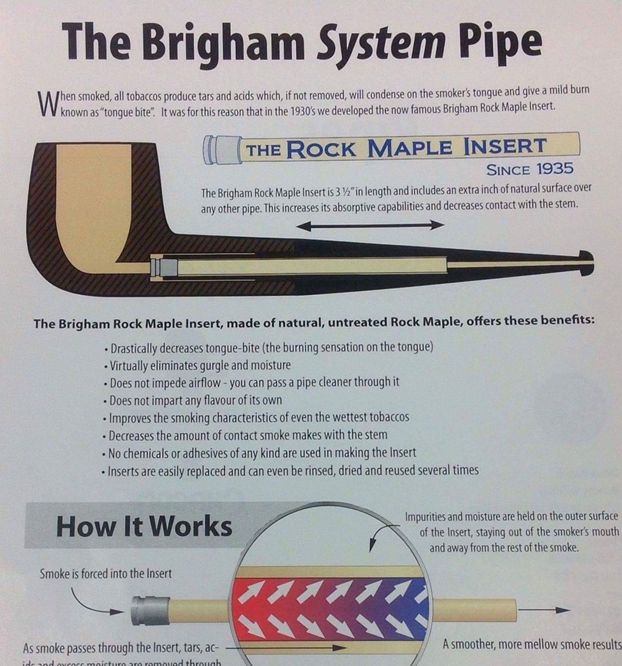

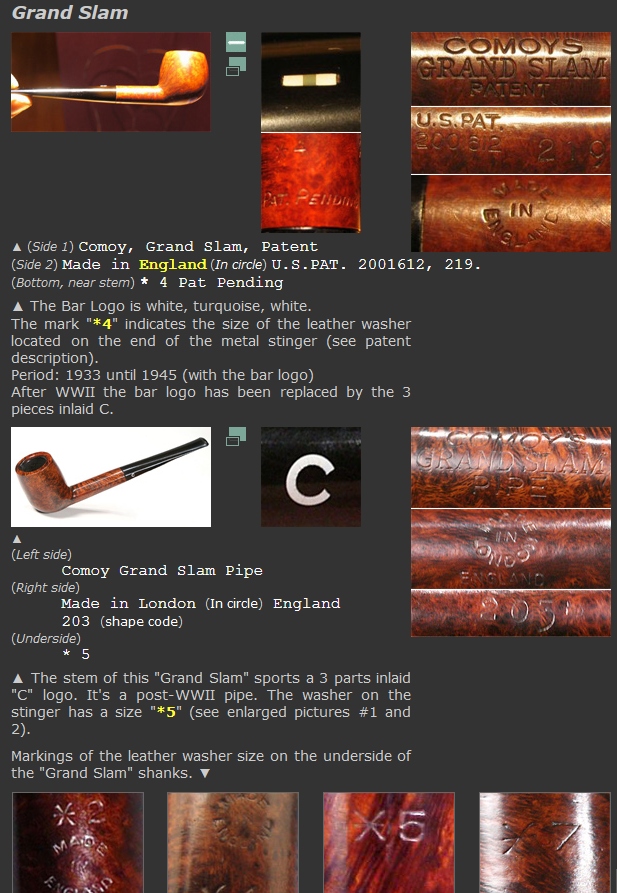

I removed the stem and took a photo of the pipe to give a sense of the whole. It is a well shaped billiard. Once the stem was off I noted that tenon had a Comoy’s Grand Slam metallic stinger threaded in the stem. It was missing the cap on the end that held the leather washer in place the apparatus was damaged and I would not be able to fit a new cap on the end. I would remove it from the tenon so that I could clean the stem and do the repairs. I looked on Pipephil’s site for information on the Comoy’s Grand Slam Pipe and found the following information I have included a screen capture (http://www.pipephil.eu/logos/en/logo-comoy.html). The one I am working on is like the second one in the screen capture below. It has the three part C which dated it to 1946 and following. The stamping is the same as the one I am working on. The *6 is the size of the washer on the end of the stinger.

I looked on Pipephil’s site for information on the Comoy’s Grand Slam Pipe and found the following information I have included a screen capture (http://www.pipephil.eu/logos/en/logo-comoy.html). The one I am working on is like the second one in the screen capture below. It has the three part C which dated it to 1946 and following. The stamping is the same as the one I am working on. The *6 is the size of the washer on the end of the stinger. I turned to the article on Pipedia about dating Comoy’s pipes but the style of the stamping (https://pipedia.org/index.php?title=Comoy%27s_Dating_Guide#1917_to_the_end_of_the_1930.27s_.28at_least_1938.29). I have include the section in the screen capture below that date this pipe to the 1950s.

I turned to the article on Pipedia about dating Comoy’s pipes but the style of the stamping (https://pipedia.org/index.php?title=Comoy%27s_Dating_Guide#1917_to_the_end_of_the_1930.27s_.28at_least_1938.29). I have include the section in the screen capture below that date this pipe to the 1950s.

Now the Comoy’s stamp can be found in three variants in the 1950s

- A simple block-letter style without serifs but with the C larger than the other letters and the apostrophe before the “S”.

- A return to the slightly more fancy block letters with serifs and the apostrophe. (It seems that some grades carried different stamps, or at least that the stamping changed in different years for some grades.)

- A simple block-letter style without serifs and without the apostrophe and with the “C” the same size as the rest of the letters. This stamp was probably not used very long.

- A simple block-letter style without serifs but with the apostrophe before the “S” and with the “C” the same size as the rest of the letters.

Appears in two versions. This is again stamped in a circle with “MADE” at the top, “IN” in the middle, and “LONDON” at the bottom, with “ENGLAND” in a straight line beneath. It can be assumed that this stamp was first used in the export drive in the early 1950s. On a Bulldog Sandblast from the early 50s the Comoy name no. 2 above was used together with “MADE IN LONDON” over “ENGLAND”. There are no known examples of pre-WW II Comoy’s stamped in this way. The second version is the same as above but in a “rugby ball ” shape. This shape is verified on Comoy´s “Extraordinaire” pipes.

Inlaid “C”

“C” was first inlaid in the side of the mouthpiece around 1919. This was a complex inlay needing three drillings. First, a round white inlay was inserted, then the centre of the white was drilled out, and a smaller round black inlay was inserted. Finally, another drilling was made to remove the open part of the “C,” and an even smaller black inlay was inserted. This inlaid “C,” known as the “three-piece C,” was continued until the Cadogan era in the 1980s. However, the “C” in the 1920s and early 30s is much thinner and more delicate than the one post-WW II.

That article gave me some helpful information regarding the pipe that I was working on. I knew that the stamping and logos identified the pipe as having been made in following WW2 and from what I can see from the above information it is a 1950s era pipe.

I reamed the bowl with a PipNet pipe reamer using the 2nd and 3rd cutting head to remove the remaining cake back to briar. I followed up with a Savinelli Fitsall pipe knife to remove the remnants of cake. I sanded the walls of the bowl with a piece of 220 grit sandpaper wrapped around a piece of dowel.

I scrubbed out the mortise and the airway in the shank and the stem with alcohol, cotton swabs and pipe cleaners.

I scrubbed out the mortise and the airway in the shank and the stem with alcohol, cotton swabs and pipe cleaners.  I scrubbed the exterior of the bowl, rim, shank and stem with a tooth brush and Murphy’s Oil Soap to remove the oils and tars on the rim and the grime on the finish of the bowl. I rinsed it under running water and dried it off with a soft cloth.

I scrubbed the exterior of the bowl, rim, shank and stem with a tooth brush and Murphy’s Oil Soap to remove the oils and tars on the rim and the grime on the finish of the bowl. I rinsed it under running water and dried it off with a soft cloth.

I was able to remove some of the lava build up on the rim top and finished by scraping it with the Fitsall knife and then a piece of 220 grit sandpaper.

I was able to remove some of the lava build up on the rim top and finished by scraping it with the Fitsall knife and then a piece of 220 grit sandpaper.  There were some deep cuts on the bottom right side of the bowl and on the top right side near the edge. I filled these in with a spot of clear super glue.

There were some deep cuts on the bottom right side of the bowl and on the top right side near the edge. I filled these in with a spot of clear super glue.  I polished the bowl and the rim top, sides and shank with micromesh sanding pads – wet sanding with 1500-12000 grit pads and wiping it down after each pad with a damp cloth. I carefully avoided the stamping on the shank so as not to damage the stamping.

I polished the bowl and the rim top, sides and shank with micromesh sanding pads – wet sanding with 1500-12000 grit pads and wiping it down after each pad with a damp cloth. I carefully avoided the stamping on the shank so as not to damage the stamping.

I rubbed the bowl and shank down with Before & After Restoration Balm. I worked it into the surface of the bowl sides and shank with my fingertips to clean, enliven and protect the briar. I let the balm sit for a little while and then buffed with a cotton cloth to raise the shine.

I rubbed the bowl and shank down with Before & After Restoration Balm. I worked it into the surface of the bowl sides and shank with my fingertips to clean, enliven and protect the briar. I let the balm sit for a little while and then buffed with a cotton cloth to raise the shine.

I set the bowl aside and turned my attention to the stem. I heated the stinger with a Bic lighter and unscrewed it with a pair of pliers.

I set the bowl aside and turned my attention to the stem. I heated the stinger with a Bic lighter and unscrewed it with a pair of pliers. I set aside the bowl and turned my attention to the stem repairs. I cut a piece of cardboard for a pallet, put aside two charcoal capsules, and set out the spatula and the Loctite 380 black CA glue. I greased a pipe cleaner with Vaseline and inserted it in the stem. I filled in the hole in the stem with a mixture of charcoal powder and Loctite. I used the spatula to fill in the bite throughs on all of the stems. I sprayed the repair with an accelerator to set the glue and removed the pipe cleaners from the stems.

I set aside the bowl and turned my attention to the stem repairs. I cut a piece of cardboard for a pallet, put aside two charcoal capsules, and set out the spatula and the Loctite 380 black CA glue. I greased a pipe cleaner with Vaseline and inserted it in the stem. I filled in the hole in the stem with a mixture of charcoal powder and Loctite. I used the spatula to fill in the bite throughs on all of the stems. I sprayed the repair with an accelerator to set the glue and removed the pipe cleaners from the stems.

I filled in the deep tooth marks on the top side of the stem with black super glue and set the stems aside to let the repairs cure. I took a photo of the three pipes at this point to give a feel for where things stood.

I filled in the deep tooth marks on the top side of the stem with black super glue and set the stems aside to let the repairs cure. I took a photo of the three pipes at this point to give a feel for where things stood.

I smoothed out the repairs with a needle file and started blending them into the surface of the stem. I sanded the remaining repairs with 220 grit sandpaper to further blend it into the stem surface. I started polishing it with 400 grit wet dry sandpaper.

I smoothed out the repairs with a needle file and started blending them into the surface of the stem. I sanded the remaining repairs with 220 grit sandpaper to further blend it into the stem surface. I started polishing it with 400 grit wet dry sandpaper.

I polished the vulcanite stem with micromesh sanding pads – 1500-12000 grit pads. I wiped it down with a damp cloth after each sanding pad. I took photos of both sides of the stem to show the repair work on both sides.

I polished the vulcanite stem with micromesh sanding pads – 1500-12000 grit pads. I wiped it down with a damp cloth after each sanding pad. I took photos of both sides of the stem to show the repair work on both sides.

This 50s era Comoy’s Grand Slam Pipe 64 Billiard with a vulcanite taper stem is a great looking pipe now that it has been restored. I did a lot of work on the bowl and repaired the bite through on the stem. The rich browns and blacks of the contrasting stains came alive with the polishing and waxing. I put the stem back on the bowl and carefully buffed the pipe with Blue Diamond on the buffing wheel using a light touch on the briar. I gave the bowl and the stem multiple coats of carnauba wax on the buffing wheel and followed that by buffing the entire pipe with a clean buffing pad. I hand buffed the pipe with a microfiber cloth to deepen the shine. The finished Comoy’s Medium Billiard is a beauty and fits nicely in the hand and looks very good. Give the finished pipe a look in the photos below. The dimensions of the pipe are Length: 5 ½ inches, Height: 1 ¾ inches, Outside diameter of the bowl: 1 ¼ inches, Chamber diameter: ¾ of an inch. I am looking forward to what Stanley thinks of his repaired pipe. He had said the threesome were his favourite pipes. This is the first of the three. Thanks for reading this blog and my reflections on the pipe while I worked on it. There are many more to come!

This 50s era Comoy’s Grand Slam Pipe 64 Billiard with a vulcanite taper stem is a great looking pipe now that it has been restored. I did a lot of work on the bowl and repaired the bite through on the stem. The rich browns and blacks of the contrasting stains came alive with the polishing and waxing. I put the stem back on the bowl and carefully buffed the pipe with Blue Diamond on the buffing wheel using a light touch on the briar. I gave the bowl and the stem multiple coats of carnauba wax on the buffing wheel and followed that by buffing the entire pipe with a clean buffing pad. I hand buffed the pipe with a microfiber cloth to deepen the shine. The finished Comoy’s Medium Billiard is a beauty and fits nicely in the hand and looks very good. Give the finished pipe a look in the photos below. The dimensions of the pipe are Length: 5 ½ inches, Height: 1 ¾ inches, Outside diameter of the bowl: 1 ¼ inches, Chamber diameter: ¾ of an inch. I am looking forward to what Stanley thinks of his repaired pipe. He had said the threesome were his favourite pipes. This is the first of the three. Thanks for reading this blog and my reflections on the pipe while I worked on it. There are many more to come!