Blog by Steve Laug

After brief foray into restoring pipes referred to me by my local pipe shop I am back to Bob Kerr’s estate (his photo is to the left). If you have not “met” the man and would like to read a bit of the history of the pipeman, his daughter has written a great tribute that is worth a read. Because I have included it in over 60 restorations to date I thought that I would leave it out this time. Be sure to check out some of the recent Dunhill restoration blog (https://rebornpipes.com/2020/01/01/restoring-the-last-of-bob-kerrs-dunhills-a-1962-dunhill-bruyere-656-f-t-bent-billiard/).

After brief foray into restoring pipes referred to me by my local pipe shop I am back to Bob Kerr’s estate (his photo is to the left). If you have not “met” the man and would like to read a bit of the history of the pipeman, his daughter has written a great tribute that is worth a read. Because I have included it in over 60 restorations to date I thought that I would leave it out this time. Be sure to check out some of the recent Dunhill restoration blog (https://rebornpipes.com/2020/01/01/restoring-the-last-of-bob-kerrs-dunhills-a-1962-dunhill-bruyere-656-f-t-bent-billiard/).

The next pipe I have chosen from his estate is an interesting looking Bulldog. It is stamped Royal Crown on the left top side of the shank. There is no other stamping on the shank sides or marks on the stem. The Saddle stem is oxidized and has tooth marks and chatter on both sides near the button. The finish is worn and dirty. There is a cake and lava overflow on the rim top. There is some damage on top & edges and the bowl is slightly out of round. Jeff took photos of the pipe to show its general condition before he did his cleanup work.

The finish on the pipe was very dirty – grime and grit from years of use and sitting fill the crevices in the rustication. The rim top was covered with a coat of thick lava that overflowed the bowl. There was also some darkening on the rim top. The bowl itself had a thick cake with flecks of tobacco stuck in the cake on the sides.

The finish on the pipe was very dirty – grime and grit from years of use and sitting fill the crevices in the rustication. The rim top was covered with a coat of thick lava that overflowed the bowl. There was also some darkening on the rim top. The bowl itself had a thick cake with flecks of tobacco stuck in the cake on the sides. Jeff took photos of the sides of the bowl to give a better feel for the grain around the sides and heel of the bowl.

Jeff took photos of the sides of the bowl to give a better feel for the grain around the sides and heel of the bowl. He took a photo of the stamping on the top left side of the diamond shank. You can see that the stamping is very clear.

He took a photo of the stamping on the top left side of the diamond shank. You can see that the stamping is very clear. The stem was dirty and very oxidized. The stem appeared to be a replacement and did not fit perfectly to the shank. It was diamond shaped and worked well on two sides of the shank but the other two were off. It did not have the characteristic bite marks that were on Bob’s pipes.

The stem was dirty and very oxidized. The stem appeared to be a replacement and did not fit perfectly to the shank. It was diamond shaped and worked well on two sides of the shank but the other two were off. It did not have the characteristic bite marks that were on Bob’s pipes. Before I started my work on the pipe I decided to do a bit of research. I had no recollection of working on this brand before but I could be wrong as I have worked on a lot of pipes now. I turned first to Pipephil’s site (http://www.pipephil.eu/logos/en/logo-r6.html) and found out to my surprise that there was a connection to the Hardcastle brand. I have included a screen capture to show the link on the site to Hardcastle.

Before I started my work on the pipe I decided to do a bit of research. I had no recollection of working on this brand before but I could be wrong as I have worked on a lot of pipes now. I turned first to Pipephil’s site (http://www.pipephil.eu/logos/en/logo-r6.html) and found out to my surprise that there was a connection to the Hardcastle brand. I have included a screen capture to show the link on the site to Hardcastle. From there I turned to Pipedia and was directed to the Hardcastle page. I turned to that page to see what I could learn about the pipe (https://pipedia.org/wiki/Hardcastle). I read through the page and found some more information. The Timeline for the Family Period (which is what I was interested in) is shown below. It seems to begin in 1903 when Edmund Hardcastle establishes the brand and ends 1946 when Dunhill buys out the shares and leaves the family to manage the company.

From there I turned to Pipedia and was directed to the Hardcastle page. I turned to that page to see what I could learn about the pipe (https://pipedia.org/wiki/Hardcastle). I read through the page and found some more information. The Timeline for the Family Period (which is what I was interested in) is shown below. It seems to begin in 1903 when Edmund Hardcastle establishes the brand and ends 1946 when Dunhill buys out the shares and leaves the family to manage the company.

1903: Edmund Hardcastle establishes the brand

1936: Family sells 49% of the Hardcastle Pipes Limited shares to Dunhill

1946: Dunhill buys the remaining shares, but the family continues to manage the company

I did a screen capture of the Models and Grades of pipes in the Family Period. It shows the Royal Crown brand listed. Now I knew about the brand. Up until I had read this I thought it was a Danish made pipe. Now I knew that it was British made and came out of the Hardcastle factory. Armed with that information it was time to work on the pipe. Jeff cleaned this filthy pipe with his usual penchant for thoroughness that I really appreciate. This one was a real mess and I was looking forward to seeing what he had done with this one when I took it out of his box. It looked amazing and CLEAN and other than the stem work needing a little effort on my part. He reamed the bowl with a PipNet pipe reamer and cleaned up the reaming with a Savinelli Fitsall Pipe Knife. He scrubbed out the internals with alcohol, pipe cleaners and cotton swabs until the pipe was clean. He scrubbed the exterior of the bowl with Murphy’s Oil Soap and a tooth brush to remove the grime and grit on the briar and the lava on the rim top. The finish looks good with great looking grain around the bowl and shank. The rim top and front of the bowl was severely damaged with burns. The condition of the inner and outer edges was rough. The stem looked a lot better but damage was evident on the button. Jeff soaked the stem in Before & After Deoxidizer to remove the oxidation on the rubber. The pipe was ready for me to carry on the next part of the process.

Now I knew about the brand. Up until I had read this I thought it was a Danish made pipe. Now I knew that it was British made and came out of the Hardcastle factory. Armed with that information it was time to work on the pipe. Jeff cleaned this filthy pipe with his usual penchant for thoroughness that I really appreciate. This one was a real mess and I was looking forward to seeing what he had done with this one when I took it out of his box. It looked amazing and CLEAN and other than the stem work needing a little effort on my part. He reamed the bowl with a PipNet pipe reamer and cleaned up the reaming with a Savinelli Fitsall Pipe Knife. He scrubbed out the internals with alcohol, pipe cleaners and cotton swabs until the pipe was clean. He scrubbed the exterior of the bowl with Murphy’s Oil Soap and a tooth brush to remove the grime and grit on the briar and the lava on the rim top. The finish looks good with great looking grain around the bowl and shank. The rim top and front of the bowl was severely damaged with burns. The condition of the inner and outer edges was rough. The stem looked a lot better but damage was evident on the button. Jeff soaked the stem in Before & After Deoxidizer to remove the oxidation on the rubber. The pipe was ready for me to carry on the next part of the process.

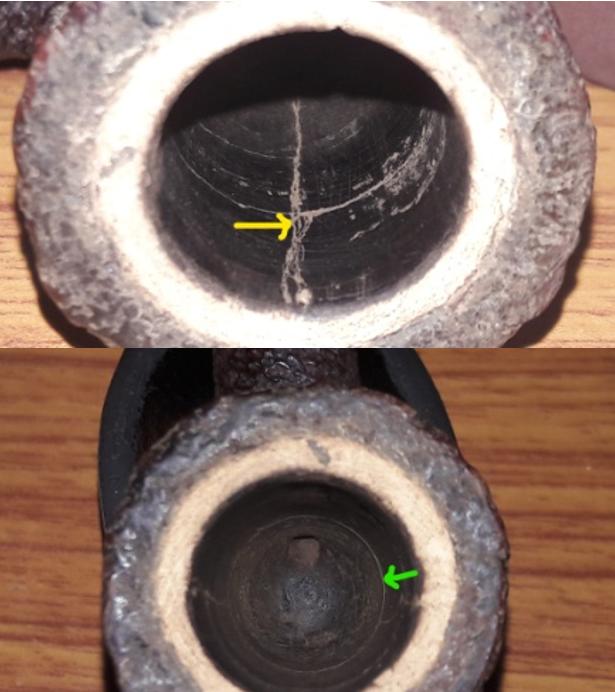

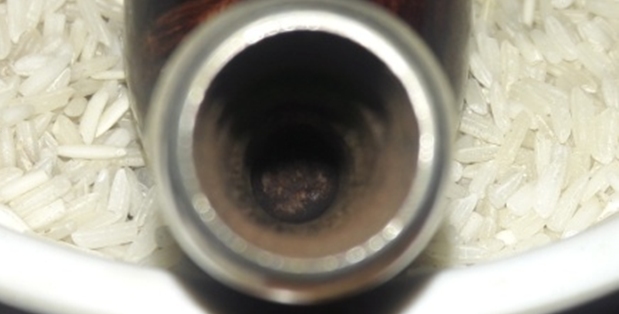

I took some close up photos of the rim top and also of the stem surface. I wanted to show how well it had cleaned up. The rim top was clean and the damage was very evident. There were marks across the top of the rim and damage to the inner beveled edge. I also took close up photos of the stem to show how well surface looked on both sides. I also noted that the stem also is a replacement stem rather than the original as the fit against the shank is not perfect.

I took some close up photos of the rim top and also of the stem surface. I wanted to show how well it had cleaned up. The rim top was clean and the damage was very evident. There were marks across the top of the rim and damage to the inner beveled edge. I also took close up photos of the stem to show how well surface looked on both sides. I also noted that the stem also is a replacement stem rather than the original as the fit against the shank is not perfect. I took a photo of the stamping on the left topside of the diamond shank. You can see that it is stamped as noted above.

I took a photo of the stamping on the left topside of the diamond shank. You can see that it is stamped as noted above. I decided to start my restoration work on this one by dealing with the damaged rim top. I topped it lightly on a topping board with 220 grit sandpaper. I remove the damaged surface of the rim top and then a folded piece of 220 to work on the bevel on the inner edge. The pipe looks much better than when I started.

I decided to start my restoration work on this one by dealing with the damaged rim top. I topped it lightly on a topping board with 220 grit sandpaper. I remove the damaged surface of the rim top and then a folded piece of 220 to work on the bevel on the inner edge. The pipe looks much better than when I started.

I polished the briar with micromesh sanding pads – wet sanding it with 1500-12000 grit pads. After each pad I wiped the briar down with a damp cloth.

I polished the briar with micromesh sanding pads – wet sanding it with 1500-12000 grit pads. After each pad I wiped the briar down with a damp cloth.

I touched up the rim top colour with an Oak Stain Pen to match the colour of the rest of the bowl. I let it dry and buffed it by hand.

I touched up the rim top colour with an Oak Stain Pen to match the colour of the rest of the bowl. I let it dry and buffed it by hand. I worked some Before & After Restoration Balm into the surface of the briar with my fingertips to clean, enliven and protect the briar. I let the balm sit for a little while and then buffed with a cotton cloth to raise the shine. The photos show the bowl at this point in the restoration process.

I worked some Before & After Restoration Balm into the surface of the briar with my fingertips to clean, enliven and protect the briar. I let the balm sit for a little while and then buffed with a cotton cloth to raise the shine. The photos show the bowl at this point in the restoration process.

With that done the bowl was finished other than the final buffing. I set it aside and turned my attention to the stem. I sanded out the repaired with 220 grit sand paper to blend them into the rest of the stem surface. I started to polish it with a folded piece of 400 wet dry sandpaper. Once it was finished it had begun to shine.

With that done the bowl was finished other than the final buffing. I set it aside and turned my attention to the stem. I sanded out the repaired with 220 grit sand paper to blend them into the rest of the stem surface. I started to polish it with a folded piece of 400 wet dry sandpaper. Once it was finished it had begun to shine. I polished the stem with Denicare Mouthpiece Polish from a tin of it I have in the drawer here. It is a gritty red paste that I rub on with my finger tips and work into the surface of the stem and button and buff off with a cotton pad. It gives me a bit of a head start on the polishing work.

I polished the stem with Denicare Mouthpiece Polish from a tin of it I have in the drawer here. It is a gritty red paste that I rub on with my finger tips and work into the surface of the stem and button and buff off with a cotton pad. It gives me a bit of a head start on the polishing work. I polished the stem with micromesh sanding pads – wet sanding with 1500-12000 grit sanding pads. I wiped it down after each sanding pad with Obsidian Oil. I polished it with Before & After Pipe Stem Polish – both Fine and Extra Fine. I am continuing to experiment with Briarville Pipe Repairs new product, No Oxy Oil so I rubbed the stem down with the oil on the cloth that was provided with it.

I polished the stem with micromesh sanding pads – wet sanding with 1500-12000 grit sanding pads. I wiped it down after each sanding pad with Obsidian Oil. I polished it with Before & After Pipe Stem Polish – both Fine and Extra Fine. I am continuing to experiment with Briarville Pipe Repairs new product, No Oxy Oil so I rubbed the stem down with the oil on the cloth that was provided with it.

This Royal Crown was another interesting pipe to work on. It is a classic shaped Bulldog. It has a saddle vulcanite stem that I am pretty certain is a replacement stem. The grain on the pipe is very nice and the shape has a great look and feel in the hand. The smooth finish is beautiful and highlights the grain. I polished stem and the bowl with Blue Diamond polish on the buffing wheel. I gave the bowl and the stem multiple coats of carnauba wax. I buffed the pipe with a clean buffing pad to raise the shine. I hand buffed it with a microfiber cloth to deepen the shine. The pipe polished up pretty nicely. The deeply grained briar took on life with the buffing. The rich dark brown and black colour of the briar works well with the polished vulcanite stem. The finished pipe has a rich look that is quite catching. Have a look at it with the photos below. The shape, finish and flow of the Bulldog are very well done even with the replacement stem. The dimensions are Length: 5 ½ inches, Height: 2 inches, Outside diameter of the bowl: 1 ¼ inches, Chamber diameter: ¾ of an inch. It is a beautiful pipe and one that will be on the rebornpipes store soon. If you are interested in adding it to your collection let me know. Thanks for walking through the restoration with me as I worked over this pipe.

This Royal Crown was another interesting pipe to work on. It is a classic shaped Bulldog. It has a saddle vulcanite stem that I am pretty certain is a replacement stem. The grain on the pipe is very nice and the shape has a great look and feel in the hand. The smooth finish is beautiful and highlights the grain. I polished stem and the bowl with Blue Diamond polish on the buffing wheel. I gave the bowl and the stem multiple coats of carnauba wax. I buffed the pipe with a clean buffing pad to raise the shine. I hand buffed it with a microfiber cloth to deepen the shine. The pipe polished up pretty nicely. The deeply grained briar took on life with the buffing. The rich dark brown and black colour of the briar works well with the polished vulcanite stem. The finished pipe has a rich look that is quite catching. Have a look at it with the photos below. The shape, finish and flow of the Bulldog are very well done even with the replacement stem. The dimensions are Length: 5 ½ inches, Height: 2 inches, Outside diameter of the bowl: 1 ¼ inches, Chamber diameter: ¾ of an inch. It is a beautiful pipe and one that will be on the rebornpipes store soon. If you are interested in adding it to your collection let me know. Thanks for walking through the restoration with me as I worked over this pipe.