Blog by Steve Laug

In my previous 3 blogs on Craig’s pipes I spoke of the five pipes that I am working on for him. In this blog I am taking on the fourth of his pipes – one of my favourite Dr. Grabow shapes – Starfire 39. It was another one with a cake in the bowl that was thick and hard. Once more I am going to include what Craig wrote me about his pipes. I have included it in the previous three blogs but I think it adds context to the bunch.

I was recently given a bag of pipes…literally, a BAG of 20 or so pipes that are 50+yrs in age and VERY used. I was wondering if you would have time to either Skype or FaceTime with me, and go through what I have in order to determine which are worth sending to you to have them refurbished. If you would be so kind, I’d really appreciate it.

We met on FaceTime and he pulled out a grocery bag with no rhyme or reason to it. It was filled with a jumble of no name or low-end drug store pipes. The only pipes that stood out for me were an old WDC Campaign pipe and a Grabow Starfire. He had several others that he liked. But we excluded all but five of the pipes. The amount of work necessary to bring them back was not worth the price. These are the five that we chose to work on. As I finish them, I will include the link to the blog covering that pipe.

– A No Name Meerschaum that looked interesting – https://rebornpipes.com/2018/01/31/is-it-a-meerschaum-looks-like-one-feels-like-one-but/

– A leather clad billiard marked R20 and bearing a shield – https://rebornpipes.com/2018/02/01/rejuvenating-a-leather-clad-billiard/

– A Wally Frank Bulldog marked Natural Unvarnished lacking a stem https://rebornpipes.com/2018/02/02/craigs-pipes-3-restemming-and-restoring-a-wally-frank-natural-bulldog/

– A Dr. Grabow Starfire 39 that had great grain

– A WDC Campaign underslung pipe

After our conversation, he packed up the pipes and threw the rest of the pipes in a separate bag for me to scavenge parts. The box did not take too long to get to Vancouver and when it did I opened the box and had a look. Here are pics of what I saw – there were two bags inside. One bag held the discards for the scrap pile and the other held the five pipes he wanted restored.

The fourth pipe was the pickaxe shaped Dr. Grabow on the upper left of the above photo, just below the meerschaum. The briar was very dirty with lots of grime and residue that had hardened on the surface of the bowl around the front and right side of the bowl. It was hard to tell what the rim top was like because of the lava overflow from the bowl up and over the scooped rim. The outer edges had some nicks at the front of the bowl. The inner edge looked pretty rough but I could not tell if it was just the lava or actually damage to the briar. There appeared to be some darkening on the rim but it may also be thin tars and oils. The bowl had a thick cake in it and remnants of tobacco. The shank is stamped on the left side Starfire over Dr. Grabow. On the right side it is stamped with the shape number 39 at the shank stem junction and next to that it reads Imported Briar over Adjustomatic over Pat.2461905. The patent is for the Adjustomatic apparatus in the stem. The stem was in pretty decent condition with some scratches on the top and underside at the button and a light oxidation. I took the following photos of the pipe before I started cleaning it up.

The fourth pipe was the pickaxe shaped Dr. Grabow on the upper left of the above photo, just below the meerschaum. The briar was very dirty with lots of grime and residue that had hardened on the surface of the bowl around the front and right side of the bowl. It was hard to tell what the rim top was like because of the lava overflow from the bowl up and over the scooped rim. The outer edges had some nicks at the front of the bowl. The inner edge looked pretty rough but I could not tell if it was just the lava or actually damage to the briar. There appeared to be some darkening on the rim but it may also be thin tars and oils. The bowl had a thick cake in it and remnants of tobacco. The shank is stamped on the left side Starfire over Dr. Grabow. On the right side it is stamped with the shape number 39 at the shank stem junction and next to that it reads Imported Briar over Adjustomatic over Pat.2461905. The patent is for the Adjustomatic apparatus in the stem. The stem was in pretty decent condition with some scratches on the top and underside at the button and a light oxidation. I took the following photos of the pipe before I started cleaning it up.

I took close up photos of the bowl and rim top as well as the stem. The rim top had been beaten on a hard surface to knock out the dottle and there were some nicks along the outer edge of the bowl, particularly on the front edge. There was a lot of overflow on the rim, particularly heavy on the back side. The stem had some minor tooth chatter on both sides near the button and scratching on the surface. There were some small nicks on the top side of the stem. It was lightly oxidized and it was slightly overturned to the right. The Dr. Grabow metal “spear” stinger was missing. The pipe was very dirty.

I took close up photos of the bowl and rim top as well as the stem. The rim top had been beaten on a hard surface to knock out the dottle and there were some nicks along the outer edge of the bowl, particularly on the front edge. There was a lot of overflow on the rim, particularly heavy on the back side. The stem had some minor tooth chatter on both sides near the button and scratching on the surface. There were some small nicks on the top side of the stem. It was lightly oxidized and it was slightly overturned to the right. The Dr. Grabow metal “spear” stinger was missing. The pipe was very dirty. I looked up the brand and the line on Pipedia to see what I could find out about it. I have often wondered about how Grabow came up with the names like Regal, Eldorado, Starfire etc. The article solved that mystery for me so I have included that portion for easy reference. The link is:(https://pipedia.org/wiki/Dr._Grabow_Models_(Series,Line)_Names_Through_the_Years).

I looked up the brand and the line on Pipedia to see what I could find out about it. I have often wondered about how Grabow came up with the names like Regal, Eldorado, Starfire etc. The article solved that mystery for me so I have included that portion for easy reference. The link is:(https://pipedia.org/wiki/Dr._Grabow_Models_(Series,Line)_Names_Through_the_Years).

Before I get started in this section here is a great piece of trivia that I learned from a devoted and caring Dr. Grabow employee recently. You have probably wondered, as I have, just where these names originated or what inspired them. Maybe you have even guessed the connection, but I sure didn’t! When this employee mentioned this to me, he brought it up like a riddle: “THINK CARS!” Now, see if you came up with what I did:

Eldorado — Cadillac

Viscount — Dodge (Car built by Chrysler Corporation of Canada Ltd, for Canadian Markets only ca1959.)

Starfire — Oldsmobile (The original Oldsmobile Ninety-Eight Starfire, named after the Lockheed F9413 Starfire fighter jet, was first introduced as a show car in 1953 at GM’s Motorama along with the Buick Skylark and the Cadillac Eldorado.)

Regal — Buick

Savoy — Plymouth (by the way, my friend at Dr. Grabow didn’t say, but there was also a Plymouth BELVEDERE!)

Riviera — Buick, I think first produced for model year 1963, which would have made it known in 1962. The pipe name precedes that, but maybe I missed something.

Lark – Studebaker

All of these cars had roots or beginnings in the 1950s and early 1960s I believe, and perhaps I should do a little more research along those lines to get more accurate facts. If anyone finds better info, just let me know. I never thought of a “car” connection, but had looked at some sort of Royalty thing, what with the DUKEs, VISCOUNT, ROYALTON AND SAVOY, etc. I haven’t checked to see if they were also car names or not.

The article also included the following information on the date of the line. It stated that the STARFIRE (c1956) — First appears in a magazine ad for $3.50 as early as December 1956. “E” selection of briar was used on both the Starfire and Westbrook.

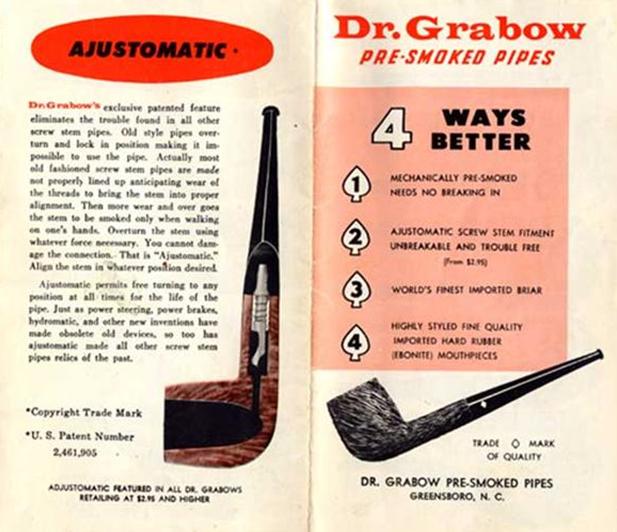

I also wanted to refresh my memory on the Patent information for the Adjustomatic stem and found a page from a catalogue in the same Pipedia article. I have included that page below. The description of the patented system and the cutaway picture are helpful in understanding how the system works. Armed with a refreshed memory I was eager to dive into the restoration of the Starfire. It really was a beautiful piece of briar and I could not wait to see the finished pipe. I started by removing the stem. I found that not only was the stinger apparatus missing but it had actually broken off in the tenon itself. I knew from past experience that the stinger were threaded and unscrewed from the tenon. In this case the upper part of the spade stinger had been twisted off leaving the stem clogged and useless. There was no airflow in the stem at all as the broken stinger cut off all air. I used a piece of wire to pry the edges of the broken stinger to the middle of the tenon, thinking I might be able to use some needle nose pliers to twist it out. But that did not work. It was time to resort to more intrusive measures. I set up my cordless drill and a small drill bit and drilled the tenon. I was careful to keep the bit in the centre of the tenon so as to not damage the threads should I want to put a new stinger in place. It was not too long before the broken stinger end came out on the drill bit. I blew air through the stem and was happy that it was clear and unimpeded.

Armed with a refreshed memory I was eager to dive into the restoration of the Starfire. It really was a beautiful piece of briar and I could not wait to see the finished pipe. I started by removing the stem. I found that not only was the stinger apparatus missing but it had actually broken off in the tenon itself. I knew from past experience that the stinger were threaded and unscrewed from the tenon. In this case the upper part of the spade stinger had been twisted off leaving the stem clogged and useless. There was no airflow in the stem at all as the broken stinger cut off all air. I used a piece of wire to pry the edges of the broken stinger to the middle of the tenon, thinking I might be able to use some needle nose pliers to twist it out. But that did not work. It was time to resort to more intrusive measures. I set up my cordless drill and a small drill bit and drilled the tenon. I was careful to keep the bit in the centre of the tenon so as to not damage the threads should I want to put a new stinger in place. It was not too long before the broken stinger end came out on the drill bit. I blew air through the stem and was happy that it was clear and unimpeded. I used a piece of 000 steel wool to clean off the debris from the threads and body of the metal tenon. I cleaned the airway in the stem, shank and mortise with pipe cleaners, cotton swabs and alcohol. I scrubbed those areas out until the pipe cleaners and swabs came out clean.

I used a piece of 000 steel wool to clean off the debris from the threads and body of the metal tenon. I cleaned the airway in the stem, shank and mortise with pipe cleaners, cotton swabs and alcohol. I scrubbed those areas out until the pipe cleaners and swabs came out clean. The stem was slightly overturned so I worked it back and forth until it lined up. That is the purpose of the Adjustomatic system. I took photos of the pipe with the stem in place and aligned.

The stem was slightly overturned so I worked it back and forth until it lined up. That is the purpose of the Adjustomatic system. I took photos of the pipe with the stem in place and aligned.

I reamed the bowl with a PipNet reamer starting with the smallest cutting head and working my way up to the second cutting head as it was the same diameter as the bowl. I reamed it back to bare briar. I cleaned up the remnants with a Savinelli Fitsall Pipe Knife.

I reamed the bowl with a PipNet reamer starting with the smallest cutting head and working my way up to the second cutting head as it was the same diameter as the bowl. I reamed it back to bare briar. I cleaned up the remnants with a Savinelli Fitsall Pipe Knife.

I carefully sanded the scooped rim top with 220 grit sandpaper to remove the thick lava coat and to minimize the damage on the front outer edge of the bowl.

I carefully sanded the scooped rim top with 220 grit sandpaper to remove the thick lava coat and to minimize the damage on the front outer edge of the bowl. I polished the bowl and rim with micromesh sanding pads – wet sanding it with 1500-2400 grit pads and dry sanding with 3200-12000 grit pads. I wiped the bowl down after each pad with acetone to clean off the sanding dust. The photos show the progress of the polishing. I decided to do this before the deep cleaning with Before & After Restoration Balm this time.

I polished the bowl and rim with micromesh sanding pads – wet sanding it with 1500-2400 grit pads and dry sanding with 3200-12000 grit pads. I wiped the bowl down after each pad with acetone to clean off the sanding dust. The photos show the progress of the polishing. I decided to do this before the deep cleaning with Before & After Restoration Balm this time.

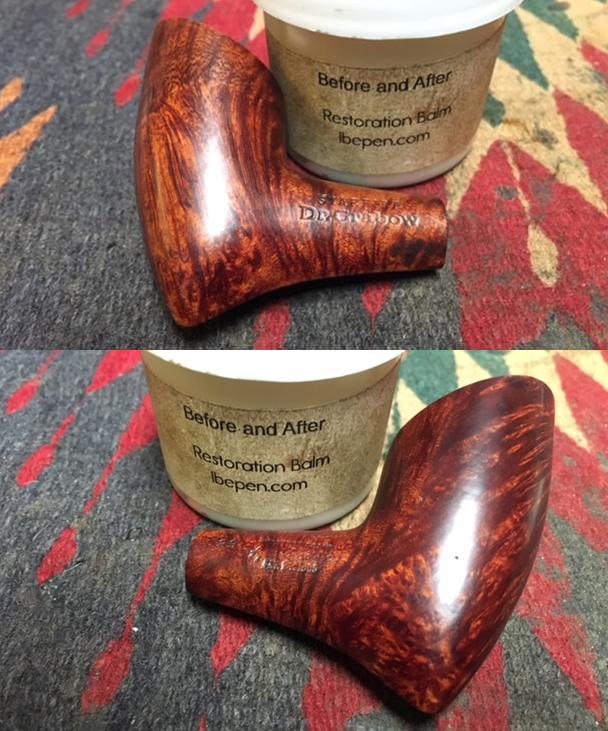

I decided to leave the rim unstained as the polishing had blended the colours with the bowl really well. Instead I worked some Before & After Restoration Balm into the surface of the briar with my finger tips to deep clean the finish, enliven and protect the wood. I worked the balm into the rim top to polish the cleaned up area. I let it sit for a few minutes and then buffed it with a cotton cloth. The grain in the wood came alive and there was a rich shine to the briar. I took some photos of the bowl at this point to mark the progress in the restoration.

I decided to leave the rim unstained as the polishing had blended the colours with the bowl really well. Instead I worked some Before & After Restoration Balm into the surface of the briar with my finger tips to deep clean the finish, enliven and protect the wood. I worked the balm into the rim top to polish the cleaned up area. I let it sit for a few minutes and then buffed it with a cotton cloth. The grain in the wood came alive and there was a rich shine to the briar. I took some photos of the bowl at this point to mark the progress in the restoration.

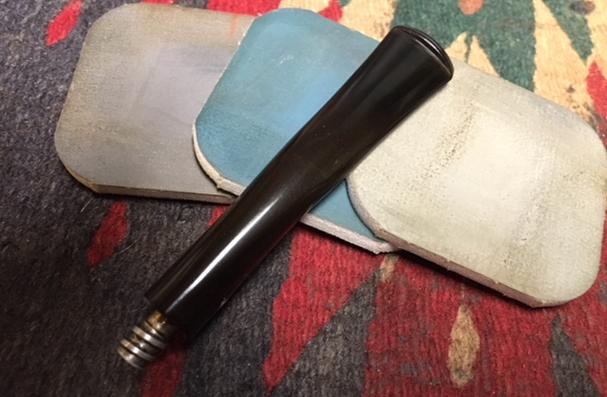

I set the bowl aside in my rack and worked on the stem. I started by sanding it with 220 grit sandpaper to remove the light oxidation, tooth chatter and nicks in the surface.

I set the bowl aside in my rack and worked on the stem. I started by sanding it with 220 grit sandpaper to remove the light oxidation, tooth chatter and nicks in the surface. I worked over the stem with micromesh sanding pads. I polished out the sanding scratches and marks from the reshaping work. I wet sanded it with 1500-2400 grit pads and dry sanded it with 3200-12000 grit pads and wiped it down with Obsidian Oil after each one. When I finished with the last micromesh pad I gave it a final coat of oil and let it dry.

I worked over the stem with micromesh sanding pads. I polished out the sanding scratches and marks from the reshaping work. I wet sanded it with 1500-2400 grit pads and dry sanded it with 3200-12000 grit pads and wiped it down with Obsidian Oil after each one. When I finished with the last micromesh pad I gave it a final coat of oil and let it dry.

With the stem polished I put it back on the pipe and buffed the entire pipe with Blue Diamond polish on the buffing wheel. I buffed it with the polishing compound until it was shiny. I gave the entire pipe several coats of carnauba wax and buffed it with a clean buffing pad to raise the shine. I hand buffed it with a microfibre cloth to deepen the shine. The stem and the bowl polished up pretty nicely. The finished pipe is shown in the photos below. This is the fourth of Craig’s five pipes. Once I finish the last of the pipes I will pack them up and get them out to him. I am looking forward to hearing what he will think once he has them in hand. Thanks for walking through these restorations with me. Once again I can’t help thinking that the pipeman who gave Craig these pipes would be happy that they are back in service and that Craig is carrying on the pipeman’s trust with them. Cheers.

With the stem polished I put it back on the pipe and buffed the entire pipe with Blue Diamond polish on the buffing wheel. I buffed it with the polishing compound until it was shiny. I gave the entire pipe several coats of carnauba wax and buffed it with a clean buffing pad to raise the shine. I hand buffed it with a microfibre cloth to deepen the shine. The stem and the bowl polished up pretty nicely. The finished pipe is shown in the photos below. This is the fourth of Craig’s five pipes. Once I finish the last of the pipes I will pack them up and get them out to him. I am looking forward to hearing what he will think once he has them in hand. Thanks for walking through these restorations with me. Once again I can’t help thinking that the pipeman who gave Craig these pipes would be happy that they are back in service and that Craig is carrying on the pipeman’s trust with them. Cheers.