Blog by Steve Laug

This is the second pipe from the lot my brother Jeff picked up an estate sale a few weekends ago. He had received a call from the auction house that was running the sale to let him know that there were going to be some pipes in the sale. They said that many of the pipes were what they called higher end pipes. They talked a bit and he asked if they would mind sending him a list of the pipes that were coming up. They went one step better and sent him the two photos to the left of the pipes as a preview of what was going on sale. Using FaceBook Messenger we went through the pipes and picked the ones that we wanted to purchase. He would go to the sale the next day and see what he could find. It is times like this that I wish I lived close so I could go with him to these sales.

This is the second pipe from the lot my brother Jeff picked up an estate sale a few weekends ago. He had received a call from the auction house that was running the sale to let him know that there were going to be some pipes in the sale. They said that many of the pipes were what they called higher end pipes. They talked a bit and he asked if they would mind sending him a list of the pipes that were coming up. They went one step better and sent him the two photos to the left of the pipes as a preview of what was going on sale. Using FaceBook Messenger we went through the pipes and picked the ones that we wanted to purchase. He would go to the sale the next day and see what he could find. It is times like this that I wish I lived close so I could go with him to these sales.

Friday morning he went into the sale and they handed him a bucket and the box of pipes that they had set back behind the counter for him. There were indeed some nice pipes in the batch and certainly pricier than the average lot we usually find at estate or antique sales and malls. There were quite a few Savinelli pipes as well as Stanwell, GBD, Aldo Velani, Nording, Il Ceppo, Barlings, DiMonte and a Chacom Sahara. They made him a proposition for the entire lot of pipes and he went for it. He came home with all of the pipes in the photos to the left.

When he got home he called me on FaceTime and went through the pipes he had picked up. We were both pretty excited by the lot. As we went through them we noted the names, brands and the stamping on the shank of each pipe. I got more excited as we noted each pipe and its condition. We realized that these pipes were in pretty decent shape other than the usual dirtiness and grime from smoking. There was not any significant damage to rims or bowls. Almost all the stems had tooth marks near the button on both sides that would need to be cleaned up. But other than that, it was a very nice lot of pipes. We had done well with the purchase.

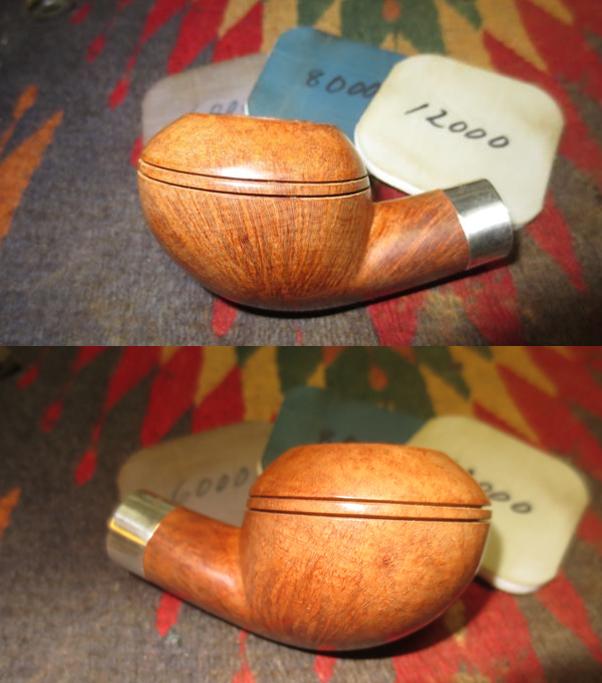

I chose to work on the Aldo Velani Italian Dublin next. It is a beautiful Dublin shaped pipe that was in pretty good shape. It was stamped on the left side of the shank with the brand ALDO VELANI. On the underside of the shank next to the stem shank junction it bore the stamp ITALY. The saddle stem was Lucite and had not stamping or logo on it. My brother took the following photos before he worked on the pipes. The finish on the bowl was in pretty decent shape. The rim surface was dirty and had some tars and oil build up. Around the inner edge of the bowl some of varnish coat was peeling off and the briar was showing through. There were some dents and nicks in the surface. On the front right of the bowl there was a spot where the varnish was damaged like the bowl had been rubbed against a rough surface (it is visible in the second photo below). I would need to smooth out those areas and stain and give them a top coat to replace the shine. The finish on the sides and the bottom of the bowl was in excellent shape.

The finish on the bowl was in pretty decent shape. The rim surface was dirty and had some tars and oil build up. Around the inner edge of the bowl some of varnish coat was peeling off and the briar was showing through. There were some dents and nicks in the surface. On the front right of the bowl there was a spot where the varnish was damaged like the bowl had been rubbed against a rough surface (it is visible in the second photo below). I would need to smooth out those areas and stain and give them a top coat to replace the shine. The finish on the sides and the bottom of the bowl was in excellent shape.

The next two photos show the stamping on the pipe – the brand on the left side and the country of origin on the underside next to the silver band.

The next two photos show the stamping on the pipe – the brand on the left side and the country of origin on the underside next to the silver band. The stem had tooth chatter on the top side next to the button and on top of it. On the underside there were tooth marks and chatter that would need to be sanded out. Fortunately none of them were too deep.

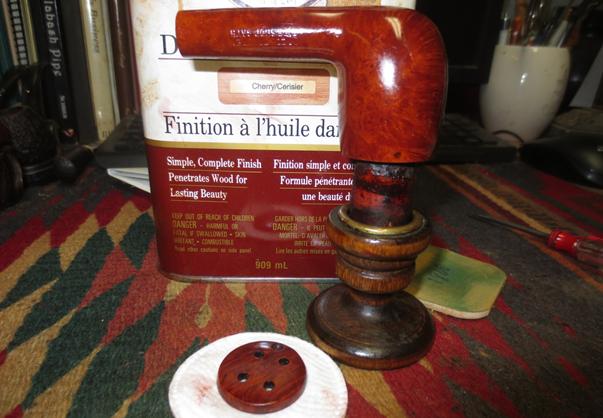

The stem had tooth chatter on the top side next to the button and on top of it. On the underside there were tooth marks and chatter that would need to be sanded out. Fortunately none of them were too deep. Once again Jeff did his usual thorough cleanup of the pipe. He scrubbed the interior and exterior and sent me a very clean pipe that I only needed to put the finishing touches on. The next four photos show the pipe when I brought it to my work table. The pipe looked really good. The finish on the bowl sides, bottom and shank were in excellent condition. The scrape on the front of the bowl and the rim scrapes where the varnish coat was missing were clean and ready to repair. The stem was clean as well other than the light oxidation and the tooth chatter.

Once again Jeff did his usual thorough cleanup of the pipe. He scrubbed the interior and exterior and sent me a very clean pipe that I only needed to put the finishing touches on. The next four photos show the pipe when I brought it to my work table. The pipe looked really good. The finish on the bowl sides, bottom and shank were in excellent condition. The scrape on the front of the bowl and the rim scrapes where the varnish coat was missing were clean and ready to repair. The stem was clean as well other than the light oxidation and the tooth chatter.

I took a photo of the rim top to show the damage on the inner edge. You can see the area on the right side of the inner edge and the back side. There was also some damage on the front inner edge of the bowl. These would need to be sanded and repaired.

I took a photo of the rim top to show the damage on the inner edge. You can see the area on the right side of the inner edge and the back side. There was also some damage on the front inner edge of the bowl. These would need to be sanded and repaired. The stem was very clean other than the tooth chatter and tooth marks.

The stem was very clean other than the tooth chatter and tooth marks. When I removed the stem the silver band fell off in my hands. The glue that had held it in place had dried and cracked. I used a tooth pick to spread all purpose glue around the end of the shank and pressed the band in place.

When I removed the stem the silver band fell off in my hands. The glue that had held it in place had dried and cracked. I used a tooth pick to spread all purpose glue around the end of the shank and pressed the band in place. I sanded the inner edge of the rim to remove the damaged finish. I used 1500-6000 grit micromesh sanding pads to smooth out the damaged areas. I wet sanded the areas to minimize the damage. I touched up the sanded areas with a dark brown stain pen. It matched the stain on the surrounding bowl.

I sanded the inner edge of the rim to remove the damaged finish. I used 1500-6000 grit micromesh sanding pads to smooth out the damaged areas. I wet sanded the areas to minimize the damage. I touched up the sanded areas with a dark brown stain pen. It matched the stain on the surrounding bowl.

I ran a pipe cleaner and alcohol through the mortise and airway in the shank and stem. The pipe cleaner came out very clean and showed that the pipe was spotless.

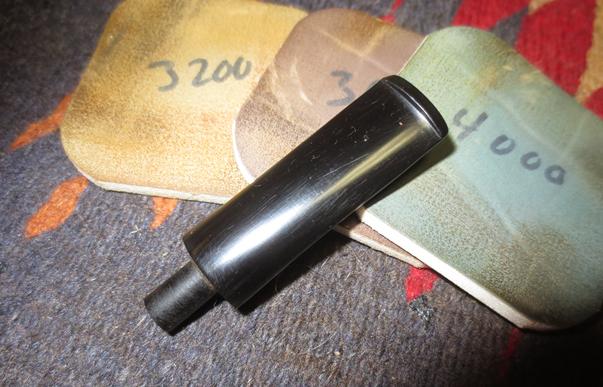

I ran a pipe cleaner and alcohol through the mortise and airway in the shank and stem. The pipe cleaner came out very clean and showed that the pipe was spotless. I sanded out the tooth chatter and tooth marks with 220 grit sandpaper until the surface of the stem was smooth. Once I had it sanded smooth I polished it with micromesh sanding pad – wet sanding it with 1500-2400 grit pads and dry sanding it with 3200-12000 grit pads. I wiped the stem down with a damp cotton pad to remove the sanding dust after each pad so that I could see how it was polishing.

I sanded out the tooth chatter and tooth marks with 220 grit sandpaper until the surface of the stem was smooth. Once I had it sanded smooth I polished it with micromesh sanding pad – wet sanding it with 1500-2400 grit pads and dry sanding it with 3200-12000 grit pads. I wiped the stem down with a damp cotton pad to remove the sanding dust after each pad so that I could see how it was polishing.

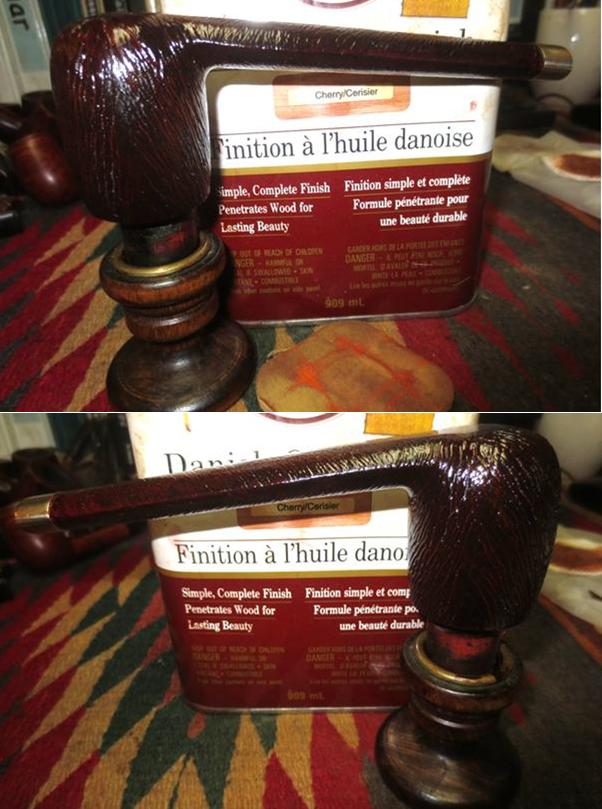

To give the repaired areas on the rim top a shine like the rest of the bowl I buffed it with Blue Diamond and then applied some Cherry Danish Oil to the rim top with a cotton swab. I repeated the process until the top of the rim shone. It looked like the rest of the bowl once again. I buffed the bowl and stem with Blue Diamond polish on the buffing wheel. It polished out all of the minute scratches in the surface of the Lucite and the briar. It does a great job with a soft touch when polishing briar and the shine that the Blue Diamond gives Lucite is glassy. I gave the bowl and stem several coats of carnauba wax and buffed the pipe with a clean buffing pad to raise the shine. I hand buffed it with a microfibre cloth to deepen the shine. The finished pipe is shown in the photos below. It really is a beautiful looking pipe. The Dublin shape is perfectly laid out to maximize the grain. This one will soon be for sale on the rebornpipes store. If you are interested in adding it to your collection let me know either by email to slaug@uniserve.com or a private message on FaceBook. Thanks for looking.

To give the repaired areas on the rim top a shine like the rest of the bowl I buffed it with Blue Diamond and then applied some Cherry Danish Oil to the rim top with a cotton swab. I repeated the process until the top of the rim shone. It looked like the rest of the bowl once again. I buffed the bowl and stem with Blue Diamond polish on the buffing wheel. It polished out all of the minute scratches in the surface of the Lucite and the briar. It does a great job with a soft touch when polishing briar and the shine that the Blue Diamond gives Lucite is glassy. I gave the bowl and stem several coats of carnauba wax and buffed the pipe with a clean buffing pad to raise the shine. I hand buffed it with a microfibre cloth to deepen the shine. The finished pipe is shown in the photos below. It really is a beautiful looking pipe. The Dublin shape is perfectly laid out to maximize the grain. This one will soon be for sale on the rebornpipes store. If you are interested in adding it to your collection let me know either by email to slaug@uniserve.com or a private message on FaceBook. Thanks for looking.