Blog by Steve Laug

Have you ever heard of Bartlett Pipes? They are rather strange upside down looking pipes in my opinion. My brother sent me this link to a youtube video on the Bartlett pipes. We were both searching for information on the brand as neither of us had heard of them or seen them close up before. https://www.youtube.com/watch?v=dyFfLidMmws&feature=youtu.be

What made the hunt for information regarding this oddity necessary was that my brother had bid on two of these and won both of them on eBay. One of them was NOS (new old stock) and one of them was smoked and well used. In the past I had seen photos and read on the online forums about these pipes but had never really done any research to figure out what they were. They were always a bit of an oddity to me. Either way the stem sat they did not look right and when you removed the cap at the top the airway was almost at the top of the bowl (if the screw on lid was to be considered the top). The angles of the shank and the curve of the stem leads me to think that the capped surface was the top of the bowl. The bottom side of the bowl was a screen that allowed for airflow through the bowl. I am still trying to figure out if you light the pipe from the bottom or the top of the bowl.

From what I read on the various online forums and in the articles that I could find I was able to piece together how the pipe functioned. The pipe bowl was open at the top and the bottom. The airway into the shank was near the top opening and led directly to the pipe stem. A polished aluminum cover is screwed onto the threaded briar bowl top and is left in place when the pipe is smoked. At the other end of the bowl there is a screen that covers the bottom opening that keeps the tobacco in the bowl while permitting access to the tobacco to light it. The screen is supposedly fine enough that the ash does not fall out of the bowl into the lap of the smoker. With the cover in place on the top opening, the tobacco is ignited via the screen on the bottom, causing the tobacco to burn from the bottom up. New tobacco may be added at any time by removing the cap from the top of the pipe. It is said that the burning the tobacco from the bottom reduces the moisture that usually collects and thus makes it unnecessary to dry out the bowl between pipes. The bottom lighting also makes lighting the pipe in the wind or rain much simpler.

From what I read on the various online forums and in the articles that I could find I was able to piece together how the pipe functioned. The pipe bowl was open at the top and the bottom. The airway into the shank was near the top opening and led directly to the pipe stem. A polished aluminum cover is screwed onto the threaded briar bowl top and is left in place when the pipe is smoked. At the other end of the bowl there is a screen that covers the bottom opening that keeps the tobacco in the bowl while permitting access to the tobacco to light it. The screen is supposedly fine enough that the ash does not fall out of the bowl into the lap of the smoker. With the cover in place on the top opening, the tobacco is ignited via the screen on the bottom, causing the tobacco to burn from the bottom up. New tobacco may be added at any time by removing the cap from the top of the pipe. It is said that the burning the tobacco from the bottom reduces the moisture that usually collects and thus makes it unnecessary to dry out the bowl between pipes. The bottom lighting also makes lighting the pipe in the wind or rain much simpler.

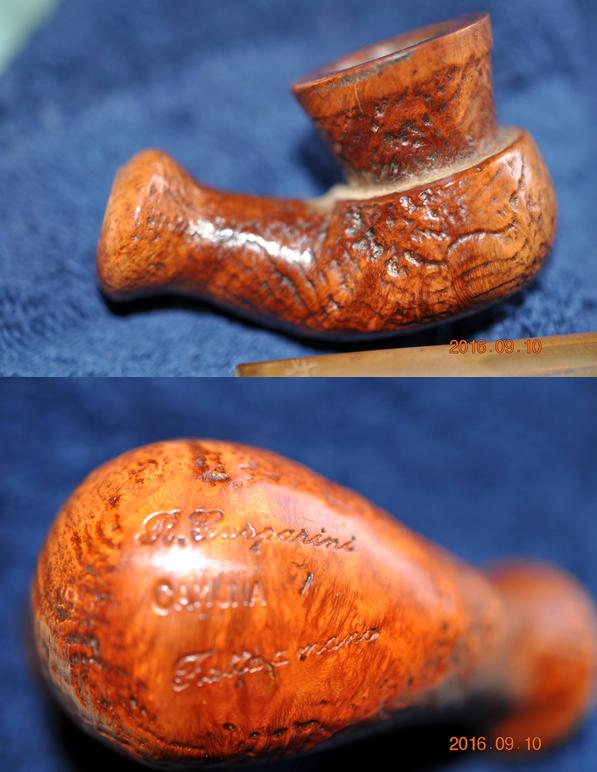

The next photos show the screened bottom of the two pipes that I was going to work on. The smooth pipe is new and unsmoked the sandblasted pipe is used and you can see some charring around the inner edges on the bottom of the bowl. The bowl bottom on the unsmoked pipe was stained black to minimize the darkening that occurs when the pipe is lit. Both pipes were stamped with the name Bartlett over a Patent Number – 4235252. The stamping on the sandblast version was on the right side of the shank and the one on the smooth was on the left side of the shank. Both stampings were very sharp and legible. The smooth briar pipe was also stamped on the right side of the shank with the work Imported Briar.

Both pipes were stamped with the name Bartlett over a Patent Number – 4235252. The stamping on the sandblast version was on the right side of the shank and the one on the smooth was on the left side of the shank. Both stampings were very sharp and legible. The smooth briar pipe was also stamped on the right side of the shank with the work Imported Briar. At this point I wanted to know more about the pipe. It was a brand that I was unfamiliar with. In usual unhelpful fashion I found that the Bartlett Pipe was made by the Bartlett Pipe Company Inc. of Bartlett, NH (which I assume is New Hampshire).

At this point I wanted to know more about the pipe. It was a brand that I was unfamiliar with. In usual unhelpful fashion I found that the Bartlett Pipe was made by the Bartlett Pipe Company Inc. of Bartlett, NH (which I assume is New Hampshire).

On the Pipesmokers Forum I found some interesting information from a friend of the inventor of the pipe. Here is the link to the conversation on that website. http://pipesmokersforum.com/community/threads/an-interesting-surprise.46690/

Adam Hirshan comments: “A friend of mine invented and patented a revolutionary smoking pipe that lights from the bottom. A major manufacturer saw the promise and bought the idea 15 years ago, but it never took off. My friend got the patent back a few years ago and we’ve developed a new rock maple version that we call The Freedom Smoking Pipe.”

“It smokes cool and easy. A stainless steel screen holds the tobacco and ash in place – nothing falls out. No moisture or resin accumulate in the bowl. A cork and leather top makes it wind and rain proof.”

“We had initial success wholesaling through a well-known distributor. We were in about 100 tobacco shops nationwide, and appeared in the Levin catalog. Response from our early customers was strong – most loved it, some hated it. Then interest dropped off and left us wondering what happened.”

I did some more digging and found some information on the Dr. Grabow Collectors Forum. Here is the link: http://drgrabows.myfreeforum.org/viewcardtopic.php?t=1236

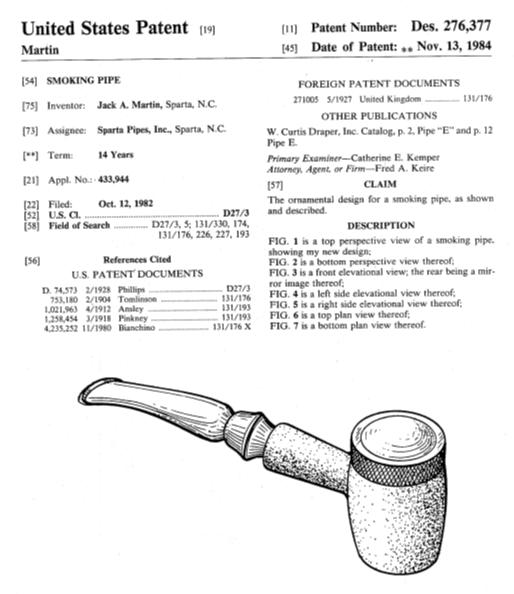

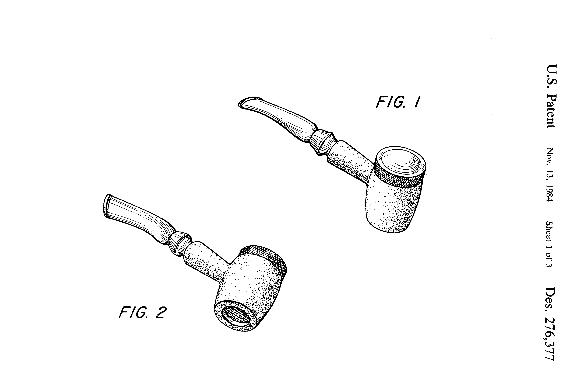

I quote: “I was asked what I thought about my Bartlett pipe and figured I’d start a new topic. If you don’t know what it is, it’s the ‘Upside down pipe’. The history as I know it is there have been 3 variations. It was invented in the 70’s. Sparta picked up the rights and produced them in the 80’s for 8-10yrs. Didn’t take off. Rights were returned to the inventor. Seems they are no longer produced. (ed. This seems to go along with the information from Adam Hirshan in the above comment).”

The quote goes on with an interesting reference to the Sparta example of the pipe: “Mine has a red stain, and the chain to hold the cap. My stem is from a junk pipe I had. The weirdest thing is not seeing the baccy burn. First smoke required a tamp halfway through and the bowl got dang hot! Second time out, the pack was perfect. One light, no tamp. Just weird not tending the bowl like normal…….Guess this is why the never went anywhere.”

I was also able to find the patent information for US Pat.4235252. Interestingly it read much like an earlier paragraph that I pieced together regarding the pipe. Here is the document in full. First the written description and then the drawings of the pipe. It read that “the patent was for a smoking pipe having improved smoking characteristics. The smoking pipe includes a bowl having top and bottom openings and a breather hole near the top opening and in communication with a pipe stem. A cover assembly is attached to the bowl adjacent to the top opening and covers the top opening when the pipe is to be smoked. A retainer having a screen cooperates with the bottom opening for retaining smoking tobacco within the bowl while permitting access to the tobacco for the ignition thereof. The retainer may also be removed from its position relative to the bottom opening for the removal of ashes. Tobacco is inserted into the bowl via either opening, but preferably via the top opening and to a level just below the breather hole. With the cover assembly covering the top opening, the tobacco is ignited via the screen of the retainer, causing combustion of the tobacco in a bottom-to-top fashion. New tobacco may be added to existing tobacco via the top opening and ashes may be removed via the bottom opening, even as the smoking process takes place. The bottom-to-top combustion minimizes puddling of tobacco juices or the requirement of drying out periods and facilitates lighting the pipe in the presence of wind, rain, etc. The lack of obstruction of the breather hole by the presence of tobacco results in a smooth draw with the generation of a substantial, satisfying volume of smoke.” (ed. On the two pipes I have the screen on the bottom is not removable and the top is a threaded aluminum cap.)

My brother took some photos of the sandblast version of the pipe that shows the shape but also interestingly shows a hidden benefit. When he removed the cap from the top of the bowl the bowl was already filled with a broken flake tobacco. Unfortunately it was dry and crumbled to dust when he cleaned out the bowl.

My brother took some photos of the sandblast version of the pipe that shows the shape but also interestingly shows a hidden benefit. When he removed the cap from the top of the bowl the bowl was already filled with a broken flake tobacco. Unfortunately it was dry and crumbled to dust when he cleaned out the bowl.

My brother cleaned and reamed the smoked sandblast pipe and cleaned out the dust from the unsmoked smooth one. He scrubbed the briar with Murphy’s Oil Soap and cleaned out the mortise and the airway in the shank and the stem. The stems on both pipes were lightly oxidized and on the smoked pipe there was a small tooth dent on the top of the stem near the button. I took the following photos to show what the pair looked like when I brought them to my work table.

My brother cleaned and reamed the smoked sandblast pipe and cleaned out the dust from the unsmoked smooth one. He scrubbed the briar with Murphy’s Oil Soap and cleaned out the mortise and the airway in the shank and the stem. The stems on both pipes were lightly oxidized and on the smoked pipe there was a small tooth dent on the top of the stem near the button. I took the following photos to show what the pair looked like when I brought them to my work table.

He did a great job cleaning up the aluminum caps on both the inside and the outside. He also cleaned up the thread on the top of both bowls allowing the caps to screw on easily.

He did a great job cleaning up the aluminum caps on both the inside and the outside. He also cleaned up the thread on the top of both bowls allowing the caps to screw on easily. He cleaned the screen on the smoked pipe with cotton swabs and alcohol until it looked as good as the unsmoked pipe. The inner edge of the rim on the bottom of the bowl was charred and showed some wear and tear from lighting the pipe from the bottom. I think one of the draw backs on this pipe is not being able to see the flame hitting the tobacco. The rim on this bowl shows significant rim damage.

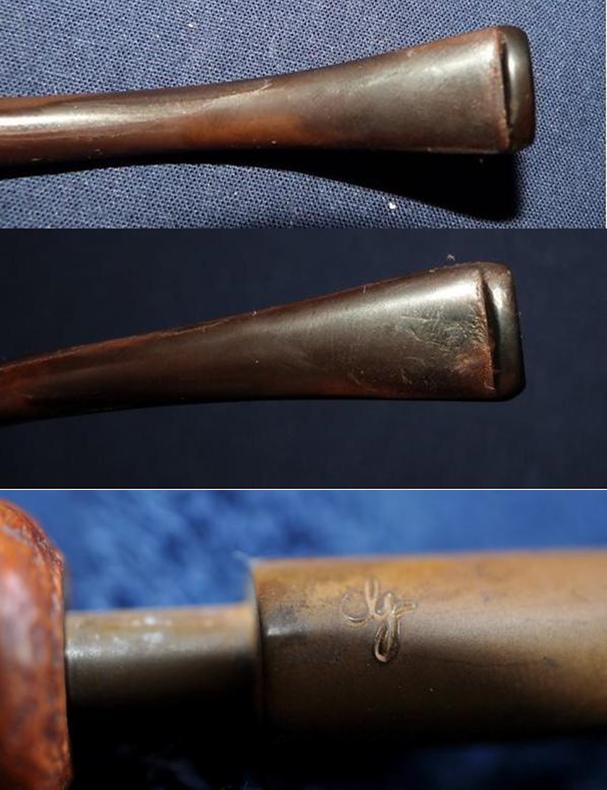

He cleaned the screen on the smoked pipe with cotton swabs and alcohol until it looked as good as the unsmoked pipe. The inner edge of the rim on the bottom of the bowl was charred and showed some wear and tear from lighting the pipe from the bottom. I think one of the draw backs on this pipe is not being able to see the flame hitting the tobacco. The rim on this bowl shows significant rim damage. I took close up photos of the stems to show the light oxidation – it is not deep in the vulcanite and the overall condition of the stems. The stem on the sandblast pipe had a small pinprick tooth mark on the top of the stem. I have circled it in red on the first photo below.

I took close up photos of the stems to show the light oxidation – it is not deep in the vulcanite and the overall condition of the stems. The stem on the sandblast pipe had a small pinprick tooth mark on the top of the stem. I have circled it in red on the first photo below. I took some photos of each of the pipes before I cleaned them up. They really were in pretty decent shape. There were some rough spots on the bottom of the bowl around the inner edge of the rim but it looked to be original. The smooth briar is new and has a shiny varnish coat that I decided to leave as the pipe is NOS. It was interesting to me to note that the bottom of the bowl was stained with a flat black stain on the new pipe so when I restored the smoked version I would match them. The sandblast is also in really good shape other than the inner edge of the bottom rim on the bowl.

I took some photos of each of the pipes before I cleaned them up. They really were in pretty decent shape. There were some rough spots on the bottom of the bowl around the inner edge of the rim but it looked to be original. The smooth briar is new and has a shiny varnish coat that I decided to leave as the pipe is NOS. It was interesting to me to note that the bottom of the bowl was stained with a flat black stain on the new pipe so when I restored the smoked version I would match them. The sandblast is also in really good shape other than the inner edge of the bottom rim on the bowl.

On both pipes the aluminum cap was in perfect condition on both the inside and the polished outside of the cap. I took photos of the pipes with the covers removed and the bowl tilted to give some idea of what the inside of the bowl looked like. It really is no more than a tube with a cap on one end and a screen on the other end.

On both pipes the aluminum cap was in perfect condition on both the inside and the polished outside of the cap. I took photos of the pipes with the covers removed and the bowl tilted to give some idea of what the inside of the bowl looked like. It really is no more than a tube with a cap on one end and a screen on the other end.

I used the topping board on the damaged bottom of the bowl. I topped it (or maybe bottomed it is more appropriate) until the damage was removed.

I used the topping board on the damaged bottom of the bowl. I topped it (or maybe bottomed it is more appropriate) until the damage was removed. The small crevices that had opened around the inner edge of the bowl were not really cracks but rather areas that had burned with the heat of the flame. I filled them with briar dust and super glue to make them smooth and then retopped the bowl to smooth them out. I stained it with a black aniline stain and touched it up after sanding the repairs.

The small crevices that had opened around the inner edge of the bowl were not really cracks but rather areas that had burned with the heat of the flame. I filled them with briar dust and super glue to make them smooth and then retopped the bowl to smooth them out. I stained it with a black aniline stain and touched it up after sanding the repairs. I sanded the two stems with 220 grit sandpaper to remove the oxidation on the surface of both stems. I used a spot of clear super glue to fill in the tooth mark and sanded the repaired area smooth to match the surface of the stem.

I sanded the two stems with 220 grit sandpaper to remove the oxidation on the surface of both stems. I used a spot of clear super glue to fill in the tooth mark and sanded the repaired area smooth to match the surface of the stem.

I polished both stems with micromesh sanding pads – wet sanding with 1500-2400 grit pads and dry sanding with 3200-12000 grit pads. I rubbed the stem down with Obsidian Oil after each set of three pads. After the last pad I gave it a final rubdown with the oil and set it aside to dry.

I polished both stems with micromesh sanding pads – wet sanding with 1500-2400 grit pads and dry sanding with 3200-12000 grit pads. I rubbed the stem down with Obsidian Oil after each set of three pads. After the last pad I gave it a final rubdown with the oil and set it aside to dry.

I took a photo of the pipes and stems before I took them to the buffer to show what they looked like at this point in my restoration.

I took a photo of the pipes and stems before I took them to the buffer to show what they looked like at this point in my restoration. Here are some photos of the bowls from a variety of angles. There is a nice blasé and some pretty grain – they are a nice pair of pipes.

Here are some photos of the bowls from a variety of angles. There is a nice blasé and some pretty grain – they are a nice pair of pipes.

I buffed the pipes with Blue Diamond on the buffing wheel and then gave the stems several coats of carnauba wax. I gave the sandblast bowl several coats of Conservator’s Wax and left the varnish coat alone on the smooth briar bowl. I buffed both pipe with a clean buffing wheel to raise a shine. I hand buffed them both with a microfibre cloth to deepen the shine. The finished pipe is shown in the photos below. It is a unique piece of pipe and tobacco history. It certainly speaks of the inventiveness of pipesmokers who are perpetually looking for the better and drier smoke. Thanks for taking this journey through the restoration and the history of the Bartlett pipe.

I buffed the pipes with Blue Diamond on the buffing wheel and then gave the stems several coats of carnauba wax. I gave the sandblast bowl several coats of Conservator’s Wax and left the varnish coat alone on the smooth briar bowl. I buffed both pipe with a clean buffing wheel to raise a shine. I hand buffed them both with a microfibre cloth to deepen the shine. The finished pipe is shown in the photos below. It is a unique piece of pipe and tobacco history. It certainly speaks of the inventiveness of pipesmokers who are perpetually looking for the better and drier smoke. Thanks for taking this journey through the restoration and the history of the Bartlett pipe.