Blog by Steve Laug

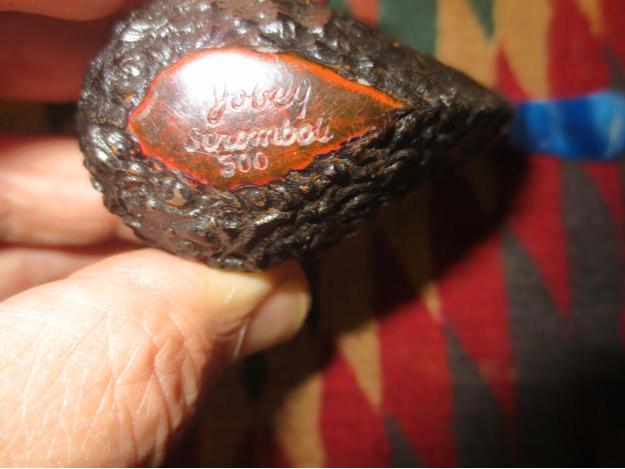

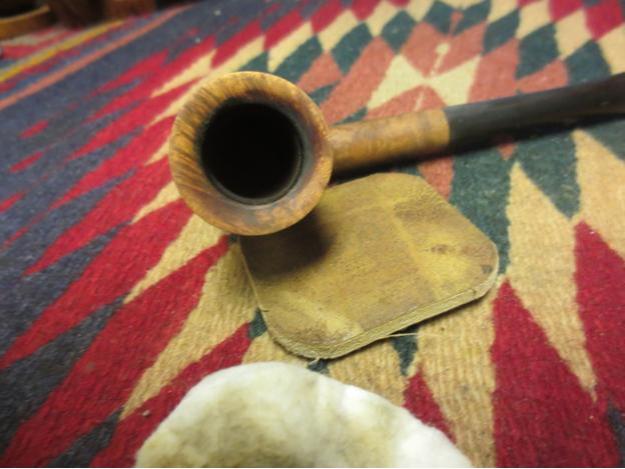

As I said before I never paid much attention to Jobey pipes. My brother has given me a new appreciation for them. The pipe he sent me that I chose to work on next is stamped Jobey Shellmoor on the underside of the shank. There is no shape number or other stamping on the pipe. There is a Jobey logo stamped on the yellow acrylic/Lucite stem. When I first saw the pipe I was pretty certain that the stem was a replacement. Now that I have it in hand I have to admit I was wrong it is the original. When I first picked it up I thought it would be a pretty straightforward repair. I could not have been more wrong but that would come out in the process of the restoration.

The rustication was very dirty on the sides of the bowl but it had that rough rustication that I have come to expect on Shellmoor pipes. The rim was in rough shape with lava in all of the grooves. That would have been easily remedied but there was also a burned area on the top of the rim at the front that had left a deep groove. The bowl was thickly caked (I removed much of it in Idaho when I was there). When I brought it to the work table and tried to finish reaming the bowl I was reminded of the rock hard cake. It took two different reamers to take out the cake. The stem had some tooth marks and the airway was black with tars. When I removed the stem the Jobey Link was stuck in the stem. Not a big deal but it would make getting the black out of the airway.

The rustication was very dirty on the sides of the bowl but it had that rough rustication that I have come to expect on Shellmoor pipes. The rim was in rough shape with lava in all of the grooves. That would have been easily remedied but there was also a burned area on the top of the rim at the front that had left a deep groove. The bowl was thickly caked (I removed much of it in Idaho when I was there). When I brought it to the work table and tried to finish reaming the bowl I was reminded of the rock hard cake. It took two different reamers to take out the cake. The stem had some tooth marks and the airway was black with tars. When I removed the stem the Jobey Link was stuck in the stem. Not a big deal but it would make getting the black out of the airway.

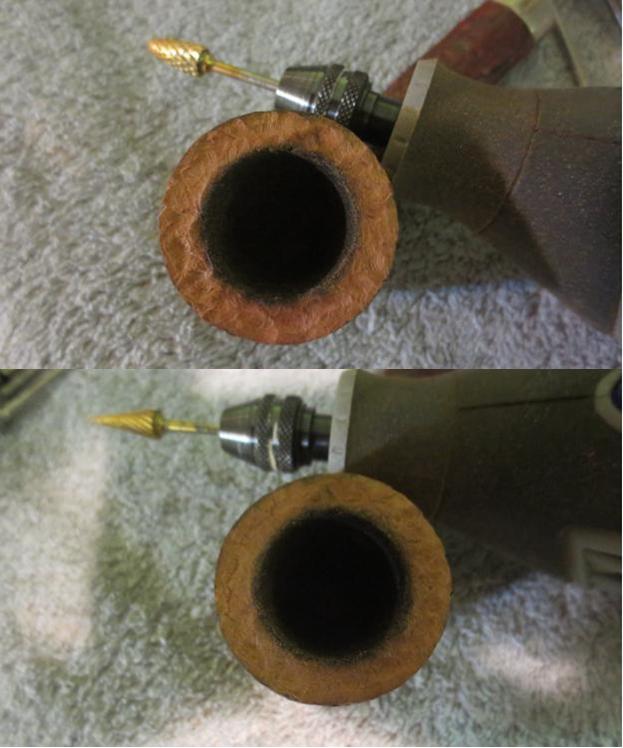

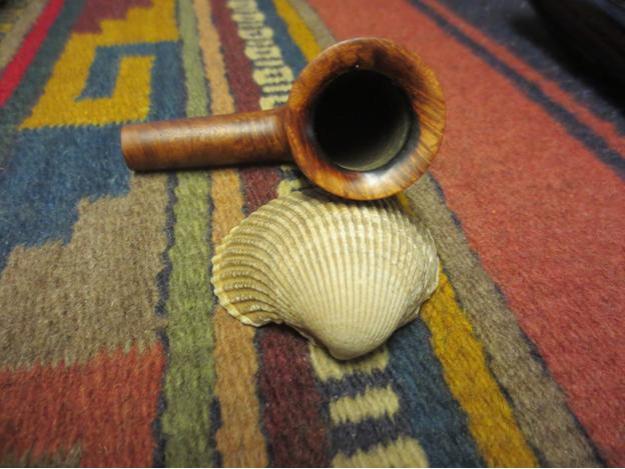

When I examined the rim more closely I saw that it was actually quite damaged. I took two close-up photos of it to show the thick lava and the burned area on the front of the bowl. It is a little hard to see in the second photo (forgive the slightly out of focus photo) but it extends down the front of the bowl about ¼ inch.

When I examined the rim more closely I saw that it was actually quite damaged. I took two close-up photos of it to show the thick lava and the burned area on the front of the bowl. It is a little hard to see in the second photo (forgive the slightly out of focus photo) but it extends down the front of the bowl about ¼ inch.

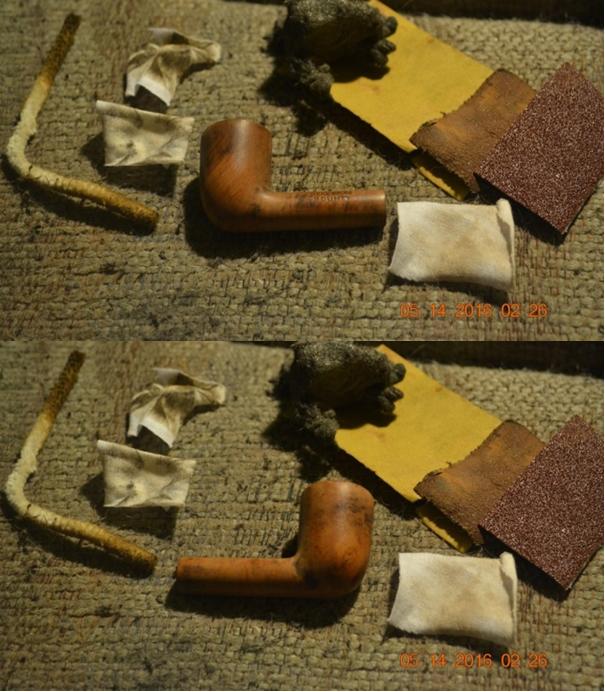

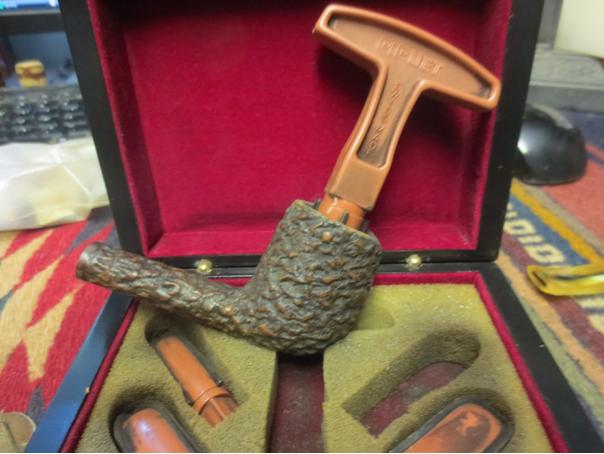

I worked on the Jobey Link and was able to dribble alcohol down the stem to soften the tars that held it in the stem. I wiggled it free. The photo below shows the pipe taken apart.

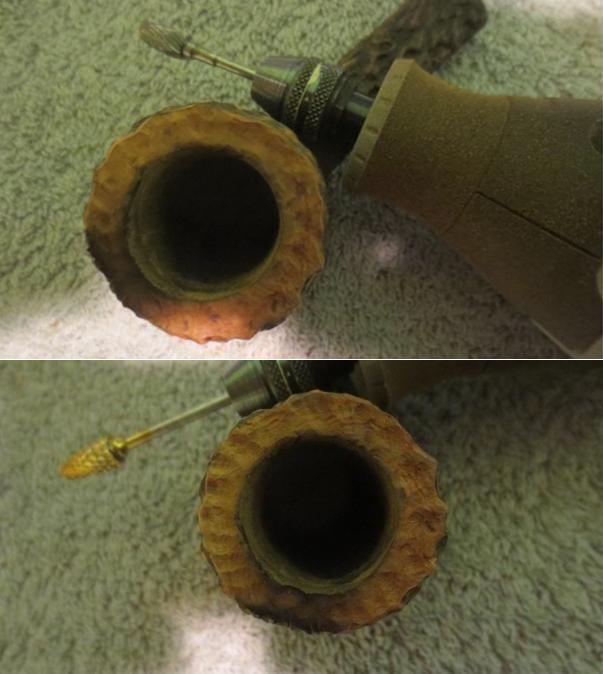

I worked on the Jobey Link and was able to dribble alcohol down the stem to soften the tars that held it in the stem. I wiggled it free. The photo below shows the pipe taken apart. I started working on the bowl by reaming it completely. The cake was exceptionally. I hard I used the PipNet reamer with the first three cutting heads to take the cake back to bare briar. I used a Savinelli Pipe Knife to complete the job at the bottom of the bowl. When I had finished reaming the bowl I noticed that the airway into the bowl was absolutely invisible. I could not see it on the back wall of the bowl. I used the drill bit from the KleenReem pipe reamer to hand drill out the airway from the shank into the bowl. The tars in the shank were almost as hard as the cake in the bowl. It took a lot of elbow grease and pressing the bit into the airway. I was finally rewarded with it popping through into the bowl.

I started working on the bowl by reaming it completely. The cake was exceptionally. I hard I used the PipNet reamer with the first three cutting heads to take the cake back to bare briar. I used a Savinelli Pipe Knife to complete the job at the bottom of the bowl. When I had finished reaming the bowl I noticed that the airway into the bowl was absolutely invisible. I could not see it on the back wall of the bowl. I used the drill bit from the KleenReem pipe reamer to hand drill out the airway from the shank into the bowl. The tars in the shank were almost as hard as the cake in the bowl. It took a lot of elbow grease and pressing the bit into the airway. I was finally rewarded with it popping through into the bowl.

With the rough cleaning done on the bowl and shank I decided to work on the rim surface. I topped it with 220 grit sandpaper on the topping board. (If you look closely at the shank end in the photo it appears that there is a crack in the shank. It is merely a scratch in the top surface of the briar at that point.)

With the rough cleaning done on the bowl and shank I decided to work on the rim surface. I topped it with 220 grit sandpaper on the topping board. (If you look closely at the shank end in the photo it appears that there is a crack in the shank. It is merely a scratch in the top surface of the briar at that point.) After topping it for a while I took a photo to show the extent of the damage to the rim. This photo clarifies what I saw in the original scan of the bowl.

After topping it for a while I took a photo to show the extent of the damage to the rim. This photo clarifies what I saw in the original scan of the bowl. I continued topping the bowl until I got to solid wood under the burned area. The rim surface was darkened but the briar was hard. I picked the burned area on the front of the bowl clean of soft burned wood with a dental pick.

I continued topping the bowl until I got to solid wood under the burned area. The rim surface was darkened but the briar was hard. I picked the burned area on the front of the bowl clean of soft burned wood with a dental pick. I was not too worried about the rim darkening as I intended to rusticate it again to match the rough finish of the bowl. I filled in the burned area with clear super glue to build it up. I also intended to rusticate the burned area on the front of the bowl at the same time. The next series of photos show the process of rustication and the different burrs I used on the Dremel to get the pattern on the rim I wanted. I also worked on the front of the bowl to remove the damage of the burned area with the same burrs. I tried to match the pattern on the rest of the bowl. The success of that will be seen in later photos.

I was not too worried about the rim darkening as I intended to rusticate it again to match the rough finish of the bowl. I filled in the burned area with clear super glue to build it up. I also intended to rusticate the burned area on the front of the bowl at the same time. The next series of photos show the process of rustication and the different burrs I used on the Dremel to get the pattern on the rim I wanted. I also worked on the front of the bowl to remove the damage of the burned area with the same burrs. I tried to match the pattern on the rest of the bowl. The success of that will be seen in later photos.

Once I had the work down with the Dremel and burrs I took it back to the worktable and used a brass bristle brush to knock of the sharp edges and the loose pieces of briar from the rim and the bowl front. The second and third photos show the bowl front and the work that I did to match the pattern in that area.

Once I had the work down with the Dremel and burrs I took it back to the worktable and used a brass bristle brush to knock of the sharp edges and the loose pieces of briar from the rim and the bowl front. The second and third photos show the bowl front and the work that I did to match the pattern in that area.

I scrubbed the briar with Murphy’s Oil Soap and a tooth brush to remove the grime so that I could restain the bowl. I rinsed it with warm running water to remove the soap from the grooves and crevices along with the loosened grime.

I scrubbed the briar with Murphy’s Oil Soap and a tooth brush to remove the grime so that I could restain the bowl. I rinsed it with warm running water to remove the soap from the grooves and crevices along with the loosened grime. I used a black Sharpie to colour in the depths of the rustication on the rim and the repaired area at the front of the bowl. I wanted to approximate the contrast in the rest of the finish.

I used a black Sharpie to colour in the depths of the rustication on the rim and the repaired area at the front of the bowl. I wanted to approximate the contrast in the rest of the finish. I restained the bowl with a dark brown aniline stain and flamed it to set it in the grain. I repeated the process until the coverage was what I wanted.

I restained the bowl with a dark brown aniline stain and flamed it to set it in the grain. I repeated the process until the coverage was what I wanted. I wiped down the bowl with alcohol on cotton pads to remove some of the dark brown stain from the high spots on the bowl and add some contrast and depth to the finish.

I wiped down the bowl with alcohol on cotton pads to remove some of the dark brown stain from the high spots on the bowl and add some contrast and depth to the finish.

I took another close-up photo of the rustication on the rim to show what it looked like with the stain coat.

I took another close-up photo of the rustication on the rim to show what it looked like with the stain coat. I cleaned out the mortise threads and the airway with pipe cleaners, cotton swabs and alcohol.

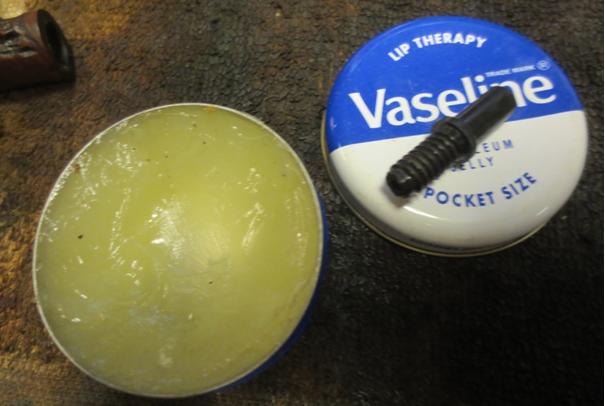

I cleaned out the mortise threads and the airway with pipe cleaners, cotton swabs and alcohol. Once it was clean I greased the threads on the Jobey Link with Vaseline and turned it in place in the shank with a small screwdriver.

Once it was clean I greased the threads on the Jobey Link with Vaseline and turned it in place in the shank with a small screwdriver. The stem turned out to be another issue that I had not taken into real consideration. The dark stain of tars and oils in the airway turned out to be a real pain. I used cotton swabs and alcohol to clean out the portion of the stem that slid over the Link. That was the easy part. I then scrubbed out the airway with alcohol and pipe cleaners. I used a dental pick to clean out the slot in the button. The tars in the airway were stubborn. I mixed a batch of Oxyclean, inserted pipe cleaners in the airway to wick the mixture up the stem and then dropped the pipe in the mixture to soak overnight. I took it out in the morning and scrubbed it with several different brushes and pipe cleaners. I removed about 50% of the black in the stem but not all of it. I put it back in the Oxy soak for another night.

The stem turned out to be another issue that I had not taken into real consideration. The dark stain of tars and oils in the airway turned out to be a real pain. I used cotton swabs and alcohol to clean out the portion of the stem that slid over the Link. That was the easy part. I then scrubbed out the airway with alcohol and pipe cleaners. I used a dental pick to clean out the slot in the button. The tars in the airway were stubborn. I mixed a batch of Oxyclean, inserted pipe cleaners in the airway to wick the mixture up the stem and then dropped the pipe in the mixture to soak overnight. I took it out in the morning and scrubbed it with several different brushes and pipe cleaners. I removed about 50% of the black in the stem but not all of it. I put it back in the Oxy soak for another night. I buffed the bowl by hand with a shoe brush to see what the finish would look like. The following photos give a good picture of where things stand with the bowl at this point.

I buffed the bowl by hand with a shoe brush to see what the finish would look like. The following photos give a good picture of where things stand with the bowl at this point.

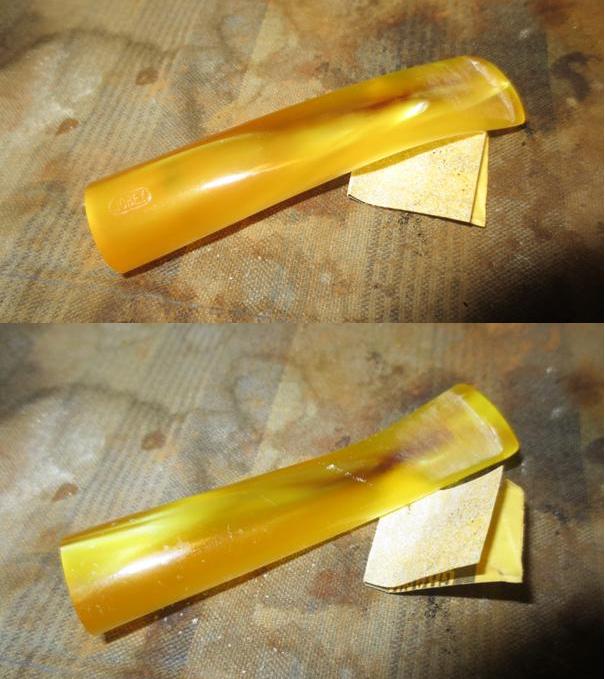

I took the stem out of the Oxy bath and cleaned out a bit more of the darkened area. I used pipe cleaners dipped in Bar Keepers Friend scouring powder and was able to get out more of the tars and darkening. I stopped for a little while and worked on the externals. There were several deep tooth marks in the stem near the button on the top and bottom sides. I sanded and cleaned the stem then filled the tooth marks with clear super glue. When the glue set I sanded the repairs smooth to match the surface of the stem.

I took the stem out of the Oxy bath and cleaned out a bit more of the darkened area. I used pipe cleaners dipped in Bar Keepers Friend scouring powder and was able to get out more of the tars and darkening. I stopped for a little while and worked on the externals. There were several deep tooth marks in the stem near the button on the top and bottom sides. I sanded and cleaned the stem then filled the tooth marks with clear super glue. When the glue set I sanded the repairs smooth to match the surface of the stem.

I went back to scrubbing the airway. I remembered reading about someone using soft scrub successfully so I ran upstairs and asked my wife if she had any I could use. I push it through the airway in the stem with thick, fluffy pipe cleaners and rotated them to scrub. It took out some more of the darkening but still not enough to my liking. Finally I set up a retort on the stem alone. I boiled alcohol through the stem to remove more. Finally I used an ear syringe to shoot boiling water through the stem. I gave up after using all of those methods. I think I had removed as much of the darkening as I was going to get out of the stem. The stem definitely looks better than it did when I started. I wet sanded the stem with 1500-2400 grit micromesh sanding pads and wiped it down. I dry sanded with 3200-12000 grit pads and wiped it down.

I went back to scrubbing the airway. I remembered reading about someone using soft scrub successfully so I ran upstairs and asked my wife if she had any I could use. I push it through the airway in the stem with thick, fluffy pipe cleaners and rotated them to scrub. It took out some more of the darkening but still not enough to my liking. Finally I set up a retort on the stem alone. I boiled alcohol through the stem to remove more. Finally I used an ear syringe to shoot boiling water through the stem. I gave up after using all of those methods. I think I had removed as much of the darkening as I was going to get out of the stem. The stem definitely looks better than it did when I started. I wet sanded the stem with 1500-2400 grit micromesh sanding pads and wiped it down. I dry sanded with 3200-12000 grit pads and wiped it down.

I lightly buffed the bowl and stem with Blue Diamond on the wheel and then gave the stem several coats of carnauba. I polished the stem and bowl with a clean buffing pad and then by hand with a microfibre cloth. The finished pipe is shown below. The first photos show the areas of the rim and the front of the bowl that I cleaned up and re-rusticated with the burrs and Dremel.

I lightly buffed the bowl and stem with Blue Diamond on the wheel and then gave the stem several coats of carnauba. I polished the stem and bowl with a clean buffing pad and then by hand with a microfibre cloth. The finished pipe is shown below. The first photos show the areas of the rim and the front of the bowl that I cleaned up and re-rusticated with the burrs and Dremel.

The remaining photos are of the pipe in its entirety. I have never seen a Jobey Shellmoor pipe with a Lucite stem but this golden stem goes really well with the dark brown stain. The finished pipe is 6 ½ inches long and looks rather dapper and stylish. It has come a long way from when I started on it. I picked this pipe to work on while I was restoring the La Strata because I thought it would be easy. I could not have been more wrong. But I am glad it is finished. Thanks for looking.

The remaining photos are of the pipe in its entirety. I have never seen a Jobey Shellmoor pipe with a Lucite stem but this golden stem goes really well with the dark brown stain. The finished pipe is 6 ½ inches long and looks rather dapper and stylish. It has come a long way from when I started on it. I picked this pipe to work on while I was restoring the La Strata because I thought it would be easy. I could not have been more wrong. But I am glad it is finished. Thanks for looking.