Blog by Steve Laug

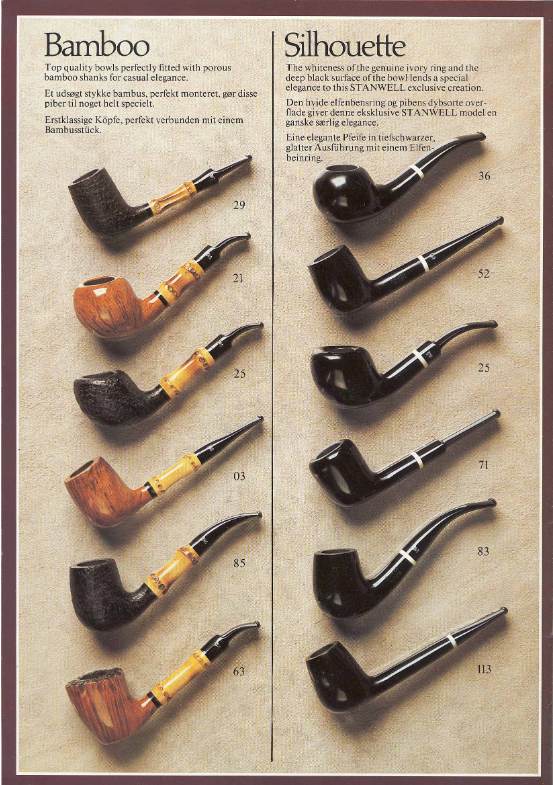

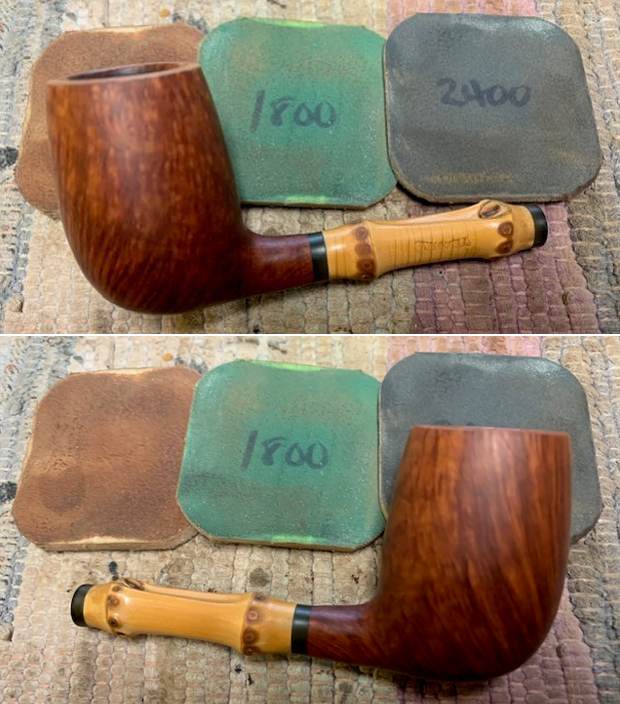

The next pipe on the table is one that was sent to my by a friend who had just purchased it. The shape reminded me of a large version of a Peterson’s 02 shape. He sent me the following photos of the pipe before he mailed it to me and I was interested. I am including those photos for you to see what I saw when he sent it to me. It is dirty for sure but it has some amazing grain around the bowl and shank and a Sterling Silver Band on the shank. The stem is a P stamped fishtail and looks great on the bowl.

The pipe arrived on Monday and I opened the box to find this pipe. It is stamped on the left side of the shank and reads Peterson’s [over] Dublin. On the right side it is stamped Made in the Republic of Ireland in 3 lines [over] the shape number XL02. The silver band is stamped with a US Flag in the center of a circle with Peterson’s arced over the top of the circle and July 4, 2000 arced below the circle. Below that there are hallmarks – Hibernia (Ireland), Harp (quality of silver) and the date stamp of an italic O which is the date stamp for the year 2000. The fishtail saddle stem is vulcanite and has the Peterson’s P stamp on the left side of the saddle. The stem was lightly oxidized with some tooth marks and chatter on both the top and underside ahead of the button. It was tight in the shank and would definitely fit better once cleaned. The bowl had a light cake in it and smelled strongly of Latakia/English blends. The finish was in good condition but there was some dust and grime ground into it. I took some photos of the pipe when I unpacked it. I have included them below.

The pipe arrived on Monday and I opened the box to find this pipe. It is stamped on the left side of the shank and reads Peterson’s [over] Dublin. On the right side it is stamped Made in the Republic of Ireland in 3 lines [over] the shape number XL02. The silver band is stamped with a US Flag in the center of a circle with Peterson’s arced over the top of the circle and July 4, 2000 arced below the circle. Below that there are hallmarks – Hibernia (Ireland), Harp (quality of silver) and the date stamp of an italic O which is the date stamp for the year 2000. The fishtail saddle stem is vulcanite and has the Peterson’s P stamp on the left side of the saddle. The stem was lightly oxidized with some tooth marks and chatter on both the top and underside ahead of the button. It was tight in the shank and would definitely fit better once cleaned. The bowl had a light cake in it and smelled strongly of Latakia/English blends. The finish was in good condition but there was some dust and grime ground into it. I took some photos of the pipe when I unpacked it. I have included them below.

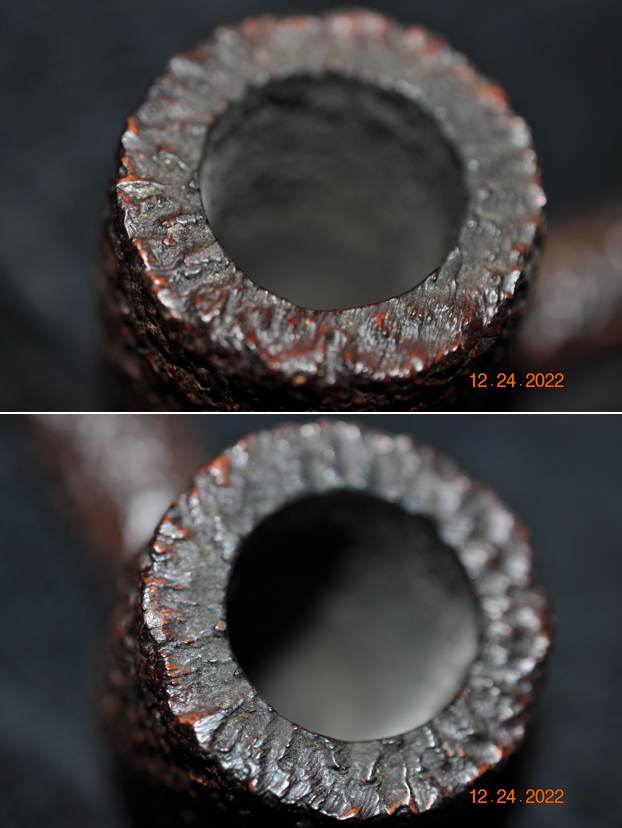

I took photos of the bowl and rim top to show what they looked like before my clean up. I also took some of the stem to show the condition of both sides.

I took photos of the bowl and rim top to show what they looked like before my clean up. I also took some of the stem to show the condition of both sides.  The photos of the sides and heel of the bowl show the grain around the bowl and shank. The mixture of brown stains adds depth to finish on the pipe. Even under the grime it is a real beauty.

The photos of the sides and heel of the bowl show the grain around the bowl and shank. The mixture of brown stains adds depth to finish on the pipe. Even under the grime it is a real beauty.

The stamping on the sides of the shank are shown in the photos below. They are clear and readable as noted above. The “P” stamp on the left side of the saddle is also in good condition.

The stamping on the sides of the shank are shown in the photos below. They are clear and readable as noted above. The “P” stamp on the left side of the saddle is also in good condition.

I removed the stem and took a photo of the parts to give a sense of the proportions of the pipe and its overall look. It is a real beauty.

I removed the stem and took a photo of the parts to give a sense of the proportions of the pipe and its overall look. It is a real beauty. The band on the shank of the pipe was loose and the glue had dried out. It slid off the shank with little effort. I cleaned up the shank end with alcohol on a cotton pad. I spread some all purpose white glue around the area with a dental spatula and pressed the band in place. I wiped off the excess glue with a damp cotton pad and took photos of the newly glued band.

The band on the shank of the pipe was loose and the glue had dried out. It slid off the shank with little effort. I cleaned up the shank end with alcohol on a cotton pad. I spread some all purpose white glue around the area with a dental spatula and pressed the band in place. I wiped off the excess glue with a damp cotton pad and took photos of the newly glued band.

Once the glue hardened I polished the silver band with a jewelers cloth. It removed most of the oxidation but a little more work on it would leave it shining bright.

Once the glue hardened I polished the silver band with a jewelers cloth. It removed most of the oxidation but a little more work on it would leave it shining bright.

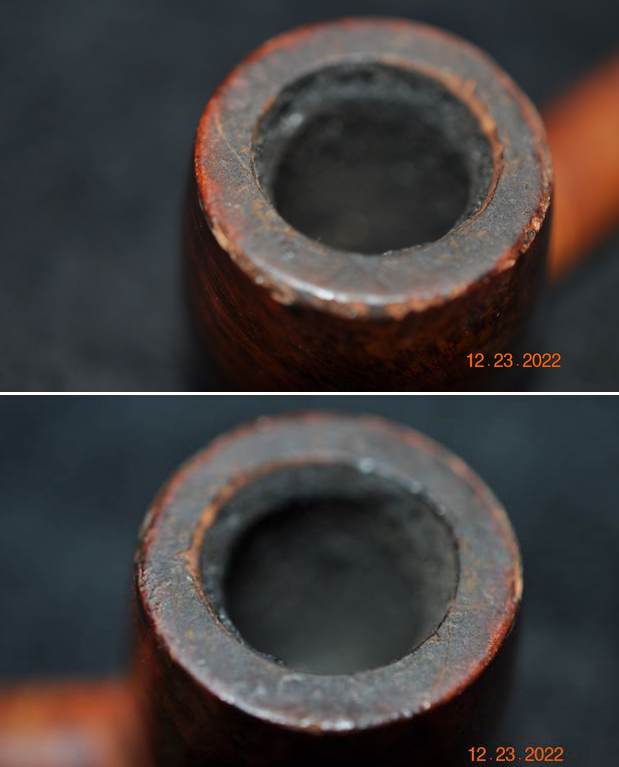

I reamed out the light cake in the bowl with a PipNet pipe reamer. I cleaned up the reaming with a Savinelli Pipe Knife and finished by sanding the bowl walls with a piece of dowel wrapped with 220 grit sandpaper.

I reamed out the light cake in the bowl with a PipNet pipe reamer. I cleaned up the reaming with a Savinelli Pipe Knife and finished by sanding the bowl walls with a piece of dowel wrapped with 220 grit sandpaper.

I cleaned out the shank and the airway into the bowl and the shank with pipe cleaners, cotton swabs and 99% isopropyl alcohol.

I cleaned out the shank and the airway into the bowl and the shank with pipe cleaners, cotton swabs and 99% isopropyl alcohol.  To deghost the pipe of the heavy Latakia smells I stuffed bowl with cotton bolls and used a twisted cotton boll in the shank. I filled the bowl with alcohol using an ear syringe to place the alcohol directly in the bowl. I set it aside to let it do its work drawing out the tars and oils from the walls of the bowl and the shank. I let it sit overnight and then removed the dirty and oily cotton and debris that had accumulated. I ran a pipe cleaner through the shank and removed any remnants of debris. The pipe smelled significantly better.

To deghost the pipe of the heavy Latakia smells I stuffed bowl with cotton bolls and used a twisted cotton boll in the shank. I filled the bowl with alcohol using an ear syringe to place the alcohol directly in the bowl. I set it aside to let it do its work drawing out the tars and oils from the walls of the bowl and the shank. I let it sit overnight and then removed the dirty and oily cotton and debris that had accumulated. I ran a pipe cleaner through the shank and removed any remnants of debris. The pipe smelled significantly better.

I polished the bowl with micromesh sanding pads – dry sanding with 1500-12000 grit pads. I wiped the bowl down with a damp cloth after each sanding pad. It really began to take on a shine. It is a beautiful piece of briar.

I polished the bowl with micromesh sanding pads – dry sanding with 1500-12000 grit pads. I wiped the bowl down with a damp cloth after each sanding pad. It really began to take on a shine. It is a beautiful piece of briar.

I rubbed the bowl down with Before & After Restoration Balm. I worked it into the briar with my finger tips. I let it sit for 10 minutes and the Balm did its magic. It enlivens, cleans and preserves the briar. It certainly brought this bowl back to life. I buffed it off with a clean cloth and took the following photos.

I rubbed the bowl down with Before & After Restoration Balm. I worked it into the briar with my finger tips. I let it sit for 10 minutes and the Balm did its magic. It enlivens, cleans and preserves the briar. It certainly brought this bowl back to life. I buffed it off with a clean cloth and took the following photos.

I set the bowl aside and turned my attention to the stem. I “painted” the stem with the flame of a Bic lighter to lift the tooth marks. The majority of them were lifted. I sanded out what remained with 220 grit sandpaper and then started the polishing with 600 grit wet dry sandpaper.

I set the bowl aside and turned my attention to the stem. I “painted” the stem with the flame of a Bic lighter to lift the tooth marks. The majority of them were lifted. I sanded out what remained with 220 grit sandpaper and then started the polishing with 600 grit wet dry sandpaper.

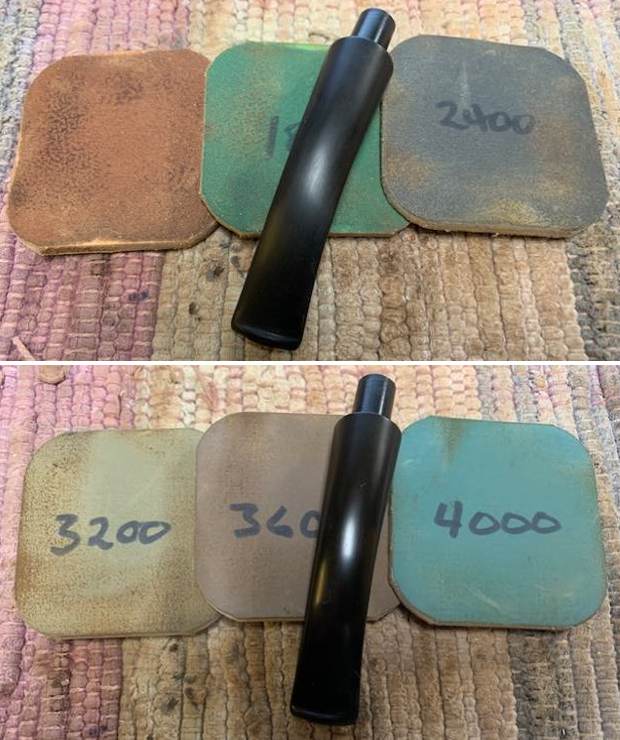

I polished the vulcanite with micromesh sanding pads – 1500-12000 grit pads. I wiped it down with a damp cloth after each sanding pad. I used Before & After Pipe Polish – both Fine and Extra Fine to further polish the stem.

I polished the vulcanite with micromesh sanding pads – 1500-12000 grit pads. I wiped it down with a damp cloth after each sanding pad. I used Before & After Pipe Polish – both Fine and Extra Fine to further polish the stem.

This Peterson’s 4th of July 2000 XL02 Bent Apple with a vulcanite saddle stem is a great looking pipe now that it has been restored. The beautiful finish really highlights the grain and the polished finish is stunning. I polished the silver band with a jewelers cloth to protect and shine the silver. I put the stem back on the bowl and carefully buffed the pipe with Blue Diamond on the buffing wheel. I gave the bowl and the stem multiple coats of carnauba wax on the buffing wheel and followed that by buffing the entire pipe with a clean buffing pad. I hand buffed the pipe with a microfiber cloth to deepen the shine. The finished Peterson’s Dublin 4th of July 2000 XL02 fits nicely in the hand and feels great. Give the finished pipe a look in the photos below. The dimensions of the pipe are Length: 5 ½ inches, Height: 1 ½ inches, Outside diameter of the bowl: 1 ¼ inch, Chamber diameter: ¾ of an inch. The weight of the pipe is 69 grams / 2.43 ounces. I will be sending it back to the pipeman so that he can enjoy his “new” pipe. Thanks for reading this blog and my reflections on the pipe while I worked on it.

This Peterson’s 4th of July 2000 XL02 Bent Apple with a vulcanite saddle stem is a great looking pipe now that it has been restored. The beautiful finish really highlights the grain and the polished finish is stunning. I polished the silver band with a jewelers cloth to protect and shine the silver. I put the stem back on the bowl and carefully buffed the pipe with Blue Diamond on the buffing wheel. I gave the bowl and the stem multiple coats of carnauba wax on the buffing wheel and followed that by buffing the entire pipe with a clean buffing pad. I hand buffed the pipe with a microfiber cloth to deepen the shine. The finished Peterson’s Dublin 4th of July 2000 XL02 fits nicely in the hand and feels great. Give the finished pipe a look in the photos below. The dimensions of the pipe are Length: 5 ½ inches, Height: 1 ½ inches, Outside diameter of the bowl: 1 ¼ inch, Chamber diameter: ¾ of an inch. The weight of the pipe is 69 grams / 2.43 ounces. I will be sending it back to the pipeman so that he can enjoy his “new” pipe. Thanks for reading this blog and my reflections on the pipe while I worked on it.