by Steve Laug

I received an email from a fellow a bit ago about two of his pipes that he wanted me to restore. I have included his email below.

Hey Steve,

It’s been a little while but I’d like to send in the Kaywoodie President for restoration. I also have a Marxman apple that I would like an assessment on–it’s a bit more of a challenge than a standard restoration. Can you let me know if you have an opening and if so, what address to send them to? Thanks! – Devin

I asked him to send me some photos of the pipes before he shipped them to me. I gave my address and he shipped them to me. Here are the photos of the Marxman pipe that he sent. He included some close up photos of the bowl and shank to show the condition they were in. The shank had a lot of flaws in the briar on the heel and the shank. The flaws on the heel appeared to have lost the fills somewhere along the process. There were also some twisted flaws on the underside of the shank and the sides as well. The flaws and cracks ran through all the stamping on both sides. Some of them were deep as they leaked smoke when the pipe was smoked. The shank end had a lot of flaws following the grain on the shank from the shank end toward the bowl. It really was a flawed piece of briar that has opened up over time.

He included some close up photos of the bowl and shank to show the condition they were in. The shank had a lot of flaws in the briar on the heel and the shank. The flaws on the heel appeared to have lost the fills somewhere along the process. There were also some twisted flaws on the underside of the shank and the sides as well. The flaws and cracks ran through all the stamping on both sides. Some of them were deep as they leaked smoke when the pipe was smoked. The shank end had a lot of flaws following the grain on the shank from the shank end toward the bowl. It really was a flawed piece of briar that has opened up over time.

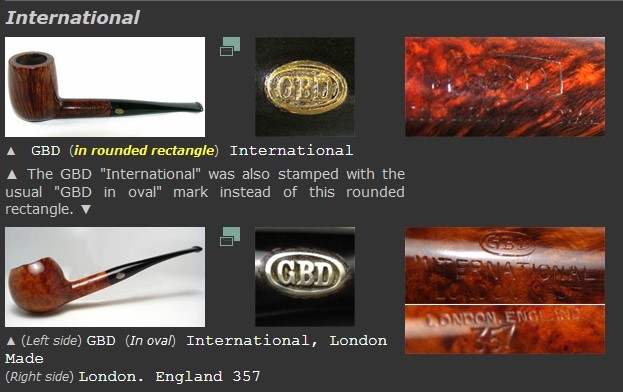

The stem was in excellent condition. The bowl and shank had been reamed and cleaned by Devin before he sent it to me. He included photos of the stem.

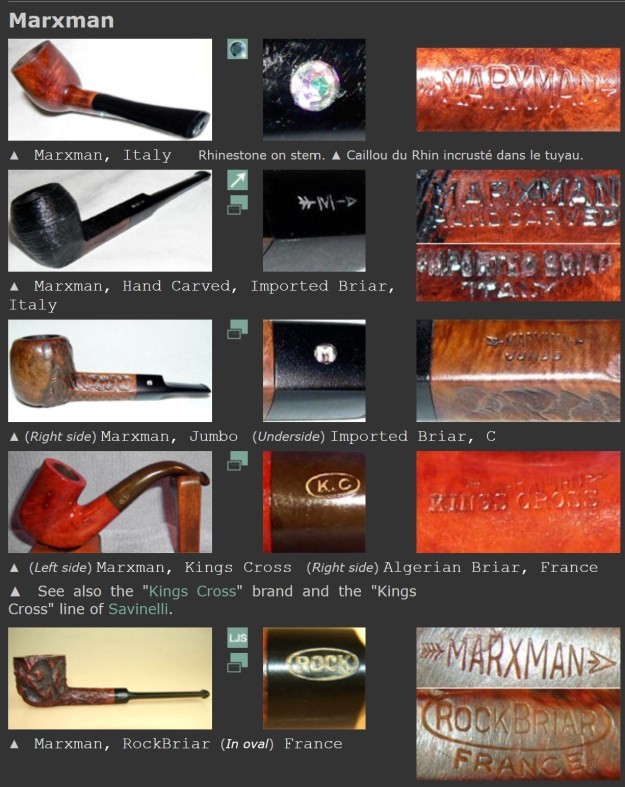

The stem was in excellent condition. The bowl and shank had been reamed and cleaned by Devin before he sent it to me. He included photos of the stem.  The pipes arrived here last evening. I took the Marxman to the table to look it over. It was very clean inside and out. The pipe was stamped on the left side of the shank read Marxman with the arrow through the letters (Marxman logo). On the right side it is stamped Algerian Briar [over] France. The shank is riddled with flaws running along the grain horizontally from the shank end forward through the stamping. There were also spots on the shank that spidered from the flaws in the shank and in spots left holes. Devin said that smoke came through some of the holes in the shank. It a mess in terms of the amount repairs that need to be done. The vulcanite stem has a Marxman arrow logo on the left side of the shank.

The pipes arrived here last evening. I took the Marxman to the table to look it over. It was very clean inside and out. The pipe was stamped on the left side of the shank read Marxman with the arrow through the letters (Marxman logo). On the right side it is stamped Algerian Briar [over] France. The shank is riddled with flaws running along the grain horizontally from the shank end forward through the stamping. There were also spots on the shank that spidered from the flaws in the shank and in spots left holes. Devin said that smoke came through some of the holes in the shank. It a mess in terms of the amount repairs that need to be done. The vulcanite stem has a Marxman arrow logo on the left side of the shank.

I took a photo of the rim top to show the condition. You can see the clean bowl. The bowl is in excellent condition and the rim top looks very good. You can also see all the flaws in the briar on the top of the shank and around the shank end. The stem came out looking quite good. It only needed to be polished.

I took a photo of the rim top to show the condition. You can see the clean bowl. The bowl is in excellent condition and the rim top looks very good. You can also see all the flaws in the briar on the top of the shank and around the shank end. The stem came out looking quite good. It only needed to be polished.  I took photos of sides of the shank to show the stamping. The photos clearly show the stamping and is actually more readable in person. I removed the stem from the shank and took a photo of the pipe parts to show what I was working with. It is a nicely shaped apple.

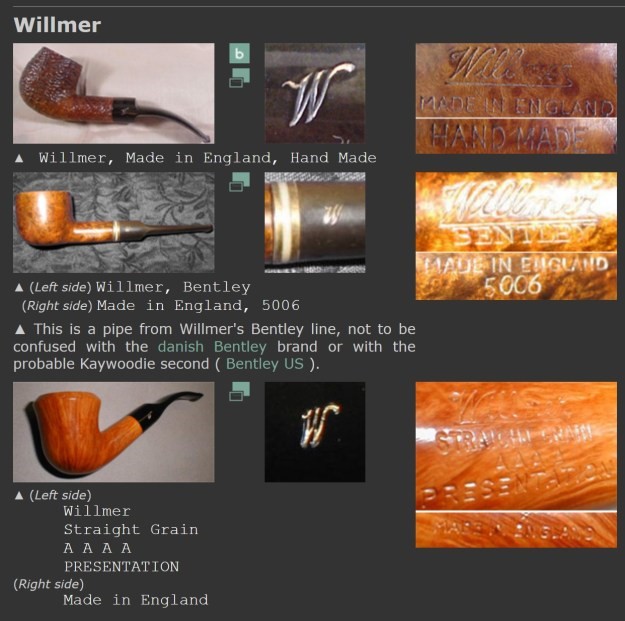

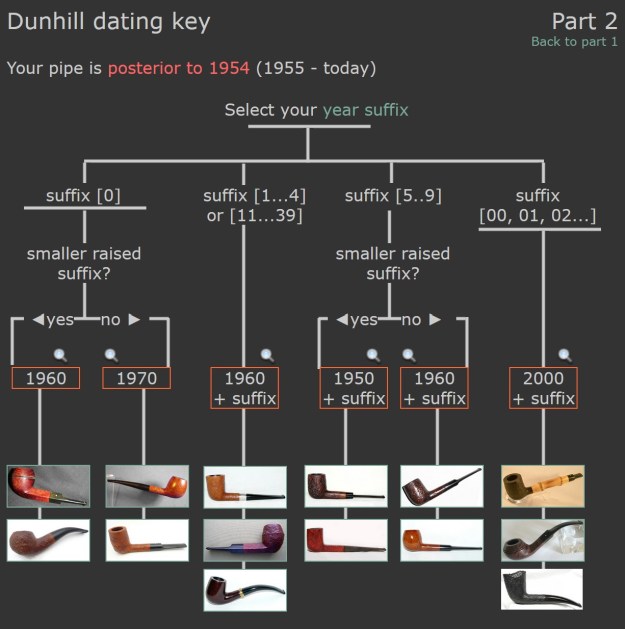

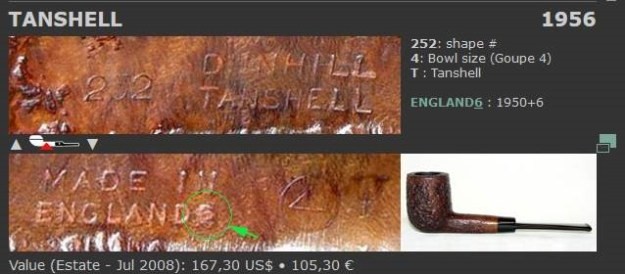

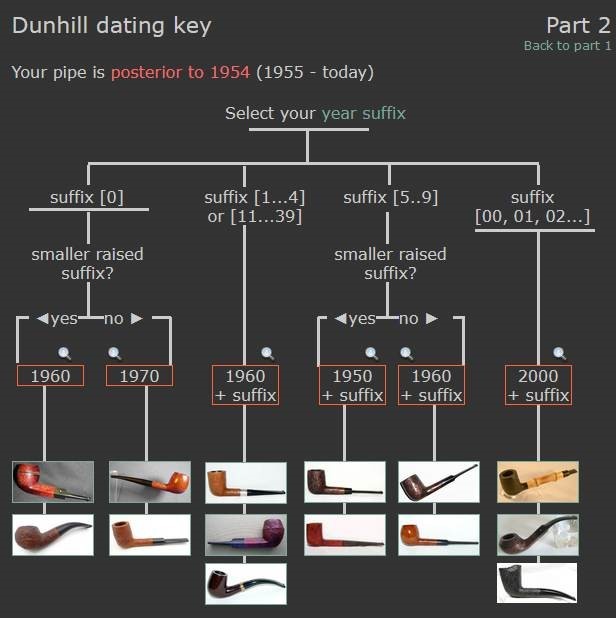

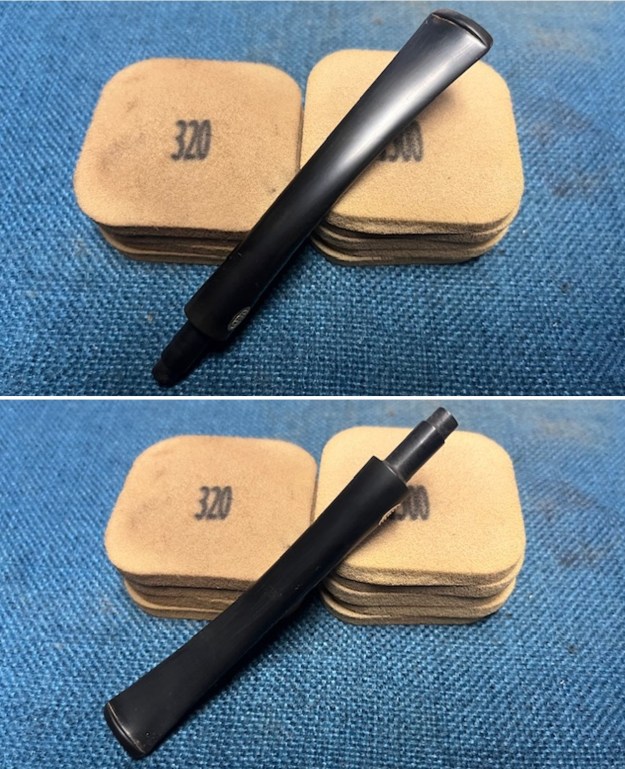

I took photos of sides of the shank to show the stamping. The photos clearly show the stamping and is actually more readable in person. I removed the stem from the shank and took a photo of the pipe parts to show what I was working with. It is a nicely shaped apple. I turned to Pipephil’s site to look at the data that was available on Marxman pipes and see if there were any pipes like the bowl I had (http://www.pipephil.eu/logos/en/logo-m2.html). There was nothing in the photos there but the stamping and data available was helpful. I have included a screen capture and the sidebar information below the screen capture.

I turned to Pipephil’s site to look at the data that was available on Marxman pipes and see if there were any pipes like the bowl I had (http://www.pipephil.eu/logos/en/logo-m2.html). There was nothing in the photos there but the stamping and data available was helpful. I have included a screen capture and the sidebar information below the screen capture. Brand created in 1934 and merged with Mastercraft in 1953.

Brand created in 1934 and merged with Mastercraft in 1953.

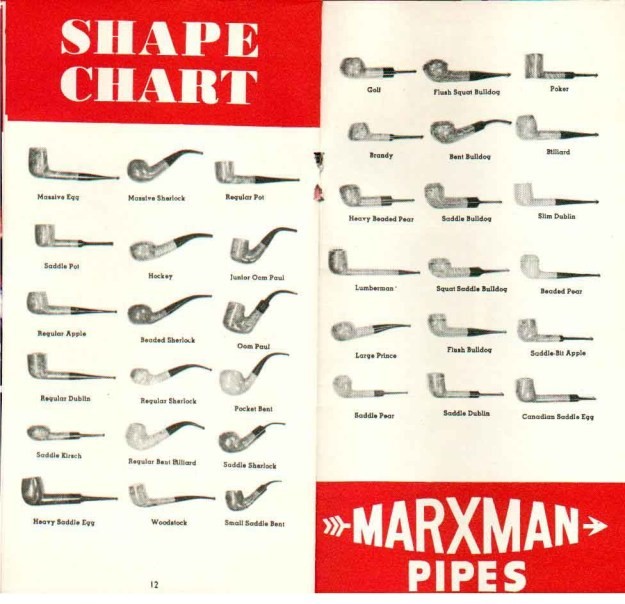

The article also included a shape chart that was helpful. It looked to me that the pipe was a Regular Apple (third pipe down in the first column below). It is the top pipe in the second column in the photo below. From the above information I knew that I was working on a Marxman Regular Apple and that it was made before the merger with Mastercraft in 1953.

From the above information I knew that I was working on a Marxman Regular Apple and that it was made before the merger with Mastercraft in 1953.

With that I was ready to begin working on the pipe. I decided to address the flaws in the briar. I pressed briar dust into the cracks and flaws with a dental spatula. Once the dust was in place I used a tooth pick to press clear CA glue into the flawed areas on the shank and the spots on the heel and bottom sides.

To bind the shank end repairs and to keep the cracks and separations in the briar firm I went through my thin brass bands and fit one on the shank end. I heated it and pressed it on the end of the shank. It was a good tight fit and would serve its purpose well. You could see the repairs on the shank and bowl in the photos.

To bind the shank end repairs and to keep the cracks and separations in the briar firm I went through my thin brass bands and fit one on the shank end. I heated it and pressed it on the end of the shank. It was a good tight fit and would serve its purpose well. You could see the repairs on the shank and bowl in the photos.

I used a folded piece of 220 grit sandpaper to smooth out the repairs. I was able to carefully work my way around the stamping on the shank. It looked much better. I also smooth out some of the nicks in the inwardly bevelled rim top. The repairs began to blend in very well.

I used a folded piece of 220 grit sandpaper to smooth out the repairs. I was able to carefully work my way around the stamping on the shank. It looked much better. I also smooth out some of the nicks in the inwardly bevelled rim top. The repairs began to blend in very well.

I sanded the repairs a little more, then stained them with an Oak and Maple stain pen to blend them into the colour of the surrounding briar on the bowl and the shank.

I sanded the repairs a little more, then stained them with an Oak and Maple stain pen to blend them into the colour of the surrounding briar on the bowl and the shank.

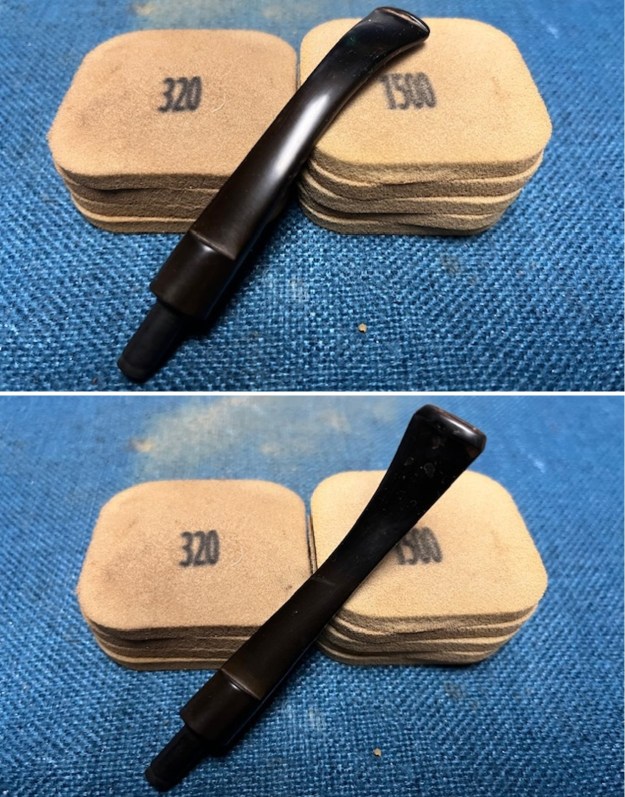

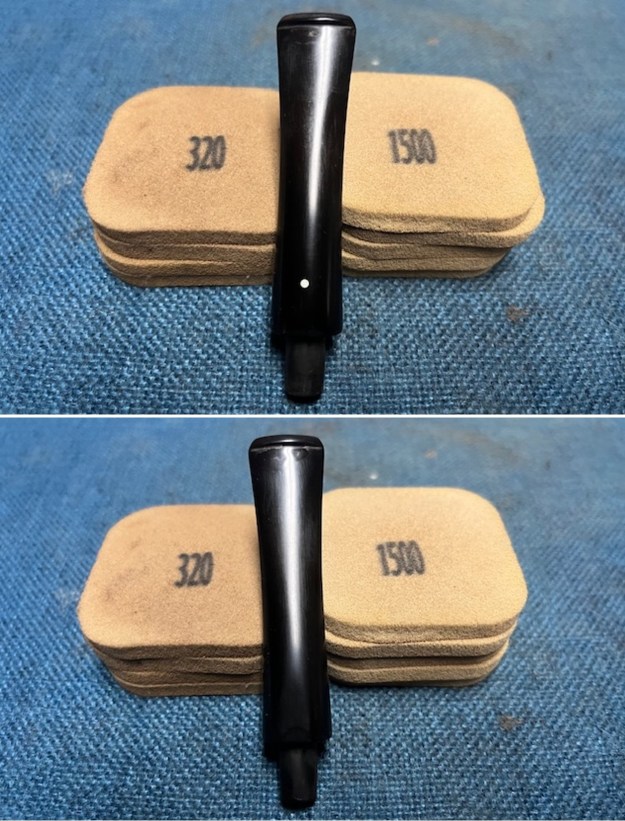

I sanded the surface of the bowl and the shank with 320-3500 grit 2×2 inch sanding pads to further blend in the repairs and to remove the scratches in the surface of the briar. The bowl and shank began to look very good.

I sanded the surface of the bowl and the shank with 320-3500 grit 2×2 inch sanding pads to further blend in the repairs and to remove the scratches in the surface of the briar. The bowl and shank began to look very good.

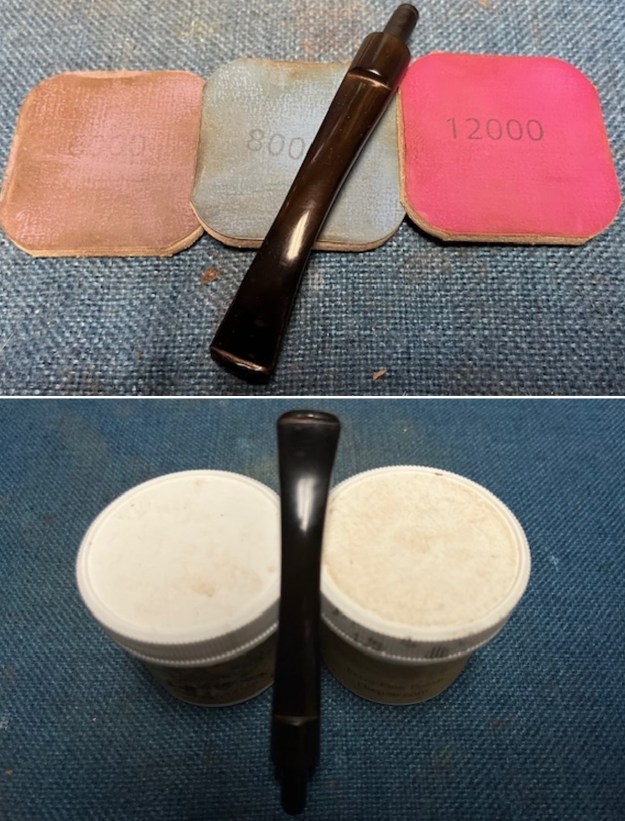

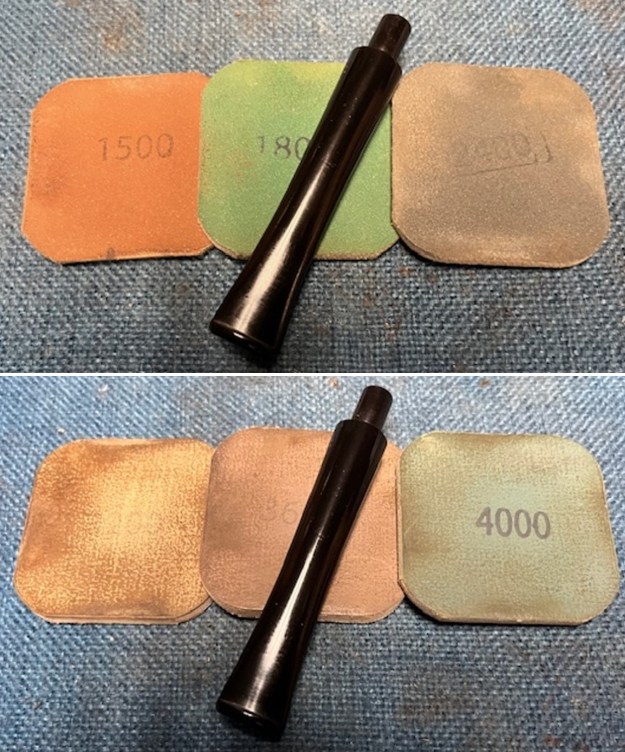

I polished the briar with 1500-12000 grit micromesh sanding pads – dry sanding the briar and wiping down the bowl after each sanding pad. It really began to take on a rich shine and the grain stood out beautifully.

I polished the briar with 1500-12000 grit micromesh sanding pads – dry sanding the briar and wiping down the bowl after each sanding pad. It really began to take on a rich shine and the grain stood out beautifully.

I rubbed the briar down with Before & After Restoration Balm and worked it into the briar and the repaired areas. The product works to clean, enliven and preserve the briar and give it a rich lustre. The briar came alive and the grain really pops.

I rubbed the briar down with Before & After Restoration Balm and worked it into the briar and the repaired areas. The product works to clean, enliven and preserve the briar and give it a rich lustre. The briar came alive and the grain really pops.

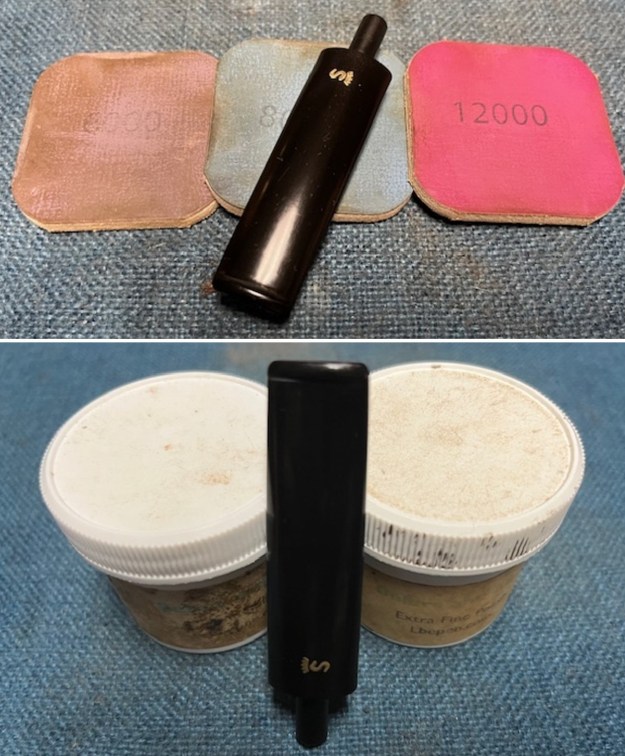

I set the bowl aside and turned my attention to the stem. I touched up the Marxman logo on the left side of the stem with Rub’n Buff Antique Gold. I pressed it into the logo with a tooth pick and then buffed it off with a soft cloth.

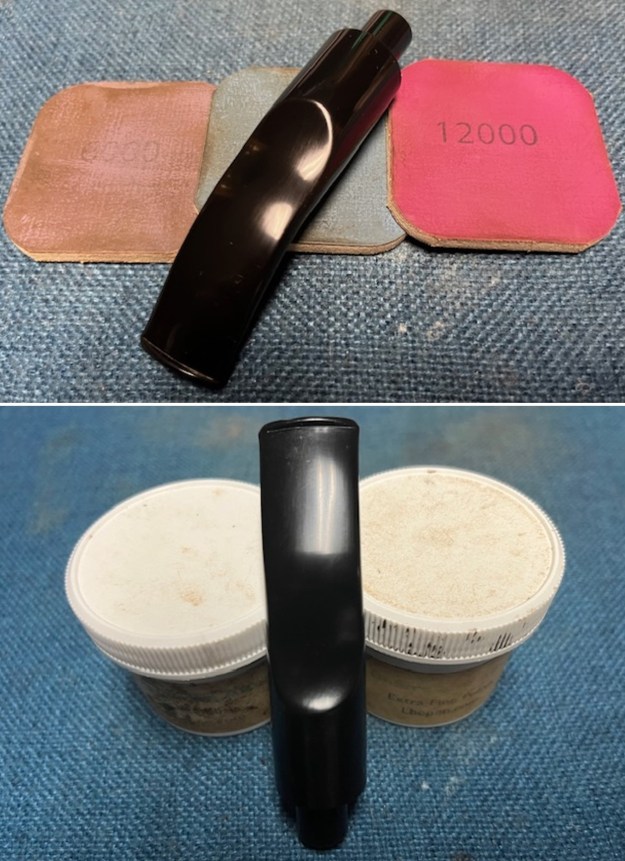

I set the bowl aside and turned my attention to the stem. I touched up the Marxman logo on the left side of the stem with Rub’n Buff Antique Gold. I pressed it into the logo with a tooth pick and then buffed it off with a soft cloth. I went over the work that Devin had done with micromesh sanding pads. I used 1500-12000 grit sanding pads. I wiped the stem down after each sanding pad with an Obsidian Oil Cloth. The stem looked very good.

I went over the work that Devin had done with micromesh sanding pads. I used 1500-12000 grit sanding pads. I wiped the stem down after each sanding pad with an Obsidian Oil Cloth. The stem looked very good.

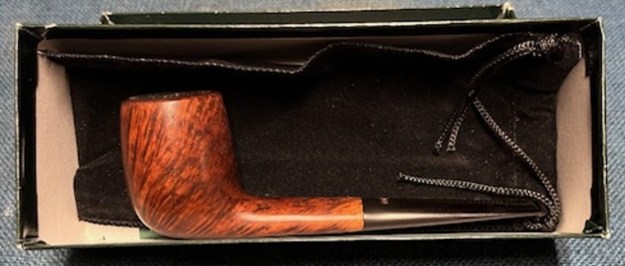

I put the Marxman Select Briar Algerian France Apple back together and buffed it on the buffing wheel with Blue Diamond. It raised a shine on the briar and the stem and gave some depth to the grain. I gave both the bowl and the stem multiple coats of carnauba wax on the wheel and buffed the pipe with a clean buffing pad to raise the shine. I hand buffed it with a microfiber cloth to deepen the shine. The pipe turned out to be a unique beauty in its own way. I really like the grain and the shape of this Marxman Select BriarApple. The thin brass band and the taper stem go well with the rich briar. The dimensions of the pipe are Length: 6 inches, Height: 1 ½ inches, Outer diameter of the bowl: 1 ¼ inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 1.41 ounces/39 grams. It is a uniquely beautiful pipe. Once I finish Devin’s second pipe both will head back to him to enjoy!

I put the Marxman Select Briar Algerian France Apple back together and buffed it on the buffing wheel with Blue Diamond. It raised a shine on the briar and the stem and gave some depth to the grain. I gave both the bowl and the stem multiple coats of carnauba wax on the wheel and buffed the pipe with a clean buffing pad to raise the shine. I hand buffed it with a microfiber cloth to deepen the shine. The pipe turned out to be a unique beauty in its own way. I really like the grain and the shape of this Marxman Select BriarApple. The thin brass band and the taper stem go well with the rich briar. The dimensions of the pipe are Length: 6 inches, Height: 1 ½ inches, Outer diameter of the bowl: 1 ¼ inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 1.41 ounces/39 grams. It is a uniquely beautiful pipe. Once I finish Devin’s second pipe both will head back to him to enjoy!