Blog by Kenneth Lieblich

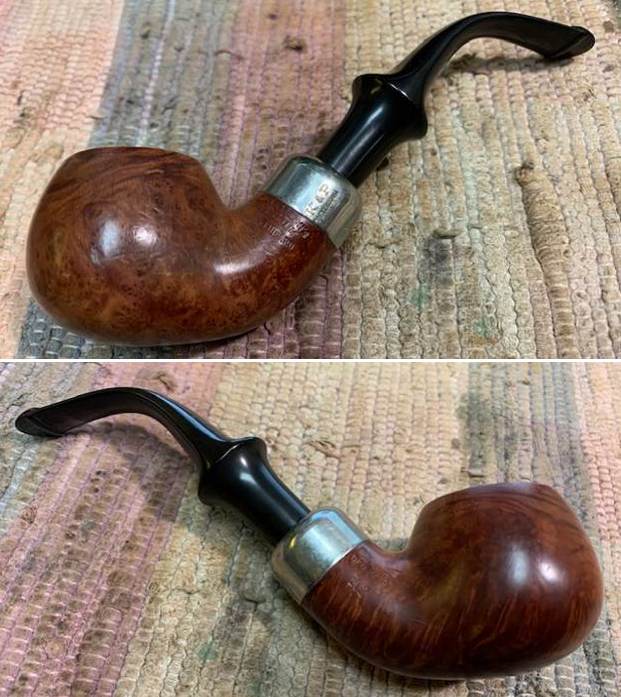

Next on the chopping block is this lovely Brebbia Marco. It came to me in a large lot from France. It was a decent lot of pipes, but the person who sold it to me decided that the best way of shipping to Canada would be to simply throw them all in a box and tape it up. Ugh. The pipes in this lot were figuratively all over the map: some beautiful, some hideous; some very old, some newish; some pristine, some mostly destroyed. This pipe called out to me as being very attractive and one that could easily be brought back to life. It was also the only Italian pipe in the lot.

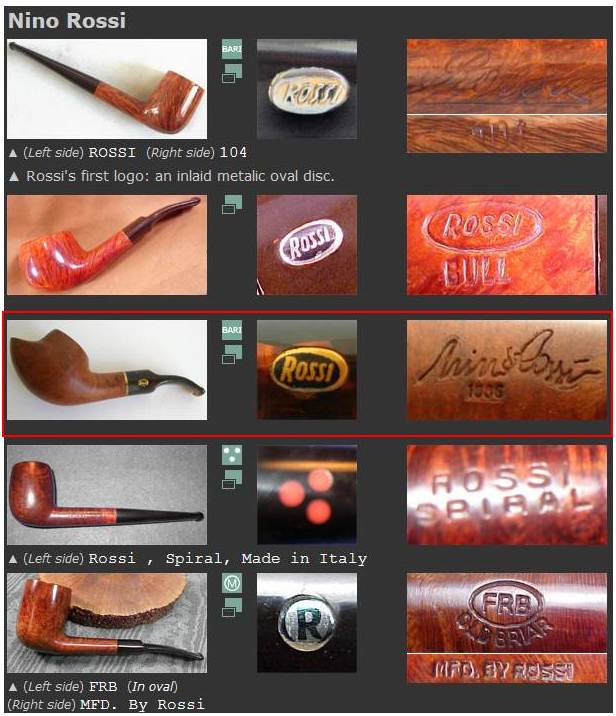

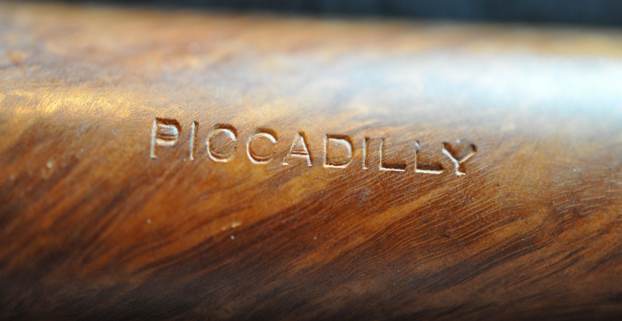

This pipe is a Brebbia. Or maybe it is a Marco. Or maybe Marco is a line of Brebbia pipes. Or maybe Marco is a sub-brand/second of Brebbia. Or maybe Marco is the name of a pipe shop that sold Brebbia. There is not much information to be found specifically for the name Marco in connection with Brebbia. The markings on the top of the shank read Marco [over] Real Briar. On the underside of the shank, the markings read Disp. Reg. [over] Brebbia. Also, on the stem, there is an encircled, cursive M. If you have any information on the connection between Marco and Brebbia, please let me know in the comments below. Thank you.

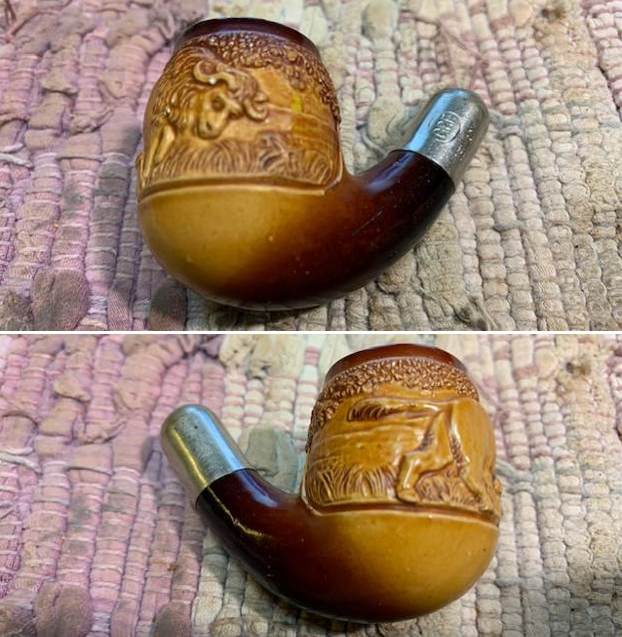

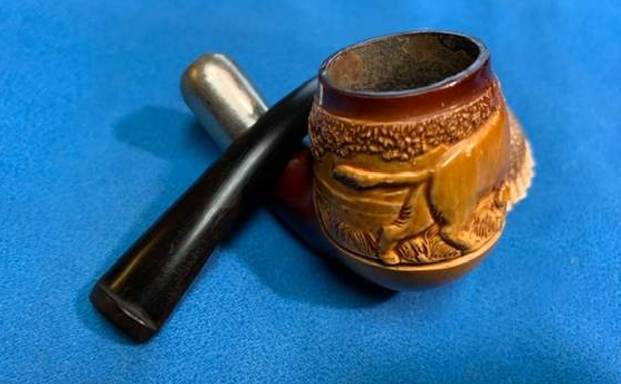

This pipe is a Brebbia. Or maybe it is a Marco. Or maybe Marco is a line of Brebbia pipes. Or maybe Marco is a sub-brand/second of Brebbia. Or maybe Marco is the name of a pipe shop that sold Brebbia. There is not much information to be found specifically for the name Marco in connection with Brebbia. The markings on the top of the shank read Marco [over] Real Briar. On the underside of the shank, the markings read Disp. Reg. [over] Brebbia. Also, on the stem, there is an encircled, cursive M. If you have any information on the connection between Marco and Brebbia, please let me know in the comments below. Thank you. This is a brandy-shaped pipe – and a really pretty one too. It felt very comfortable in the hand. It was obvious from the start that this was a great pipe that just needed some attention and TLC. I learned from Pipedia and Pipephil that the Brebbia pipe company was named after the locality of Bosco Grosso di Brebbia in Lombardy, Italy. The company was founded by Enea Buzzi and Achille Savinelli in 1947, but they parted ways in 1953. Mr Savinelli went on to form his eponymous company, while Mr Buzzi kept the factory and created Maniffatura Pipe Brebbia – they produce MPB and Brebbia pipes. Mr Buzzi’s family still run the company today.

This is a brandy-shaped pipe – and a really pretty one too. It felt very comfortable in the hand. It was obvious from the start that this was a great pipe that just needed some attention and TLC. I learned from Pipedia and Pipephil that the Brebbia pipe company was named after the locality of Bosco Grosso di Brebbia in Lombardy, Italy. The company was founded by Enea Buzzi and Achille Savinelli in 1947, but they parted ways in 1953. Mr Savinelli went on to form his eponymous company, while Mr Buzzi kept the factory and created Maniffatura Pipe Brebbia – they produce MPB and Brebbia pipes. Mr Buzzi’s family still run the company today. On to the pipe – and it had a few issues. The stem was mostly fine. No significant oxidation or calcification to speak of, plenty of tooth chatter and scratches, and a filthy inner-tube. The stem also had a strange piece sticking out of the end of the bit – more about that later. Meanwhile, the stummel was where the real problems lay. The outside of the bowl had many scratches and deep gouges. I was not at all sure that they were going to come out. There were also several burn marks on the rim and what looked like ink on the bowl. The inside was pretty dirty too.

On to the pipe – and it had a few issues. The stem was mostly fine. No significant oxidation or calcification to speak of, plenty of tooth chatter and scratches, and a filthy inner-tube. The stem also had a strange piece sticking out of the end of the bit – more about that later. Meanwhile, the stummel was where the real problems lay. The outside of the bowl had many scratches and deep gouges. I was not at all sure that they were going to come out. There were also several burn marks on the rim and what looked like ink on the bowl. The inside was pretty dirty too.

The stem was first on my list. The inner-tube was extracted fairly easily. It then went for a soak in some lemon-infused isopropyl alcohol. I let it sit for several hours and then cleaned it off and it looked much improved. I then finished it with some metal polish and moved on.

The stem was first on my list. The inner-tube was extracted fairly easily. It then went for a soak in some lemon-infused isopropyl alcohol. I let it sit for several hours and then cleaned it off and it looked much improved. I then finished it with some metal polish and moved on. I wiped down the outside of the stem with Murphy’s Oil Soap on some cotton pads. I also took a BIC lighter and ‘painted’ the stem with its flame in order to lift the bite marks and dents. This was not particularly successful in raising the damage. Then, I cleaned out the insides with pipe cleaners and isopropyl alcohol. The problem I had was the odd-shaped piece coming out the end of the bit. Steve explained that it was an implement to prevent bite-through on the stem. Aha! I learn something from Steve every day. This certainly made sense, but it made cleaning the stem a real problem, since I could not be sure that the bit was fully clean with that piece in place. In order to solve the problem, however, I needed to clean out the stummel first.

I wiped down the outside of the stem with Murphy’s Oil Soap on some cotton pads. I also took a BIC lighter and ‘painted’ the stem with its flame in order to lift the bite marks and dents. This was not particularly successful in raising the damage. Then, I cleaned out the insides with pipe cleaners and isopropyl alcohol. The problem I had was the odd-shaped piece coming out the end of the bit. Steve explained that it was an implement to prevent bite-through on the stem. Aha! I learn something from Steve every day. This certainly made sense, but it made cleaning the stem a real problem, since I could not be sure that the bit was fully clean with that piece in place. In order to solve the problem, however, I needed to clean out the stummel first. This stummel was a bit of a mess inside. I first decided to ream out the bowl. I used both the PipNet Reamer and the KleenReem to remove the built-up cake and followed that with 220-grit sandpaper to eliminate as much as I could. In fact, I also used the drill bit that came with the KleenReem in order to loosen the debris that blocked the draught hole. I took the bowl down to bare briar, as I wanted to ensure there were no hidden flaws in the walls of the bowl. Fortunately, there were none. I then proceeded to clean out the insides of the shank with Q-tips, pipe cleaners, and isopropyl alcohol. There was some filth inside this stummel and it took some cotton to get it clean.

This stummel was a bit of a mess inside. I first decided to ream out the bowl. I used both the PipNet Reamer and the KleenReem to remove the built-up cake and followed that with 220-grit sandpaper to eliminate as much as I could. In fact, I also used the drill bit that came with the KleenReem in order to loosen the debris that blocked the draught hole. I took the bowl down to bare briar, as I wanted to ensure there were no hidden flaws in the walls of the bowl. Fortunately, there were none. I then proceeded to clean out the insides of the shank with Q-tips, pipe cleaners, and isopropyl alcohol. There was some filth inside this stummel and it took some cotton to get it clean.

A de-ghosting session also seemed in order, so I thrust cotton balls in the bowl and the shank, and saturated them with 99% isopropyl alcohol. I let the stummel sit for 24 hours. This caused the oils, tars and smells to leech out into the cotton. Finally, a relatively clean and fresh-smelling bowl emerged.

A de-ghosting session also seemed in order, so I thrust cotton balls in the bowl and the shank, and saturated them with 99% isopropyl alcohol. I let the stummel sit for 24 hours. This caused the oils, tars and smells to leech out into the cotton. Finally, a relatively clean and fresh-smelling bowl emerged. Then, to finish off cleaning the inside of the stem, I put it back together with the stummel and used my pipe retort system. This system uses boiling isopropyl alcohol and a vacuum (a void space, not the household item) to clean the interior of a pipe. As you can see by the brownish colour of the alcohol, the retort worked well. I managed to extract lots of otherwise inaccessible filth from inside the pipe. After the retort, I then used all nine Micromesh pads (1,500 through 12,000 grit) to bring out the lovely black lustre on the stem. I also used Obsidian Pipe Stem Oil in between each pad scrubbing.

Then, to finish off cleaning the inside of the stem, I put it back together with the stummel and used my pipe retort system. This system uses boiling isopropyl alcohol and a vacuum (a void space, not the household item) to clean the interior of a pipe. As you can see by the brownish colour of the alcohol, the retort worked well. I managed to extract lots of otherwise inaccessible filth from inside the pipe. After the retort, I then used all nine Micromesh pads (1,500 through 12,000 grit) to bring out the lovely black lustre on the stem. I also used Obsidian Pipe Stem Oil in between each pad scrubbing.

Back to the stummel: I finished cleaning up the insides with some dish soap and tube brushes. I then moved on to cleaning the outside of the stummel with Murphy’s Oil Soap and some cotton pads. Some stains were pretty stubborn and I had to scrub hard, but this did eventually remove the remaining dirt. After that, a light application of Before & After Restoration Balm brought out the best in the stummel’s grain.

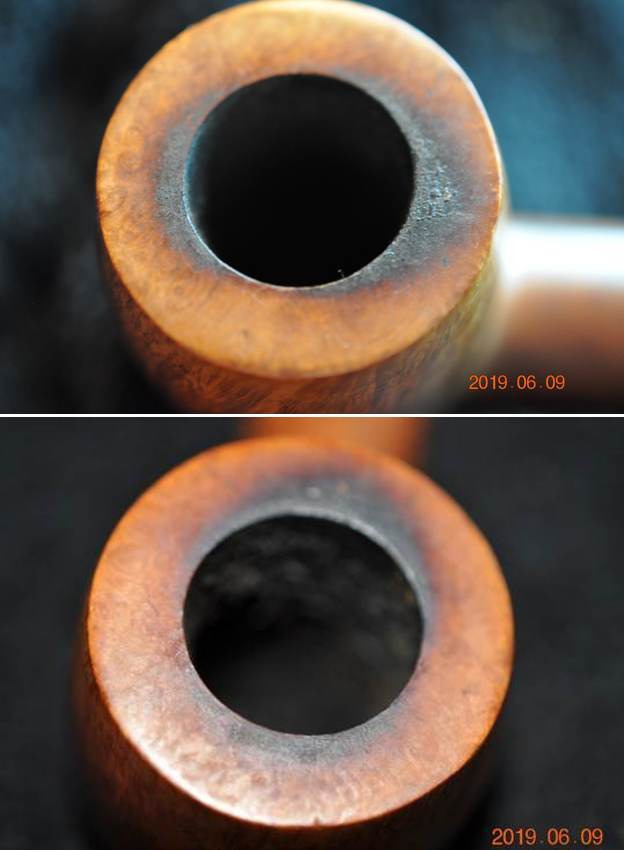

Back to the stummel: I finished cleaning up the insides with some dish soap and tube brushes. I then moved on to cleaning the outside of the stummel with Murphy’s Oil Soap and some cotton pads. Some stains were pretty stubborn and I had to scrub hard, but this did eventually remove the remaining dirt. After that, a light application of Before & After Restoration Balm brought out the best in the stummel’s grain. Now that it was clean, I could address the gouges and burn on the stummel. I took some oxalic acid, used several Q-tips, and rubbed. The burn did improve but never fully disappeared. I gently poked at it with a dental tool in order to assess the wood. I took solace from the fact that the burn was very superficial and did not affect the integrity of the wood at all. In order to fully remove the burns on the rim, I “topped” the pipe – that is to say, I gently and evenly sanded down the rim on a piece of 220-grit sandpaper. This effectively removed the damage, without altering the look of the pipe.

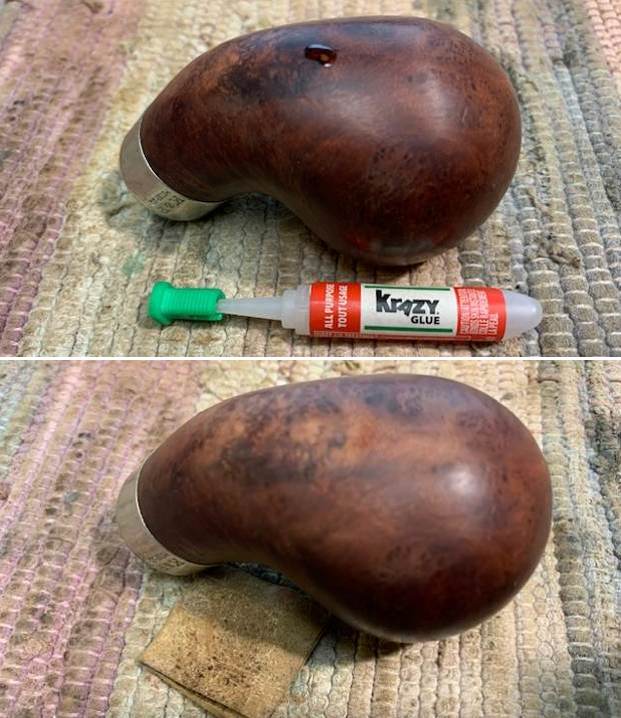

Now that it was clean, I could address the gouges and burn on the stummel. I took some oxalic acid, used several Q-tips, and rubbed. The burn did improve but never fully disappeared. I gently poked at it with a dental tool in order to assess the wood. I took solace from the fact that the burn was very superficial and did not affect the integrity of the wood at all. In order to fully remove the burns on the rim, I “topped” the pipe – that is to say, I gently and evenly sanded down the rim on a piece of 220-grit sandpaper. This effectively removed the damage, without altering the look of the pipe.

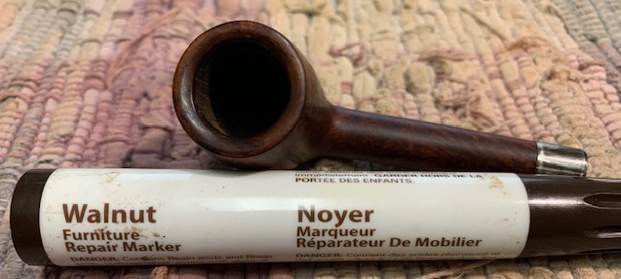

Having completed that, I was able to address the scratches and gouges. I took out my steam iron and a damp cloth to try and raise the nicks. The hot and moist steam created can often cause the wood to swell slightly and return to shape. I was concerned about this because there were so many marks all over the wood. Fortunately, there was considerable movement – I was really pleased with the results. The repair was not perfect, but the remaining scratches would be improved by sanding.

With the damage mostly repaired, it was time to sand down the stummel. I used all nine Micromesh pads (1,500 through 12,000 grit) to wet/dry sand everything smooth. Then I added a bit more Before & After Restoration Balm and something unusual appeared. Beneath the markings on the top of the shank, I could see the remnants of an old set of markings. Amazing! It was difficult to figure out exactly what it read, but Steve and I think it might be Fiammata [over] Straight Grain. If you have any information/thoughts, please let me know in the comments below!

With the damage mostly repaired, it was time to sand down the stummel. I used all nine Micromesh pads (1,500 through 12,000 grit) to wet/dry sand everything smooth. Then I added a bit more Before & After Restoration Balm and something unusual appeared. Beneath the markings on the top of the shank, I could see the remnants of an old set of markings. Amazing! It was difficult to figure out exactly what it read, but Steve and I think it might be Fiammata [over] Straight Grain. If you have any information/thoughts, please let me know in the comments below!

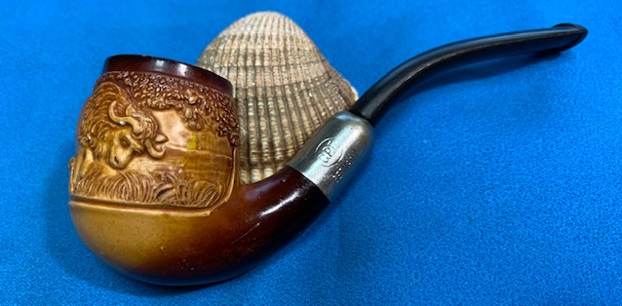

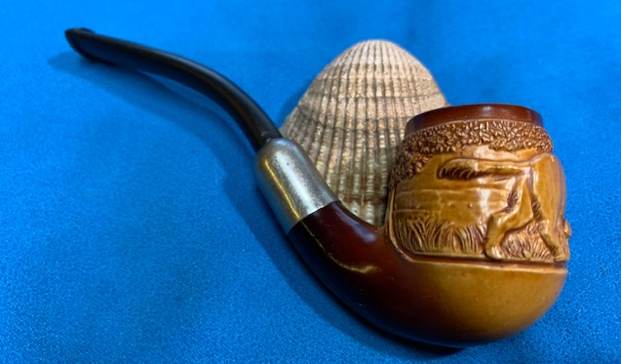

Upon completion of the stummel, there was a brief moment when I considered whether I should stain the pipe. On reflection, however, I just loved the light colour of the wood so much that I wanted to leave it as is. I applied more Before & After Restoration Balm, then took it to the buffer.

Upon completion of the stummel, there was a brief moment when I considered whether I should stain the pipe. On reflection, however, I just loved the light colour of the wood so much that I wanted to leave it as is. I applied more Before & After Restoration Balm, then took it to the buffer. A dose of White Diamond and a few coats of carnauba wax were just what this pipe needed. The lovely shine made the wood look absolutely beautiful. In fact, it turned out so well that this pipe has already sold! I know that the new owner will enjoy smoking it for many years to come. I hope you enjoyed reading the story of this pipe as much I as I did restoring it. If you are interested in more of my work, please follow me here on Steve’s website or email me directly at kenneth@knightsofthepipe.com. Thank you very much for reading and, as always, I welcome and encourage your comments.

A dose of White Diamond and a few coats of carnauba wax were just what this pipe needed. The lovely shine made the wood look absolutely beautiful. In fact, it turned out so well that this pipe has already sold! I know that the new owner will enjoy smoking it for many years to come. I hope you enjoyed reading the story of this pipe as much I as I did restoring it. If you are interested in more of my work, please follow me here on Steve’s website or email me directly at kenneth@knightsofthepipe.com. Thank you very much for reading and, as always, I welcome and encourage your comments.