Blog by Steve Laug

I thought I would take you through my process of working on each pipe that we purchase. This is one that I am working on for a friend so it is not a purchase. When I am working on a pipe from the start I take the same photos. By now you should now why I included these photos. Even when I am starting from scratch myself I take the photos because they tend to show things clearly in a way that I might miss when I am looking at it in person. Combing the two gives a good view of what is going on with the pipe. I also take the photos to record the condition that the pipe was in when I received it and to assess what kind of work will need to be done on. When I look at the pipe along with these photos this is what I see.

I thought I would take you through my process of working on each pipe that we purchase. This is one that I am working on for a friend so it is not a purchase. When I am working on a pipe from the start I take the same photos. By now you should now why I included these photos. Even when I am starting from scratch myself I take the photos because they tend to show things clearly in a way that I might miss when I am looking at it in person. Combing the two gives a good view of what is going on with the pipe. I also take the photos to record the condition that the pipe was in when I received it and to assess what kind of work will need to be done on. When I look at the pipe along with these photos this is what I see.

- The finish is dull and very dirty with dust ground into the grooves of the sandblast finish around the bowl. There oils from holding the pipe on the sides of the bowl. The blast is rugged and shows some interesting grain patterns.

- The rim top is dirty with grime and lava all around the bowl and filling in much of the sandblast on the rim top. There was also darkening on the top and on the edge of the rim.

- The bowl has a thick cake in it and it had overflowed onto the inner edge of the bowl. It actually looks to be undamaged from what I can see at this point. There is a trough carved in the bottom of the bowl from either overdrilling or more likely from zealous use of pipe cleaners. There does not appear to be any burning or reaming damage to the inner edges of the bowl. There were some nicks in the briar on the outer edge.

- The stem is vulcanite and has the Vauen white dot logo inlaid into the vulcanite on the saddle stem. It fits the shank very well. It is made for a filter but significantly smaller than a 9mm. Could well be the Vauen 6mm filters would fit.

- The vulcanite stem had oxidation, calcification and tooth chatter and some deeper marks ahead of the button that are visible in the photos below. Nothing to deep but nonetheless present.

Overall my impressions of this German made Billiard was that it was in solid shape with no significant damage to the briar on the bowl sides and rim. The cake does not seem to hide any burns or checking and the exterior of the bowl does not show any hot spots or darkening. My examination of the bowl and what I see in the photos below confirm the assessment above.

I took close up photos so that I could have a clearer picture of the condition of the bowl and rim edges and top. The rim top photos confirm my assessment above. The cake in the bowl is quite thick and the rim top is filled in with lava and is dirty. You can also see the darkening on the inner edge and the rim top. You can also see the condition of the outer edge of the rim and see that nicks toward the back of the bowl. This is what I look for when assessing a pipe. The photos of the stem surface confirmed my assessment of the condition. You can see that the stem is dirty – oxidized and calcified. You can also see the tooth chatter and marks on the surface. The white dot logo on the top of the saddle stem is in great condition.

I took close up photos so that I could have a clearer picture of the condition of the bowl and rim edges and top. The rim top photos confirm my assessment above. The cake in the bowl is quite thick and the rim top is filled in with lava and is dirty. You can also see the darkening on the inner edge and the rim top. You can also see the condition of the outer edge of the rim and see that nicks toward the back of the bowl. This is what I look for when assessing a pipe. The photos of the stem surface confirmed my assessment of the condition. You can see that the stem is dirty – oxidized and calcified. You can also see the tooth chatter and marks on the surface. The white dot logo on the top of the saddle stem is in great condition.  I took photos of the sides and heel of the bowl. While this definitely shows the grain patterns around a bowl it also allows me have a different look at the of the condition of the briar and the finish. I look at the finish to make sure there are no nicks and damage. The stain on the bowl is spotty but highlights the grain.There were no cracks or splits following the grain or coming down from the rim edges. There were no cracks in the shank. I also look for flaws in the grain as those can also hide cracks or damage. In this case the bowl exterior is darkened on the sides by hand oil but is still sound and should clean up very well. The grain patterns are nice.

I took photos of the sides and heel of the bowl. While this definitely shows the grain patterns around a bowl it also allows me have a different look at the of the condition of the briar and the finish. I look at the finish to make sure there are no nicks and damage. The stain on the bowl is spotty but highlights the grain.There were no cracks or splits following the grain or coming down from the rim edges. There were no cracks in the shank. I also look for flaws in the grain as those can also hide cracks or damage. In this case the bowl exterior is darkened on the sides by hand oil but is still sound and should clean up very well. The grain patterns are nice.

I took photos of the stamping so I can see if it is faint in any spots or double stamped or unclear. It often takes several photos to capture what I am looking for. The stamping on the underside of the shank are clear and readable in the pictures below. It reads Vauen [over] Luxus. It is followed by the shape number 4234 followed by the stamp of crossed pipes.

I took photos of the stamping so I can see if it is faint in any spots or double stamped or unclear. It often takes several photos to capture what I am looking for. The stamping on the underside of the shank are clear and readable in the pictures below. It reads Vauen [over] Luxus. It is followed by the shape number 4234 followed by the stamp of crossed pipes.  As usual I do some background reading to remind myself of the background on the Vauen brand before I started my work on the pipe. It is an important part of the restoration to me as it adds colour to the pipe I am working on. I turned to Pipephil’s site (http://pipephil.eu/logos/en/logo-v1.html). I did a screen capture of the information on the site. There was a great sidebar that gave some history of the brand. I include both of them below.

As usual I do some background reading to remind myself of the background on the Vauen brand before I started my work on the pipe. It is an important part of the restoration to me as it adds colour to the pipe I am working on. I turned to Pipephil’s site (http://pipephil.eu/logos/en/logo-v1.html). I did a screen capture of the information on the site. There was a great sidebar that gave some history of the brand. I include both of them below.  In 1848, Karl Ellenberger and his partner Carl August Ziener establish a pipe factory in Nuremberg. In 1901 they merge with Gebhard Ott an other factory in town and they create a firm named Vereinigten Pfeifenfabriken Nürnberg (abbreviated : VPFN*). Shortly after Ernst Eckert, a member of the Ott family became manager of the society. During the 20th century Adolf, Ernst (jr) and Alexander Eckert (CEO in 2012) followed one another at Vauen’s head.* VPFN : “V” is said VAU in German (pronounce faou) and “N” becomes EN. Hence VAUEN.

In 1848, Karl Ellenberger and his partner Carl August Ziener establish a pipe factory in Nuremberg. In 1901 they merge with Gebhard Ott an other factory in town and they create a firm named Vereinigten Pfeifenfabriken Nürnberg (abbreviated : VPFN*). Shortly after Ernst Eckert, a member of the Ott family became manager of the society. During the 20th century Adolf, Ernst (jr) and Alexander Eckert (CEO in 2012) followed one another at Vauen’s head.* VPFN : “V” is said VAU in German (pronounce faou) and “N” becomes EN. Hence VAUEN.

Dal Stanton (Pipesteward.com) wrote a great piece on the history of the brand on a Vauen pipe that he worked on. I reread that and quote a section from the blog below that gives a great sense of the history of the German brand and some photos from the website (https://rebornpipes.com/2021/04/27/breathing-new-life-into-a-german-vauen-6294-p-lip-saddle-billiard-for-a-special-young-lady/).

… I turn to the question of the history of the VAUEN name? I look to the History section of the VAUEN website and again, I am impressed with the presentation. Whenever I work on a pipe, and especially when a pipe name is new to me, I enjoy looking at its history to appreciate the pipe more fully now on my worktable. From VAUEN’s website: Quality and a wealth of ideas have a long tradition at VAUEN. 160 years of VAUEN: that means 160 years of skilled workmanship and modern technology and 160 years of experience in fulfilling the individual wishes of today’s pipe lovers, and those of tomorrow.

Quality and a wealth of ideas have a long tradition at VAUEN. 160 years of VAUEN: that means 160 years of skilled workmanship and modern technology and 160 years of experience in fulfilling the individual wishes of today’s pipe lovers, and those of tomorrow.

In Nuremberg in 1848, Karl Ellenberger and his partner Carl August Ziener turned an idea into reality: Germany’s first pipe manufacturer produced tobacco pipes for connoisseurs around the world using a selection of the best wood. In an amalgamation with the Gebhard Ott pipe factory, which was founded in 1866 in Nuremberg, the Vereinigten Pfeifenfabriken Nuremberg (United Pipe Factories Nuremberg, or VPFN) was born in 1901. Under the management of Ernst Eckert, a descendent of the founding Ott family, a company was born whose products and services would shape the tobacco and smoking culture in Europe and overseas for the next 160 years and counting.

The question about the name, VAUEN, not being a name of a person and why it is capitalized throughout is explained:

In his search for a name that would be easily remembered by all pipe lovers, Ernst Eckert’s son, Adolf Eckert, coined a new name for the company in 1909: VAUEN – a composition of the first letters V (pronounced vow) of Vereinigte Pfeifenfabriken and N (pronounced en) of Nuremberg. A brand for the future was born.

Knowing that about me you can guess that I started working on this pipe by turning to the bowl. I turned to the bowl and started working on the cake to remove it. I reamed back the cake on the bowl walls with a PipNet Pipe reamer and cleaned it up with a Savinelli Fitsall Pipe Knife. I sanded the walls smooth with 220 grit sandpaper wrapped around a piece of dowel. I used a brass bristle wire brush to remove the debris in the sandblast of the rim top.

I scrubbed the sandblast exterior of the bowl with undiluted Murphy’s Oil Soap and a tooth brush. I rinsed it off with warm water to remove the grime and the soap. It looked much better once it was clean.

I scrubbed the sandblast exterior of the bowl with undiluted Murphy’s Oil Soap and a tooth brush. I rinsed it off with warm water to remove the grime and the soap. It looked much better once it was clean.

Once the bowl had dried the finish was very spotty. There were dark places on the bowl and the rim top was dark. The spottiness really had to go. I generally start with this kind of thing by wiping the bowl down with acetone on cotton pads. I was able to get a lot of the spots off but there were still dark spots on the sides and rim top. It would need to be restained.

Once the bowl had dried the finish was very spotty. There were dark places on the bowl and the rim top was dark. The spottiness really had to go. I generally start with this kind of thing by wiping the bowl down with acetone on cotton pads. I was able to get a lot of the spots off but there were still dark spots on the sides and rim top. It would need to be restained.

It dried out and it was much better even though the spots were bothersome to me. There were also some putty fills that were visible in the finish. I mixed up a wash of light brown stain and isopropyl alcohol. I stained the bowl and shank with the stain was using a dauber. I lit the stain on fire with a lighter and flamed the stain to set it in the grain. I repeat the process until I am happy with the look of the finish.

It dried out and it was much better even though the spots were bothersome to me. There were also some putty fills that were visible in the finish. I mixed up a wash of light brown stain and isopropyl alcohol. I stained the bowl and shank with the stain was using a dauber. I lit the stain on fire with a lighter and flamed the stain to set it in the grain. I repeat the process until I am happy with the look of the finish. I set the bowl aside to let the stain cure. It was a bit dark to my liking but it was no longer spotty looking. Usually the stain will dry to the point of being able to work on it in about 40 minutes.

I set the bowl aside to let the stain cure. It was a bit dark to my liking but it was no longer spotty looking. Usually the stain will dry to the point of being able to work on it in about 40 minutes.

I wanted to get a bit more opacity to the stain coat and show the various layers in the grooves and high points of the finish. I wiped it down with some isopropyl alcohol to remove the heaviness of the stain coat. I really like the way it is looking at this point.

I wanted to get a bit more opacity to the stain coat and show the various layers in the grooves and high points of the finish. I wiped it down with some isopropyl alcohol to remove the heaviness of the stain coat. I really like the way it is looking at this point.

Then I remembered I had not cleaned out the shank and stem. I went back and cleaned out the mortise and airway into the bowl and the stem with cotton swabs, pipe cleaners and isopropyl alcohol until they came out clean. It looked much better.

Then I remembered I had not cleaned out the shank and stem. I went back and cleaned out the mortise and airway into the bowl and the stem with cotton swabs, pipe cleaners and isopropyl alcohol until they came out clean. It looked much better. I rubbed the bowl and shank down with Before & After Restoration Balm. I worked it into the finish with my fingers and used a shoe brush to press it deep into the crevices of the sandblast. The product works to deep clean the finish on the bowl and shank and enliven and protect the briar. After it sat for 15 minutes I wiped it off with a soft cloth. The briar really came alive with a rich shine. I took some photos of the bowl at this point to mark the progress in the restoration. It is a beautiful bowl. I will need to buff the bowl to finish the shine.

I rubbed the bowl and shank down with Before & After Restoration Balm. I worked it into the finish with my fingers and used a shoe brush to press it deep into the crevices of the sandblast. The product works to deep clean the finish on the bowl and shank and enliven and protect the briar. After it sat for 15 minutes I wiped it off with a soft cloth. The briar really came alive with a rich shine. I took some photos of the bowl at this point to mark the progress in the restoration. It is a beautiful bowl. I will need to buff the bowl to finish the shine.

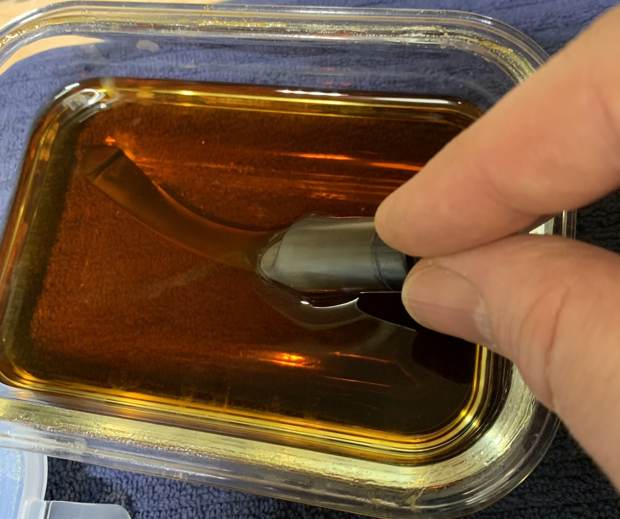

I decided to address the “overdrill” or overzealous pipe cleaner damage to the inside front bottom and wall of the bowl by mixing a batch of cigar mud – a mixture of fine cigar ash and water to form a paste (I added a bit too much water so it needed to sit for a while to evaporate).

I decided to address the “overdrill” or overzealous pipe cleaner damage to the inside front bottom and wall of the bowl by mixing a batch of cigar mud – a mixture of fine cigar ash and water to form a paste (I added a bit too much water so it needed to sit for a while to evaporate).  Once it was the right consistency I put a pipe cleaner in the airway entry to the bowl and pressed the mud into the trough. I used a dental spatula to lay the mud in place and pressed it against the wall and bottom of the bowl. I layered it into the groove and set it aside to harden.

Once it was the right consistency I put a pipe cleaner in the airway entry to the bowl and pressed the mud into the trough. I used a dental spatula to lay the mud in place and pressed it against the wall and bottom of the bowl. I layered it into the groove and set it aside to harden.

I set it aside in the evening and in the morning when I checked on the bowl to make sure the bowl had cured. I was happy to see that the repair had cured very well.

I set it aside in the evening and in the morning when I checked on the bowl to make sure the bowl had cured. I was happy to see that the repair had cured very well. I set the bowl aside to let the repair to the bowl bottom cure. It is wet and dark but will dry hard and a light grey. I turned my attention to the stem. I “painted” the stem surface with the flame of a Bic lighter to lift the tooth marks. I was able to lift them all to the point that I would be able to sand the remnants of them out. I sanded the stem surface with 220 grit sandpaper and started the polishing the stem with 600 grit wet dry sand paper. I wiped it down with some Obsidian Oil and moved on to polishing the stem.

I set the bowl aside to let the repair to the bowl bottom cure. It is wet and dark but will dry hard and a light grey. I turned my attention to the stem. I “painted” the stem surface with the flame of a Bic lighter to lift the tooth marks. I was able to lift them all to the point that I would be able to sand the remnants of them out. I sanded the stem surface with 220 grit sandpaper and started the polishing the stem with 600 grit wet dry sand paper. I wiped it down with some Obsidian Oil and moved on to polishing the stem.

I polish the stem to remove the light chatter and scratches. Over the years I have developed my own process for this. It is all preparation for the buffing that will come last. I use micromesh sanding pads and water to wet sand the stem with 1500-12000 grit sanding pads. I wiped it down after each sanding pad with Obsidian Oil on a cotton rag after each sanding pad as I find it does two things – first it protects the stem and second it give the sanding pads bite in the polishing process.

I polish the stem to remove the light chatter and scratches. Over the years I have developed my own process for this. It is all preparation for the buffing that will come last. I use micromesh sanding pads and water to wet sand the stem with 1500-12000 grit sanding pads. I wiped it down after each sanding pad with Obsidian Oil on a cotton rag after each sanding pad as I find it does two things – first it protects the stem and second it give the sanding pads bite in the polishing process.

After finishing with the micromesh pads I always rub the stem down with Before & After Fine and Extra Fine stem polish as it seems to really remove the fine scratches in the acrylic. I rub the Fine Polish on the stem and wipe it off with a paper towel and then repeat the process with the Extra Fine polish. I finish the polishing of the stem by wiping it down with a final coat of Obsidian Oil and set the stem aside to let the oil dissipate. This process gives the stem a shine and also a bit of protection for the stem surface.

After finishing with the micromesh pads I always rub the stem down with Before & After Fine and Extra Fine stem polish as it seems to really remove the fine scratches in the acrylic. I rub the Fine Polish on the stem and wipe it off with a paper towel and then repeat the process with the Extra Fine polish. I finish the polishing of the stem by wiping it down with a final coat of Obsidian Oil and set the stem aside to let the oil dissipate. This process gives the stem a shine and also a bit of protection for the stem surface. Once I finish a filter stem I like to fit it with a clean filter. In this case I do not have the filters to fit it. My thinking is that it is a Dr. Perl Junior 6mm filter. The pipeman I am restoring it for will have to pick some up. I have included a photo of what I think the filters will be.

Once I finish a filter stem I like to fit it with a clean filter. In this case I do not have the filters to fit it. My thinking is that it is a Dr. Perl Junior 6mm filter. The pipeman I am restoring it for will have to pick some up. I have included a photo of what I think the filters will be. The final steps in my process involve using the buffer. I first buff the stem and the briar with Blue Diamond on the buffing wheel. Blue Diamond is a plastic polish but I find that it works very well to polish out the light scratches in the acrylic and the briar. I work the pipe over on the wheel with my finger or thumb in the bowl to keep it from becoming airborne. It works well and I am able to carefully move forward with the buffing.

The final steps in my process involve using the buffer. I first buff the stem and the briar with Blue Diamond on the buffing wheel. Blue Diamond is a plastic polish but I find that it works very well to polish out the light scratches in the acrylic and the briar. I work the pipe over on the wheel with my finger or thumb in the bowl to keep it from becoming airborne. It works well and I am able to carefully move forward with the buffing.

I finished with the Blue Diamond and moved on to buffing with carnauba wax. Once I have a good shine in the briar and vulcanite I always give the bowl multiple coats of Conservator’s Wax and the stem multiple coats of carnauba wax. I have found that I can get a deeper shine if I following up the wax buff with a clean buffing pad. It works to raise the shine and then I follow that up with a hand buff with a microfiber cloth to deepen the shine. It is always fun for me to see what the polished bowl looks like with the polished stem. It really is a beautiful pipe. The bowl coating and build up of cigar mud should harden and provide a base for the build up of new cake. The sand blast finish around the bowl sides and shank show the grain patterns underneath the rich brown stains of this Vauen Luxus 4234 Filter Billiard and the polished vulcanite stem is a great addition. The finished pipe feels great in my hand. It is light and well balanced. Have a look at it with the photos below. The dimensions are Length: 5 ¾ inches, Height: 1 ¾ inches, Outside diameter of the bowl: 1 ¼ inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 1.10 ounces/31 grams. It is a beautiful pipe that I will be sending to a friend of mine who is collecting older Vauen pipes. I look forward to hearing what he thinks of it.

I finished with the Blue Diamond and moved on to buffing with carnauba wax. Once I have a good shine in the briar and vulcanite I always give the bowl multiple coats of Conservator’s Wax and the stem multiple coats of carnauba wax. I have found that I can get a deeper shine if I following up the wax buff with a clean buffing pad. It works to raise the shine and then I follow that up with a hand buff with a microfiber cloth to deepen the shine. It is always fun for me to see what the polished bowl looks like with the polished stem. It really is a beautiful pipe. The bowl coating and build up of cigar mud should harden and provide a base for the build up of new cake. The sand blast finish around the bowl sides and shank show the grain patterns underneath the rich brown stains of this Vauen Luxus 4234 Filter Billiard and the polished vulcanite stem is a great addition. The finished pipe feels great in my hand. It is light and well balanced. Have a look at it with the photos below. The dimensions are Length: 5 ¾ inches, Height: 1 ¾ inches, Outside diameter of the bowl: 1 ¼ inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 1.10 ounces/31 grams. It is a beautiful pipe that I will be sending to a friend of mine who is collecting older Vauen pipes. I look forward to hearing what he thinks of it.

Hopefully this tack of writing this blog is helpful to you in some way. In it I show both what I am looking for and how I move forward in addressing what I see when work on a pipe has been helpful to you. It is probably the most straightforward detailed description of my work process. As always I encourage your questions and comments as you read the blog. Thanks to each of you who are reading this blog. Remember we are not pipe owners; we are pipemen and women who hold our pipes in trust until they pass on into the trust of those who follow us.