Blog by Dal Stanton

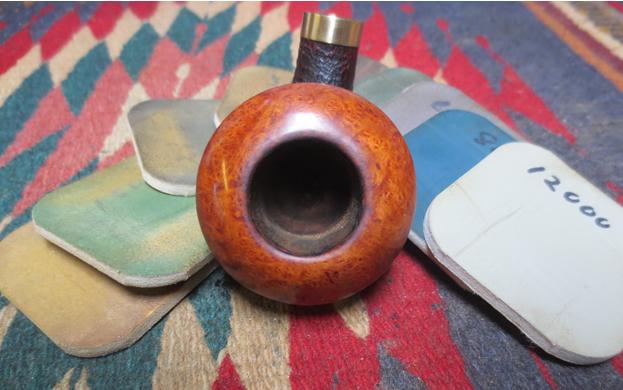

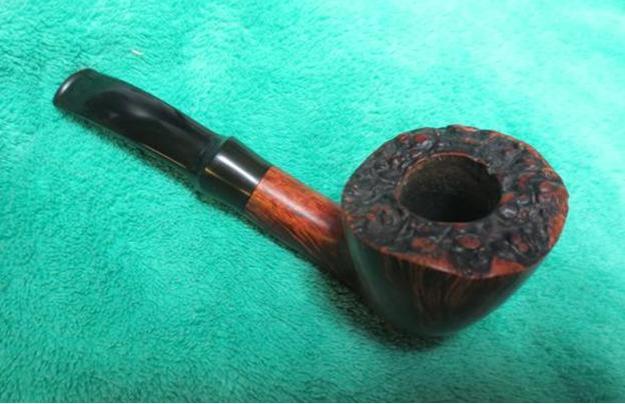

Stephen, a friend visiting Bulgaria from Rainbow City, Alabama, and I were walking through the Antique Market in the shadow of Nevski Cathedral in center city Sofia, when I my roving ‘pipe eyes’ spied an unbelievably nice looking, hefty, handful of a sand blasted Ball or Apple shaped pipe waiting on a table gratuitously mixed with WWII paraphernalia, old Communist memorabilia, skeleton keys and an assortment of cork screws, lighters and want-a-be Rolex watches.  This pipe, though, was the real deal. With Stephen by my side, I did my best not to lock my eyes on the prize. Finally, after I gave serious non-interested examination of the seller’s other offerings, I picked up the pipe and gave it a cursory, equally, non-interested look over. As I looked down into the chamber, I saw my opportunity. There was daylight at the bottom of the chamber – a hole, my leverage for the negotiation. A quintessential burn through. With my index finger at the chamber floor, it was sharply wedged downwardly so that the wearing, digging and burning finally was more than the briar could handle. Turning the pipe over in my hand I read the nomenclature stamped on the underside of the shank – STANWELL (barely visible in the blasted briar) [over] ROUGE 109 [over] MADE IN DENMARK. The hefty sand blasted stummel received my initial attention, and then the vulcanite shank extension I had not seen too often. I laughed after the seller gave me his opening volley. At the end of the day, both Stephen and I were happy. The deal struck for the Stanwell Rouge was very satisfactory given that the hole in the bottom of the pipe just would not go away no matter what the seller said. As we headed to the Metro Subway, Stephen proposed that he become the next steward of the Stanwell after I tackled the burn through. So, some time later, Stephen emailed me from Alabama, saying he was still interested in the Stanwell. Now on my worktable here in Sofia, Bulgaria, the time has come to recommission him. Here are the pictures from my worktable.

This pipe, though, was the real deal. With Stephen by my side, I did my best not to lock my eyes on the prize. Finally, after I gave serious non-interested examination of the seller’s other offerings, I picked up the pipe and gave it a cursory, equally, non-interested look over. As I looked down into the chamber, I saw my opportunity. There was daylight at the bottom of the chamber – a hole, my leverage for the negotiation. A quintessential burn through. With my index finger at the chamber floor, it was sharply wedged downwardly so that the wearing, digging and burning finally was more than the briar could handle. Turning the pipe over in my hand I read the nomenclature stamped on the underside of the shank – STANWELL (barely visible in the blasted briar) [over] ROUGE 109 [over] MADE IN DENMARK. The hefty sand blasted stummel received my initial attention, and then the vulcanite shank extension I had not seen too often. I laughed after the seller gave me his opening volley. At the end of the day, both Stephen and I were happy. The deal struck for the Stanwell Rouge was very satisfactory given that the hole in the bottom of the pipe just would not go away no matter what the seller said. As we headed to the Metro Subway, Stephen proposed that he become the next steward of the Stanwell after I tackled the burn through. So, some time later, Stephen emailed me from Alabama, saying he was still interested in the Stanwell. Now on my worktable here in Sofia, Bulgaria, the time has come to recommission him. Here are the pictures from my worktable.

I recalled that Steve had posted a blog by Bas Stevens, who, according to Steve, was one of the foremost authorities on Stanwell pipes (See: LINK HERE). Bas Steven’s extensive list of Stanwell shape numbers and designers also included this Rouge’s shape 109, which is described as: 109. Flat, ball-shaped bowl, slightly bent, full mouthpiece.

I recalled that Steve had posted a blog by Bas Stevens, who, according to Steve, was one of the foremost authorities on Stanwell pipes (See: LINK HERE). Bas Steven’s extensive list of Stanwell shape numbers and designers also included this Rouge’s shape 109, which is described as: 109. Flat, ball-shaped bowl, slightly bent, full mouthpiece.

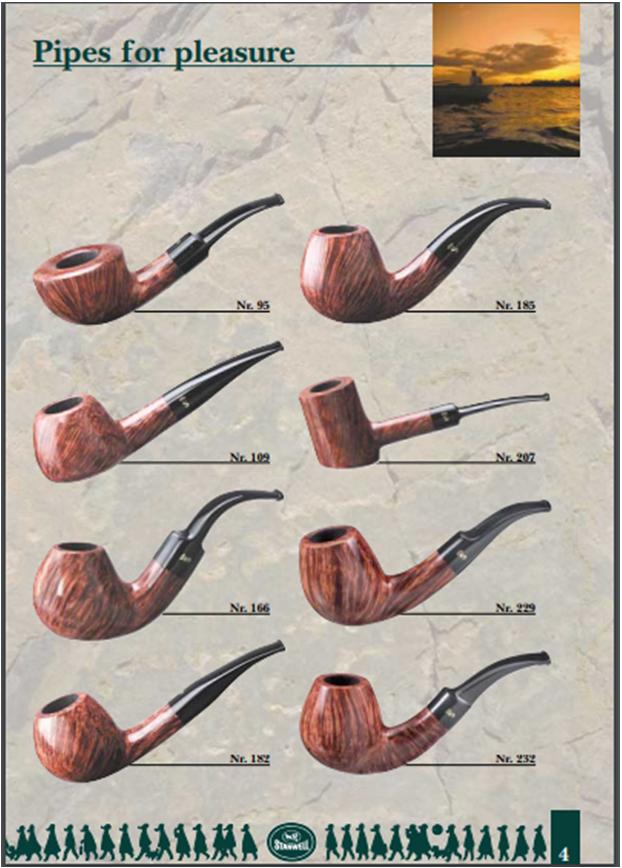

I did searches on Rouge and I could not find a Stanwell listing for only ‘Rouge’ but ‘Royal Rouge’ was evident. This BollitoPipe.it listing has for sale, a ‘Royal Rouge’ 109 which is a smooth version described with information that matches the ‘Rouge’ in dimension with the difference of the briar shank compared to the vulcanite extension on my Rouge.  Pipedia’s site links to Stanwell catalogues shows this 2008 9mm catalogue listing the 109 shape (2nd down on left) with others. Rouge simply means ‘Red’ in French which is a good description of what the Rouge’s sand blasted stummel formerly revealed, as the ‘Royal Rouge’ exemplifies above.

Pipedia’s site links to Stanwell catalogues shows this 2008 9mm catalogue listing the 109 shape (2nd down on left) with others. Rouge simply means ‘Red’ in French which is a good description of what the Rouge’s sand blasted stummel formerly revealed, as the ‘Royal Rouge’ exemplifies above.  The Danish pipe company, Stanwell, according to Pipedia’s article closed its doors in 2009 ending an interesting chapter of pipe history as the only remaining pipe manufacturer in Scandinavia. The ‘Stanwell’ name moved to Italy where pipes were produced bearing the name since 2010. The ‘Made in Denmark’ on the Rouge indicates that it was produce pre-2010 before the closing. With a better appreciation for the Stanwell Rouge 109 before me, the first thing I do in his recommissioning is to put the stem in an OxiClean bath after putting petroleum jelly on the Stanwell Crown stamping to protect it.

The Danish pipe company, Stanwell, according to Pipedia’s article closed its doors in 2009 ending an interesting chapter of pipe history as the only remaining pipe manufacturer in Scandinavia. The ‘Stanwell’ name moved to Italy where pipes were produced bearing the name since 2010. The ‘Made in Denmark’ on the Rouge indicates that it was produce pre-2010 before the closing. With a better appreciation for the Stanwell Rouge 109 before me, the first thing I do in his recommissioning is to put the stem in an OxiClean bath after putting petroleum jelly on the Stanwell Crown stamping to protect it.  Before I tackle the repair of the burn-through the stummel’s heel, I like working on clean pipes because it helps with the assessment of needs. I start by carefully reaming the bowl to remove the light carbon build up. I say, “careful” because the floor of the fire chamber is dangerously thin. The last thing I want is the floor to drop through! For the gentle approach, I use the Savinelli Pipe Knife and work the sides of the chamber without reaching too deeply. Next, I take 240 grit paper wrapped around a Sharpie Pen and sand the chamber ridding it of more carbon and exposing fresh briar. Finally, I wipe the chamber out with a cotton pad wetted with alcohol.

Before I tackle the repair of the burn-through the stummel’s heel, I like working on clean pipes because it helps with the assessment of needs. I start by carefully reaming the bowl to remove the light carbon build up. I say, “careful” because the floor of the fire chamber is dangerously thin. The last thing I want is the floor to drop through! For the gentle approach, I use the Savinelli Pipe Knife and work the sides of the chamber without reaching too deeply. Next, I take 240 grit paper wrapped around a Sharpie Pen and sand the chamber ridding it of more carbon and exposing fresh briar. Finally, I wipe the chamber out with a cotton pad wetted with alcohol.  Using undiluted Murphy’s Oil soap, a cotton pad and a bristled tooth brush, I scrub the exterior of the sand blasted bowl working the brush well into the surface as well as the rim (pictured below) before starting the cleaning. The surface had a good bit of grime. The good news is the rim is in good shape – it still shows the blasted sculpting over it, though it is darkened.

Using undiluted Murphy’s Oil soap, a cotton pad and a bristled tooth brush, I scrub the exterior of the sand blasted bowl working the brush well into the surface as well as the rim (pictured below) before starting the cleaning. The surface had a good bit of grime. The good news is the rim is in good shape – it still shows the blasted sculpting over it, though it is darkened.

Now to the internals of the stummel – using pipe cleaners and cotton swabs and isopropyl 95%, I clean the internals. Oh my. This old boy I believe was like the old proverbial horse saying, ‘he’s been road hard and put up wet’! There was no end to the gunk in the mortise. I scraped it with straight edge files and small screw drivers, and with scads of cotton swabs – the effort was immense to clean the internals. After some time, things would start to look up, I would scrape a bit more and it was like I was starting over. Yet thankfully, eventually the tide turned. The picture shows the aftermath.

Now to the internals of the stummel – using pipe cleaners and cotton swabs and isopropyl 95%, I clean the internals. Oh my. This old boy I believe was like the old proverbial horse saying, ‘he’s been road hard and put up wet’! There was no end to the gunk in the mortise. I scraped it with straight edge files and small screw drivers, and with scads of cotton swabs – the effort was immense to clean the internals. After some time, things would start to look up, I would scrape a bit more and it was like I was starting over. Yet thankfully, eventually the tide turned. The picture shows the aftermath. The stem has been soaking in the OxiClean bath and I take it out to reveal the raised oxidation on the stem. The petroleum jelly is still intact covering the Stanwell stem Crown stamping, protecting it from the OxiClean process. I start by putting a disk between the stem and the shank to protect the stem from shouldering as I wet sand with 600 grade sanding paper to remove the raised oxidation. Then, I had one of those ‘Duh!’ moments – the shank extension on the stummel is also vulcanite with a white acrylic divider. Removing the disk, I treat the two together. First, with the shank extension, I lightly use 240 grit sanding paper around the extension because it did not have the benefit of the OxiClean bath. I do this to loosen the oxidation. Then, with the shank and stem united I wet sand using the 600 grade paper, careful to protect the stem Crown stamping.

The stem has been soaking in the OxiClean bath and I take it out to reveal the raised oxidation on the stem. The petroleum jelly is still intact covering the Stanwell stem Crown stamping, protecting it from the OxiClean process. I start by putting a disk between the stem and the shank to protect the stem from shouldering as I wet sand with 600 grade sanding paper to remove the raised oxidation. Then, I had one of those ‘Duh!’ moments – the shank extension on the stummel is also vulcanite with a white acrylic divider. Removing the disk, I treat the two together. First, with the shank extension, I lightly use 240 grit sanding paper around the extension because it did not have the benefit of the OxiClean bath. I do this to loosen the oxidation. Then, with the shank and stem united I wet sand using the 600 grade paper, careful to protect the stem Crown stamping.  With this completed, I look to the bit area with minor tooth chatter. Using 240 grit paper I sand the chatter out, following with 600 grit again, then finish off this phase of the stem’s polishing using 0000 grade steel wool over the entire shank and stem. To try to remove any oxidation in the Stanwell Crown stem stamp, I use a MagicEraser sponge to apply a non-abrasive cleaner. The pictures show the progress with the stem.

With this completed, I look to the bit area with minor tooth chatter. Using 240 grit paper I sand the chatter out, following with 600 grit again, then finish off this phase of the stem’s polishing using 0000 grade steel wool over the entire shank and stem. To try to remove any oxidation in the Stanwell Crown stem stamp, I use a MagicEraser sponge to apply a non-abrasive cleaner. The pictures show the progress with the stem.

With the stem completed up to the micromesh phase, I put it aside to focus on the stummel repairs. I have been developing the plan since I first saw this incredibly desirable and redeemable Stanwell Rouge beckoning on the table in the Antique Market. There are two main steps in the burn through repair. The first is to patch the external presentation of the stummel using a putty created from CA glue and briar dust. This patch will fill the hole leaving an external mound for eventual sanding and shaping aiming at blending with the sand blasted finish. When the Briar Dust Putty is applied from the external side, there also will form an internal mounding as the putty presses through the hole. This is good and desired. This internal mound will form the primary internal encasing of the burn through area, which is extremely thin and therefore weakened. This internal covering of Briar Putty will form the hole fill as well as the initial reinforcement of the chamber floor. The second step is to augment this initial reinforcement internally by using JB Weld. I first saw the use of this from Charles Lemon on Dad’s Pipes. I will mix a batch of JB Weld and apply it on top of the patch area and rebuild and level the floor of the fire chamber, bringing the new floor almost up to the draft hole. That is the theoretical plan – of course, the best laid plans are often…. You know the story 😊!

With the stem completed up to the micromesh phase, I put it aside to focus on the stummel repairs. I have been developing the plan since I first saw this incredibly desirable and redeemable Stanwell Rouge beckoning on the table in the Antique Market. There are two main steps in the burn through repair. The first is to patch the external presentation of the stummel using a putty created from CA glue and briar dust. This patch will fill the hole leaving an external mound for eventual sanding and shaping aiming at blending with the sand blasted finish. When the Briar Dust Putty is applied from the external side, there also will form an internal mounding as the putty presses through the hole. This is good and desired. This internal mound will form the primary internal encasing of the burn through area, which is extremely thin and therefore weakened. This internal covering of Briar Putty will form the hole fill as well as the initial reinforcement of the chamber floor. The second step is to augment this initial reinforcement internally by using JB Weld. I first saw the use of this from Charles Lemon on Dad’s Pipes. I will mix a batch of JB Weld and apply it on top of the patch area and rebuild and level the floor of the fire chamber, bringing the new floor almost up to the draft hole. That is the theoretical plan – of course, the best laid plans are often…. You know the story 😊!

I begin by taking another close picture of the external hole area as well as the floor of the chamber, with a pipe cleaner inserted to mark the gap the new floor will need to fill. This marks the starting point. The second picture below does not reveal the depth, but I estimate a good, 3 to 4 mm between the hole and the draft hole level. I clean the stummel external surface with a cotton pad wetted with alcohol. The pictures show the prep.

Using an index card, I mix briar dust and Hot Stuff Special ‘T’ CA Instant Glue (thicker) with a toothpick to form a putty. I’m shooting for the thickness of molasses so that the putty will not run and spread but stay where I apply it. When the putty reaches the viscosity I desire, I apply the putty to the hole pressing it through until I achieve sufficient mounding on the inside. As I press the putty through with the toothpick, the putty spreads out a bit more than I desire. I use an accelerator on the inside and outside to cure the putty more rapidly. I take pictures to mark the completion of step one. It will be tricky filing and sanding on the sand blasted surface, but not impossible with patience. As I reflect further, a different approach that may have lessened the mounding on the external side would have been to apply the putty internally and pushed it through…. The approaches for smooth briar and blasted briar may not be the same! Next time.

Using an index card, I mix briar dust and Hot Stuff Special ‘T’ CA Instant Glue (thicker) with a toothpick to form a putty. I’m shooting for the thickness of molasses so that the putty will not run and spread but stay where I apply it. When the putty reaches the viscosity I desire, I apply the putty to the hole pressing it through until I achieve sufficient mounding on the inside. As I press the putty through with the toothpick, the putty spreads out a bit more than I desire. I use an accelerator on the inside and outside to cure the putty more rapidly. I take pictures to mark the completion of step one. It will be tricky filing and sanding on the sand blasted surface, but not impossible with patience. As I reflect further, a different approach that may have lessened the mounding on the external side would have been to apply the putty internally and pushed it through…. The approaches for smooth briar and blasted briar may not be the same! Next time.

I’m back to the worktable after a day’s work and unfortunately, in the back of my mind the application of briar dust putty to the external surface as I did yesterday, has blossomed in my mind into a colossal blunder! In my mind, I picture the way I should have done it and it was perfect – in my mind! But, I have a salvage plan coming together, also in my mind and my hope is that my blunder might spare others from the same fate 😊.

I’m back to the worktable after a day’s work and unfortunately, in the back of my mind the application of briar dust putty to the external surface as I did yesterday, has blossomed in my mind into a colossal blunder! In my mind, I picture the way I should have done it and it was perfect – in my mind! But, I have a salvage plan coming together, also in my mind and my hope is that my blunder might spare others from the same fate 😊.

Before I work on the salvage plan coming together in my mind, I will complete the floor build-up using JB Weld. One of the difficulties that I’ve thought about is a delivery system – how to get the JB Weld mixture to the chamber floor where it’s needed and not smeared on chamber walls trying to place it. I’ve come up with plan of using a plastic bottle nozzle as the delivery system – load the mixture in the nozzle and force it down with a dowel rod and cotton swab. It looks like it should work. I also insert a pipe cleaner into the airway to protect the draft hole from being clogged by the JB Weld. It also helps me know where the floor should be. The mixture sets up in about 4 minutes after the Hardener and Steel are combined. Thankfully, everything works as hoped. I take pictures through the process.

Regarding the external surface patch mound, I realize that with a sandblasted surface it will be very difficult to remove the entire patch mound by filing and sanding as is the method with smooth briar. This will damage the blasted briar surface. After doing research on the internet, I discover that acetone dissolves CA glue. Acetone is the primary active ingredient in nail polish removers. What I’m hoping is a salvage plan; I begin by filing the patch mound down as far as possible without impacting the surface briar terrain. I then apply acetone to the remaining patch mound with a cotton swab to dissolve the surface overflow of the patch. I work the briar dust patch with the cotton swab and gradually the surface patch begins to loosen and dissolve. I’m encouraged. I continue patiently, allowing the acetone to set its own pace. The putty patch dissolves toward the center and leaves ridges which I scrape with my fingernail. At the end of the process, I am relieved – it works. Not only did it work, but the blending is incredible! I cannot see where the hole was without very close scrutiny. The blunder becomes a teachable moment and a bit more experience for future restorations! The pictures tell the story and I’m thankful a disaster was averted with this Stanwell.

Regarding the external surface patch mound, I realize that with a sandblasted surface it will be very difficult to remove the entire patch mound by filing and sanding as is the method with smooth briar. This will damage the blasted briar surface. After doing research on the internet, I discover that acetone dissolves CA glue. Acetone is the primary active ingredient in nail polish removers. What I’m hoping is a salvage plan; I begin by filing the patch mound down as far as possible without impacting the surface briar terrain. I then apply acetone to the remaining patch mound with a cotton swab to dissolve the surface overflow of the patch. I work the briar dust patch with the cotton swab and gradually the surface patch begins to loosen and dissolve. I’m encouraged. I continue patiently, allowing the acetone to set its own pace. The putty patch dissolves toward the center and leaves ridges which I scrape with my fingernail. At the end of the process, I am relieved – it works. Not only did it work, but the blending is incredible! I cannot see where the hole was without very close scrutiny. The blunder becomes a teachable moment and a bit more experience for future restorations! The pictures tell the story and I’m thankful a disaster was averted with this Stanwell.

The next day, after several hours of curing for the JB Weld, I look at the new rebuilt floor of the chamber. I rub my finger over it and it, as expected, is flat. I want to introduce a slightly bowled chamber bottom. To do this I employ the round grinding stone attachment which I mount on the Dremel. I will remove just enough of the JB Weld floor to create this bowl. With the speed at 40%, I start in the center with a circular motion creating the initial rounding. I gradually expand it outwardly by moving it in circular motions. This works well. Afterwards, I use 240 grit paper to sand it more and wipe the bowl out with a cotton pad and alcohol to clean the chamber. Done. Later, near the end of the project, I will coat the chamber with a mixture of activated charcoal dust and sour cream that will form a hard base for forming a new cake for the bowl. Bowl repair officially complete. Yes!

The next day, after several hours of curing for the JB Weld, I look at the new rebuilt floor of the chamber. I rub my finger over it and it, as expected, is flat. I want to introduce a slightly bowled chamber bottom. To do this I employ the round grinding stone attachment which I mount on the Dremel. I will remove just enough of the JB Weld floor to create this bowl. With the speed at 40%, I start in the center with a circular motion creating the initial rounding. I gradually expand it outwardly by moving it in circular motions. This works well. Afterwards, I use 240 grit paper to sand it more and wipe the bowl out with a cotton pad and alcohol to clean the chamber. Done. Later, near the end of the project, I will coat the chamber with a mixture of activated charcoal dust and sour cream that will form a hard base for forming a new cake for the bowl. Bowl repair officially complete. Yes!

Before I address the Rouge’s stummel finish, I continue the sanding and finishing of the vulcanite shank extension so it doesn’t get in the way. I reattach the stem and beginning with micromesh pads 1500 to 2400, I wet sand the extension and stem and then apply Obsidian Oil to the vulcanite. At this point I realize that I have forgotten to clean the internals of the stem (again!). Before moving on, I clean the airway and the 9mm filter bay – which really needed some cleaning. With a ‘proof of cleaning’ picture taken, I follow by dry sanding the extension and stem with pads 3200 to 4000, then 6000 to 12000. After each set of three, I apply Obsidian Oil to the stem and extension to revitalize the vulcanite. While sanding, I notice that the stem is a bit loose in the mortise extension. I will look at this later. The stem and extension look good!

Before I address the Rouge’s stummel finish, I continue the sanding and finishing of the vulcanite shank extension so it doesn’t get in the way. I reattach the stem and beginning with micromesh pads 1500 to 2400, I wet sand the extension and stem and then apply Obsidian Oil to the vulcanite. At this point I realize that I have forgotten to clean the internals of the stem (again!). Before moving on, I clean the airway and the 9mm filter bay – which really needed some cleaning. With a ‘proof of cleaning’ picture taken, I follow by dry sanding the extension and stem with pads 3200 to 4000, then 6000 to 12000. After each set of three, I apply Obsidian Oil to the stem and extension to revitalize the vulcanite. While sanding, I notice that the stem is a bit loose in the mortise extension. I will look at this later. The stem and extension look good!

Turning now to the Stanwell Rouge’s stummel, and it is evident that the historic color of this stout, blasted ball shape was in keeping with its namesake – red. My sense is a deeper burgundy tone would fit well. My plan is to use 2 parts Fiebing’s Oxblood Leather Dye with 1 part of Fiebing’s Black Leather Dye. I want it on the darker side. Let’s see what happens! Taking a close look at the stummel, I probe around with the sharp dental tool and see that there’s bits of dust and residues in the crevices of the blasted texture of the briar. I use a cotton pad and alcohol to clean the stummel, and I use a bristled brush as well to dislodge debris. I then tightly wrap masking tape around the vulcanite extension so that the dye does not possibly impact it – in a note from Steve, he said that some vulcanite will absorb the stains, others not…. Better to be on the safe side. I mix the dyes in a shot glass using a large dropper at 2 to 1, insert a cork in the shank as my handle – and then realize later that the shank extension works just fine as a handle. I take a picture of the set-up. I then warm the stummel with a hot air gun and then apply the 2 to 1 dye mixture to the stummel with a folded pipe cleaner. I work the dye into the crevices – I want good coverage. I then ‘fire’ the aniline dye and the alcohol immediately burns off and sets the dye pigment in the briar. After a few minutes, I repeat the process and set the stummel aside to rest.

Turning now to the Stanwell Rouge’s stummel, and it is evident that the historic color of this stout, blasted ball shape was in keeping with its namesake – red. My sense is a deeper burgundy tone would fit well. My plan is to use 2 parts Fiebing’s Oxblood Leather Dye with 1 part of Fiebing’s Black Leather Dye. I want it on the darker side. Let’s see what happens! Taking a close look at the stummel, I probe around with the sharp dental tool and see that there’s bits of dust and residues in the crevices of the blasted texture of the briar. I use a cotton pad and alcohol to clean the stummel, and I use a bristled brush as well to dislodge debris. I then tightly wrap masking tape around the vulcanite extension so that the dye does not possibly impact it – in a note from Steve, he said that some vulcanite will absorb the stains, others not…. Better to be on the safe side. I mix the dyes in a shot glass using a large dropper at 2 to 1, insert a cork in the shank as my handle – and then realize later that the shank extension works just fine as a handle. I take a picture of the set-up. I then warm the stummel with a hot air gun and then apply the 2 to 1 dye mixture to the stummel with a folded pipe cleaner. I work the dye into the crevices – I want good coverage. I then ‘fire’ the aniline dye and the alcohol immediately burns off and sets the dye pigment in the briar. After a few minutes, I repeat the process and set the stummel aside to rest.

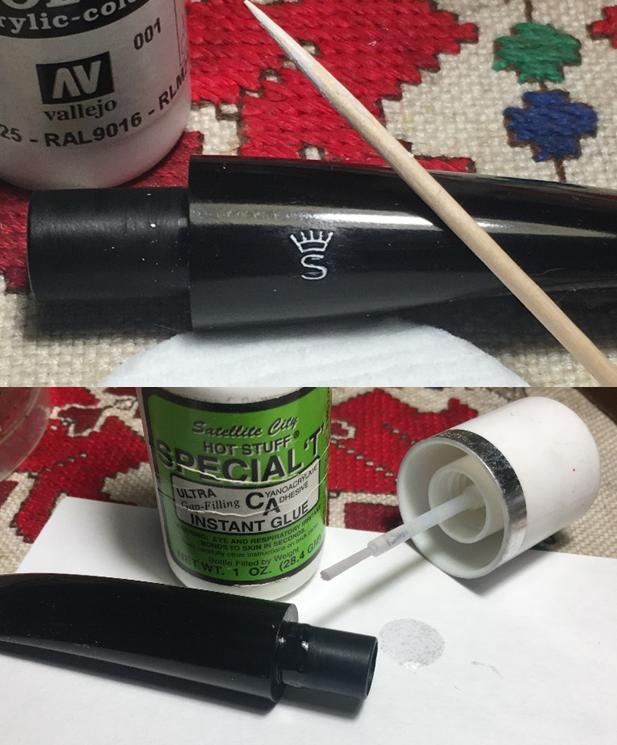

With the stummel now resting, I want to freshen the Stanwell Crown stamp on the stem. Using white acrylic paint, I dab a bit of paint over the Crown with a tooth pick. After the paint sets well, I scrape the excess off gently with the flat edge of a toothpick which goes over the stamp patterns leaving color in the stamp. It looks good. I had noted that the stem was a bit loose when seated in the mortise. As I slowly insert the stem into the mortise extension, it is properly snug until the very end – at home station. The tightness is generated by the white acrylic divider garnishing the end of the extension. This lets me know that the tenon has thinned only at the base – where it ties in to the stem. I use Special ‘T’ CA glue and a manicure brush and paint a line around the circumference of the tenon base. We’ll see if this tightens the stem a bit after the CA glue cures.

With the stummel now resting, I want to freshen the Stanwell Crown stamp on the stem. Using white acrylic paint, I dab a bit of paint over the Crown with a tooth pick. After the paint sets well, I scrape the excess off gently with the flat edge of a toothpick which goes over the stamp patterns leaving color in the stamp. It looks good. I had noted that the stem was a bit loose when seated in the mortise. As I slowly insert the stem into the mortise extension, it is properly snug until the very end – at home station. The tightness is generated by the white acrylic divider garnishing the end of the extension. This lets me know that the tenon has thinned only at the base – where it ties in to the stem. I use Special ‘T’ CA glue and a manicure brush and paint a line around the circumference of the tenon base. We’ll see if this tightens the stem a bit after the CA glue cures.

After several hours, I’m anxious to unwrap the fire crusted stummel. With the surface being sand blasted, I use a softer cotton cloth buffing wheel on the Dremel instead of the felt wheel, that I use with smooth briar pipes. The softer cotton wheel better navigates the textured blasted surface. With the speed at 20%, I utilize Tripoli compound to remove the crusting and to begin the buffing process. After a short time, I decide to up the speed to 40% and this works better with the cotton wheel. I take a picture to show the unwrapping. After completing with the Tripoli, I wipe the bowl down with a cotton pad and alcohol to blend the dye better. Then, loading another cotton cloth wheel, I apply Blue Diamond compound to the stummel. I am liking the very, very subtle oxblood reds tucked away in the contours of the 3-D grain of the sand blasted surface. This was exactly the classic, smoking jacket effect I was aiming for. I press on and after changing to another cotton cloth wheel, I apply carnauba wax to the stummel, shank extension and stem.

After several hours, I’m anxious to unwrap the fire crusted stummel. With the surface being sand blasted, I use a softer cotton cloth buffing wheel on the Dremel instead of the felt wheel, that I use with smooth briar pipes. The softer cotton wheel better navigates the textured blasted surface. With the speed at 20%, I utilize Tripoli compound to remove the crusting and to begin the buffing process. After a short time, I decide to up the speed to 40% and this works better with the cotton wheel. I take a picture to show the unwrapping. After completing with the Tripoli, I wipe the bowl down with a cotton pad and alcohol to blend the dye better. Then, loading another cotton cloth wheel, I apply Blue Diamond compound to the stummel. I am liking the very, very subtle oxblood reds tucked away in the contours of the 3-D grain of the sand blasted surface. This was exactly the classic, smoking jacket effect I was aiming for. I press on and after changing to another cotton cloth wheel, I apply carnauba wax to the stummel, shank extension and stem.

One last project. I use a mixture of sour cream (or plain yogurt may be used) and activated charcoal powder to apply to the fire chamber wall. When this mixture hardens, it provides a good foundation for a new carbon cake to grow – but the new steward needs to be gentle with this after the first few bowls, not scraping the chamber but simply using a folded over bristled pipe cleaner to rub the sides. This will remove the needed leftovers but protect the walls. Over time, a cake grows and life as usual! After mixing the sour cream and charcoal powder to a non-running thickness (like mayonnaise), and inserting a pipe cleaner through the draft hole, using a pipe nail tool, I scoop the mixture into the bowl and spread it over the surface. After spreading, I see that there is too much here and there as the mix thickened. I would scoop a little out and spread again. After it starts to dry, it is thicker. It takes about 15 to 20 minutes for it to set totally. I let it set for at least 24 hours before smoking the pipe. The pictures show the progress.

One last project. I use a mixture of sour cream (or plain yogurt may be used) and activated charcoal powder to apply to the fire chamber wall. When this mixture hardens, it provides a good foundation for a new carbon cake to grow – but the new steward needs to be gentle with this after the first few bowls, not scraping the chamber but simply using a folded over bristled pipe cleaner to rub the sides. This will remove the needed leftovers but protect the walls. Over time, a cake grows and life as usual! After mixing the sour cream and charcoal powder to a non-running thickness (like mayonnaise), and inserting a pipe cleaner through the draft hole, using a pipe nail tool, I scoop the mixture into the bowl and spread it over the surface. After spreading, I see that there is too much here and there as the mix thickened. I would scoop a little out and spread again. After it starts to dry, it is thicker. It takes about 15 to 20 minutes for it to set totally. I let it set for at least 24 hours before smoking the pipe. The pictures show the progress. After the sour cream/charcoal powder mixture dries, I check the fit of the stem and shank extension after applying CA glue to tighten the fit. The patch is too thick so I sand it down using 600 grade sanding paper until the stem slides into the mortise. I fine tune the cleaning of the tenon and apply some Obsidian Oil to it. I complete the restoration with a rigorous hand buffing using a microfiber cloth to bring out the striking shine of this Stanwell Rouge.

After the sour cream/charcoal powder mixture dries, I check the fit of the stem and shank extension after applying CA glue to tighten the fit. The patch is too thick so I sand it down using 600 grade sanding paper until the stem slides into the mortise. I fine tune the cleaning of the tenon and apply some Obsidian Oil to it. I complete the restoration with a rigorous hand buffing using a microfiber cloth to bring out the striking shine of this Stanwell Rouge.

I thought I was facing disaster with the burn through repair when I mounded briar dust putty on the external surface with no way of removing it without damaging the sand blasted briar grain. Yet, I was bailed out by acetone. Now, as I look at this Stanwell Rouge, I can’t believe I could see daylight through it and that most people would pass it by as a loss. I’m glad to have restored it for his new steward. I’m pleased with the subtle red – burgundy tones in the finish. The hefty Ball shape is a distinctive presence in the palm and the sand blasted grain stands out well. This Stanwell Rouge 109, Made in Denmark, is ready to go. All my restorations benefit the work we do here in Bulgaria with the Daughters of Bulgaria – women and girls who have been trafficked and sexually exploited. Check out my blog, The Pipe Steward for more information about this, why I do what I do and other pipes I have for sale in the store! Thanks for joining me!