Blog by Dal Stanton

I acquired this interesting Kiko 343 Meer-lined Billiard in a Lot of 66 which has provided many stewards with newly restored pipes. Aaron saw this uniquely rustified pipe in the “For ‘Pipe Dreamers’ Only!” page on The Pipe Steward site and commissioned it to add to his collection AND this pipe will benefit the Daughters of Bulgaria, our work here in Bulgaria helping women and girls who have been sexually exploited. Here are the pictures that got Aaron’s attention.

I’ve looked forward to working on this pipe because of its country of origin – Made in Tanganyika. The pipe design itself gives hints of its African origin with a rustification that has a safari motif on a classic Billiard and the stem stamp of an elephant is very cool! The briar surface also reminds me of cork – a surface that combines smooth and texture which I think is unique. I assume the shape number 343, stamped on the lower shank, points to the Kiko’s Billiard shape.

I’ve looked forward to working on this pipe because of its country of origin – Made in Tanganyika. The pipe design itself gives hints of its African origin with a rustification that has a safari motif on a classic Billiard and the stem stamp of an elephant is very cool! The briar surface also reminds me of cork – a surface that combines smooth and texture which I think is unique. I assume the shape number 343, stamped on the lower shank, points to the Kiko’s Billiard shape. Dating the minimal age of this pipe is made easy by the fact that Tanganyika is no longer a country. According to the Wikipedia article, in 1922 the Tanganyika Territory was taken by the British as their share of German East Africa under the League of Nations Mandate. After WW 2,

Dating the minimal age of this pipe is made easy by the fact that Tanganyika is no longer a country. According to the Wikipedia article, in 1922 the Tanganyika Territory was taken by the British as their share of German East Africa under the League of Nations Mandate. After WW 2,  Tanganyika became a United Nations Trust Territory yet remained part of the British Common Wealth. Claiming independence from the crown, Tanganyika adopted a new constitution in 1962 that abolished the monarchy and became present day Tanzania. The picture to the left shows the location of Tanganyika – marked #11. This puts the date of this Kiko at no later than 1962 which gives a bit of vintage as it carries its former Commonwealth history to the present.

Tanganyika became a United Nations Trust Territory yet remained part of the British Common Wealth. Claiming independence from the crown, Tanganyika adopted a new constitution in 1962 that abolished the monarchy and became present day Tanzania. The picture to the left shows the location of Tanganyika – marked #11. This puts the date of this Kiko at no later than 1962 which gives a bit of vintage as it carries its former Commonwealth history to the present.

I posted some pictures of the Kiko during the restoration on the Facebook group, The Gentlemen’s Pipe Smoking Society, and fellow member, Jonny Mullis commented on the Kiko name that they were wonderful pipes with the animal stamping. He also said that they were becoming quite collectible and affordable. That was all good news to me!

The Kiko seems generally to be in good condition but carries with it some fills that I’ll need to take a closer look. The Meer-lined bowl looks solid, but I will be able to see better after cleaning it. The rim has a fill or composite material that occupies about a quarter of the rim. Structurally, the rim looks good and should clean up well. The saddle stem has some oxidation and tooth chatter on the bit which needs addressing.

I begin the Kiko of Tanganyika’s restoration by cleaning the airway of the stem with pipe cleaners dipped in isopropyl. After this, I add it to a soak of Before & After Deoxidizer with several other pipe’s and their stems in the queue for restoration. I leave the stem in the soak overnight and after fishing it out of the Deoxidizer, I wipe the fluid off with cotton pads wetted with light paraffin oil. The raised oxidation also is removed as I wipe. Unfortunately, the paint used for the elephant stamping did not hold. I should have covered it! I will need to retouch the stem stamp later. To be on the safe side, I also use 600 grade sanding paper and wet sand the stem to remove any residual oxidation. After this, I remember reading a Charles Lemon’s blog on Dad’s Pipes (LINK) about practices he has learned over the years, and one of them was utilizing Tripoli compound and a buffing wheel to remove oxidation. I decide to try it out. To do this, I mount a new, clean felt buffing wheel on the Dremel, set at the slowest speed and apply Tripoli over the stem. It seems to work well as I’m able to concentrate on areas of oxidation – especially around the button and the curve of the saddle that are more difficult to reach. The pictures show the deoxidation process.

Turning now to the Meerschaum lined stummel, I take a picture of the chamber showing the minor cake that has collected on the Meer surface. Unlike briar pipes, Meerschaum needs no protective cake. Therefore, the goal in cleaning is to reveal the Meerschaum surface. To remove the carbon, I begin by gently using the Savinelli Fitsall Tool to scrape the chamber wall. When the crunchy texture stops as I gently scrape, lets me know that the carbon is removed. I then follow by sanding with 240 grade paper wrapped around a Sharpie Pen. I sand it until it is totally smooth in the chamber. There is still darker Meer in the chamber, but to remove more simply for aesthetics is not necessary. I then wipe the chamber with a cotton pad wetted with isopropyl 95% to remove the Meerschaum dust left behind. The Meer lining is in good shape – no cracks or crevices in the chamber – though there are some age scratches here and there. The pictures show the progress.

Turning now to the Meerschaum lined stummel, I take a picture of the chamber showing the minor cake that has collected on the Meer surface. Unlike briar pipes, Meerschaum needs no protective cake. Therefore, the goal in cleaning is to reveal the Meerschaum surface. To remove the carbon, I begin by gently using the Savinelli Fitsall Tool to scrape the chamber wall. When the crunchy texture stops as I gently scrape, lets me know that the carbon is removed. I then follow by sanding with 240 grade paper wrapped around a Sharpie Pen. I sand it until it is totally smooth in the chamber. There is still darker Meer in the chamber, but to remove more simply for aesthetics is not necessary. I then wipe the chamber with a cotton pad wetted with isopropyl 95% to remove the Meerschaum dust left behind. The Meer lining is in good shape – no cracks or crevices in the chamber – though there are some age scratches here and there. The pictures show the progress.

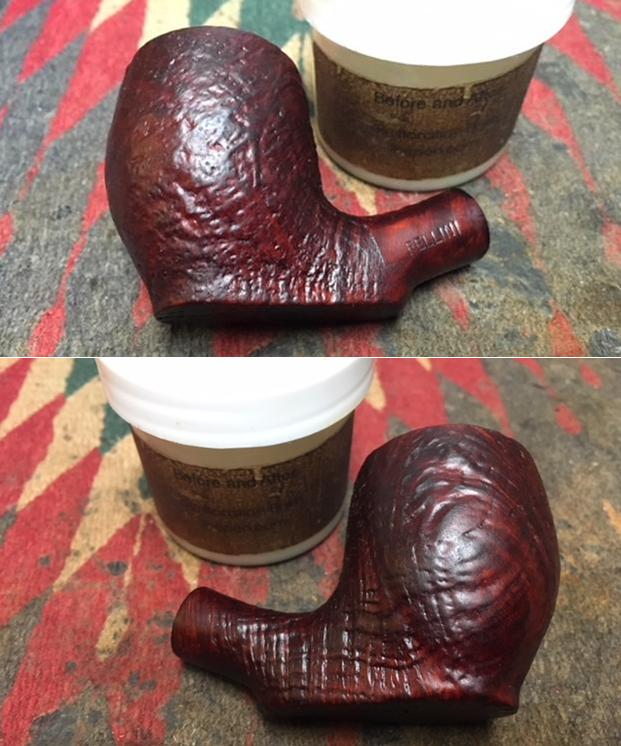

Moving to the external surface, I use undiluted Murphy’s Soap with cotton pads to clean. I also utilize a bristled tooth brush to work the rustification divots. To freshen the Meer rim top, I use a piece of 240 grit paper to lightly sand and clean the Meer surface. This enhances the appearance with the contrast between the Meer and the briar rim. I take some pictures of the cleaning process and this is when I discover a problem.

Moving to the external surface, I use undiluted Murphy’s Soap with cotton pads to clean. I also utilize a bristled tooth brush to work the rustification divots. To freshen the Meer rim top, I use a piece of 240 grit paper to lightly sand and clean the Meer surface. This enhances the appearance with the contrast between the Meer and the briar rim. I take some pictures of the cleaning process and this is when I discover a problem.

I detect a crack running from the left side of the bowl downward until it disappears when it intersects with the fill that wraps around the heel and up the right side. The fill looks like a briar dust/CA glue patch material which I use regularly. The same patch material quarters the rim. These pictures show the patch material.

I detect a crack running from the left side of the bowl downward until it disappears when it intersects with the fill that wraps around the heel and up the right side. The fill looks like a briar dust/CA glue patch material which I use regularly. The same patch material quarters the rim. These pictures show the patch material.

To address the crack, my first step is to determine the integrity of the old patch material. I will try to remove the patch material to see what is underneath. If I can do this, then I can assess the nature of the repair needed. The crack that is exposed appears to me to be a fresher progression of crack ‘creep’ – that has grown beyond the original patch. This repair is straight forward by drilling a counter hole at the end of the crack to stop the creep and applying additional patch material.

To address the crack, my first step is to determine the integrity of the old patch material. I will try to remove the patch material to see what is underneath. If I can do this, then I can assess the nature of the repair needed. The crack that is exposed appears to me to be a fresher progression of crack ‘creep’ – that has grown beyond the original patch. This repair is straight forward by drilling a counter hole at the end of the crack to stop the creep and applying additional patch material.  To test the integrity of the patch material I try to remove it by dissolving it with acetone and cotton pads. The acetone doesn’t make a dent. These patches are solid. I work the acetone over the rim and it has no effect on the patch material. I’m not sure what the patch material is, but it’s not going anywhere soon! At this point, I will repair the exposed crack and shore up some gaps I detect in the old patch material. The rustic, craggy look is what makes this Kiko stand out and after working on the patches, I’ll seek to blend this rustic look with the finishing process. To start, to aid me in drilling a hole at the end of the crack to arrest the crack creep, I use a magnifying glass to identify the end and using a sharp dental probe to press a guide hole. The guide hole helps when drilling. I mount a 1mm drill into the Dremel and drill – but not too much! Going through the Meer lining would not be a happy situation.

To test the integrity of the patch material I try to remove it by dissolving it with acetone and cotton pads. The acetone doesn’t make a dent. These patches are solid. I work the acetone over the rim and it has no effect on the patch material. I’m not sure what the patch material is, but it’s not going anywhere soon! At this point, I will repair the exposed crack and shore up some gaps I detect in the old patch material. The rustic, craggy look is what makes this Kiko stand out and after working on the patches, I’ll seek to blend this rustic look with the finishing process. To start, to aid me in drilling a hole at the end of the crack to arrest the crack creep, I use a magnifying glass to identify the end and using a sharp dental probe to press a guide hole. The guide hole helps when drilling. I mount a 1mm drill into the Dremel and drill – but not too much! Going through the Meer lining would not be a happy situation.

The black highlighted rustification patterns, make it much easier to blend the repair. To do this, using a toothpick to run a drop off the end, I spot drop Black CA glue into the counter hole and let it cure. After filling the offset hole, using a toothpick in the same way, I run a line of clear, thin CA glue down the crack. I use the thin CA glue because it penetrates the crevice of the crack for a solid fill. After the CA glue cures, I spot drop clear CA glue in a few other places where there were gaps around the old patch work.

The black highlighted rustification patterns, make it much easier to blend the repair. To do this, using a toothpick to run a drop off the end, I spot drop Black CA glue into the counter hole and let it cure. After filling the offset hole, using a toothpick in the same way, I run a line of clear, thin CA glue down the crack. I use the thin CA glue because it penetrates the crevice of the crack for a solid fill. After the CA glue cures, I spot drop clear CA glue in a few other places where there were gaps around the old patch work.

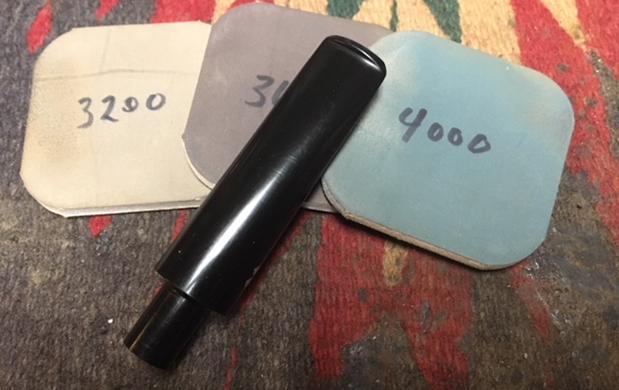

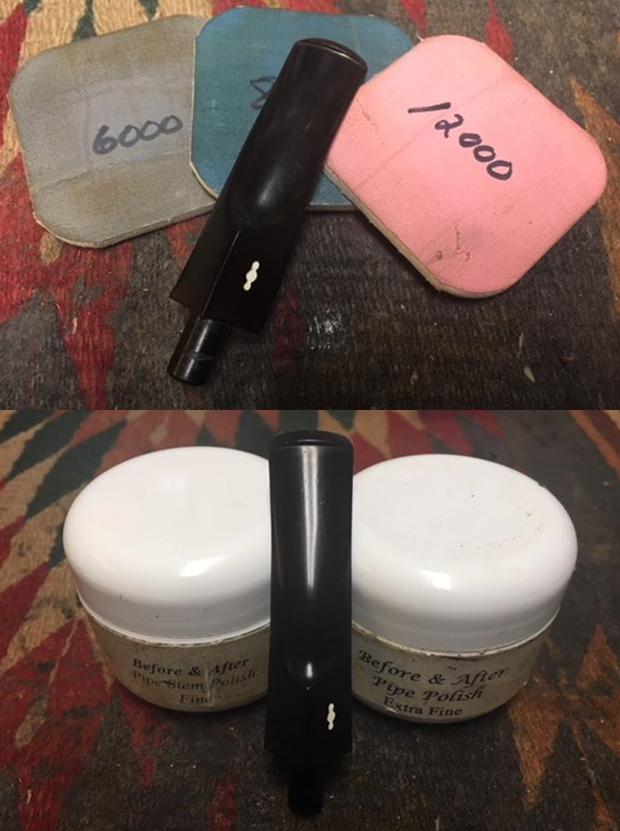

With the CA glue patches curing, I turn to the stem. Using micromesh pads 1500 to 2400, I wet sand the stem. Following this, I dry sand using pads 3200 to 4000 and 6000 to 12000. After each set of three pads, I apply Obsidian Oil to the stem to revitalize the vulcanite. I love the freshly polished vulcanite pop!

With the CA glue patches curing, I turn to the stem. Using micromesh pads 1500 to 2400, I wet sand the stem. Following this, I dry sand using pads 3200 to 4000 and 6000 to 12000. After each set of three pads, I apply Obsidian Oil to the stem to revitalize the vulcanite. I love the freshly polished vulcanite pop!

With the crack patch cured, I start sanding out the excess CA glue using 240 grade paper followed by 600 grade.

With the crack patch cured, I start sanding out the excess CA glue using 240 grade paper followed by 600 grade.

To bring out the natural briar shine and hue, I run the stummel through the full battery of 9 micromesh pads from 1500 to 12000. Before I apply any dye color to the stummel to mask and blend the patches, I want to have an idea of the presentation of the briar.

To bring out the natural briar shine and hue, I run the stummel through the full battery of 9 micromesh pads from 1500 to 12000. Before I apply any dye color to the stummel to mask and blend the patches, I want to have an idea of the presentation of the briar. As expected, the briar darkened through the micromesh cycles. There is still a lightened area around the sanded patch areas which I will blend. I also want to blend the patches more.

As expected, the briar darkened through the micromesh cycles. There is still a lightened area around the sanded patch areas which I will blend. I also want to blend the patches more. After applying several different dye sticks and fan blending with a cotton pad wetted with a bit of alcohol, I tried to darken the lower part of the stummel to provide more blending. I succeeded to a degree, but not enough that would mask the patch areas. To do that, I would need to stain the entire stummel darker and that would lose the ‘cork’ or safari appearance of this Kiko Billiard made in Tanganyika. That, I’m not willing to do. His trademark is rough and rustic!

After applying several different dye sticks and fan blending with a cotton pad wetted with a bit of alcohol, I tried to darken the lower part of the stummel to provide more blending. I succeeded to a degree, but not enough that would mask the patch areas. To do that, I would need to stain the entire stummel darker and that would lose the ‘cork’ or safari appearance of this Kiko Billiard made in Tanganyika. That, I’m not willing to do. His trademark is rough and rustic!  So, with a little embarrassment, I remember that I have not cleaned the internals of the stummel. After some pipe cleaners and cotton buds dipped in isopropyl 95%, I now have a clear conscience.

So, with a little embarrassment, I remember that I have not cleaned the internals of the stummel. After some pipe cleaners and cotton buds dipped in isopropyl 95%, I now have a clear conscience. Reconnecting stem and stummel, I mount a cotton cloth buffing wheel on the Dremel, set the speed at the lowest speed, I apply Blue Diamond compound to both stem and stummel. After completing an application of the compound, I buff the pipe with a felt cloth to clean off the compound dust in preparation for the application of wax. Before I apply the wax, I have one more project to complete. The white elephant stamping’s paint disintegrated in the Deoxidation soak and I need to repair this very cool stamping. Using white acrylic paint, I dab it over the elephant imprint and dab it with a cotton pad to thin it and allow it to dry more evenly.

Reconnecting stem and stummel, I mount a cotton cloth buffing wheel on the Dremel, set the speed at the lowest speed, I apply Blue Diamond compound to both stem and stummel. After completing an application of the compound, I buff the pipe with a felt cloth to clean off the compound dust in preparation for the application of wax. Before I apply the wax, I have one more project to complete. The white elephant stamping’s paint disintegrated in the Deoxidation soak and I need to repair this very cool stamping. Using white acrylic paint, I dab it over the elephant imprint and dab it with a cotton pad to thin it and allow it to dry more evenly. Well…, in the interest of full disclosure, none of the usual methods worked – paint, wipe while wet – paint, let dry fully, scrape off lightly…. At the end of the day, and some hours of experimentation using a paint brush, needles and toothpicks, I finally arrived at an acceptable result for me. With a picture of the original on my computer screen to compare, I used a toothpick to ‘sculpt’ the acrylic paint onto the Elephant canvas bit by bit. Then, before the paint dried, I scrape the unwanted portion from the canvas to shape the image. This was not a straight forward, slam dunk process! After many starts and restarts working with a magnifying glass to paint, I came to a place where I am satisfied. I’m not an artist in anyone’s conversations, but through trial and error, the Kiko Elephant mosaic – it’s no longer a stamping, is not perfect, but looks pretty good.

Well…, in the interest of full disclosure, none of the usual methods worked – paint, wipe while wet – paint, let dry fully, scrape off lightly…. At the end of the day, and some hours of experimentation using a paint brush, needles and toothpicks, I finally arrived at an acceptable result for me. With a picture of the original on my computer screen to compare, I used a toothpick to ‘sculpt’ the acrylic paint onto the Elephant canvas bit by bit. Then, before the paint dried, I scrape the unwanted portion from the canvas to shape the image. This was not a straight forward, slam dunk process! After many starts and restarts working with a magnifying glass to paint, I came to a place where I am satisfied. I’m not an artist in anyone’s conversations, but through trial and error, the Kiko Elephant mosaic – it’s no longer a stamping, is not perfect, but looks pretty good.  With the Elephant again standing guard on the Kiko’s stem, I mount the Dremel with a cotton cloth buffing wheel, increase the speed to about 40% and apply a few coats of carnauba wax to the stummel and stem. After applying the wax, I give the pipe a good hand buffing with a clean microfiber cloth to raise the shine on the unique ‘cork’ rustified stummel and stem.

With the Elephant again standing guard on the Kiko’s stem, I mount the Dremel with a cotton cloth buffing wheel, increase the speed to about 40% and apply a few coats of carnauba wax to the stummel and stem. After applying the wax, I give the pipe a good hand buffing with a clean microfiber cloth to raise the shine on the unique ‘cork’ rustified stummel and stem.

The rustification on this pipe is unique. It pulls one toward the African roots of Tanganyika, now Tanzania. The texture reminds me of cork which by the very nature of the material is not perfect. This Kiko wears his imperfections well – the fills, evident on the stummel surface, belong and mark the difficulties this pipe has had along the way, but now ready to go again. The grain nuanced as a backdrop to the rustification, has subtle patterns that remind one of tiger fur. The Meerschaum lining looks great and will provide the Kiko’s next steward the ability to enjoy a bowl of his favorite blend, and immediately reload for another smoke without the need of resting the pipe. Aaron commissioned this Kiko from the “For ‘Pipe Dreamers’ Only!” page and now he will have the first opportunity to acquire it in The Pipe Steward Store and what is really good, this benefits our work, the Daughters of Bulgaria – helping women and girls who have been trafficked and sexually exploited. Thanks for joining me!