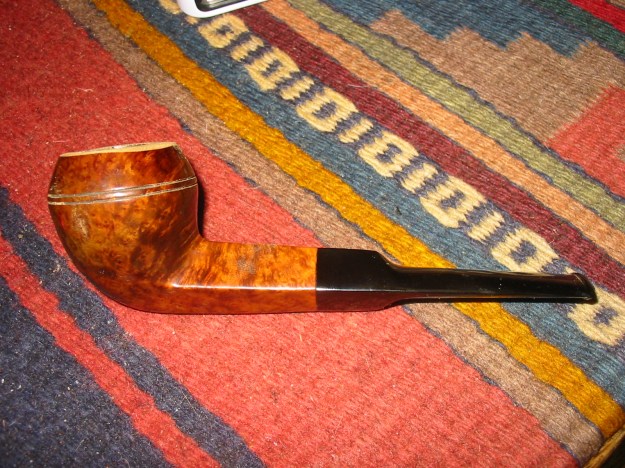

On October 26, 2013, I wrote about a pipe I found and my questioning whether it was a Sasieni Blue Dot billiard. I refurbished the billiard and wrote about it in this blog post https://rebornpipes.wordpress.com/2013/10/26/when-i-saw-it-i-thought-it-was-a-sasieni-one-dot-billiard/ . I was never satisfied with my conclusions regarding the manufacture of this particular pipe. Last weekend (December 28, 2013) I went pipe hunting again and stopped at the same location. There were two more of the blue dot pipes in his case. One of them had been smoked quite a lot and one of them was pretty clean. The one had a cracked shank and the other was clean. The clean one had a stinger apparatus in it while neither the earlier find or the other one this time had one present. The interesting thing to me was that on both of these pipes there was a single line stamped on the bottom of the shank. On the relatively clean pipe the stamping was gold filled and read ATLAS POWDER CO. On the other pipe it had the same stamping though the gold was long gone. I checked the previous pipe and sure enough the same stamping, though fainter was present. Suddenly I had in my possession a trio of billiards. All had the single blue dot on the stem, all were stamped Genuine Briar. All had the same English style tapered stem. All were nice pieces of briar with no fills or flaws. All were stamped ATLAS POWDER CO.

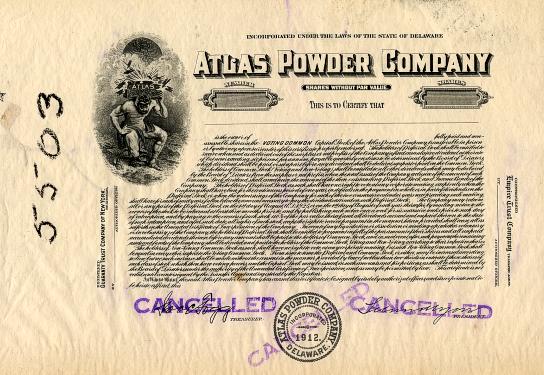

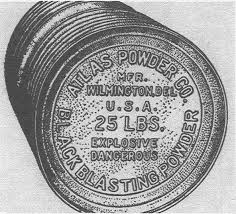

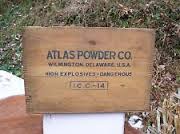

Now I had some work to do – not just restoring these two old pipes to the same state as the other one but really digging into the ATLAS POWDER CO. to find out who they were. Was it possible that what I had were three specialty pipes, stamped with the Company name in gold lettering were made as gift pipes or award pipes? That raised a second question that to me was at least as important. Who made the pipes for the company? Is it possible that they were made by Sasieni, specially stamped with the name of the company to be given out to executives or share holders as gifts? Being able to read the stamping on the bottom of the shank gave me an important clue regarding what to look for on the web. With my questions clearly in my I began to do research on the company. I quickly found out that in 1912, Atlas Powder Company was created in Wilmington, Delaware, when DuPont Company sold two explosives divisions, as mandated by “trust busting” enactments during the Theodore Roosevelt presidency. In the 1960s, Atlas Powder Company changed its corporate name to Atlas Chemical Industries. I wanted more details on that formation and the other companies that may have been included in the process.

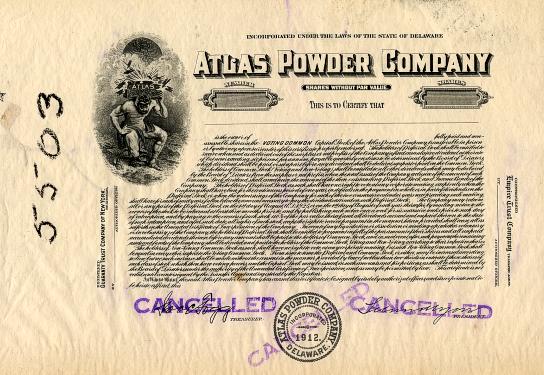

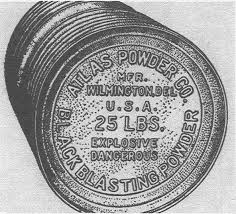

I found a facsimile of an old stock certificate that had some corporate information on it as well as the back side of a mailing envelope with the name and products that were produced by the Atlas Company.

Further research took me to the company archives at this site http://beta.worldcat.org/archivegrid/collection/data/776641025 There I found information and company minutes from a variety of their meetings and activities. I also found information on lawsuits and actions pending against them at various times in their history. There were corporate memos and data that was marginally interesting but nothing that definitively spoke of pipe being made, purchased or given away. Quoting from the site:

“… The Atlas Powder Company was incorporated in Delaware on October 18, 1912 as part of the court-ordered breakup of the explosives monopoly of E.I. du Pont de Nemours & Company. As part of the settlement, parts of DuPont’s black powder and dynamite business were spun off to two new companies, the Hercules Powder Company, capitalized at $13 million, and the Atlas Powder Company, capitalized at $6 million. Atlas functioned as an independent explosives and chemicals company until July 21, 1971, when it was purchased by Imperial Chemical Industries Limited (U.K.) and became its American affiliate under the name ICI Americas Inc.

Atlas began business on Jan. 1, 1913, with four former DuPont black powder plants at Ooltewah, Tenn., Belleville, Ill., Pittsburg, Kan., and Patterson, Okla., and three ex-DuPont dynamite plants at Landing, N.J., Hancock, Mich., and Webb City, Mo. Later that year, it purchased the Reynolds Works near Tamaqua, Pa. from the Potts Powder Company, where it manufactured electric exploders, blasting caps, nitric and sulphuric acids, dynamite, and blasting detonators. In 1915, Atlas purchased The Giant Powder Company, Consolidated, which held the first U.S. rights to the Nobel dynamite patents, giving it a presence on the West Coast.

Following the lead of DuPont and Hercules, Atlas began diversifying from explosives into other chemical lines with the 1917 acquisition of Richards & Co., Inc., of Connecticut, and its sales subsidiaries Zapon Leather Cloth Company and Celluloid Zapon Company, manufacturers of lacquers and artificial leather. In 1925, the Pacific Lacquer & Bronze Company was added to the Zapon family. In 1921, Atlas contracted with the Darco Corporation to build an activated carbon plant in Marshall, Tex., and in 1928 Richards & Co., Inc., purchased the Duratex Corporation, a manufacturer of pyroxylin and rubber coated fabrics which also brought a controlling interest in Darco. Atlas bought the assets of the Brevolite Lacquer Company of North Chicago in 1933 and combined it with the Midwest business to the Zapon Company as the Zapon-Brevolite Lacquer Company. Traditional explosives capacity increased with the 1932 purchase of the Peerless-Union Explosives Company. The Atlas Research Laboratory was established at the Reynolds Plant in 1930, and Atlas de Mexico, S.A., was organized as a sales company in 1937.

Atlas devoted all of its plants to military needs during World War II and operated three ordnance plants under contract from the government. However, despite a second surge during the Korean War, the post-World War II years brought a major restructuring. The Duratex line of coated fabrics and plastics was discontinued in 1948, and the Zapon-Darco industrial finishes business was sold in 1955. The following year, Atlas bought the Thermaflow Chemical Corporation of Pennsylvania, makers of high-impact reinforced plastic molding compounds, and the Aquaness Corporation of Houston, Texas, a maker of chemical compounds used in the petroleum industry. In 1959, Atlas formed Solar Nitrogen Chemicals, Inc., as a joint venture with the Standard Oil Company (Ohio) to manufacture ammonia fertilizers. At the same time, explosives plants were being closed. As a consequence, Atlas changed its name to Atlas Chemical Industries, Inc., on May 31, 1961, and the next day completed a merger with The Stuart Company, a Pasadena pharmaceuticals maker. In 1997, after numerous spinoffs and restructurings, the pharmaceuticals business of Atlas became AstraZeneca LP, which has its headquarters in the former Atlas facilities in the Wilmington suburbs.”

Armed with that information and information gleaned by looking at sales of gift memorabilia on EBay it became at least a real possibility that these pipes were given to stock holders as gifts. I was not able to find definitive information regarding the gifting of the pipes or who made them the implications were strong that they were made for that purpose.

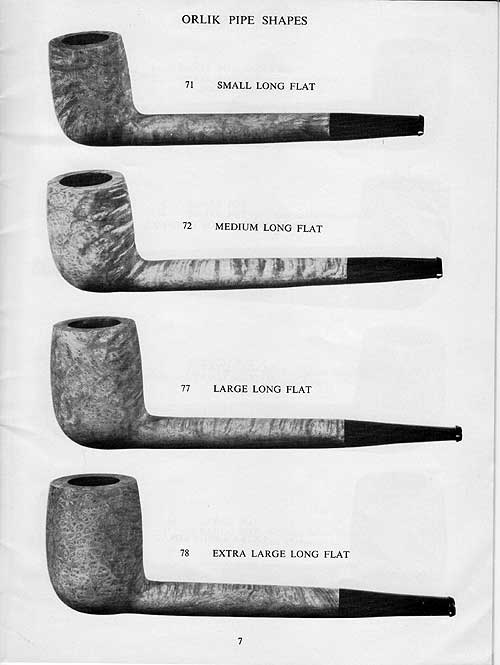

The question still remained regarding the pipes. That took me to a search on the history of Sasieni pipes and any potential connections between the companies. The first article that I turned to was a definitive piece on the history of the brand by Stephen Smith entitled, “Connecting the Dots: A Concise History of the Sasieni Pipe”. http://murderofravens.org/my-sasieni-pipe-article/

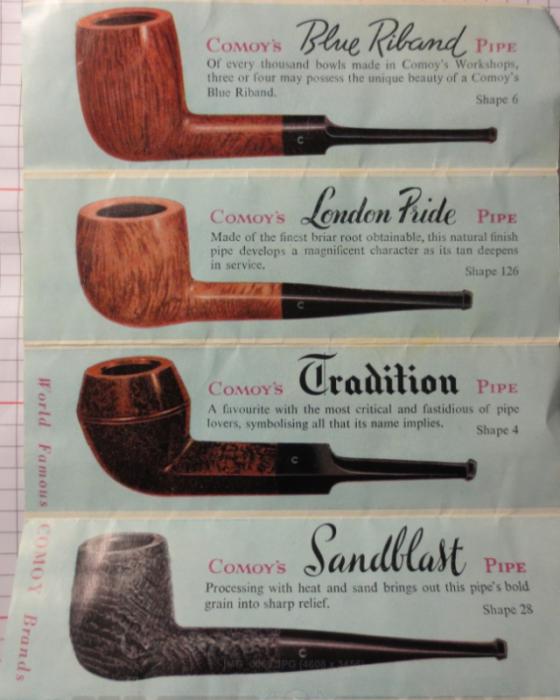

From the article I learned a brief review of the history of the brand. I learned that the Sasieni Company began in 1919 and continued in the family until 1979 when it was sold (this period is the Pre-Transition Period). The Transition period lasted from 1979 to 1986. The company had been bought by Ian Chase and a group of South African investors. In 1986, the company was once again sold to James B. Russell and after him to Cadogan Investments Ltd (Oppenheimer & Co. Ltd.). This Post-Transition period has continued since 1986 to the present. The time period of the pipe and the ATLAS POWDER CO. overlap. However interesting that may be there is still no proof of the connection at this point in my search. I included the above advertisement photo from Stephen’s article because the shape of the billiard in the photo is virtually identical to the three that I have that are the cause of this research.

I am on holiday so I had the time to spare and I spent several hours tracing down leads and dead ends on the links between the two companies. There are no links that I can find. So I am left with just a hunch, a supposition that the pipes were made for the Atlas Powder Co. as gift pipes and that they were potentially made by Sasieni. I may never know more than that but it still leaves more room for digging in the future.

Leaving the mystery to stew for a bit longer I will walk through the refurbishing of the two additional one dot pipes. Here is the pair of bowls in question. The one on the left is solid and less used than the one on the right. It had very little cake in the bowl and the shank and stem were in good shape. The one on the right was more heavily smoked and had a cracked shank. The stem was in fairly decent shape on this one as well. I began my refurbishing on this pair with the pipe on the right.

I use a dental pick to remove the scotch tape that held the shank together. It was not clear how bad the crack was until I could get the tape completely removed. I wetted a cotton pad with acetone and wiped down the scotch tape to facilitate its removal.

The next photo is horrible and for that I apologize. I would not have included it if it did not still show the damage to the cracked shank on the first pipe. I glued the cracked piece in place with superglue and then found a band that I could pressure fit on the shank. The combination of gluing the damaged shank and banding it would make it useable once more. I heated the band on the shank over a heat gun and then pressure fit it onto the shank.

The next series of three photos show the newly banded shank. The repair is finished and with the band in place the rest of the refurbishing of the bowl can take place.

With the band in place on the shank the tenon had to be reduced slightly for a comfortable fit. I cleaned out the shank before I sanded the tenon as I wanted a clean surface for the tenon to sit against. I used cotton swabs and Everclear to clean out the shank. Once it was done I sanded the tenon with 220 grit sand paper to remove enough of the tenon for it to have a snug fit in the shank. I reamed the bowl with a PipNet reamer to remove the carbon build up in the bowl. I lightly topped the bowl to remove the tars and buildup on the rim and to remove some of the slight burn marks on the rim top. Fortunately these were shallow and I was able to remove them completely without dramatically affecting the height of the bowl.

I wiped the bowl down with acetone on a cotton pad to remove the finish that remained on the pipe. There was a light varnish coat that came off easily with the acetone. Underneath was some very nice grain and no fills or fissures.

The airway in the stem was clogged and I was not able to blow air through it so I used a dental pick to reach into the airway at the tenon end and through the slot in the button. Fortunately the blockage was near both of these openings and I was able to remove the hardened tars and oils that were present. The tenon end also seemed to have some metallic pieces remaining from the stinger apparatus that was originally in the tenon (I know that it had a stinger as the other pipe still had one in place). It took many pipe cleaners and much Everclear to get the grime deposits removed from the airway of the stem. The photo below shows just a few of them toward the end of the process.

I stained the pipe with a Minwax Medium Walnut stain. It has a nice patina and goes well with the age of these older pipes. I rubbed it on with a cotton pad and rubbed it off with a soft cotton cloth. I reapplied the stain until I had the coverage that I wanted. My goal was to let the grain show through the stain and highlight the beauty of this old pipe.

I buffed the pipe with White Diamond once the stain was dry to bring out a shine to the finish.

The next photo shows the pipe lying next to the other one. I wanted the stamping on the unrefurbished pipe to highlight the stamping on this pipe. The golden colour of the other stamp is very clear and the stamping on the newly stained one is still visible yet not golden. Before I finished this one, the golden stamping was missing and a black stamping was present in its place.

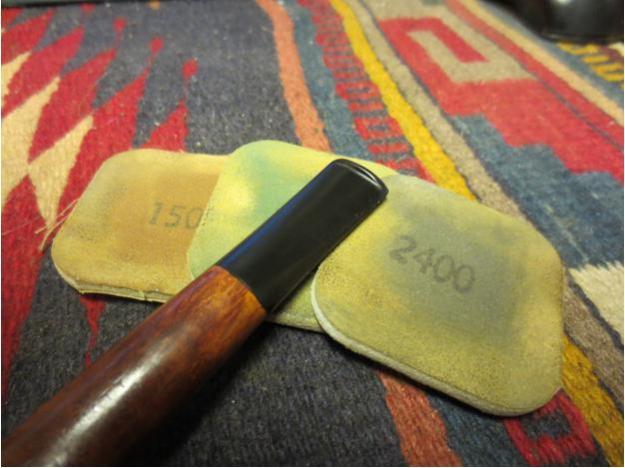

I worked on the stem with my usual regimen of micromesh sanding pads – wet sanding with 1500-2400 grit pads and dry sanding with 3200-12,000 grit pads. I buffed the stem with White Diamond after using the 12,000 grit pad and then rubbed it down with Obsidian Oil. I hand buffed it before putting it back in the shank of the pipe. I also used the micromesh pads to polish the nickel band before I buffed the pipe. I used 2400-4000 grit pads to polish the nickel and then rubbed it down with a silver polishing cloth.

The first of the two pipes was finished. I buffed the entirety with White Diamond and then gave it multiple coats of carnauba wax. I buffed the newly waxed pipe with a soft, clean flannel buff to give it a shine and set it aside while I worked on the second pipe. The next four photos show the finished pipe.

The second pipe looked worse for wear when I started on it but it was merely surface wear. The bowl itself was not even broken in and the slight cake on the top portion of the bowl was very thin. The shank and the inside of the stem were very clean. The original stinger apparatus was still in place and was slightly discoloured. The ATLAS POWDER CO. stamping on the bottom of the shank was still embossed with gold in the letters. The varnish coat on the finish was disintegrating on the surface of the briar but the briar itself was in great shape. There was no damage to the rim or the edges of the rim. The bowl had no visible fills or dents. It just needed a major cleanup.

I have included the next photo to show the ATLAS stamping on the shank more clearly.

I followed the same process on this pipe as the one above and wiped the bowl down with acetone on cotton pads. I was careful to not wipe down the bottom of the shank as I wanted to leave the gold stamping intact. With the varnish coat removed the grain on this pipe was also very nice. There is a mix of cross grain, birdseye and a swirl of mixed grain.

I removed the stinger apparatus which was pressed into the tenon of the pipe by twisting it free. Once it was removed I cleaned up the interior of the slot on the stinger and the grooves around the end of the spoon portion of the piece. I reinserted it in the stem.

I used the same regimen on the stem as noted above to polish the oxidation away. I have found that the combination of wet and dry sanding with micromesh sanding pads works well for me and gives the stem a deep shine. When I finished sanding I buffed it with White Diamond and rubbed it down with Obsidian Oil. I hand buffed the stem and set it aside while I worked on the bowl.

I used the same Minwax Medium Walnut stain on this pipe as the last. I applied it, rubbed it off, and reapplied it until I had the coverage I wanted. As before, I wanted the grain to shine through the stain and give depth to the finish of the pipe.

I inserted the stem in the shank and buffed the whole pipe with White Diamond and then gave it multiple coats of carnauba wax. The finished pipe is shown in the photos below.

With both of the new additions finished I put them together with the previous ATLAS POWDER CO. pipe and took the following photos. The first pipe has a shorter stem because when I found it the stem had a large bite through. I shortened the length on it and reshaped the button. Other than that and the added band on the middle one the pipes are much the same. All bear the same stamping and the same blue dot. Who knows who the maker of these pipes was? I am still inclined to believe that they may have been made by Sasieni for the ATLAS POWDER CO. to be given to share holders or executives. Whatever the case may be they are smooth smoking pipes and will last another lifetime.