Blog by Dal Stanton

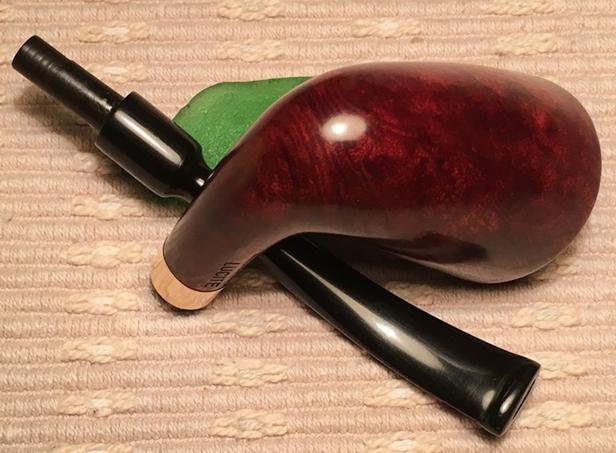

When I first saw this Eldorado Lucite, I believed it to be a Zulu or Woodstock, the Dublin’s smaller cousin. In the end, I settled on it being a bent Dublin because the stummel was larger than I would expect a Zulu’s to be. When I saw the Eldorado Lucite bent Dublin on the eBay auction block, two things, no, three things drew my attention motivating me to slog through the bidding and bring this pipe home to Bulgaria. First, the shape is very attractive – I like the curve of the Dublin’s natural ‘nose-forward’ stummel flowing to and through the stem; an attractive pipe, I wanted to try it out in my palm. Secondly, the briar’s potential. I love taking smooth briars and bringing out the grain to encourage a double-take. The straight grain of the Eldorado is nice. Thirdly, the band – a touch of class for any pipe, but for this pipe, also raises some questions. The following eBay photos from the seller show what I saw.

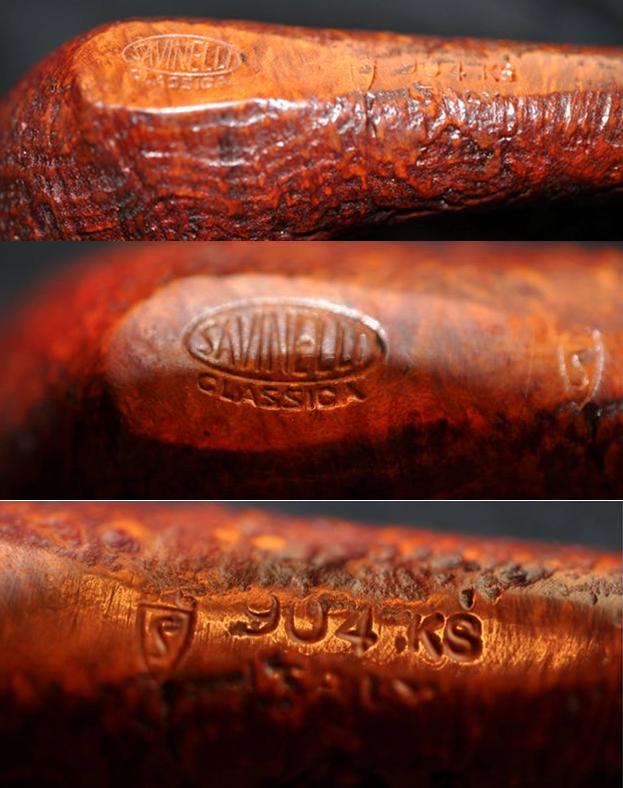

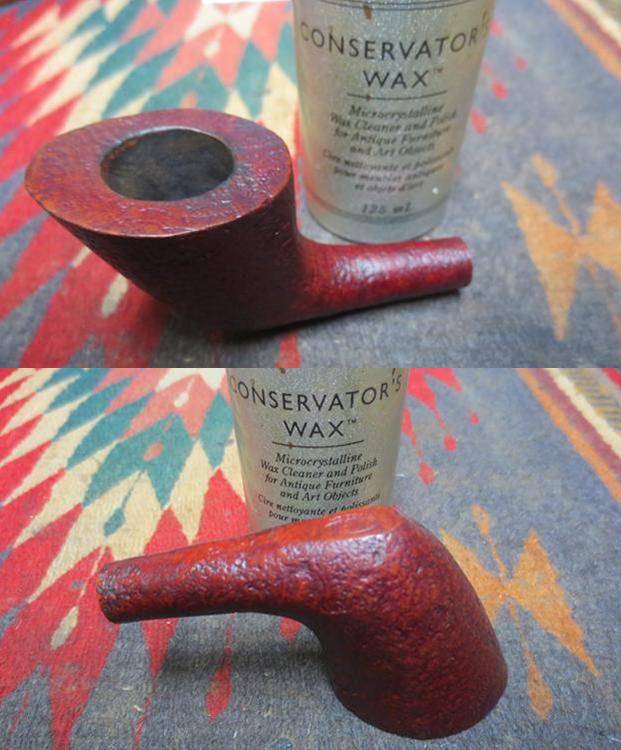

When I retrieved this pipe out of the “Help Me!” basket in Sofia, I take a fresh look at the Eldorado over Lucite – stamped distinctly on the left shank. The right shank shows Imported Briar over Italy. Both stamps are obstructed/hidden somewhat by the band which immediately brings into question the possibility of the band being part of a cracked shank repair. I would not think the original design would include a band hiding part of the nomenclature, but I might be wrong! After removing the stem, I inspect the mortise and conclude that a crack may be there, but it’s not conclusive – at least to me. The band is gold and stamped with hallmarks of 1/20 14KT (ensconced in a diamond) G.F. Looking on the internet, I discover from RareGoldJewelry.com these hallmarks indicate the ratio of gold in the band is at about 1 to 20. Rated at 14 karats means that it’s approximately 58% gold and the band is ‘gold filled’ rather than ‘gold plated.’ Regarding gold filled and gold plated, eBay’s buyers’ guide jewelry describes the difference:

When I retrieved this pipe out of the “Help Me!” basket in Sofia, I take a fresh look at the Eldorado over Lucite – stamped distinctly on the left shank. The right shank shows Imported Briar over Italy. Both stamps are obstructed/hidden somewhat by the band which immediately brings into question the possibility of the band being part of a cracked shank repair. I would not think the original design would include a band hiding part of the nomenclature, but I might be wrong! After removing the stem, I inspect the mortise and conclude that a crack may be there, but it’s not conclusive – at least to me. The band is gold and stamped with hallmarks of 1/20 14KT (ensconced in a diamond) G.F. Looking on the internet, I discover from RareGoldJewelry.com these hallmarks indicate the ratio of gold in the band is at about 1 to 20. Rated at 14 karats means that it’s approximately 58% gold and the band is ‘gold filled’ rather than ‘gold plated.’ Regarding gold filled and gold plated, eBay’s buyers’ guide jewelry describes the difference:

Gold-filled jewelry is much more valuable than gold-plated. In fact, there is almost 100 percent more gold in gold-filled items than is found in gold-plated items. Just as gold-plated jewelry is plated with gold, gold-filled jewelry is as well, but there is a big difference between the ways these products are made. Gold-filled items have a much thicker layer of gold on them, and the gold is a much higher quality. In fact, it is just a step down from solid gold when it comes to quality and value. Speaking of solid gold, pure gold is very soft and is not a good choice for jewelry; that is why an alloy is almost always used for gold jewelry items, even in jewelry pieces worth an incredible amount of money.

If this band is part of a cracked shank repair, which doesn’t appear to be the case, it seems that whoever had this pipe valued it quite a bit to add a gold band. Another question is raised regarding the name – Eldorado Lucite. According to the compilation of Herb Wilczak & Tom Colwell (3/3/97) ‘Who Made That Pipe’ (Yes, Santa brought this!) lists Eldorado as Maker or Seller as the Linkman Co./ Parker Pipe and country USA/ENGL. My subsequent research into Linkman turned up the connection to Dr. Grabow pipes – ‘Eldorado’ is a high-end pipe of Dr. Grabow – which doesn’t fit the pipe before. Dr. Grabow pipes are usually marked as such. Parker Pipe Company turned up nothing too. This pipe is also stamped, Italy, but does this mean country of manufacturer or source of the briar in this case? – as the right shank has the marking ‘IMPORTED BRIAR’ over ‘ITALY’. Would the ‘Imported Briar’ indicate a US manufacturing – the usual US marking and spelling? But this, I found is not always the case. One more question that doesn’t find answers in my research – Eldorado Lucite – does ‘Lucite’ refer to a unique pipe name or is it referring to the stem material with which it was originally outfitted? If this is the case, is the stem now with this Dublin a replacement because it certainly isn’t Lucite but vulcanite? Yet, as I look at the stem, it works VERY well with the stummel and shape – it doesn’t appear to be a replacement stem. So are the many questions this beautiful pipe creates, but now I turn to the pipe itself and take more pictures to fill in the gaps!

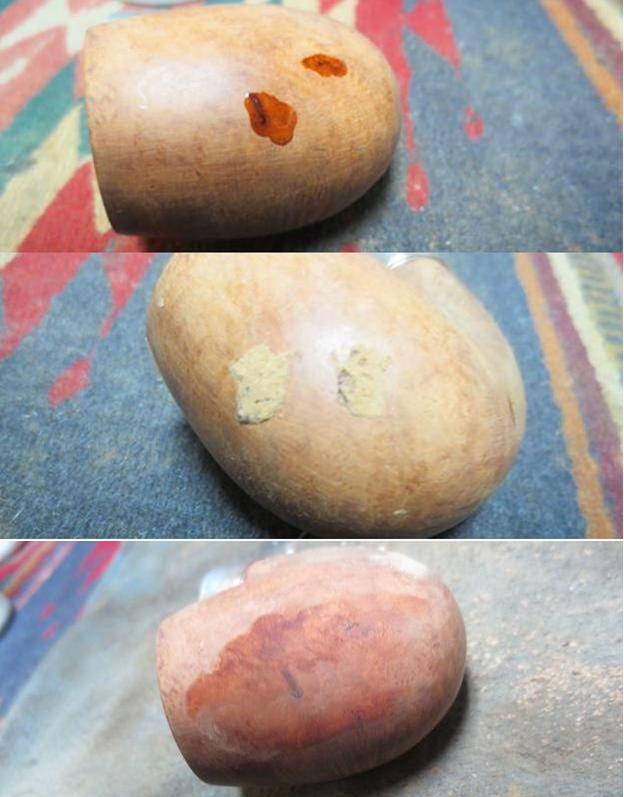

The stummel appears to be in good condition except I detect what might be an acrylic finish with normal wear marks and scratches on top of it. I’ll want to clean the old finish off. The bowl has moderate cake build up and old dottle flakes left in the bottom. I’ll remove the cake bringing the bowl down to the briar for a fresh start. The rim looks to be in good condition structurally, but has light lava flow and possibly some scorching. I need to clean the rim to assess this fully. The stem is attractive. I’m not sure if it has a special name, but it flays out from the shank and the button is fanned – a fish tail? It has minor oxidation. There are tooth dents on the upper and lower button area and a possible crack on the slot side through the button lip pictured above. I’ll need to look closely at this. The band is in good shape – I’ll polish it simply with a clean cloth, no more!

The stummel appears to be in good condition except I detect what might be an acrylic finish with normal wear marks and scratches on top of it. I’ll want to clean the old finish off. The bowl has moderate cake build up and old dottle flakes left in the bottom. I’ll remove the cake bringing the bowl down to the briar for a fresh start. The rim looks to be in good condition structurally, but has light lava flow and possibly some scorching. I need to clean the rim to assess this fully. The stem is attractive. I’m not sure if it has a special name, but it flays out from the shank and the button is fanned – a fish tail? It has minor oxidation. There are tooth dents on the upper and lower button area and a possible crack on the slot side through the button lip pictured above. I’ll need to look closely at this. The band is in good shape – I’ll polish it simply with a clean cloth, no more!

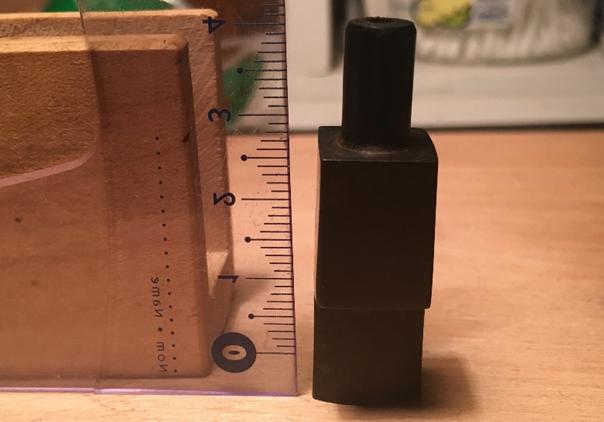

I begin the clean-up of the Eldorado Lucite by plopping the stem into the Oxi-Clean bath to work the oxidation to the surface of the vulcanite. I take the Pipnet reaming kit out and discover that the conical chamber is too tight and angled in the Dublin’s shape to employ the reaming blades. I’ll use the Savinelli pipe knife instead to ream the bowl. With the Savinelli pipe knife I make good progress removing the cake in the tight quarters of this chamber. Following the reaming, I sand the chamber walls with 240 grit paper wrapped around a Sharpie pen and then finish by wiping the chamber with cotton pads and isopropyl 95% to remove the carbon dust. The chamber looks good. The pictures show the progress.

Before continuing with cleaning the external stummel, I tackle the internals with pipe cleaners and Q-tips and isopropyl 95%. The cleaning job proves to be a bit more than I expected. I’m not positive about the internal layout and drilling of the mortise but it ‘feels’ like there is a gunk trap slightly below the air passage leading out toward the draft hole in the chamber. After building a good mountain of expended Q-tips and pipe cleaners, and after looking at the lateness of the hour, I decide to give the stummel a salt soak, and let the Kosher salt and alcohol do some of the work for me. I put the stummel in an egg crate to keep it stable, and fill the bowl with kosher salt which is not iodized – iodine can leave a taste (Thanks to Charles Lemon of Dad’s Pipes for this information). I cover the bowl with my hand and give it a bit of a shake to displace the salt. After corking the shank side, I fill the bowl with isopropyl 95% and turn out the light. The next morning I see that the salt has darkened a bit and I toss the used salt into the waste basket. I take a paper towel and wipe out the remaining salt from the bowl and use a bristle bush both in the bowl and the mortise making sure that salt residue is purged. I then return to cleaning with Q-tips, pipe cleaners and isopropyl and finish the internals very quickly. Done! The pictures show the progress.

Before continuing with cleaning the external stummel, I tackle the internals with pipe cleaners and Q-tips and isopropyl 95%. The cleaning job proves to be a bit more than I expected. I’m not positive about the internal layout and drilling of the mortise but it ‘feels’ like there is a gunk trap slightly below the air passage leading out toward the draft hole in the chamber. After building a good mountain of expended Q-tips and pipe cleaners, and after looking at the lateness of the hour, I decide to give the stummel a salt soak, and let the Kosher salt and alcohol do some of the work for me. I put the stummel in an egg crate to keep it stable, and fill the bowl with kosher salt which is not iodized – iodine can leave a taste (Thanks to Charles Lemon of Dad’s Pipes for this information). I cover the bowl with my hand and give it a bit of a shake to displace the salt. After corking the shank side, I fill the bowl with isopropyl 95% and turn out the light. The next morning I see that the salt has darkened a bit and I toss the used salt into the waste basket. I take a paper towel and wipe out the remaining salt from the bowl and use a bristle bush both in the bowl and the mortise making sure that salt residue is purged. I then return to cleaning with Q-tips, pipe cleaners and isopropyl and finish the internals very quickly. Done! The pictures show the progress.

Time to retrieve the stem from the Oxi-Clean bath and I see that the oxidation has risen to the vulcanite surface which is shown very nicely in the first picture below. I attack the oxidation by wet sanding with 600 grit paper. I follow this by using 0000 steel wool to remove more oxidation and begin the smoothing process as well. Following this, I work on cleaning the internals of the stem with pipe cleaners and isopropyl. It was going so well until it wasn’t! Earlier, you recall, as I was doing the initial inspection of the stem, I identified what appeared to be a crack on the left side of the button. The pressure exerted by the pipe cleaners exacerbated this crack and now I see fissures developing in the vulcanite – not only at the original crack sighting but now also on the right side of the button. It would not be difficult to project the path of the fault line and the ultimate stem break if not addressed. Ugh! The pictures tell the story.

Time to retrieve the stem from the Oxi-Clean bath and I see that the oxidation has risen to the vulcanite surface which is shown very nicely in the first picture below. I attack the oxidation by wet sanding with 600 grit paper. I follow this by using 0000 steel wool to remove more oxidation and begin the smoothing process as well. Following this, I work on cleaning the internals of the stem with pipe cleaners and isopropyl. It was going so well until it wasn’t! Earlier, you recall, as I was doing the initial inspection of the stem, I identified what appeared to be a crack on the left side of the button. The pressure exerted by the pipe cleaners exacerbated this crack and now I see fissures developing in the vulcanite – not only at the original crack sighting but now also on the right side of the button. It would not be difficult to project the path of the fault line and the ultimate stem break if not addressed. Ugh! The pictures tell the story.

Oh, ‘the best laid plans of mice and men’ – my plan is to apply thin CA Instant Glue to the cracks to seal them and hopefully to stop the fissure’s progress. I fold a piece of index card and cover it with tape and insert it in the slot to keep glue from possibly entering the airway. It also serves to ‘torque up’ a bit, and opening the cracks a hair to allow better glue penetration. After this, I will build up the button with a mixture of charcoal dust and super glue and redefine the bit hopefully to reinforce the area. I put the stem aside for the glue to cure. The pictures show the progress.

Oh, ‘the best laid plans of mice and men’ – my plan is to apply thin CA Instant Glue to the cracks to seal them and hopefully to stop the fissure’s progress. I fold a piece of index card and cover it with tape and insert it in the slot to keep glue from possibly entering the airway. It also serves to ‘torque up’ a bit, and opening the cracks a hair to allow better glue penetration. After this, I will build up the button with a mixture of charcoal dust and super glue and redefine the bit hopefully to reinforce the area. I put the stem aside for the glue to cure. The pictures show the progress.

After the initial CA glue cures, I start the button rebuild. I use 240 grit sanding paper to rough up the button area, upper and lower. Then I clean the area with a cotton pad and isopropyl to prepare for the charcoal/glue putty. While in the States for Christmas, I picked up a bottle of activated charcoal capsules. In the past, using a mortar and pestle, I had to grind up granulated charcoal which was sold for an aquarium filtration application for use with charcoal patches. Generally, I was not satisfied with the results. After the patches were applied, sanded/shaped, and polished, etc., I found a very porous and speckled result – not smooth as I wanted. I suspected the cause was that the charcoal grade was not fine enough. So, we’ll see if better results are realized with current charcoal powder. I decide to re-use the ‘slot insert’ that I earlier made from an index card. With the crack going through the lip of the button, I make sure I have sufficient ‘overage’ of charcoal putty to cover the crack. After opening a charcoal capsule, I empty it onto the index card and then add a puddle of Hot Stuff Special ‘T’ CA glue next to the charcoal. The ‘T’ stands for extra thick. Using a toothpick, I begin to draw the charcoal into the glue puddle to form the putty. I’m aiming at a honey-like viscosity for the putty – not to thin that it won’t remain where I put it and not to thick that it doesn’t shape well. When I arrive at what looks good, I use the toothpick as a trowel and apply the putty to the button – the top receiving the most attention. With charcoal putty applied to the button, I put the stem aside giving time for the curing process. The pictures show the progress.

After the initial CA glue cures, I start the button rebuild. I use 240 grit sanding paper to rough up the button area, upper and lower. Then I clean the area with a cotton pad and isopropyl to prepare for the charcoal/glue putty. While in the States for Christmas, I picked up a bottle of activated charcoal capsules. In the past, using a mortar and pestle, I had to grind up granulated charcoal which was sold for an aquarium filtration application for use with charcoal patches. Generally, I was not satisfied with the results. After the patches were applied, sanded/shaped, and polished, etc., I found a very porous and speckled result – not smooth as I wanted. I suspected the cause was that the charcoal grade was not fine enough. So, we’ll see if better results are realized with current charcoal powder. I decide to re-use the ‘slot insert’ that I earlier made from an index card. With the crack going through the lip of the button, I make sure I have sufficient ‘overage’ of charcoal putty to cover the crack. After opening a charcoal capsule, I empty it onto the index card and then add a puddle of Hot Stuff Special ‘T’ CA glue next to the charcoal. The ‘T’ stands for extra thick. Using a toothpick, I begin to draw the charcoal into the glue puddle to form the putty. I’m aiming at a honey-like viscosity for the putty – not to thin that it won’t remain where I put it and not to thick that it doesn’t shape well. When I arrive at what looks good, I use the toothpick as a trowel and apply the putty to the button – the top receiving the most attention. With charcoal putty applied to the button, I put the stem aside giving time for the curing process. The pictures show the progress.

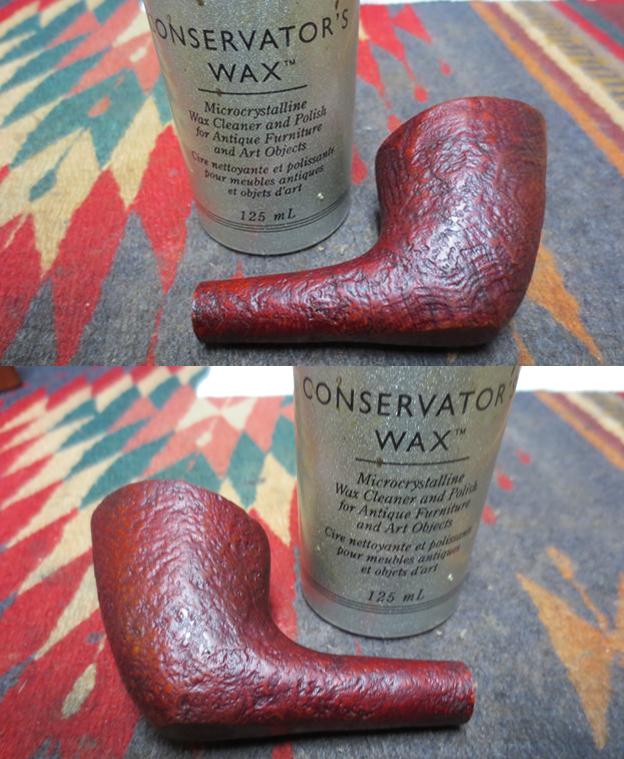

I return to the stummel to clean the externals. I’ve not worked before with a gold band and I don’t believe that any cleaning agents I use will deface the gold, but to stay on the safe side, I cover the band with a few layers of masking tape. I then take undiluted Murphy’s Soap and cotton pad and clean the stummel surface and rim. With the help of a brass brush, which will not scratch the briar, the light lava flow on the rim becomes history. I rinse the stummel with warm tap water keeping the internals dry. After the Murphy’s Soap, I still can detect the acrylic shine of the finish which is not what I like (2nd picture below). I prefer the shine of the natural briar and not what I have referred to as a ‘candy apple’ shine finish. To remove the finish, I use acetone with a cotton pad. After a few unsuccessful rounds of this, I utilize 0000 steel wool to add a little abrasion to the acetone removal process. This does the trick, though the candy apple finish did not come off easily. The pictures show the progress.

I return to the stummel to clean the externals. I’ve not worked before with a gold band and I don’t believe that any cleaning agents I use will deface the gold, but to stay on the safe side, I cover the band with a few layers of masking tape. I then take undiluted Murphy’s Soap and cotton pad and clean the stummel surface and rim. With the help of a brass brush, which will not scratch the briar, the light lava flow on the rim becomes history. I rinse the stummel with warm tap water keeping the internals dry. After the Murphy’s Soap, I still can detect the acrylic shine of the finish which is not what I like (2nd picture below). I prefer the shine of the natural briar and not what I have referred to as a ‘candy apple’ shine finish. To remove the finish, I use acetone with a cotton pad. After a few unsuccessful rounds of this, I utilize 0000 steel wool to add a little abrasion to the acetone removal process. This does the trick, though the candy apple finish did not come off easily. The pictures show the progress.

To remove nicks and some pitting in the briar I use a medium grade sanding sponge on the stummel and rim. I follow this with a light grade sanding sponge. To remove some damage in the inner rim edge and to clean it up, I use 240 grit sanding paper rolled tightly. I again follow the 240 grit paper and use the light grade sanding sponge on the rim to smooth things out.

To remove nicks and some pitting in the briar I use a medium grade sanding sponge on the stummel and rim. I follow this with a light grade sanding sponge. To remove some damage in the inner rim edge and to clean it up, I use 240 grit sanding paper rolled tightly. I again follow the 240 grit paper and use the light grade sanding sponge on the rim to smooth things out.

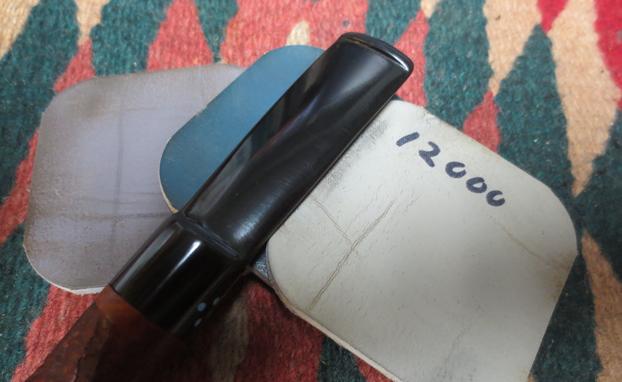

Before I move forward with sanding and finishing the stummel, I return to the stem and the shaping and repair of the button and slot. I take another close-up of both the top and bottom to mark the progress. I begin using a flat needle file and a pointed half-circle needle file to re-shape the slot and to redefine the end of the stem. I will work from stem end, having established a base line. When I finish the basic shaping with the needle files I then continue shaping the button with 240 grit paper then 0000 steel wool. The pictures show the progression. Near the completion of the button rebuild, I use K-150 Black Medium glue to fill pockets and unevenness in the upper bit area. After cured, I re-sand the area with 240 grit, then 600 grit papers then complete the process with 0000 steel wool. The last two pictures show the finished button rebuild. It took some time, but I think it looks good as well as refortifying a formerly, weak and cracked button.

Before I move forward with sanding and finishing the stummel, I return to the stem and the shaping and repair of the button and slot. I take another close-up of both the top and bottom to mark the progress. I begin using a flat needle file and a pointed half-circle needle file to re-shape the slot and to redefine the end of the stem. I will work from stem end, having established a base line. When I finish the basic shaping with the needle files I then continue shaping the button with 240 grit paper then 0000 steel wool. The pictures show the progression. Near the completion of the button rebuild, I use K-150 Black Medium glue to fill pockets and unevenness in the upper bit area. After cured, I re-sand the area with 240 grit, then 600 grit papers then complete the process with 0000 steel wool. The last two pictures show the finished button rebuild. It took some time, but I think it looks good as well as refortifying a formerly, weak and cracked button.

With button rebuild completed, I begin the micromesh sanding process first by wet sanding the stem with pads 1500 to 2400 and follow with an application of Obsidian Oil over the entire stem. I then dry sand the stem using pads 3200 to 4000 and again with pads 6000 to 12000, following each set with a fresh application of Obsidian Oil. The stem looks great and the button repair has blended well. I put the stem aside to dry. The pictures show the progress.

With button rebuild completed, I begin the micromesh sanding process first by wet sanding the stem with pads 1500 to 2400 and follow with an application of Obsidian Oil over the entire stem. I then dry sand the stem using pads 3200 to 4000 and again with pads 6000 to 12000, following each set with a fresh application of Obsidian Oil. The stem looks great and the button repair has blended well. I put the stem aside to dry. The pictures show the progress.

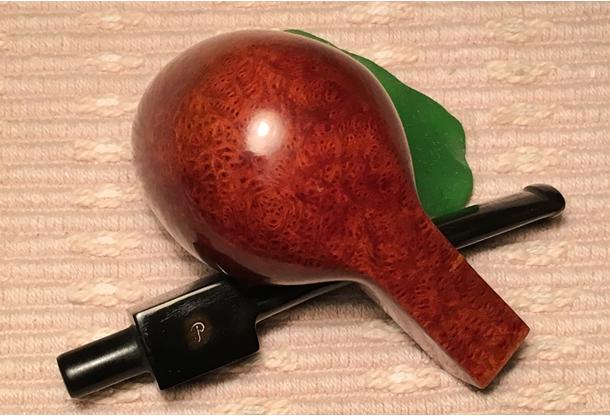

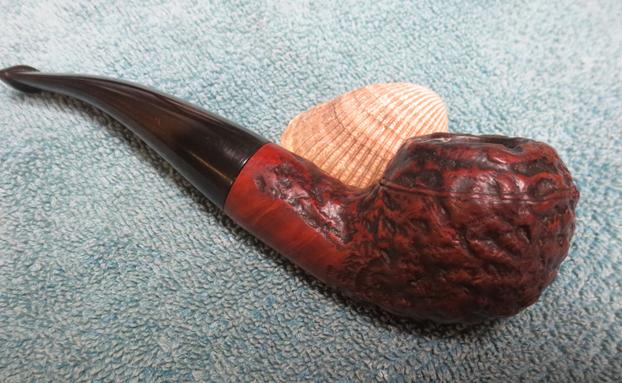

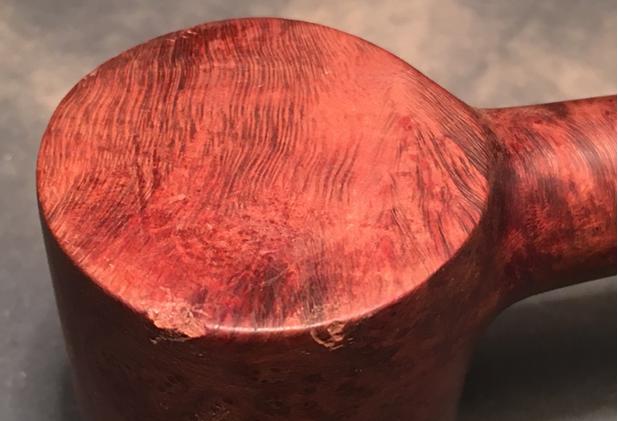

Turning again to the stummel, I wet sand the surface with micromesh pads 1500 to 2400, then 3200 to 4000, and then 6000 to 12000, taking a picture after each set to show the progress. The micromesh pads’ work is spectacular by teasing out the beautiful briar straight grain. The briar on this Eldorado Lucite is very nicely showcased cascading down the elongated Dublin canonical stummel. A very nice choice of briar for this pipe style.

Turning again to the stummel, I wet sand the surface with micromesh pads 1500 to 2400, then 3200 to 4000, and then 6000 to 12000, taking a picture after each set to show the progress. The micromesh pads’ work is spectacular by teasing out the beautiful briar straight grain. The briar on this Eldorado Lucite is very nicely showcased cascading down the elongated Dublin canonical stummel. A very nice choice of briar for this pipe style.

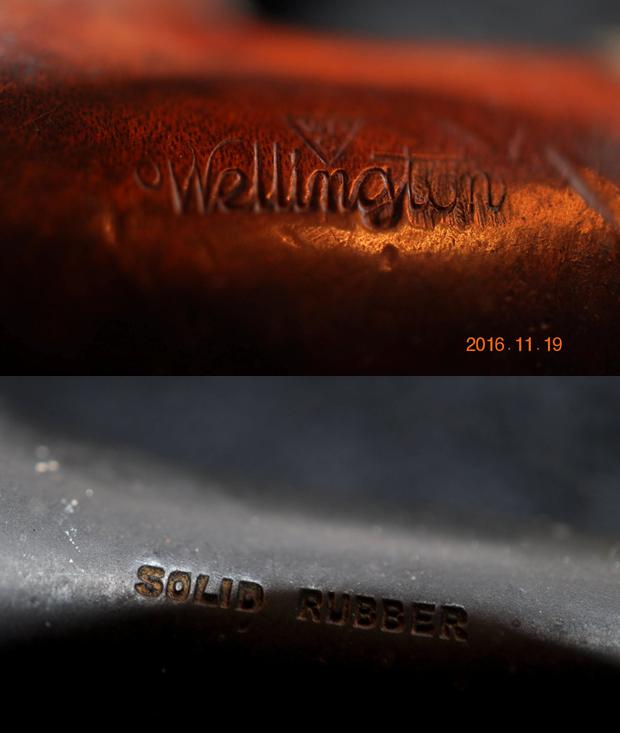

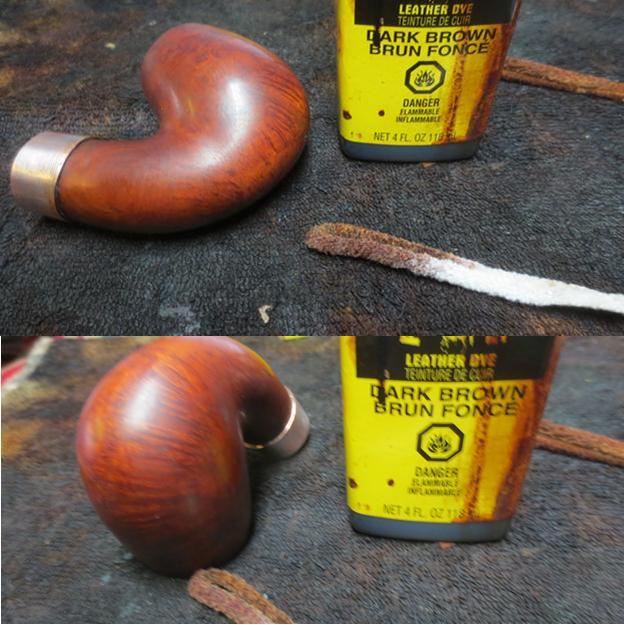

As I moved through the micromesh cycles, my usual thought processing is to ponder the finish and what approach will best showcase the briar. Should I leave the natural grain color and apply carnauba wax or apply a stain? With the 14K gold band on this sleek Dublin, I decide to leverage toward a darker brown than the original. I think the black stem and the darker stummel will give the gold band an extra pop – standing out very nicely. To expand the briar and enabling the grain to be more receptive to the dye, I warm the stummel using my wife’s hair dryer. Then, using a pipe cleaner folded in two, I apply Fiebing’s Light Brown Leather Dye liberally to the stummel and rim. I cover the surface thoroughly. When covered, I flame the wet dye using a lit candle and the alcohol in the dye immediately evaporates setting the dye hue in the grain. After a few minutes, I repeat the process including flaming the dye. I set the stummel aside for the night to rest. The picture shows the dye-crusted stummel.

As I moved through the micromesh cycles, my usual thought processing is to ponder the finish and what approach will best showcase the briar. Should I leave the natural grain color and apply carnauba wax or apply a stain? With the 14K gold band on this sleek Dublin, I decide to leverage toward a darker brown than the original. I think the black stem and the darker stummel will give the gold band an extra pop – standing out very nicely. To expand the briar and enabling the grain to be more receptive to the dye, I warm the stummel using my wife’s hair dryer. Then, using a pipe cleaner folded in two, I apply Fiebing’s Light Brown Leather Dye liberally to the stummel and rim. I cover the surface thoroughly. When covered, I flame the wet dye using a lit candle and the alcohol in the dye immediately evaporates setting the dye hue in the grain. After a few minutes, I repeat the process including flaming the dye. I set the stummel aside for the night to rest. The picture shows the dye-crusted stummel. The next morning, I’m anxious to ‘unwrap’ the crust of the fired dye from the night before. Since I live in a flat on the 10th floor of former Communist block apartment building, I do not have a lot of room for my work shop. The Dremel high speed rotary tool is how I solve the problem of not having regular high speed buffing wheels. To unwrap the stummel, I mount the Dremel with a felt polishing wheel and set the speed of the Dremel to the slowest speed. The felt material is abrasive and I don’t want to over-heat the wood with the higher speeds. Each polishing wheel is dedicated to a specific compound used in the buffing process. I mount the Tripoli wheel, and after purging it from old compound with the edge of the metal wrench, used to tighten the wheels on the Dremel, I apply Tripoli compound to remove the flamed residue of the light brown dye. I rotate the wheel around the surface of the stummel slowly, not applying much vertical pressure on the surface but allowing the RPMs, felt and compound to do the work. I use the sheen created on the surface of the briar (reflecting the bright overhead work lamp) to observe the compound’s behavior, which enables me to distribute the compound evenly over the surface. See my essay, ‘My Dremel Polishing Technique’ if you want more detail. I took a picture of the ‘unwrapping’ with the Tripoli compound and wheel. You can see the before and after comparison very easily which demonstrates my typical approach.

The next morning, I’m anxious to ‘unwrap’ the crust of the fired dye from the night before. Since I live in a flat on the 10th floor of former Communist block apartment building, I do not have a lot of room for my work shop. The Dremel high speed rotary tool is how I solve the problem of not having regular high speed buffing wheels. To unwrap the stummel, I mount the Dremel with a felt polishing wheel and set the speed of the Dremel to the slowest speed. The felt material is abrasive and I don’t want to over-heat the wood with the higher speeds. Each polishing wheel is dedicated to a specific compound used in the buffing process. I mount the Tripoli wheel, and after purging it from old compound with the edge of the metal wrench, used to tighten the wheels on the Dremel, I apply Tripoli compound to remove the flamed residue of the light brown dye. I rotate the wheel around the surface of the stummel slowly, not applying much vertical pressure on the surface but allowing the RPMs, felt and compound to do the work. I use the sheen created on the surface of the briar (reflecting the bright overhead work lamp) to observe the compound’s behavior, which enables me to distribute the compound evenly over the surface. See my essay, ‘My Dremel Polishing Technique’ if you want more detail. I took a picture of the ‘unwrapping’ with the Tripoli compound and wheel. You can see the before and after comparison very easily which demonstrates my typical approach. I follow the Tripoli compound with Blue Diamond. Again, using a dedicated Blue Diamond wheel mounted on the Dremel, I work the compound into the surface in the same manner as Tripoli. After the Blue Diamond cycle, I hand-buff the stummel with a cotton cloth simply to remove the powdery residue of the compounds from the briar surface. I do this before applying carnauba wax. Next, I mount the cotton cloth polishing wheel onto the Dremel, increase the speed of the Dremel from 1 to 2 (5 is the fastest) and apply several coats of carnauba wax to both stummel and its reunited stem. I finish with a rigorous hand-buffing with micromesh cloth not only to deepen the shine but to distribute any pockets of unintegrated carnauba wax.

I follow the Tripoli compound with Blue Diamond. Again, using a dedicated Blue Diamond wheel mounted on the Dremel, I work the compound into the surface in the same manner as Tripoli. After the Blue Diamond cycle, I hand-buff the stummel with a cotton cloth simply to remove the powdery residue of the compounds from the briar surface. I do this before applying carnauba wax. Next, I mount the cotton cloth polishing wheel onto the Dremel, increase the speed of the Dremel from 1 to 2 (5 is the fastest) and apply several coats of carnauba wax to both stummel and its reunited stem. I finish with a rigorous hand-buffing with micromesh cloth not only to deepen the shine but to distribute any pockets of unintegrated carnauba wax.

I was hoping to create a pop with the classy gold band linking a slim, gently curving stem with the rich darker brown hues of the Dublin’s cascading briar patterns. I think what I now see before me effectively does just that! This gold banded Eldorado Lucite of Italy is an elegant Dublin which feels very comfortable in the hand. It will be a great addition to some new steward’s collection.

Below, in the comments, I reposted this blog of Reborn Pipes to my new blog site, http://www.ThePipeSteward.com This site is serving not only as a ‘store front’ for pipes I’m selling, but it also describes the work we do in Bulgaria with the Daughters of Bulgaria Foundation – rescuing and restoring women and children who have been trafficked and sexually exploited. To help with this work, the profits of my sales go to the Daughters. So, if you’re interested in adding this Eldorado Lucite Bent Dublin of Italy to your collection, jump over to The Pipe Steward, and check it out! Thank you for joining me!