Blog by Steve Laug

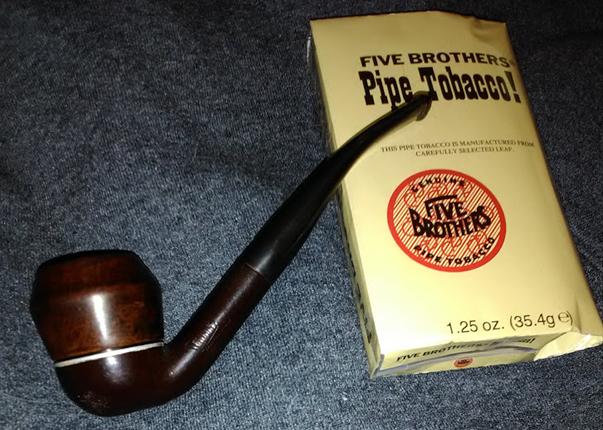

Sometimes a voice from the past is a good thing for both parties. Many years ago now, here in Vancouver I met Eric at the Vancouver Pipe Club. We talked at pipe club meetings and had a common calling as ministers in within different Christian Churches. Over time Eric moved to Eastern Canada and I moved on to work for an NGO here in Vancouver. Not too long ago I received an email from Eric about some pipes that he had that he wanted me to work on for him. We made arrangements and soon a box with three of his pipes was traveling to me from Ontario. It arrived quite quickly and I opened it when it arrived. Eric had thoughtfully included a tin of Samuel Gawith’s Commonwealth Mixture Full Strength for me to smoke and I was looking forward to cracking it open. Included in the box were three pipes – a Danbark Hand Carved from Denmark that was quite stunning, a Bewlay Sandblast Billiard and a Le Nuvole Long Shank Dublin. Each had different challenges to address but each was a beautiful example of the pipe maker’s craft. I decided to work on the Danbark Hand Carved pipe next.

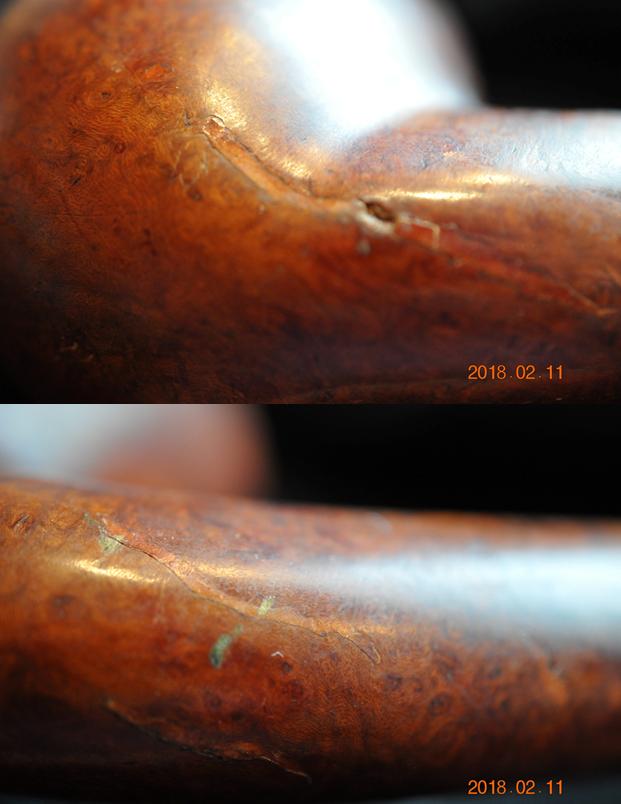

The finish on the pipe was very dirty with a lot of grit and grim in the grooves and crevices of the spiral style of rustication. The rim top was heavily tarred with lava that flowed from a caked bowl. The edges and top of the rim looked like it had burn marks on the front just left of centre and on the rear left side. Other than the burn marks it appeared to be in okay condition though I would not know for sure until I had reamed the bowl and cleaned off the rim top. The bowl was rusticated all around other than the rim top and about half of the shank. The grain on the smooth parts was very nice. The underside of the shank is stamped Danbark over Hand Carved over Denmark.The acrylic stem had the white Danbark “D” logo on the top side. There was tooth chatter on both sides at the button and a triangular shaped puncture on the top side about ¼ inch from the button. The pipe was not as dirty or smelly as the first pipe of Eric’s I worked on. I took photos of the pipe to show the condition it was in when it arrived.

I took close up photos of the bowl and rim top to show its condition. You can see the thick cake in the bowl and the overflow of lava onto the inner edge bevel and on the rim. You can also see the burn marks on the rim top just left of centre and on the back side mid rim. The rim does not look damaged on the outer edge in this photo. I also took photos of the stem to show the general condition it was in as well. It looked pretty good other than chatter on both sides ahead of the button and the puncture on the topside of the stem.

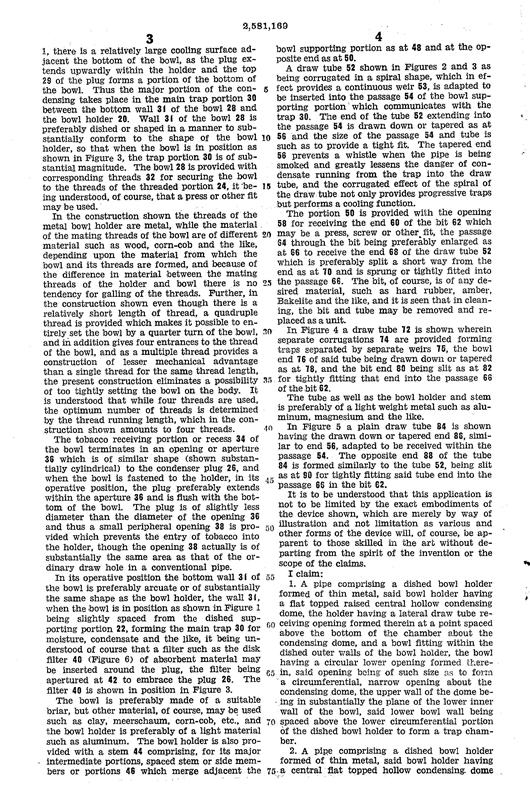

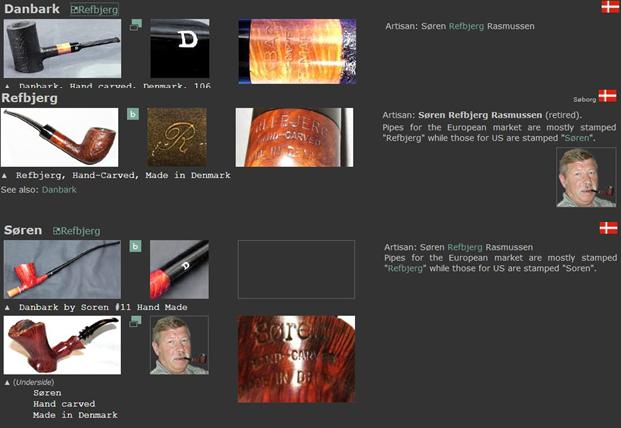

I took close up photos of the bowl and rim top to show its condition. You can see the thick cake in the bowl and the overflow of lava onto the inner edge bevel and on the rim. You can also see the burn marks on the rim top just left of centre and on the back side mid rim. The rim does not look damaged on the outer edge in this photo. I also took photos of the stem to show the general condition it was in as well. It looked pretty good other than chatter on both sides ahead of the button and the puncture on the topside of the stem. I decided to read a little about the brand and the pipemaker. It turns out that the pipe was made by Soren Refbjerg Rasmussen who also made Refbjerg and Soren pipes. That was a surprise to me as I had no recollection of the connection. This “honey stick” style pipe is a Danbark with the same stamping on the shank as the pipe in the photo from Pipephil’s site. I have cleaned and restored several or Soren’s pipes in the past, both Refbjerg and Soren stamped ones but I have never worked on a Danbark. I did a screen capture of all three of the brands carved by Soren and the information included in them. It turns out that the Refbjerg pipes were made for the European market and the Soren ones for the US market. The Danbark pipes seem to overlap on both sides of the Atlantic. The D on the stem is also the same in the photo as the pipe I am working on for Eric.

I decided to read a little about the brand and the pipemaker. It turns out that the pipe was made by Soren Refbjerg Rasmussen who also made Refbjerg and Soren pipes. That was a surprise to me as I had no recollection of the connection. This “honey stick” style pipe is a Danbark with the same stamping on the shank as the pipe in the photo from Pipephil’s site. I have cleaned and restored several or Soren’s pipes in the past, both Refbjerg and Soren stamped ones but I have never worked on a Danbark. I did a screen capture of all three of the brands carved by Soren and the information included in them. It turns out that the Refbjerg pipes were made for the European market and the Soren ones for the US market. The Danbark pipes seem to overlap on both sides of the Atlantic. The D on the stem is also the same in the photo as the pipe I am working on for Eric. The Danbark that I am working on is stamped on the underside of the bowl and shank at the stem/shank junction. It is stamped with the following information: DANBARK over Hand Carved over Denmark. Soren’s handmade stems have a funneled airway leading through the tenon to a normal rectangular slot in the end of the stem. There is no flaring or shaping done to the slot. It almost looks like a factory blank that has been reworked slightly.

The Danbark that I am working on is stamped on the underside of the bowl and shank at the stem/shank junction. It is stamped with the following information: DANBARK over Hand Carved over Denmark. Soren’s handmade stems have a funneled airway leading through the tenon to a normal rectangular slot in the end of the stem. There is no flaring or shaping done to the slot. It almost looks like a factory blank that has been reworked slightly.

I did a bit more searching and on Pipedia I found out that Danbark was a second line that came from Soren (https://pipedia.org/wiki/Refbjerg). There was also a direct quote from Soren speaking of the Danbark line on Frenchy’s Pipes online. Frenchy’s was an online seller that retailed both new and estate pipes quite a few years back. I did business with him in those years and enjoyed him – great sense of humour. Here is what he quotes from Soren and is requoted on Pipedia.

“A note from the carver: I am very proud to introduce my new (!) series of hand-carved Danbark Pipes by Søren. These pipes are crafted from the finest Corsican and Grecian briars. I take a great deal of pride in crafting the Danbark Pipes to be highly functional and so they will provide the smoker with many years of dedicated service. The Danbark Pipes by Søren are available in several different styles and finishes with my personal touch and inspirations. At this time I favor making classic shaped pipes with a slight touch of my own hands and feelings. I do not produce many pipes today but the pipes that I do make available are individually crafted from the finest Corsican and Grecian Briars available to me. I still make free-hand pipes but not as many as I once made. For the past 35 years I have always tried to make good smoking pipes in my workshop located near Copenhagen, Denmark. I have always tried to craft my pipes in such a way as they will be long lasting and best friends with the owners. I take great pride in the shape of my pipes, the drilling of the pipes, and the overall dimensions of the pipes. I enjoy spending my spare time on the very long, rugged coasts of Denmark. I derive much relaxation from being on the coast while angling for Sea Trout with my own hand-tied flies. I find this environment is a great inspiration to me for making pipes. Many times I think to myself, ‘Inspired by nature, made by me’. — Happy puffing, Søren”

I decided to start the work on this pipe by repairing the puncture in the stem. I cleaned the inside of the stem with pipe cleaners to remove the grime. I wiped the stem down with alcohol on cotton pads to remove any debris or grime on the puncture wound. I cleaned the edges of the puncture with a cotton swab and alcohol. Once it was clean, I greased a pipe cleaner with Vaseline and inserted it through the slot making sure that the space below the puncture was filled with greased fuzz. I filled in the puncture with black super glue. I sprayed it with an accelerator to set the repair quickly so that I could remove the pipe cleaner. I sanded the repair lightly to smooth it out. I refilled the repaired area with a bubble of black super glue to fill in the air bubbles in the repair. I set the stem aside until the repair had hardened.

While the repair was curing I turned my attention to the bowl. I reamed the bowl with a Savinelli Fitsall Pipe Knife to scrape away the cake and take it back to bare briar. I worked it over from top to bottom removing the thick cake coat.

While the repair was curing I turned my attention to the bowl. I reamed the bowl with a Savinelli Fitsall Pipe Knife to scrape away the cake and take it back to bare briar. I worked it over from top to bottom removing the thick cake coat. I rolled a piece of sandpaper around my finger and sanded the walls of the bowl smooth. I worked over the inner edge of the rim and the rim top to remove as much of the burn damage and damage to the edge of the bowl. I worked on it with a folded piece of 220 grit sandpaper to smooth it out. I lightly topped the bowl on the topping board with 220 grit sandpaper to remove more of the damaged wood. The top of the bowl was charred at the front edge a little left of center. I topped it to remove the char and smooth it out. The wood that is left is solid. I did not take too much of the top because of the smooth outer edge above the last spiral of rustication.

I rolled a piece of sandpaper around my finger and sanded the walls of the bowl smooth. I worked over the inner edge of the rim and the rim top to remove as much of the burn damage and damage to the edge of the bowl. I worked on it with a folded piece of 220 grit sandpaper to smooth it out. I lightly topped the bowl on the topping board with 220 grit sandpaper to remove more of the damaged wood. The top of the bowl was charred at the front edge a little left of center. I topped it to remove the char and smooth it out. The wood that is left is solid. I did not take too much of the top because of the smooth outer edge above the last spiral of rustication. I cleaned out the interior of the mortise and the airway in the shank and the stem with alcohol, cotton swabs and pipe cleaners. I cleaned it until the cleaners came out white.

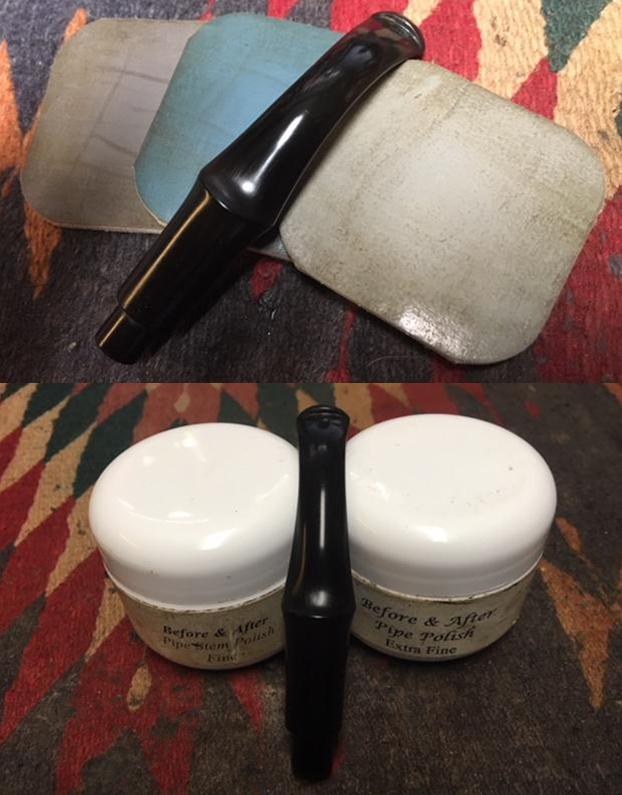

I cleaned out the interior of the mortise and the airway in the shank and the stem with alcohol, cotton swabs and pipe cleaners. I cleaned it until the cleaners came out white. I sanded newly topped rim gently with a worn piece of 220 sandpaper and wet sanded it with some 400 grit wet dry sandpaper. I polished the rim top with micromesh sanding pads – wet sanding with 1500-2400 grit pads and dry sanding it with 3200-12000 grit pads. I wiped it down after each pad with a damp cloth. The photos below tell the story of the polishing of the rim top.

I sanded newly topped rim gently with a worn piece of 220 sandpaper and wet sanded it with some 400 grit wet dry sandpaper. I polished the rim top with micromesh sanding pads – wet sanding with 1500-2400 grit pads and dry sanding it with 3200-12000 grit pads. I wiped it down after each pad with a damp cloth. The photos below tell the story of the polishing of the rim top.

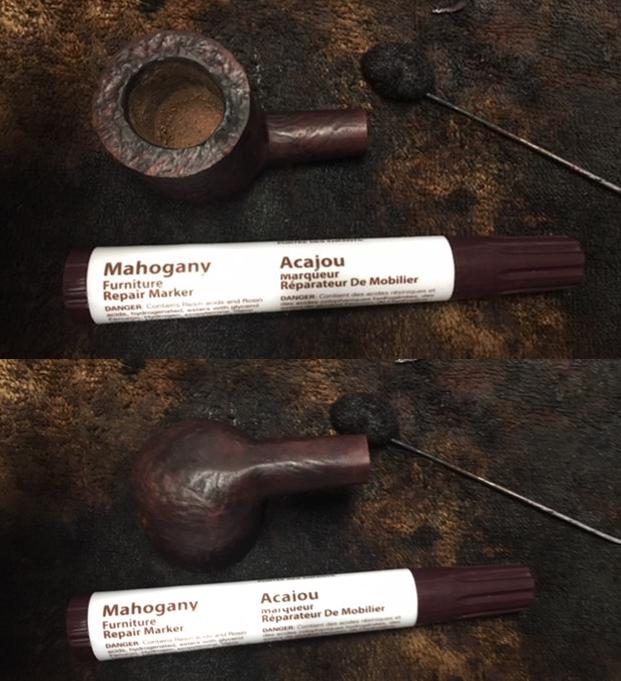

Once the rim was polished and scratch free I used a Maple stain pen to match the colour of the rest of the smooth areas around the shank and bowl. I wanted the stain to hide the burn marks on the rim. I figured that it would at least mask them a bit.

Once the rim was polished and scratch free I used a Maple stain pen to match the colour of the rest of the smooth areas around the shank and bowl. I wanted the stain to hide the burn marks on the rim. I figured that it would at least mask them a bit. I let the stain dry and then rubbed the briar down with Before & After Restoration Balm working it into the nooks and crannies of the rusticated finish with my fingertips. I am really enjoying working with the balm and it cleans, enlivens and protects the briar and removes the dust and debris in the rustication. It also helped to blend in the stain on the rim and brought new life to it as well. I rubbed it in, used a horsehair shoe brush to work the balm into the finish, let it sit for a little while then buffed it off with a cotton cloth. The photos below show the progress of the polishing.

I let the stain dry and then rubbed the briar down with Before & After Restoration Balm working it into the nooks and crannies of the rusticated finish with my fingertips. I am really enjoying working with the balm and it cleans, enlivens and protects the briar and removes the dust and debris in the rustication. It also helped to blend in the stain on the rim and brought new life to it as well. I rubbed it in, used a horsehair shoe brush to work the balm into the finish, let it sit for a little while then buffed it off with a cotton cloth. The photos below show the progress of the polishing.

I gave the bowl and shank multiple coats of Conservator’s wax – once again rubbing it into the finish with my fingertips and then letting harden slightly. I buffed it with a shoe brush and a cotton cloth. I repeated the process until I had given the bowl several coats of the wax. The finish really had taken on a shine that was beautiful.

I gave the bowl and shank multiple coats of Conservator’s wax – once again rubbing it into the finish with my fingertips and then letting harden slightly. I buffed it with a shoe brush and a cotton cloth. I repeated the process until I had given the bowl several coats of the wax. The finish really had taken on a shine that was beautiful.

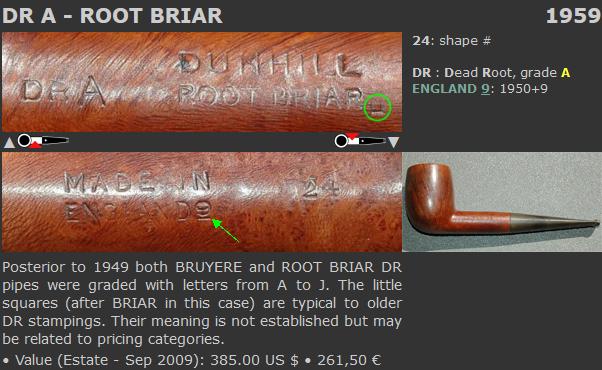

I set the bowl aside and called it a night. When I returned the next evening after work I turned my attention to the stem. The repair had hardened and looked good. I sanded it smooth with a 1500 grit micromesh sanding pad. I did not want to sand too deeply into the repair rather I wanted to have it form a protective layer over the puncture mark. I used 400 grit wet/dry sandpaper to feather in the edges of the repair. I polished the entire stem with micromesh sanding pads – wet sanding with 1500-2400 grit pads and dry sanding with 3200-12000 grit pads. I wiped it down after each pad with a damp cloth. I polished it further with Before & After Pipe Stem Polish – both the Fine and Extra Fine. I wiped it down and gave it a shine with some Obsidian Oil.

I set the bowl aside and called it a night. When I returned the next evening after work I turned my attention to the stem. The repair had hardened and looked good. I sanded it smooth with a 1500 grit micromesh sanding pad. I did not want to sand too deeply into the repair rather I wanted to have it form a protective layer over the puncture mark. I used 400 grit wet/dry sandpaper to feather in the edges of the repair. I polished the entire stem with micromesh sanding pads – wet sanding with 1500-2400 grit pads and dry sanding with 3200-12000 grit pads. I wiped it down after each pad with a damp cloth. I polished it further with Before & After Pipe Stem Polish – both the Fine and Extra Fine. I wiped it down and gave it a shine with some Obsidian Oil.

With the stem polished I put it back on the shank and polished the bowl and stem with Blue Diamond on the buffing wheel. I used a light touch on the briar so as not to fill in the rustication or the rings with buffing compound and a slightly heavier touch on the acrylic stem. I gave the bowl multiple coats of Conservator’s Wax by hand rubbing it into the finish and the stem multiple coats of carnauba on the buffing wheel. I buffed the entire pipe with a clean buffing pad to raise the shine on the briar and the acrylic. I hand buffed it with a microfiber cloth to deepen the shine. The finished pipe is shown in the photos that follow. It is a beautiful piece of pipe crafting. I am sure Eric will enjoy this beauty once it heads back to Ontario. Just one more of his pipes to work on before they all travel east. Thanks for walking with me through the restoration. Cheers.

With the stem polished I put it back on the shank and polished the bowl and stem with Blue Diamond on the buffing wheel. I used a light touch on the briar so as not to fill in the rustication or the rings with buffing compound and a slightly heavier touch on the acrylic stem. I gave the bowl multiple coats of Conservator’s Wax by hand rubbing it into the finish and the stem multiple coats of carnauba on the buffing wheel. I buffed the entire pipe with a clean buffing pad to raise the shine on the briar and the acrylic. I hand buffed it with a microfiber cloth to deepen the shine. The finished pipe is shown in the photos that follow. It is a beautiful piece of pipe crafting. I am sure Eric will enjoy this beauty once it heads back to Ontario. Just one more of his pipes to work on before they all travel east. Thanks for walking with me through the restoration. Cheers.