Blog by Steve Laug

When Jeff showed me the next pipe on the table we went back and forth about buying it or just leaving it with the seller. It was a really nice Ser Jacopo L1 Billiard at some point in its life but that time had passed. It had literally become a chew toy for someone’s dog. The bowl was in very rough shape and had deep tooth gouges around the bowl with chunks of briar missing on the rim and top. The bowl was really damaged to the point of being questionable. The shank interestingly was free of bite marks and the stem had less bite marks than some of the stems I have worked on from pipemen who chew their stems. For me the question was whether or not I wanted to work on it. There was no doubt that the pipe would be a challenge but was it a challenge I wanted to take on. That was the question we weighed before moving ahead with the buy.

After spending time talking about it we decided to pick up the pipe and see what I could do with it. When Jeff got it the story became even sadder! The bowl had amazing straight grain around the sides and it appeared to have been barely smoked. It looked as if maybe a bowl or two had been enjoyed before the dog got a hold of the pipe and did the massive damage that showed when we saw it. The bowl had some darkening but there was no cake in the bowl. It smelled smoky but otherwise was very clean. Jeff would still clean up the pipe before he sent it on to me that way I would be able to just pick it up and see what I could do with it. Jeff took the following photos before he started his cleanup work on the pipe. Just look at the damage! Oh my; the pipeman or woman must have just wept after the initial shock or anger when he or she saw the pipe dangling from the dog’s mouth.

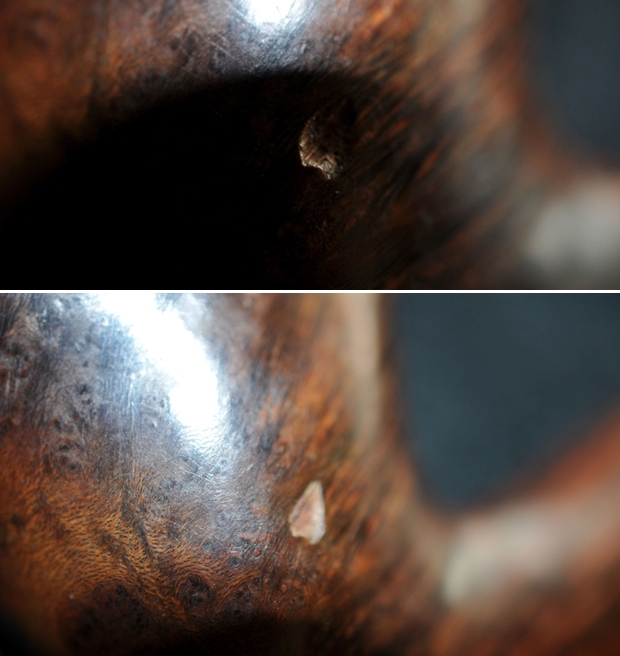

He took close-up photos of the bowl and rim top from various angles to capture the gnawing damage to the bowl and rim top edges. You can see the large bite marks and chunks of briar missing on both the inner and outer edges. The largest chunk is on the front of the bowl and the inner edges damage is on the right side. You can also see the damage to the sides of the bowl.

He took close-up photos of the bowl and rim top from various angles to capture the gnawing damage to the bowl and rim top edges. You can see the large bite marks and chunks of briar missing on both the inner and outer edges. The largest chunk is on the front of the bowl and the inner edges damage is on the right side. You can also see the damage to the sides of the bowl.

Jeff took photos of the sides and heel of the bowl to show the both the extent of the damage to the bowl and the amazing grain around the bowl. It really is a shame that this poor pipe suffered this fate.

Jeff took photos of the sides and heel of the bowl to show the both the extent of the damage to the bowl and the amazing grain around the bowl. It really is a shame that this poor pipe suffered this fate.

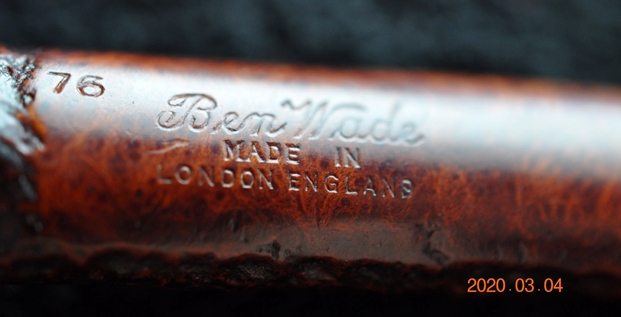

Jeff took photos of the stamping on sides of the bowl. On the left side it reads Ser Jacopo over Fatta A Mano over In Italia. On the right side it reads L1 in a circle Per Aspera Ad Aspera. On De Divina Proportione. All the stampings are very readable and clear. He took a photo of the inlays on the tapered stem top. The silver J with an I and a circle.

Jeff took photos of the stamping on sides of the bowl. On the left side it reads Ser Jacopo over Fatta A Mano over In Italia. On the right side it reads L1 in a circle Per Aspera Ad Aspera. On De Divina Proportione. All the stampings are very readable and clear. He took a photo of the inlays on the tapered stem top. The silver J with an I and a circle.

The next two photos show the top and underside of the stem. Notice the few tooth marks on both sides. It is not as bad as it could be.

The next two photos show the top and underside of the stem. Notice the few tooth marks on both sides. It is not as bad as it could be.  I wanted to know a bit more about the pipe in hand. I knew a little of the history of the brand but I wanted to understand the stamping on the shank sides and underside so I turned first to the Pipephil website (http://www.pipephil.eu/logos/en/logo-s5.html). Interestingly the first pipe they had a photo of was similar to the one that I had. It is stamped similarly on the left side of the shank with the Ser Jacopo over Fatta a Mano but the one I have also was stamped In Italia under that. The right side of mine is stamped with the L1 in a circle and the Per Aspera Ad Astra followed that. Mine also was stamped on the underside of the shank and read: De Divina Proportione. The one I am working on also had a band on the shank and the stem stamp was different as well. I also learned the L1 stamp stood for a pipe with acceptable grain. I have included a screen capture of the pertinent information.

I wanted to know a bit more about the pipe in hand. I knew a little of the history of the brand but I wanted to understand the stamping on the shank sides and underside so I turned first to the Pipephil website (http://www.pipephil.eu/logos/en/logo-s5.html). Interestingly the first pipe they had a photo of was similar to the one that I had. It is stamped similarly on the left side of the shank with the Ser Jacopo over Fatta a Mano but the one I have also was stamped In Italia under that. The right side of mine is stamped with the L1 in a circle and the Per Aspera Ad Astra followed that. Mine also was stamped on the underside of the shank and read: De Divina Proportione. The one I am working on also had a band on the shank and the stem stamp was different as well. I also learned the L1 stamp stood for a pipe with acceptable grain. I have included a screen capture of the pertinent information. Once I had that material digested a bit I turned to Pipedia to understand more about the stamping on the pipe (https://pipedia.org/wiki/Ser_Jacopo). I am including the information on that below. The standard nomenclature found on Ser Jacopo pipes is as follows: Ser Jacopo Fatta A Mano In Italia Per Aspera Ad Astra.

Once I had that material digested a bit I turned to Pipedia to understand more about the stamping on the pipe (https://pipedia.org/wiki/Ser_Jacopo). I am including the information on that below. The standard nomenclature found on Ser Jacopo pipes is as follows: Ser Jacopo Fatta A Mano In Italia Per Aspera Ad Astra.

Fatta A Mano translates to “Made By Hand”. Per Aspera Ad Astra is a Latin phrase found on Ser Jacopo pipes and is the Ser Jacopo motto. It translates to “To the Stars Through Travails”, meaning that success comes through hard work. In the Summer 1997 Pipes and Tobaccos article Giancarlo Guidi translated this as “through a difficult way until the stars are reached”.

All that remained was to find out what the De Divina Proportione on the underside of the shank meant. I turned to wikipedia (https://en.wikipedia.org/wiki/Divina_proportione) for what I assumed referred to Divine Proportion or the Golden Ratio. I quote from there a good summary.

Divina proportione (15th century Italian for Divine proportion), later also called De divina proportione (converting the Italian title into a Latin one) is a book on mathematics written by Luca Pacioli and illustrated by Leonardo da Vinci, composed around 1498 in Milan and first printed in 1509.[1] Its subject was mathematical proportions (the title refers to the golden ratio) and their applications to geometry, to visual art through perspective, and to architecture. The clarity of the written material and Leonardo’s excellent diagrams helped the book to achieve an impact beyond mathematical circles, popularizing contemporary geometric concepts and images.

Now I had a clear idea of the meaning of the stamping. The Golden Ratio refers to the mathematical proportions of this particular pipe fitting that Ratio. It is seriously a beautiful pipe and now I am even sadder at the damage that was done. That motivates me to try to bring it back to some semblance of beauty.

Now it was time to look at it up close and personal. Jeff had done an amazing job in removing all debris and bits of broken briar from the finish. He had done a quick reaming of the bowl with a Savinelli Fitsall Pipe Knife. He scrubbed the exterior of the bowl with Murphy’s Oil Soap and a tooth brush to remove the grime the grime and dirt on the finish so the pipe was clean – damaged but clean. He cleaned out the interior of the bowl and shank with pipe cleaners, cotton swabs and alcohol until they came out clean. The rim top looked quite daunting with the missing chunks of briar but it too was clean. He cleaned the stem with Soft Scrub to remove the grime on the exterior and cleaned out the airway with alcohol, cotton swabs and pipe cleaners. I took some photos of the pipe as I saw it when I brought it to the work table.

To show how the rim top and stem looked at this point I took a close-up photo of the rim and stem. The bowl was clean and the damage to the inner edge and the rim top was very visible. It was a mess! The black acrylic stem was saved from major dog chomping. There are just a few tooth marks on both sides of the stem that could be addressed fairly easily.

To show how the rim top and stem looked at this point I took a close-up photo of the rim and stem. The bowl was clean and the damage to the inner edge and the rim top was very visible. It was a mess! The black acrylic stem was saved from major dog chomping. There are just a few tooth marks on both sides of the stem that could be addressed fairly easily. I removed the stem from the bowl and took photos of the parts. I chose the left side of the bowl as really both sides were equally damaged. This is truly a sad sight to see as the great grain on the bowl shows up nicely under the damage.

I removed the stem from the bowl and took photos of the parts. I chose the left side of the bowl as really both sides were equally damaged. This is truly a sad sight to see as the great grain on the bowl shows up nicely under the damage. I had been thinking about what to do with the finish since first seeing the photos. I had decided I would rusticate it but was undecided as to what extent I would go in the process. I wanted to retain the original shape and intent of the pipe while working out the damages. I started by using three different burrs on the Dremel – a ball, a cone and cylinder. Each one gives a slightly different finish. I worked them one after another to seek to blend in the tooth marks as much as possible. I also decided to rusticate the worst areas – the base and part way up each side of the bowl and the entire bowl front. The photos show this first step.

I had been thinking about what to do with the finish since first seeing the photos. I had decided I would rusticate it but was undecided as to what extent I would go in the process. I wanted to retain the original shape and intent of the pipe while working out the damages. I started by using three different burrs on the Dremel – a ball, a cone and cylinder. Each one gives a slightly different finish. I worked them one after another to seek to blend in the tooth marks as much as possible. I also decided to rusticate the worst areas – the base and part way up each side of the bowl and the entire bowl front. The photos show this first step.

I decided to let that rustication pattern sit with me for awhile and not add more to it. I just wanted to think about it for a while. I decided then to patch the bite marks in the upper part of each side and the entire back of the bowl. I also wanted to repair as much of the rim top and edge damage as I could. I used clear super glue and briar dust to patch the many tooth marks around the bowl. The photos show the freckled sides. I built up the damaged front outer edge and the deep marks on the top of the rim with super glue and briar dust. These took some layering to do the job.

I decided to let that rustication pattern sit with me for awhile and not add more to it. I just wanted to think about it for a while. I decided then to patch the bite marks in the upper part of each side and the entire back of the bowl. I also wanted to repair as much of the rim top and edge damage as I could. I used clear super glue and briar dust to patch the many tooth marks around the bowl. The photos show the freckled sides. I built up the damaged front outer edge and the deep marks on the top of the rim with super glue and briar dust. These took some layering to do the job.

I looked over the rustication some more and was not completely satisfied with the coverage of the existing rustication or the distance I came around the sides of the bowl. I decided to use a tool that a reader of rebornpipes made for me for rusticating. You can see it in the photos. It is essential a group nails bound together in a handle and with a clamp to give me multiple points to rusticate with. The way it works is to press it into the briar and twist it. You move across the briar until it is “randomly” covered. Once I was happy with the coverage I knock off the debris left behind with a brass bristly brush. I like to knock it down and smooth it out to give it an old leather like look to the rustication.

I looked over the rustication some more and was not completely satisfied with the coverage of the existing rustication or the distance I came around the sides of the bowl. I decided to use a tool that a reader of rebornpipes made for me for rusticating. You can see it in the photos. It is essential a group nails bound together in a handle and with a clamp to give me multiple points to rusticate with. The way it works is to press it into the briar and twist it. You move across the briar until it is “randomly” covered. Once I was happy with the coverage I knock off the debris left behind with a brass bristly brush. I like to knock it down and smooth it out to give it an old leather like look to the rustication.

I left the rustication and turned to address the damage to the rim top. I topped the rim with 220 grit sandpaper on the topping board. Once it was smoother and flatter I filled in the divots and holes in the rim top and edges with briar dust and super glue once more. Once I finished I topped it once more to smooth out the repaired areas.

I left the rustication and turned to address the damage to the rim top. I topped the rim with 220 grit sandpaper on the topping board. Once it was smoother and flatter I filled in the divots and holes in the rim top and edges with briar dust and super glue once more. Once I finished I topped it once more to smooth out the repaired areas.

With that finished for the moment I turned to sanding the smooth portions of the bowl. I used my Dremel and sanding drum to flatten out the repaired areas first. I followed up by sanding them with 220 grit sandpaper. The photos below show the bowl at this point in the process. Note that there was no damage to the shank so I left it as is and would match the stain to that once I stained the repaired area. I was pretty happy with the way it was looking.

With that finished for the moment I turned to sanding the smooth portions of the bowl. I used my Dremel and sanding drum to flatten out the repaired areas first. I followed up by sanding them with 220 grit sandpaper. The photos below show the bowl at this point in the process. Note that there was no damage to the shank so I left it as is and would match the stain to that once I stained the repaired area. I was pretty happy with the way it was looking.

I was ready to stain the undercoat on the bowl. I decided to use a black aniline stain for the rusticated part of the bowl and for the undercoat on the smooth sides and rim top. Black does a great job hiding the kind of repairs that I had to do with this briar. I applied the stain and flamed with a lighter. I repeated the process to ensure the coverage was thorough. I flamed it again and set it aside to dry while I had some dinner.

I was ready to stain the undercoat on the bowl. I decided to use a black aniline stain for the rusticated part of the bowl and for the undercoat on the smooth sides and rim top. Black does a great job hiding the kind of repairs that I had to do with this briar. I applied the stain and flamed with a lighter. I repeated the process to ensure the coverage was thorough. I flamed it again and set it aside to dry while I had some dinner. I took photos of the bowl at this point to show the coverage of the black stain on the rustication and the undercoat on the smooth areas.

I took photos of the bowl at this point to show the coverage of the black stain on the rustication and the undercoat on the smooth areas.

After dinner I wiped down the smooth areas with isopropyl alcohol on a cotton pad to make them more transparent and show the grain. I then gave the smooth areas a coat of Mahogany stain using my stain pens to get into the transition areas and control the flow better. The combination of the black undercoat and the Mahogany matched the original shank colour!

After dinner I wiped down the smooth areas with isopropyl alcohol on a cotton pad to make them more transparent and show the grain. I then gave the smooth areas a coat of Mahogany stain using my stain pens to get into the transition areas and control the flow better. The combination of the black undercoat and the Mahogany matched the original shank colour!

When that coat of stain had cured I polished the smooth portions of the bowl with micromesh sanding pads. One of the pains of this process is all the flaws show up in the initial sanding. You can see my repairs in some spots but hopefully they bill disappear a bit in the polishing.

When that coat of stain had cured I polished the smooth portions of the bowl with micromesh sanding pads. One of the pains of this process is all the flaws show up in the initial sanding. You can see my repairs in some spots but hopefully they bill disappear a bit in the polishing.

I was really happy with the right side of the bowl. The repairs virtually disappeared in the staining and sanding. I worked on the left side a little more. I sanded the offending areas of the transition with 400 grit wet dry sandpaper and restained the area. I worked through all of the micromesh pads another time on that area. I was happy with the finished looked at this point. I rubbed the finish down with Before & After Restoration Balm. I worked it into the smooth areas on the bowl and rim top with my fingertips and the rusticated areas with a horsehair shoe brush. The product cleans, protects and enlivens the briar. I let it sit for about 30 minutes and buffed it off with a cotton cloth. The photos below show the bowl at this point… it is a far cry from the dog eaten bowl that I started with — at least I think it is ;).

I was really happy with the right side of the bowl. The repairs virtually disappeared in the staining and sanding. I worked on the left side a little more. I sanded the offending areas of the transition with 400 grit wet dry sandpaper and restained the area. I worked through all of the micromesh pads another time on that area. I was happy with the finished looked at this point. I rubbed the finish down with Before & After Restoration Balm. I worked it into the smooth areas on the bowl and rim top with my fingertips and the rusticated areas with a horsehair shoe brush. The product cleans, protects and enlivens the briar. I let it sit for about 30 minutes and buffed it off with a cotton cloth. The photos below show the bowl at this point… it is a far cry from the dog eaten bowl that I started with — at least I think it is ;).

I set the bowl aside and turned to the stem to address the issues that were on the top and underside. I filled in the tooth marks on the stem with clear super glue. I generally overfill them a bit so that it takes into account the shrinkage that occurs as the repair cures.

I set the bowl aside and turned to the stem to address the issues that were on the top and underside. I filled in the tooth marks on the stem with clear super glue. I generally overfill them a bit so that it takes into account the shrinkage that occurs as the repair cures. Once the repairs had cured I sanded them smooth to start to blend them in with the surround acrylic of the stem. I sanded the repairs on both sides with a folded piece of 220 sandpaper and started polishing with 400 grit wet dry sandpaper.

Once the repairs had cured I sanded them smooth to start to blend them in with the surround acrylic of the stem. I sanded the repairs on both sides with a folded piece of 220 sandpaper and started polishing with 400 grit wet dry sandpaper. I rubbed the stem down with Denicare Mouthpiece Polish – a red gritty paste a lot like Tripoli to polish it after the 400 grit sandpaper. I rub it on with my fingertips and work it into the vulcanite and buff it off with a cloth. It does a great job before I polish it further with the micromesh pads.

I rubbed the stem down with Denicare Mouthpiece Polish – a red gritty paste a lot like Tripoli to polish it after the 400 grit sandpaper. I rub it on with my fingertips and work it into the vulcanite and buff it off with a cloth. It does a great job before I polish it further with the micromesh pads. I polished the stem with micromesh sanding pads – dry sanding with 1500-12000 grit sanding pads. I wiped the stem down after each sanding pad with a cloth containing some Obsidian Oil. I finished polishing it with Before & After Pipe Stem Polish – both Fine and Extra Fine and buffed it off with a cotton cloth.

I polished the stem with micromesh sanding pads – dry sanding with 1500-12000 grit sanding pads. I wiped the stem down after each sanding pad with a cloth containing some Obsidian Oil. I finished polishing it with Before & After Pipe Stem Polish – both Fine and Extra Fine and buffed it off with a cotton cloth.

The next steps in this restoration were ones that I have been looking forward to. I was glad to reunite the bowl and stem and see what the finished pipe looked like. I polished the silver with a jeweler’s cloth and buffed the bowl and the stem with Blue Diamond on the buffing wheel. I used a light touch on the rusticated portion as I did not want to fill in the rustication with the product. I gave the bowl multiple coats of Conservator’s Wax and the stem multiple coats of carnauba wax. I carefully buffed the entire pipe with a clean buffing pad to raise the shine. I finished buffing with a microfiber cloth to deepen the shine. The finished pipe looks a lot better than dog chewed pipe that I started with. I am happy with the finished look at this point. While the repairs to the smooth areas show a bit they are smooth. The leather like rustication works well with the finish on the bowl in my opinion. The finished Ser Jacopo L1 Billiard is shown in the photos below. The dimensions of the pipe are Length: 6 ½ inches, Height: 2 ¼ inches, Outside diameter of the bowl: 1 ½ inches, Chamber diameter: ¾ of an inch. This should be a great pipe once it is broken in. The rustication on the base and front give it a very tactile feel that should only be better as it heats up during a smoke. This one will go on the rebornpipes store shortly. If you are interested in it let me know. Thanks for reading this blog and my reflections on the pipe while I worked on it.

The next steps in this restoration were ones that I have been looking forward to. I was glad to reunite the bowl and stem and see what the finished pipe looked like. I polished the silver with a jeweler’s cloth and buffed the bowl and the stem with Blue Diamond on the buffing wheel. I used a light touch on the rusticated portion as I did not want to fill in the rustication with the product. I gave the bowl multiple coats of Conservator’s Wax and the stem multiple coats of carnauba wax. I carefully buffed the entire pipe with a clean buffing pad to raise the shine. I finished buffing with a microfiber cloth to deepen the shine. The finished pipe looks a lot better than dog chewed pipe that I started with. I am happy with the finished look at this point. While the repairs to the smooth areas show a bit they are smooth. The leather like rustication works well with the finish on the bowl in my opinion. The finished Ser Jacopo L1 Billiard is shown in the photos below. The dimensions of the pipe are Length: 6 ½ inches, Height: 2 ¼ inches, Outside diameter of the bowl: 1 ½ inches, Chamber diameter: ¾ of an inch. This should be a great pipe once it is broken in. The rustication on the base and front give it a very tactile feel that should only be better as it heats up during a smoke. This one will go on the rebornpipes store shortly. If you are interested in it let me know. Thanks for reading this blog and my reflections on the pipe while I worked on it.