by Steve Laug

The next pipe on the table is one that we picked up in the lot from a good friend in Barrington, Rhode Island, USA on 08/22/2024. The smooth finish on this English made pipe and the Comoy’s stamping are what caught our eye. It is stamped on the left side of the shank and reads Comoy’s [over] Virgin [over] Straight Grain. On the right side it is Made in London in a circle [over] England. It is stamped with the shape number 66 near the bowl shank joint. There is an uppercase G on the underside of the shank ahead of the silver band. It has a classic Walnut Brown stain on the smooth finish that is a stark contrast to ornate silver band and vulcanite stem. The silver band gives the shank a length that added to the taper stem makes for a Liverpool shaped pipe. The bowl was lightly caked, though it also seems to have been recently reamed. The inner edge and the top look good though there is some darkening and some spots of lava on the top. The stem was lightly oxidized and had tooth chatter on both sides ahead of the button. The Comoy’s C logo looks to be one piece and was inset on the left side of the stem and looks to be in good condition. Jeff took some photos of the pipe to show the general condition of the pipe before he started his clean up.

He took some photos of the rim top and bowl from various angles to give me a clear picture of the condition of the rim top and bowl. It is quite clean and the inside of the bowl is lightly caked. He included photos that show the top and underside of the stem. It is as described above.

He took some photos of the rim top and bowl from various angles to give me a clear picture of the condition of the rim top and bowl. It is quite clean and the inside of the bowl is lightly caked. He included photos that show the top and underside of the stem. It is as described above.

Jeff took some photos of the sides and heel of the bowl to show the condition of the finish on the pipe. The photos showed some great grain around the bowl and shank even with the grime in the finish. It is a great looking piece of briar.

Jeff took some photos of the sides and heel of the bowl to show the condition of the finish on the pipe. The photos showed some great grain around the bowl and shank even with the grime in the finish. It is a great looking piece of briar.

He took photos of the stamping on the sides of the shank. It was clear and readable as noted above. He did not capture a photo of the G stamp on the underside of the shank. He also captured the stamping on the silver band on the shank end. It is also clear. The silver is hallmarked which should help with dating this pipe.

He took photos of the stamping on the sides of the shank. It was clear and readable as noted above. He did not capture a photo of the G stamp on the underside of the shank. He also captured the stamping on the silver band on the shank end. It is also clear. The silver is hallmarked which should help with dating this pipe.

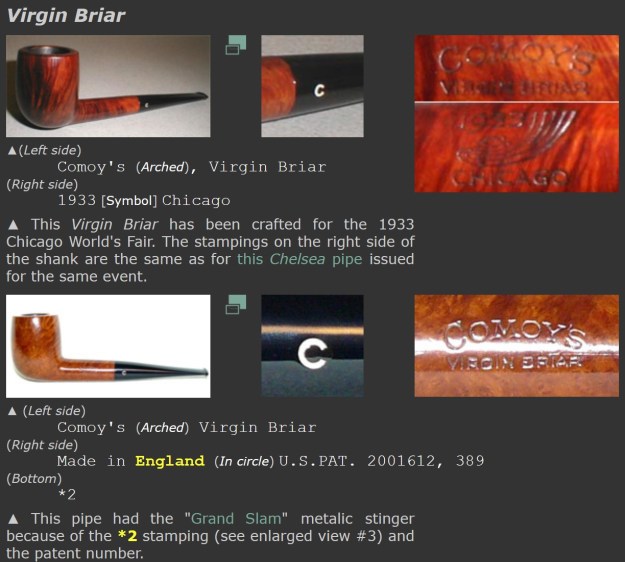

I looked on Pipephil’s site for information on the Comoy’s Virgin Straight Grain line and found the following information on pipes stamped Virgin Briar. I have included a screen capture below (http://www.pipephil.eu/logos/en/logo-comoy.html). It is interesting that the Virgin Briar originally came out in 1933 and by 1965 was no longer listed in the Comoy’s catalogues. It is different from the one I have as it is not stamped Virgin Briar and the Comoy’s is not arched but the C on the stem is similar in terms of thinness.

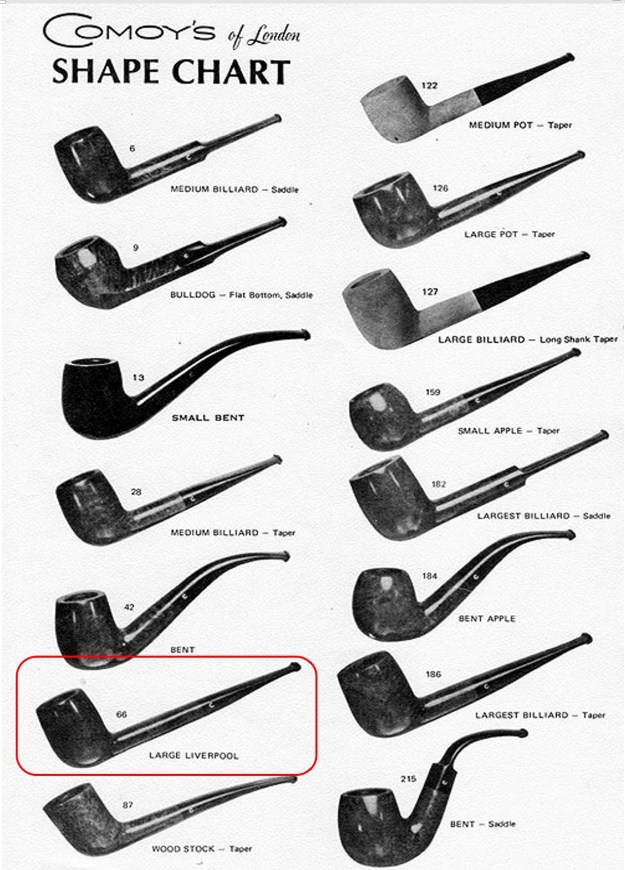

I looked on Pipephil’s site for information on the Comoy’s Virgin Straight Grain line and found the following information on pipes stamped Virgin Briar. I have included a screen capture below (http://www.pipephil.eu/logos/en/logo-comoy.html). It is interesting that the Virgin Briar originally came out in 1933 and by 1965 was no longer listed in the Comoy’s catalogues. It is different from the one I have as it is not stamped Virgin Briar and the Comoy’s is not arched but the C on the stem is similar in terms of thinness. I also went to the the Comoy’s article on Pipedia and found nothing in the great historical article that was pertinent. I did find a shape chart that listed the 66 as a Large Liverpool. I have included a screen capture of the page that included that shape number. I have outlined it in red in the photo included below(https://pipedia.org/images/d/d7/Shape_Chart_1975_1.jpg).

I also went to the the Comoy’s article on Pipedia and found nothing in the great historical article that was pertinent. I did find a shape chart that listed the 66 as a Large Liverpool. I have included a screen capture of the page that included that shape number. I have outlined it in red in the photo included below(https://pipedia.org/images/d/d7/Shape_Chart_1975_1.jpg). I turned to the article on Pipedia about dating Comoy’s pipes but the style of the stamping (https://pipedia.org/index.php?title=Comoy%27s_Dating_Guide#1917_to_the_end_of_the_1930.27s_.28at_least_1938.29). I have included the section in the screen capture below that date this pipe to the 1930s.

I turned to the article on Pipedia about dating Comoy’s pipes but the style of the stamping (https://pipedia.org/index.php?title=Comoy%27s_Dating_Guide#1917_to_the_end_of_the_1930.27s_.28at_least_1938.29). I have included the section in the screen capture below that date this pipe to the 1930s.

F rom the 1950s – Now the Comoy’s stamp can be found in three variants:

rom the 1950s – Now the Comoy’s stamp can be found in three variants:

- A simple block-letter style without serifs but with the C larger than the other letters and the apostrophe before the “S”.

- A return to the slightly more fancy block letters with serifs and the apostrophe. (It seems that some grades carried different stamps, or at least that the stamping changed in different years for some grades.)

- A simple block-letter style without serifs and without the apostrophe and with the “C” the same size as the rest of the letters. This stamp was probably not used very long.

- A simple block-letter style without serifs but with the apostrophe before the “S” and with the “C” the same size as the rest of the letter

Made in London England

Appears in two versions. This is again stamped in a circle with “MADE” at the top, “IN” in the middle, and “LONDON” at the bottom, with “ENGLAND” in a straight line beneath. It can be assumed that this stamp was first used in the export drive in the early 1950s. On a Bulldog Sandblast from the early 50s the Comoy name no. 2 above was used together with “MADE IN LONDON” over “ENGLAND”. There are no known examples of pre-WW II Comoy’s stamped in this way. The second version is the same as above but in a “rugby ball ” shape. This shape is verified on Comoy´s “Extraordinaire” pipes.

Appears in two versions. This is again stamped in a circle with “MADE” at the top, “IN” in the middle, and “LONDON” at the bottom, with “ENGLAND” in a straight line beneath. It can be assumed that this stamp was first used in the export drive in the early 1950s. On a Bulldog Sandblast from the early 50s the Comoy name no. 2 above was used together with “MADE IN LONDON” over “ENGLAND”. There are no known examples of pre-WW II Comoy’s stamped in this way. The second version is the same as above but in a “rugby ball ” shape. This shape is verified on Comoy´s “Extraordinaire” pipes.

That article gave me some helpful information. I knew that the pipe the stamping on the shank of the pipe dated as post 1950. The 1950s stamping of the Comoy’s stamp was as noted above. The 66 shape number was tied to a Large Liverpool with a taper stem. I still needed to check on the Silver hallmarks but so far I had some progress.

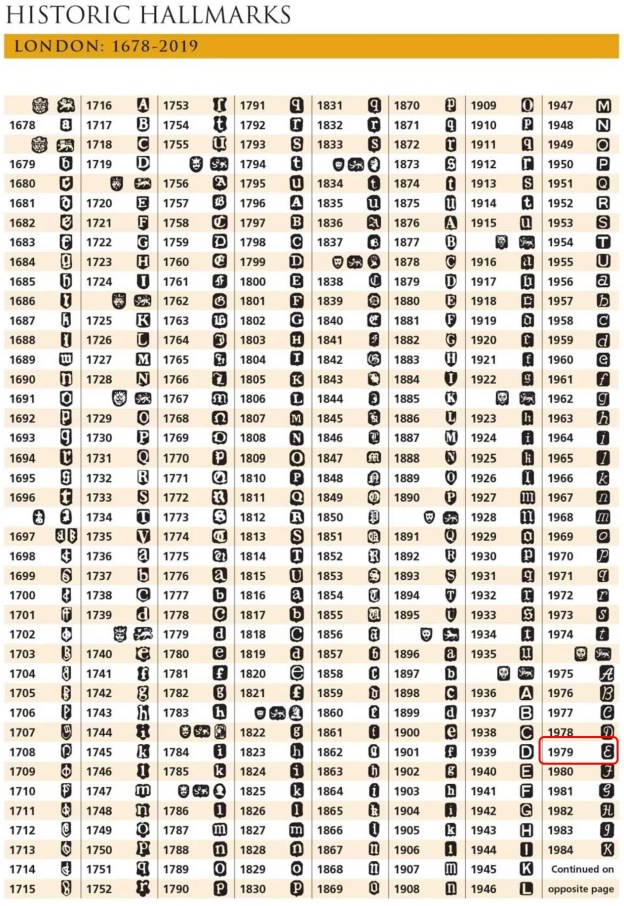

Now to look at the silver hallmarks. The hallmarking system in England comprises a series of symbols and numbers, including letters, numbers, and symbols that indicate the silver’s purity, the date of manufacture, and the location where the item was hallmarked. Each hallmark includes several symbols, such as the maker’s mark, standard mark, assay office mark, and date letter. The first on this silver band is the Rampant Lion which signifies the quality of the Sterling Silver in the band. The second is a leopard’s head which signifies the city of London, England as the location of the assay office. The third hallmark is the letter E in an italicized cursive style script that helps establish the date of the silver. The HC in the box above the hallmarks is the silversmith’s initials and in this case are those of Henri Comoy.

Now to look at the silver hallmarks. The hallmarking system in England comprises a series of symbols and numbers, including letters, numbers, and symbols that indicate the silver’s purity, the date of manufacture, and the location where the item was hallmarked. Each hallmark includes several symbols, such as the maker’s mark, standard mark, assay office mark, and date letter. The first on this silver band is the Rampant Lion which signifies the quality of the Sterling Silver in the band. The second is a leopard’s head which signifies the city of London, England as the location of the assay office. The third hallmark is the letter E in an italicized cursive style script that helps establish the date of the silver. The HC in the box above the hallmarks is the silversmith’s initials and in this case are those of Henri Comoy.

I turned to a blog on Historic Hallmarks – London 1678-2019 to determine the date of this pipe (https://huntvintage.co/blog/how-to-identify-silver-marks). I drew a red box around the date on this one – it is from 1979 as the hallmark matches the style of the E below. Since Jeff always follows the same pattern of work in his cleanup we do not include photos but rather just a simple summary. Jeff reamed the bowl with a PipNet pipe reamer and followed up with a Savinelli Fitsall pipe knife to remove the cake. He scrubbed out the mortise and the airway in the shank and the stem with alcohol, cotton swabs and pipe cleaners. He scrubbed the exterior of the bowl, rim, shank and stem with a tooth brush and Murphy’s Oil Soap to remove the oils and tars on the rim and the grime on the finish of the bowl. He rinsed it under running water. He dried it off with a soft cloth. He was able to remove the lava build up on the rim top and you could see the damages to the top and edges of the rim. I think this pipe may well been before we worked with Mark Hoover’s Before & After Deoxidizer so he cleaned the internals and externals. The stem was clean but lightly oxidized. I took photos of what the pipe looked like when I brought to my worktable.

Since Jeff always follows the same pattern of work in his cleanup we do not include photos but rather just a simple summary. Jeff reamed the bowl with a PipNet pipe reamer and followed up with a Savinelli Fitsall pipe knife to remove the cake. He scrubbed out the mortise and the airway in the shank and the stem with alcohol, cotton swabs and pipe cleaners. He scrubbed the exterior of the bowl, rim, shank and stem with a tooth brush and Murphy’s Oil Soap to remove the oils and tars on the rim and the grime on the finish of the bowl. He rinsed it under running water. He dried it off with a soft cloth. He was able to remove the lava build up on the rim top and you could see the damages to the top and edges of the rim. I think this pipe may well been before we worked with Mark Hoover’s Before & After Deoxidizer so he cleaned the internals and externals. The stem was clean but lightly oxidized. I took photos of what the pipe looked like when I brought to my worktable.

I took close up photos of the bowl, rim top and stem to show how clean the pipe was. The bowl was clean and the rim top and the inner edge look beautiful. The stem was clean and the tooth marks on the topside are visible. The chatter is light and hardly visible.

I took close up photos of the bowl, rim top and stem to show how clean the pipe was. The bowl was clean and the rim top and the inner edge look beautiful. The stem was clean and the tooth marks on the topside are visible. The chatter is light and hardly visible. I took photos of the stamping on the sides of the shank. It is very clear and readable and read as noted above. I also removed the stem from the shank and took photos of the pipe to show the look of the parts.

I took photos of the stamping on the sides of the shank. It is very clear and readable and read as noted above. I also removed the stem from the shank and took photos of the pipe to show the look of the parts.

I polished the bowl and shank with 1500-12000 grit micromesh sanding pad – dry sanding it with the pads. I wiped the bowl down with a damp cloth after each pad. It began to take on a deep shine.

I polished the bowl and shank with 1500-12000 grit micromesh sanding pad – dry sanding it with the pads. I wiped the bowl down with a damp cloth after each pad. It began to take on a deep shine.

The exterior of the bowl look better after sanding. I worked some Before & After Restoration Balm into the briar with my finger tips. I let it sit on the bowl for 10 minutes and then buffed it off with a paper towel and soft cloth. The product is a great addition to the restoration work. It enlivens, enriches and protects the briar while giving it a deep glow. It is a product I use on every pipe I restore.

The exterior of the bowl look better after sanding. I worked some Before & After Restoration Balm into the briar with my finger tips. I let it sit on the bowl for 10 minutes and then buffed it off with a paper towel and soft cloth. The product is a great addition to the restoration work. It enlivens, enriches and protects the briar while giving it a deep glow. It is a product I use on every pipe I restore.

I polished the silver band with a jeweller’s cloth to remove the tarnish and protect the silver from further tarnishing. It really took on a rich shine.

I polished the silver band with a jeweller’s cloth to remove the tarnish and protect the silver from further tarnishing. It really took on a rich shine.

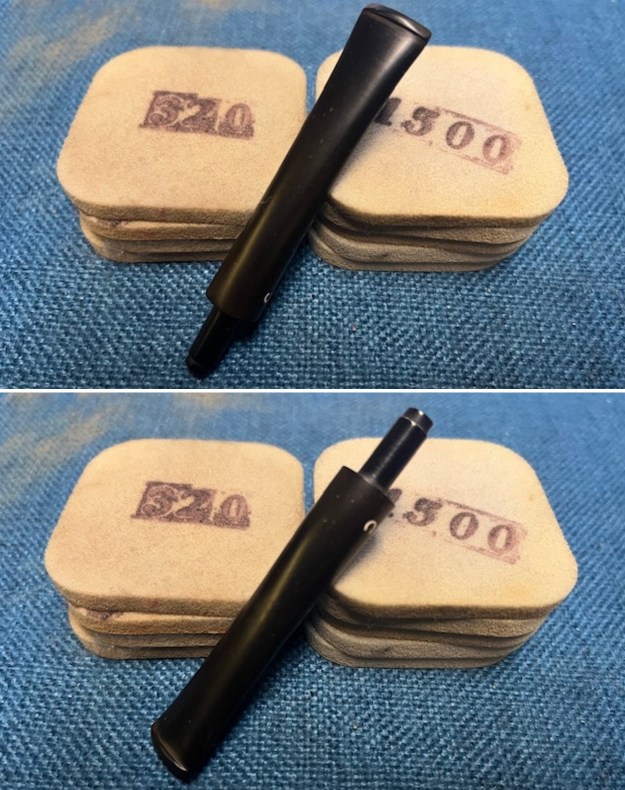

I set the bowl aside and turned to the stem. I sanded the it with 320-3500 grit sanding pads and wiped the stem down after each pad with some Obsidian Oil on a cloth. The shine is coming back beautifully.

I set the bowl aside and turned to the stem. I sanded the it with 320-3500 grit sanding pads and wiped the stem down after each pad with some Obsidian Oil on a cloth. The shine is coming back beautifully. I polished it with micromesh sanding pads – dry sanding with 1500-12000 grit pads and wiping the surface down with Obsidian Oil after each sanding pad. It is really shining. I polished it further with Before & After Stem Polish – both Fine and Extra Fine. I gave it another coat of Obsidian Oil to finish this step.

I polished it with micromesh sanding pads – dry sanding with 1500-12000 grit pads and wiping the surface down with Obsidian Oil after each sanding pad. It is really shining. I polished it further with Before & After Stem Polish – both Fine and Extra Fine. I gave it another coat of Obsidian Oil to finish this step.

This Comoy’s Virgin Straight Grain 66 Liverpool with a vulcanite taper stem is a great looking pipe now that it has been restored. The beautifully grained finish really works well with the shape and the polished finish is stunning. I put the stem back on the bowl and carefully buffed the bowl and the stem with Blue Diamond on the buffing wheel. I gave the bowl and the stem multiple coats of carnauba wax on the buffing wheel and followed that by buffing the entire pipe with a clean buffing pad. I hand buffed the pipe with a microfiber cloth to deepen the shine. I wiped down the Sterling Silver band with a jeweller’s cloth to protect and polish it. The finished 1979 Comoy’s Virgin Straight Grain Liverpool fits nicely in the hand and feels great. Give the finished pipe a look in the photos below. The dimensions of the pipe are Length: 6 inches, Height: 1 ¾ inches, Outside diameter of the bowl: 1 ¼ inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 36 grams /1.23 ounces. I will be putting it on the rebornpipes store in the British Pipe Makers Section shortly. Let me know via email or a message if you are interested in adding this pipe to your collection.

This Comoy’s Virgin Straight Grain 66 Liverpool with a vulcanite taper stem is a great looking pipe now that it has been restored. The beautifully grained finish really works well with the shape and the polished finish is stunning. I put the stem back on the bowl and carefully buffed the bowl and the stem with Blue Diamond on the buffing wheel. I gave the bowl and the stem multiple coats of carnauba wax on the buffing wheel and followed that by buffing the entire pipe with a clean buffing pad. I hand buffed the pipe with a microfiber cloth to deepen the shine. I wiped down the Sterling Silver band with a jeweller’s cloth to protect and polish it. The finished 1979 Comoy’s Virgin Straight Grain Liverpool fits nicely in the hand and feels great. Give the finished pipe a look in the photos below. The dimensions of the pipe are Length: 6 inches, Height: 1 ¾ inches, Outside diameter of the bowl: 1 ¼ inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 36 grams /1.23 ounces. I will be putting it on the rebornpipes store in the British Pipe Makers Section shortly. Let me know via email or a message if you are interested in adding this pipe to your collection.

As always, I encourage your questions and comments as you read the blog. Thanks to each of you who are reading this blog. Remember we are not pipe owners; we are pipe men and women who hold our pipes in trust until they pass on into the trust of those who follow us.