Guest Blog by Robert M. Boughton

Member, North American Society of Pipe Collectors

http://www.naspc.org

http://www.roadrunnerpipes.com

http://about.me/boughtonrobert

Photos © the Author

Bruno Antony: Each fellow does the other fellow’s murder. Then there is nothing to connect them. The one who had the motive isn’t there. Each fellow murders a total stranger. Like you do my murder and I do yours…For example, your wife, my father. Criss-cross.

― from “Strangers on a Train” (1951), directed by Alfred Hitchcock, screenplay by Raymond Chandler and Czenzi Ormonde, starring Farley Granger and Robert Walker [Bruno]

INTRODUCTION

The movie was one of Hitchcock’s greatest and a favorite of mine. How could it not be, with the legendary detective novelist Raymond Chandler as the top word-man? But this is not a blog about swapping murders. It does concern the swapping of a bit, however, or to be more accurate, the removal of one from a basic Peterson’s System Standard in my collection of pipes awaiting more extreme repair, and which won’t be missed before it can be mended, to use for the William Demuth Co. Wellington System Billiard.

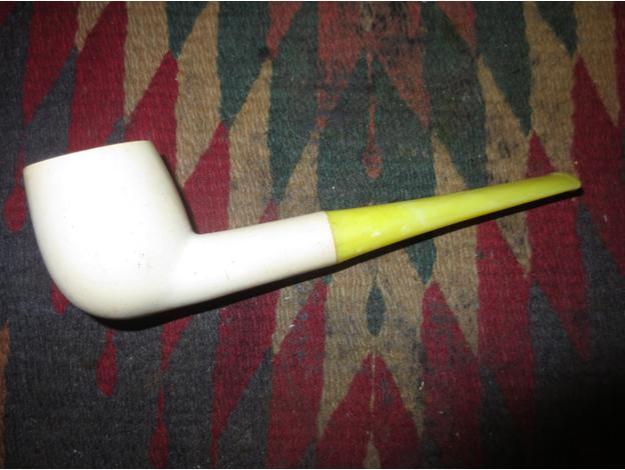

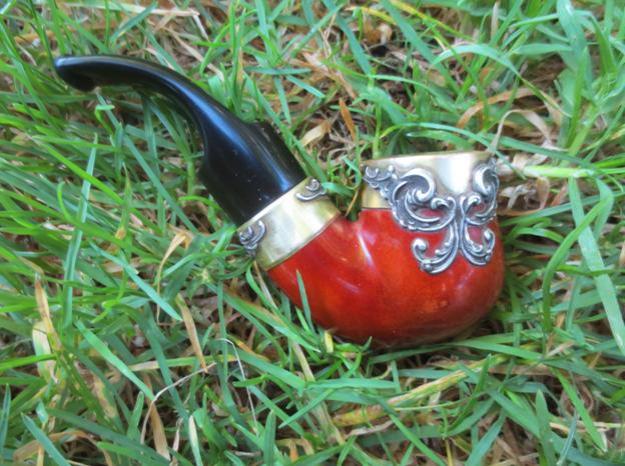

But first, let’s play Find the Pipe in the Lot. No doubt you have spotted it without trouble, or will soon deduce the answer from following photos.

No doubt you have spotted it without trouble, or will soon deduce the answer from following photos.

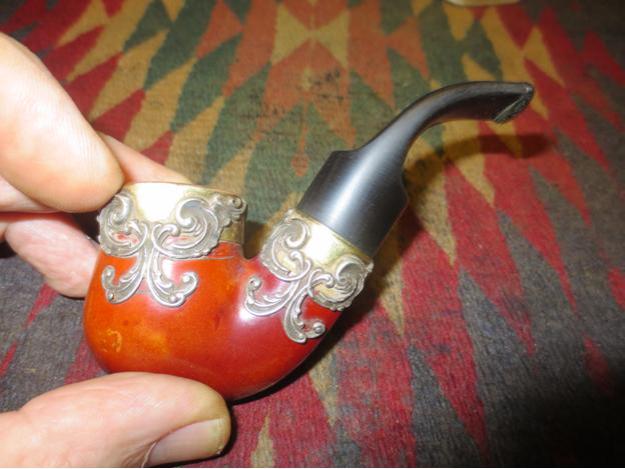

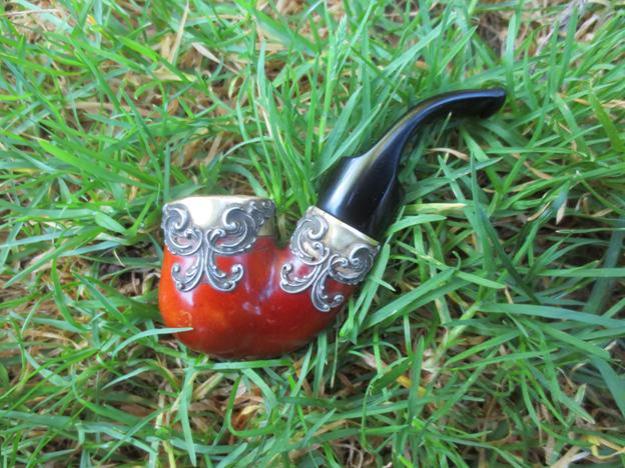

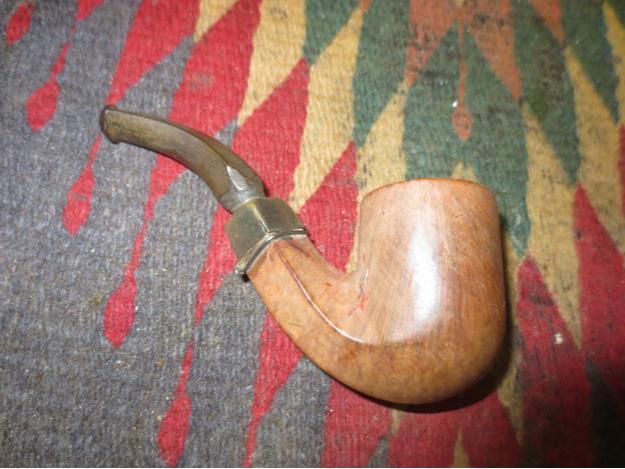

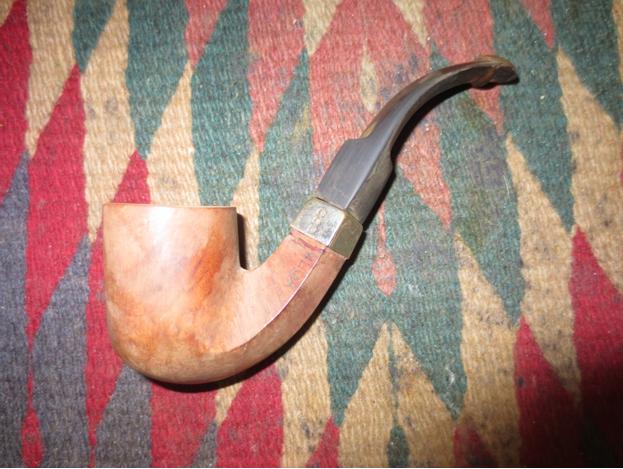

Now for the criss-cross: watch as the bit, at first loose but in place in the shank of the Peterson’s Standard System to the right in photo one, without warning falling to the trademark green sleeve along with the battered band in photo two. Look long enough, and I guarantee you’ll see the moment of selfless sacrifice for the blighted, bit-less predicament of the once proud, near-twin WDC close by. And then, in photo three – the miraculous transplant to the WDC after the donated organ has embraced its new host body, at least tentatively.

A few words concerning the William Demuth Co. are in order, for those not familiar with its illustrious history. Demuth (1835-1911) entered the U.S. as an emigrant from Germany with no money when he was 16 and worked a number of odd jobs. His break came when he attained the position of clerk for a tobacco products trade company. Demuth founded his own company in Brooklyn, New York in 1862, two years into the Civil War, when he was only 27.

A few words concerning the William Demuth Co. are in order, for those not familiar with its illustrious history. Demuth (1835-1911) entered the U.S. as an emigrant from Germany with no money when he was 16 and worked a number of odd jobs. His break came when he attained the position of clerk for a tobacco products trade company. Demuth founded his own company in Brooklyn, New York in 1862, two years into the Civil War, when he was only 27.

Success was rapid, leading to friendships with such prominent figures as James A. Garfield. [Garfield was inaugurated as the twentieth U.S. president in 1881 after winning by the narrowest popular vote margin in history, a mere 9,464 ballots, but with an extra 59 Electoral College votes. He served only four months before he was gunned down by a single shot aimed by Charles Julius Guiteau, an American lawyer denied an ambassadorship to France(evidently for good cause, as shooting the president on July 2, four months into his term, was not very diplomatic). Although Garfield lingered for about two and a half months, the assassin’s bullet caused the blood poisoning to which he succumbed. Guiteau was hanged several days short of a year after the ultimate assassination.]

At the Presidential Inauguration, Demuth presented Garfield with two meerschaum pipes, one in Garfield’s image and the other in the new First Lady’s. The friendship of the two men led to Demuth’s commissioning of a partial presidential line of pipes. But the linchpin WDC pipe was the Wellington, which lasted beyond the company’s own lifetime. Having become a subsidiary of S.M. Frank & Co. in 1937, WDC continued until the final day of 1972. The Wellington, however, was still offered in Frank’s catalog until 1976 and even had a brief reprise in the mid-1980s by way of consumer-direct sales.

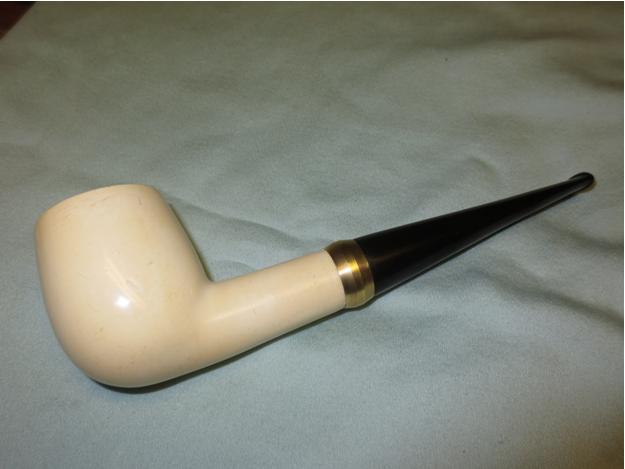

Here are two other Wellington’s, the first courtesy of pipephil.eu and the second from pipedia.org. RESTORATION

RESTORATION

In a sentence, this restoration was more about the stem than anything else. I had decided to go with a perfect replacement from a Peterson’s Standard System pipe in my personal collection. Then, when I donned my Dollar Store 3.75X glasses for a “final” close inspection, I cringed at the sight of the faint black outline of the Peterson’s P, shown below, now filled in with a white china marker.

In a sentence, this restoration was more about the stem than anything else. I had decided to go with a perfect replacement from a Peterson’s Standard System pipe in my personal collection. Then, when I donned my Dollar Store 3.75X glasses for a “final” close inspection, I cringed at the sight of the faint black outline of the Peterson’s P, shown below, now filled in with a white china marker. Note the correct shape of this bit from lip to tenon. My next brainstorm was to sand off the P, and in fact set out to do so when I came to my senses. What can I say? Sometimes I have the stupidest ideas. And so I opted to let the buck stop here and repair the bit I took off of the Peterson’s System Standard shown in the criss-cross photos of the Introduction. That System Standard needs serious work, also; not only a new, genuine bit but a replacement matching band. I will tackle that one when I have the new bit and band and am up to speed on the process of banding.

Note the correct shape of this bit from lip to tenon. My next brainstorm was to sand off the P, and in fact set out to do so when I came to my senses. What can I say? Sometimes I have the stupidest ideas. And so I opted to let the buck stop here and repair the bit I took off of the Peterson’s System Standard shown in the criss-cross photos of the Introduction. That System Standard needs serious work, also; not only a new, genuine bit but a replacement matching band. I will tackle that one when I have the new bit and band and am up to speed on the process of banding.

With a happy glow of contentment in the pit of my belly, I replaced the above bit, with the P filled in at last, on its rightful pipe in the stand-up, two sided bookshelf with doors where I store most of my collection, and opted to proceed with this restoration by doing the long, tedious work of applying layers of black Super Glue to build up the thinner, bottom section of the bit that lacks a tenon. As a result, while the rest of the Wellington has been finished for about ten days, the old bit, mangled by some wannabe pipe fixer, took days of patient layering, sanding and micro-meshing each phase, then polishing on the buffers, and was only completed moments ago.

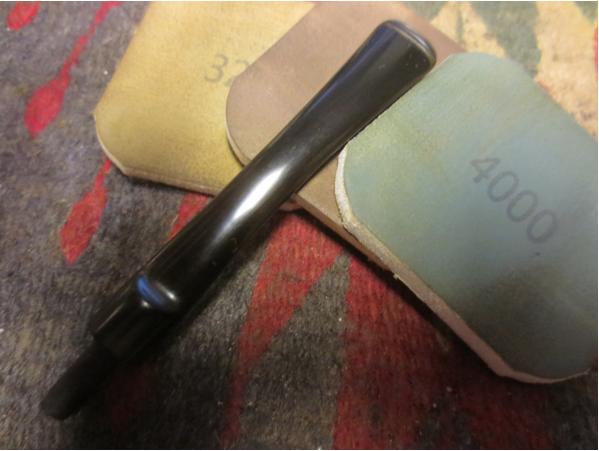

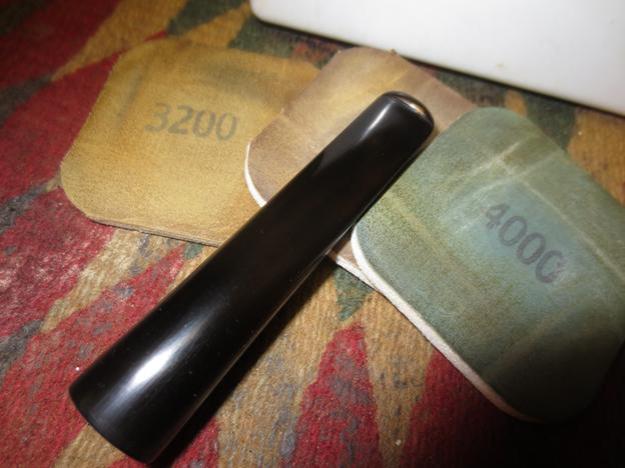

I started the bit on its way, which I knew would take some days, by filing it to a uniform tapering roundness and sanding with 150- and 320-grit paper before micro-meshing from 1500-4000.

After that I gave the entire surface of the bit below the bulge the first of four thick coats of black Super Glue. Aware of the risk, I then stripped the old finish with as short as possible of an Everclear soak.

After that I gave the entire surface of the bit below the bulge the first of four thick coats of black Super Glue. Aware of the risk, I then stripped the old finish with as short as possible of an Everclear soak.

Leaving the bowl and shank for about 10 minutes in the alcohol and time enough to dry, I reamed and sanded the chamber to the smoothness of a chamois cloth and retorted the pipe using the bit from my own Peterson’s System Standard. Starting with super fine 0000 steel wool, then micromesh every step from 1500-4000, the wood and steel band had a nice natural sheen.

Leaving the bowl and shank for about 10 minutes in the alcohol and time enough to dry, I reamed and sanded the chamber to the smoothness of a chamois cloth and retorted the pipe using the bit from my own Peterson’s System Standard. Starting with super fine 0000 steel wool, then micromesh every step from 1500-4000, the wood and steel band had a nice natural sheen.

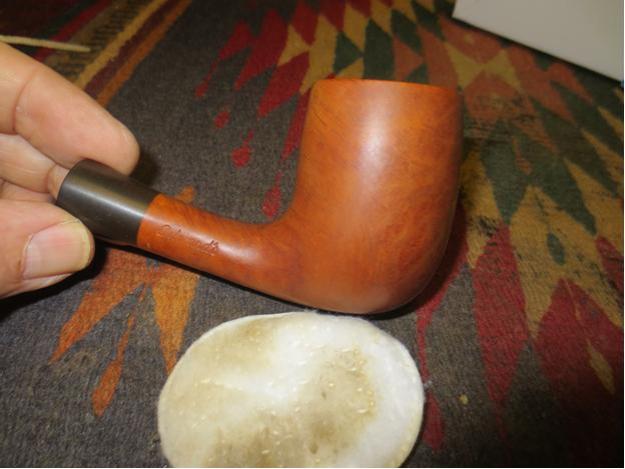

Without stain, using the natural rich color of the briar, I prepared the bowl and shank for the coming test to see if the bit worked out, the likelihood of which I had doubts, by buffing it with white Tripoli, White Diamond and two coats of carnauba, using the plain cloth buffer between each, of course.

Without stain, using the natural rich color of the briar, I prepared the bowl and shank for the coming test to see if the bit worked out, the likelihood of which I had doubts, by buffing it with white Tripoli, White Diamond and two coats of carnauba, using the plain cloth buffer between each, of course.

The following days seemed to drag with each successive layer of black Super Glue and the long drying time followed by sanding with 200-grit paper and micro-meshing up the scale each time. But in the end, the result was worth the time and effort, considerable and somewhat unnerving as they were.

CONCLUSION

CONCLUSION

Again, this battle was far more about trying to recover an available bit, so that it would fit and lock in the shank, rather than any problems I faced with the bowl and shank. As the bit was when I received the Pete System Standard with which it came, well, the bit was the tip of the iceberg with that future project. In fact, my friend and mentor, Chuck, recommended that I send it to someone he knows in Denver – not so much because the task was beyond my skills but that it was what he would do if he needed a new Peterson’s bent system pipe stem with the right measurements as well as a replacement band of the appropriate type. I was fortunate with the WDC in that it called for a bit designed after the Pete System variety.

Of course I would have preferred to place a perfect, like-new bit in this great WDC Wellington, but the personal reward came in finding out that I could take what I had and make it work.

I think I’ll do the same with the estate Peterson’s Standard System that gave its bit for this pipe, after I’ve received the new parts in the mail.

I scrubbed the bowl with Murphy’s Oil Soap and polished it with a microfibre cloth. There was a small hairline crack on the left side of the bowl coming from the rim downward about one half-inch. It was sealed so it was not currently a problem that I would need to deal with. I took some photos of the newly banded stem and the polished bowl to show the new look of the pipe. The bowl is quite thin so it will be a hot one to hold. It will need to be smoked slowly to keep it cool.

I scrubbed the bowl with Murphy’s Oil Soap and polished it with a microfibre cloth. There was a small hairline crack on the left side of the bowl coming from the rim downward about one half-inch. It was sealed so it was not currently a problem that I would need to deal with. I took some photos of the newly banded stem and the polished bowl to show the new look of the pipe. The bowl is quite thin so it will be a hot one to hold. It will need to be smoked slowly to keep it cool.

I used a coarse needle file to open up the mortise in the shank to accommodate the tenon. I used a Dremel with a sanding drum to reduce the tenon as much as possible. I worked on the mortise to file down the inside of the shank. It took some careful file work to keep the mortise round so that once the opening was sufficient the tenon would not be loose inside.

I used a coarse needle file to open up the mortise in the shank to accommodate the tenon. I used a Dremel with a sanding drum to reduce the tenon as much as possible. I worked on the mortise to file down the inside of the shank. It took some careful file work to keep the mortise round so that once the opening was sufficient the tenon would not be loose inside.

The next photo shows the finished mortise. The files worked well and the newly shaped tenon fit the shank perfectly.

The next photo shows the finished mortise. The files worked well and the newly shaped tenon fit the shank perfectly. I put the stem in place on the bowl and took some photos to get a better look at the new pipe. The newly stemmed pipe actually looked very good. I loved the delicate look of it. The slight bend in the stem worked well with the bowl and allows the pipe to sit upright on a flat surface.

I put the stem in place on the bowl and took some photos to get a better look at the new pipe. The newly stemmed pipe actually looked very good. I loved the delicate look of it. The slight bend in the stem worked well with the bowl and allows the pipe to sit upright on a flat surface.

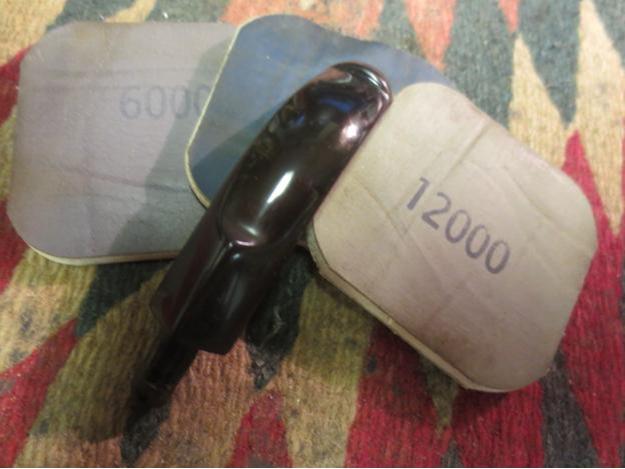

The stem was rough and lightly oxidized. I sanded it with 220 grit sandpaper to loosen the oxidation and then used a medium and a fine grit sanding sponge to smooth out the scratches on the stem. I then wet sanded the stem with 1500-2400 grit micromesh sanding pads and rubbed the stem with Obsidian Oil. I dry sanded it with 3200-4000 grit pads, gave it another coat of oil and then finished sanding with 6000-12000 grit pads. I gave the stem a final coat of Obsidian Oil and let it dry.

The stem was rough and lightly oxidized. I sanded it with 220 grit sandpaper to loosen the oxidation and then used a medium and a fine grit sanding sponge to smooth out the scratches on the stem. I then wet sanded the stem with 1500-2400 grit micromesh sanding pads and rubbed the stem with Obsidian Oil. I dry sanded it with 3200-4000 grit pads, gave it another coat of oil and then finished sanding with 6000-12000 grit pads. I gave the stem a final coat of Obsidian Oil and let it dry.

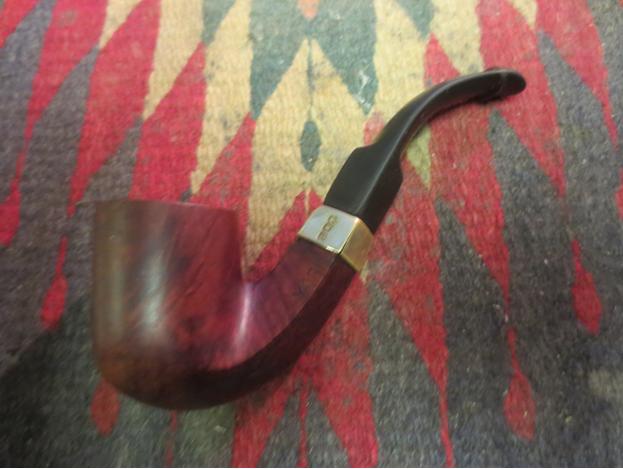

I buffed the stem and bowl lightly with Blue Diamond polish on the wheels and then gave the stem and bowl multiple coats of carnauba wax. I polished it with a clean flannel buff on the wheel making sure to hold the bowl tightly. To have the buffer grab this one and throw it would be a disaster that the pipe would not survive. Once I finished the buffing on the wheel I hand buffed it with a microfibre cloth to raise the final shine. The finished pipe is shown in the photos below. There is some slight coloring forming on the sides of the bowl midway down from the top. I am wondering if the rest of the bowl will also colour with use. The pipe looks really good with the new stem and band. It will fit well in my collection of unique older pieces.

I buffed the stem and bowl lightly with Blue Diamond polish on the wheels and then gave the stem and bowl multiple coats of carnauba wax. I polished it with a clean flannel buff on the wheel making sure to hold the bowl tightly. To have the buffer grab this one and throw it would be a disaster that the pipe would not survive. Once I finished the buffing on the wheel I hand buffed it with a microfibre cloth to raise the final shine. The finished pipe is shown in the photos below. There is some slight coloring forming on the sides of the bowl midway down from the top. I am wondering if the rest of the bowl will also colour with use. The pipe looks really good with the new stem and band. It will fit well in my collection of unique older pieces.