Blog by Robert M. Boughton

https://www.roadrunnerpipes2k.com/

https://www.facebook.com/roadrunnerpipes/

Copyright © Reborn Pipes and the author except as noted

Then I thought, boy, isn’t that just typical? You wait and wait for something, and then when it happens, you feel sad.

— Sharon Creech, U.S. children’s writer, in Absolutely Normal Chaos (1990)

RECAP

In Part 1, I hypothesized that the discontinued manufacture or illegality of certain materials, as well as the dwindling availability and in some cases complete lack of pre-fashioned parts used in antique and other very old pipes, will lead to a serious crisis in restoring these great but often damaged old friends to their original conditions. Without hashing over the details, which I already described in great although still incomplete specificity, I will add that I left out the obvious: none of the materials I discussed is irreplaceable in the sense that an old pipe with a broken amber stem or bone tenon can always be mended with Lucite or Delrin, for example. To emphasize my way of thinking, which I know is shared by many other far more experienced and better practitioners of the art of pipe restoring than I, the thought of needing to resort to such practices except in the most severe cases is unthinkable, or to use a more descriptive word, an anathema to me.

At any rate, having no idea what I was getting into when I began writing the first installment, in the order in which various materials popped into my head, I soon reached a point where more and more endangered items presented. For the sake of not breaking my train of thought any more than necessary on the one I happened to be trying to complete at the moment, I got into the habit of adding new section headings as I proceeded, as a sort of minimal outline. The research alone led me in still newer directions, and so the sections grew in number – not to mention the research, which became so out of hand I almost lost control and never did get all of my sources in good order. In the end, for those reading this who caught Part 1, believe it or not, I cut entire pages from the text and many of the sources that, due to the months spent composing my list of the most endangered materials either no longer applied or were redundant. And still my sources alone took up at least two whole pages of the 24 I submitted to Steve.

Needless to say, as sad as I was to have to face the music, my little list had reached proportions prohibitive of an illustrative restoration to accompany it. This installment will begin the phase describing the first of three projects that demonstrate the growing difficulty of restoring very old pipes to their natural beauty and even one relatively new but vintage example, despite my intentions, as if it were an antique.

INTRODUCTION

Five years ago, Chuck Richards presented the old and wounded but still spirited meerschaum to our Friday night pipe get-together. The group of devoted Albuquerque area pipers being in its heyday at the time, the little tobacconist’s shop where we still meet in lesser numbers was filled beyond fire code capacity. Folding chairs extended the normal smoker’s lounge all the way to the front glass counter, and still they were not enough.

I would regret to point out the business from cigar aficionados we pipe revelers cost the shop’s owner that memorable night, other than the few who were understanding or dogged enough to wend their ways through our standing-room-only mob. But the sales in pipes and tobacco tins, and everything else that goes with them, more than made up for the loss on those evenings that are among my best memories. Time has a way of changing all things, not just the antique meerschaum beauty Chuck passed around for all of us to ogle.

With the innate cunning and flair for dramatic understatement possessed by traveling carny operators of old, Chuck had the entire room enthralled – and yes, I was in the front row, center aisle, agog, right where he wanted me. The panache of Chuck’s delivery was not in what he said of the pipe, however, but the way he appeared to satisfy the rest of the audience with an atypical dearth of anything better than teases, what Deep Throat called leads, at least as far as my hungry ears and eyes could discern. Had I still been a news reporter with orders from my editor to get a good quote, I might have been out of a job.

That old reporter in me was accustomed to listening for diversions, avoidances and spins – every attempt “to deceive, inveigle and obfuscate,” as Special Agent Fox Mulder says in one of his most memorable lines from The X-Files (S4:E3). That good habit must have kicked in to help me pick up on the mesmerizing but fugacious choreography of the show, designed only for the moment and then to be forgotten. All I heard was “an old, now defunct pipe maker or distributor, probably in the U.S., called CPF,” “Best Make.” “still in its original case,” “with amber bit, gold band and broken bone tenon.” But what did he omit and why? During the intervening years, I’ve asked a few of those who were there that night about the occasion, and all of them indeed recollected some small part of the details, but little of substance, that are imprinted into my memory.

And then the act of mass hypnosis was over, the tiny space hot and stuffy, the crush of pipe enthusiasts swelling to the distant and narrow entrance somewhere in the background that was clogged with people coming and going beyond the usual capacity and hours of the shop’s operation, and which sole entry and exit, at any rate, lay beyond several treacherous eddies and straits still out of sight or reach. I was not in my element and wanted to bail but needed to talk to Chuck. With a distinct surreality, his bead bobbed nearby, like a life buoy in a foggy ocean. We smiled at each other in what I felt was a meeting of the minds

I called out to him – shouted as loud as I could – as close to screaming as I ever have. Imagine, not a vacuum such as space, but the opposite: chaotic babble and expansion. Everything else drowned in the roiled sea foam of voices.

“Don’t you know anything more about CPF?”

We were face to face at last, but Chuck didn’t hear a word. Neither did I, for that matter. He even cupped a hand to an ear and gave up, communicating better with a single raised finger that he would come back. When he did so, the crowd thinned out enough for us to hear each other. He said, “I want you to take this home with you and do some research. See what you can find out about CPF on your computer.”

Close your eyes if it helps and imagine the words above being cast upon you by Chuck in his always rich but then suddenly dulcet, soothing, fluid and entrancing tone

While Chuck projected these words to me, I tried my best to focus on his face, but my attention kept straying to the one-hundred-some-odd-year-old meerschaum pipe in its original tan case that looked so secure in his able custody but became more and more fragile and vulnerable as it was passed to mine. Much more was spoken between us that night before I began to understand that the dirty, damaged but reparable and, to me, priceless piece of art and history was not a loaner for research purposes as Chuck had suggested. Some blurry time later I realized he only said that so I would accept the gift from his hand. He knew I never would have touched it otherwise. About then the full truth struck me like a Mack truck with no brakes on a downslope of the Grapevine, a treacherous strip of I-5 in California with the Tejon Pass in its middle: Chuck expected me to restore it.

Much more was spoken between us that night before I began to understand that the dirty, damaged but reparable and, to me, priceless piece of art and history was not a loaner for research purposes as Chuck had suggested. Some blurry time later I realized he only said that so I would accept the gift from his hand. He knew I never would have touched it otherwise. About then the full truth struck me like a Mack truck with no brakes on a downslope of the Grapevine, a treacherous strip of I-5 in California with the Tejon Pass in its middle: Chuck expected me to restore it.

“But I’m not the right man for the job!” I went off like a maxed-out Jake break.

Chuck grinned at me a way only he can and then tried to calm the panic rising in me.

“When you’re ready,” I recall him saying. The rest is hazy.

As soon as I returned home that night, I began my computer research into “CPF tobacco pipes” as Chuck prescribed, and it became apparent that my friend indeed knew more than he let on. As Chuck suggested to the weekly pipe get-together almost six years ago in his circumspect description of the company, CPF was indeed a U.S. venture, in New York. I came across all sorts of conjecture as to the meaning of the three letters, with most agreeing the PF stood for Pipe Factory.

The C, on the other hand, was debated with unusual ferocity even for the very opinionated pipe world. The guesses included Consolidated, Chesterfield and Colossal, among others. There was even one complete rewrite of the truth suggested in a note at the bottom of the Pipedia link below, positing the amazing coincidence of a C.P. Fenner (one of two brothers who made cigarettes) as a viable candidate.

After hours of determined hunting, I was able to conclude with certainty that CPF stood for Colossus Pipe Factory, which enjoyed a relatively brief but glorious run from 1851-c. 1920. Steve later pinpointed the end of the road for CPF as 1915. In that short span of time, CPF, almost certainly employing the Old World skills of European immigrant crafters, made some of the most beautiful meerschaum and briar pipes available at the time. And it was a great time for pipes.

There were three absolute forms of proof that the Colossus Pipe Factory existed, and I later forwarded them to Steve: an antique bill of sale I no longer have, made out to a French company; a letter I found in a long scan of The Jeweler’s Circular issues (August 23, 1899) asking for the name of the pipe company doing business as CPF and receiving the above reply from the editors, confirming the Kaufman Brothers & Bondy connection, and an ad strengthening the tie between CPF and KB&B. Most sources agree KB&B assumed ownership of CPF in 1883. Here are the specific page from the jeweler’s magazine, another ad mentioning CPF, KB&B and Bakelite all in one, and an example of such a pipe.

For the most complete history of CPF, see Steve’s definitive piece in the link in my sources below. Steve’s hard work pulls together all of the available information on CPF along with very nice illustrations from his own vast portfolio of restorations.

For the most complete history of CPF, see Steve’s definitive piece in the link in my sources below. Steve’s hard work pulls together all of the available information on CPF along with very nice illustrations from his own vast portfolio of restorations.

1881: THE YEAR IN HISTORY

Until this very moment, as I edit my blog, I had put a conservative estimate of the Best Make’s date of manufacture as 1898. Now, revisiting the evidence, I notice that every ad or other official mention of CPF after KB&B took control mentions KB&B and its address at the time. Pinpoint dating being impossible, I now have good cause to revise the pipe’s manufacture to pre-1883, given the worn old case that makes no mention of KB&B despite the room to do so. Therefore, my new conservative estimate is 1881, making it 138 this year. As it turns out, 1881 was an interesting year, like every other year in my opinion, but I’ll just cite a few highlights.

January 1, 1881, Dr. John H. Watson was introduced to Mr. Sherlock Holmes.

February 24, work began on the Panama Canal.

March 4, James A. Garfield was inaugurated as the 20th U.S. president.

March 16, the Barnum & Bailey Circus debuted.

April 28, Henry McCarty, originally of New York City, escaped from the Lincoln County Jail in Mesilla, New Mexico. Best known as Billy the Kid and widely but erroneously believed to have been born William H. Bonney, McCarty had three other aliases. I had to mention this particular historical tidbit because I live in the natural born killer’s old stomping grounds.

May 21, Clara Barton founded the American Red Cross.

July 1, the first international telephone conversation occurred, Calais, Maine to St Stephen, New Brunswick

July 2, President Garfield was shot by a delusional speech writer who fancied himself responsible for Garfield’s victory. Being denied an ambassadorship was the last straw.

September 19, President Garfield died from an infection caused by the gunshot.

December 4, the first edition of the Los Angeles Times was published.

The Wright Brothers’ first flight at Kitty Hawk, NC was not for another 22 years. The 19th Amendment to the U.S. Constitution granting women the right to vote, ratified August 18, 1920, was still 39 years from reality. The 25th Amendment to the U.S. Constitution defining presidential disability and the line of succession was not ratified until February 10, 1967 – 85 years after Garfield’s vice president, Chester A. Arthur, was sworn in as the 21st U.S. president.

The year 1881 was also 19 years before the revolutionary scientific and technological century that forever and exponentially robbed people of the little daily pleasures that were perhaps our greatest inclinations, for taking time to read and write and contemplate life. And toward those goals, some Old World meerschaum carver had the idea to create a pipe with a bowl turned just enough to allow smokers to see the pages of the books, newspapers or literary magazines they enjoyed reading during moments of the day when they could escape the rat race. Few such clever pipes can be found today. The photo below shows another pipe with a design that nevertheless has an amazing similarity to my CPF Best Make and could very well be its brother.

RESTORATION

I should make one final point clear now: the reason this part of the blog is short on the actual restoration steps and includes relatively few photos is that most of the work involved – meaning everything other than reconnecting the stem – turned out not to be anywhere nearly as difficult as I had at first projected. That’s easy to say now, after having restored other meerschaums and removed an unknown number of broken tenons from shanks. Also, knowing the final key to this restore was finding a suitable bone tenon and getting it to fit snugly and securely in the shank afforded me time to, well, take my time.

All of that said, the most important factor in terms of my readiness to finish my part of this project is all of the experience I have had working out problems with other pipes during the five years this process wound up taking due to the one vital step. Most of those times, my impulse, and often my first step, were to seek the help of someone who had more experience than I. That left plenty of options. Although the friends I’ve pestered most for advice may not realize it, I began to research possible solutions steadily more often. Above all, I exercised the part of my brain that allows me, when I use it, to think my own way out of corners. That habit proved to be of particular benefit to this restoration, as I will soon explain.

For the first year, I sat on the pipe, in the figurative sense, other than taking it out of the case now and then to admire its regal elegance. That time was in no way wasted or idle. I accomplished considerable online homework on various approaches to restorations of antique meerschaums. I had a fair number of successful meerschaum restorations under my belt, but I’d never even touched an antique pipe before, and they are a whole different ball of wax, so to speak. Here are the problems I anticipated:

For the first year, I sat on the pipe, in the figurative sense, other than taking it out of the case now and then to admire its regal elegance. That time was in no way wasted or idle. I accomplished considerable online homework on various approaches to restorations of antique meerschaums. I had a fair number of successful meerschaum restorations under my belt, but I’d never even touched an antique pipe before, and they are a whole different ball of wax, so to speak. Here are the problems I anticipated:

1. The rim char was transformed by the power of time – which may heal all wounds but is more apt to cause them, and thus allow us to grow – from the more or less expected norm of bad to full crystallization around the top of the chamber.

2. The entire surface of the pipe was filthy, whether from improper handling or about a century in storage or both, but the deep, even gold of the patina indicated it had been well-loved and tended. Cleaning meerschaum should not be approached without caution as the first try can limit later options or, worse, show places where the pipe was handled with bare hands from the ghosts of ingrained skin oil and dirt, sometimes as permanent blotches..

3. The original bone tenon was broken, half jammed deep inside the draught hole and the other half in the amber stem. Removing it from both narrow, fragile holes would be problematic, to use a gross euphemism. Replacing it would be a challenge – but a pleasant one, I imagined in my determination to honor my personal pledge to restore this great pipe to its original glory.

4. The shank looked as if it would need to be re-threaded. Wonderful.

5. I have also never worked with amber but knew enough to realize it is brittle stuff, in particular the 133-year-old (at the time I took possession of the pipe) variety. There would be no thought of subjecting this precious bit to the perils of an electric buffer or even sandpaper.

That’s it. Nothing serious, just a mine field. But after long, intense consideration, I concluded the integrity of the wonderful patina must be preserved at all costs and opted for a traditional basic cleaning rather than one of the experimental processes of which I had read. That was in 2014.

Recalling the one dragon Harry Potter had to face in his quest to survive the Goblet of Fire competition, I decided to be done with one of several I saw swooping my way. I began the slow extraction of the original bone tenon broken off and entrenched by time in the stem and shank. .In this kinder, gentler age of Vulcanite/Ebonite/Lucite/ Delrin tenon removal, by and large, the material being non-organic makes it less vulnerable to easy damage. My situation presented a triad of evils with the bone tenon packed into meerschaum and amber.

In most cases, not to postpone a fight but to confront the problems in a more systematic order, I would have started elsewhere. This time I went straight for the mother dragon protecting its young. The bone tenon screw piece in the stem is difficult to see, but trust me, it’s there in the first pic. Against the odds, it was easier to extract, or I was just lucky, but it popped out in one piece. In contrast, the shank took a couple of hours of on-edge, sweaty browed finagling with alternating and bizarre tools such as a jeweler’s screwdriver, the extended end of a large paper clip and the shank reamer of a three-piece pipe tool, to name a few. Breaking away a layer at a time, eight pieces later I reached the end of the blockage. The photo of the pieces is worthless.  Confronted with the need for careful removal of the char and crystallization spreading from the upper chamber onto the lion’s mane and left ear, I admit I’ve never read of super fine “0000” steel wool being appropriate for meerschaum or even wood pipes, but I’ve found that when milder approaches don’t remove all of the char (which they almost never do), in almost all cases the steel wool does the job without damage. What’s more, it even leaves a nice polish on the regular meerschaum rims that have some real width to them, which the CPF’s does not. Some readers have told me they like the steel wool approach also. For the chamber I started with 200-grit paper and finished with 320, which also is discouraged unless great care is taken as I did, and then gave the outside of the stummel a vigorous but only preliminary cleaning with small cotton pads soaked with purified water.

Confronted with the need for careful removal of the char and crystallization spreading from the upper chamber onto the lion’s mane and left ear, I admit I’ve never read of super fine “0000” steel wool being appropriate for meerschaum or even wood pipes, but I’ve found that when milder approaches don’t remove all of the char (which they almost never do), in almost all cases the steel wool does the job without damage. What’s more, it even leaves a nice polish on the regular meerschaum rims that have some real width to them, which the CPF’s does not. Some readers have told me they like the steel wool approach also. For the chamber I started with 200-grit paper and finished with 320, which also is discouraged unless great care is taken as I did, and then gave the outside of the stummel a vigorous but only preliminary cleaning with small cotton pads soaked with purified water.

For all of the dirt apparent on the cotton pads, note how much was still left.

For all of the dirt apparent on the cotton pads, note how much was still left.

I waited – another year and a half. During that time I continued the grueling online search for bone tenons with the idea of finishing the work myself and asked friends at my local pipe club and internet sites for pipe enthusiasts for help, to no avail. The intensified hunt was infused with a sense that the time was fast approaching the now or never point, and even found a site that seemed to have every size available. However, after going back and forth with the owner several times and never hearing from him again, I began to despair. That was in 2016.

Then, almost exactly one year ago, at the end of February last year, I thought, what the heck, why not try again? So I posted an identical thread on Smokers Forums UK, but in a different category. The first response included a link to Norwoods Pipe Repair in Clifton, Tennessee. Not wanting to get my hopes up, I checked it out and found that the father and son team of Floyd and Kenneth Norwood seemed to have all the right stuff for my lion’s head pipe and a second, antique briar that needed a still rarer stem that had to be replaced with the bone tenon. All about that in part 3.

I had to wait until early in April, after employing the skilled services of Kenneth Norwood in March to repair the briar pipe first because it belonged to a customer who wanted it back for good reason, to send the CPF via USPS Priority 2-Day delivery. I can tell you, the Separation Anxiety I experienced was acute, not having been away from the pipe or failed to look in on it at least once a day for the previous five years and being fully aware of the ability of the Postal Service to lose packages or deliver them to the wrong person who then keeps them. I paid to insure the package for $500, which could never replace the irrecoverable, and waited.

From the almost immediate turn-around time I had with the briar pipe, but fearing that may have been a fluke, I knew it would not be too long but was nevertheless surprised when it arrived again at my door less than a week after I mailed it.

I took a picture showing the masterful work completed by Kenneth, who had done better than re-thread the shank, but what with the wonders of the new and improved Windows 10 that have required so many full system restores of my computers that I’ve lost count, that photo and who knows how many others have gone missing. I’m sure they’re floating around somewhere because we all know Microsoft never lets us really and truly delete anything, but heaven knows where it is.

By the way, Kenneth mentioned that he would need the stem to be straight for his work aligning it to the new tenon, and so I put the amber stem with a pipe cleaner through the air hole on a small sheet of aluminum foil in the over pre-heated to 150° F. About 15 minutes later, I removed the sheet and stem. Amber is the easiest material to bend or straighten, I suppose because of its resinous nature that makes it heat quickly to the point where it is so malleable it will literally bend in half from its own weight if picked up by one end when removed from the oven.

Knowing this from an experiment I did almost a year and a half ago, I took hold of both ends of the cleaner and still saw the middle sag a little as I rushed the stem that straightened in the oven on its own to the tap to fix with cold water. I can’t emphasize enough the importance of speed in this process. If you’re bending the amber, it tends to straighten out again fast, and if you’re straightening the stem, it’s easy to bend it even by a tiny degree before fixing.

With that said, the next shots start with the pipe as it was returned to me, with the stem still straight before re-bending, and after thinking to use a toothbrush and purified water to scrub every intricate detail of the amazingly realistic lion’s head. This was quite a job, as the hand-carved details I noted are minute and almost as breathtaking as a real life, face-to-face encounter with the real thing: the ears alert and mane flowing backward, glaring eyes almost hidden beneath big brows, huge nose with fur and whiskers on either side, and that mouth with a hungry tongue and sharp teeth! And that’s just the face. The lion’s mouth is wide open, by the way, as if roaring or growling, and at times I had the idea it didn’t really care for my attentions – at least not until the task was done. I have a bit of an imagination, you see, and another result was a flash to the story of Androcles pulling the thorn from the lion’s paw. Here are two shots of the work Kenneth did.

Here are two shots of the work Kenneth did. And the rest.

And the rest. Now, the original real, cherry red amber stem was in remarkable condition for one that was used for a couple of years with loving attention, but the fact that it is well more than a century old makes its physical integrity achieve the level of astounding. There were no dings or pits, and the scratches, if they could be called that, were so minor some people might have let them be.

Now, the original real, cherry red amber stem was in remarkable condition for one that was used for a couple of years with loving attention, but the fact that it is well more than a century old makes its physical integrity achieve the level of astounding. There were no dings or pits, and the scratches, if they could be called that, were so minor some people might have let them be.

I’m a far cry from perfect and always will be, but I’m not some people. Here it is from every angle before I did anything to freshen it up.

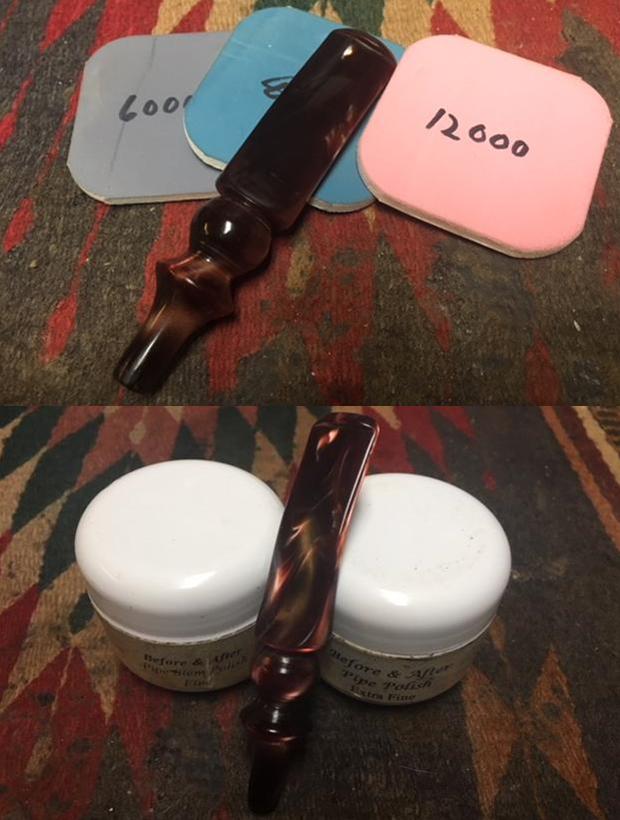

I gave it a wet micro mesh from 1500-12000. And I did a dry micro mesh the same way.

And I did a dry micro mesh the same way. Thinking a little more about it, I was still bent, as it were, on not putting the wonderful piece of expertly carved, polished, polymerized and fossilized prehistoric pine tree resin – an organic material neither gem nor stone – anywhere near an electric buffer. After all, accidents can happen. For such a catastrophe to occur to a piece of amber, even brand new, would be the end of it. Amber’s biggest problems are its extreme softness, a 2 on the Moh’s Scale of 1-10, just a full step above talc, and its natural brittleness that begins to worsen the instant it is exposed to sunlight. In other words, the exceptional suppleness of this antique stem makes it museum quality. Whoever owned it kept it in a nice, safe place away from natural light, and when he died it must have stayed in its case in an attic or some other dark place.

Thinking a little more about it, I was still bent, as it were, on not putting the wonderful piece of expertly carved, polished, polymerized and fossilized prehistoric pine tree resin – an organic material neither gem nor stone – anywhere near an electric buffer. After all, accidents can happen. For such a catastrophe to occur to a piece of amber, even brand new, would be the end of it. Amber’s biggest problems are its extreme softness, a 2 on the Moh’s Scale of 1-10, just a full step above talc, and its natural brittleness that begins to worsen the instant it is exposed to sunlight. In other words, the exceptional suppleness of this antique stem makes it museum quality. Whoever owned it kept it in a nice, safe place away from natural light, and when he died it must have stayed in its case in an attic or some other dark place.

At any rate, thinking on the idea of how to give it a little polish without the wheel, the obvious occurred to me. I took out my little jar of Decatur’s Pipe Shield that I decided to give a try as opposed to the standard Halcyon II Wax, both of which are generally reserved for hand application to rusticated or sandblasted wooden stummels before rubbing into the wood with a soft rag. As far as I know, it couldn’t hurt, and in fact gave the unique stem a higher sheen that at least I see in the final shots.

Finished with all of the visible cleaning, I remembered the pipe still needed sanitizing, meaning the shank, but a retort was impossible for reasons that should be obvious, yet every now and then we hear of some poor fellow – because any woman who might practice pipe cleaning or restoration would never make such a mistake – boiling alcohol through the insides of a meerschaum or even using the cold alcohol/kosher salt method and ending up heartbroken from the ruinous results.

On the other hand, a little alcohol mixed with water can go far to clean and sanitize a meerschaum shank. Fred Bass, one of the leading meerschaum collectors and authorities, writes in an essay cited below that his traditional inside-out cleaning method for meerschaums includes careful application of straight alcohol to the dirty outer areas of the pipe with a cotton pad or cloth – and he suggests Everclear, which as most folks know is almost as strong as it gets at 95% grain alcohol, or 190-proof. Residual alcohol should be tamped dry. For the shank, he recommends a pipe cleaner or more if necessary dipped in Everclear followed by a dry cleaner.

Well, I’m sure that works since Fred (we don’t know each other, but I don’t think he’d mind the familiarity) has been restoring meerschaums for quite a while now. But I just did not have the heart or nerve or courage or whatever you want to call it to make my first such try on my beloved CPF. Also, I think Fred would agree that building up to the Everclear cleaning approach is always a good idea, and my initial cotton pads followed by a toothbrush, both with purified water, got all of the dirt off this beauty. My compromise for the chamber sanitizing was to add a cap-full of Everclear to about a quarter-cup of water.

Here is the finished pipe, hand-buffed with a special heavy micro-fiber cloth.

CONCLUSION

CONCLUSION

With the longest restoration job I’ve ever performed complete, I was almost said – with an emphasis on almost. The relief and satisfaction with a job well done, if I say so myself and even though I did not do the shank work myself, were more than enough to compensate for any post-project blues. That turns out to be the perfect word to segue to my final comments.

For anyone who noticed the damage to the CPF’s leather-covered wood case between the first and last picture in this blog, I can, with complete honesty and justification, blame it on the dog, Blu. I kid you not.

For anyone who noticed the damage to the CPF’s leather-covered wood case between the first and last picture in this blog, I can, with complete honesty and justification, blame it on the dog, Blu. I kid you not.

She has admirable spirit, but a little too much of a good thing. The problem with the pipe is that Blu will snatch, run outside and devour anything left out and unattended if it smells tasty or even different – cooked or raw food, ice cream, soda cans or bottles, coffee mugs, Vaseline, OTC meds in their bottles and, as I found out the hard way one morning, a mysterious little object that simply looked too good to pass up.

My heart stopped when I returned to the living from my bedroom and noticed the tan case that had been in the center of the coffee table missing. I knew who stole it without a moment’s thought and almost saw red as vivid images and plans of canicide filled my mind. You see, the CPF Best Make turned lion’s head meerschaum with a gold band and cherry red amber stem c. 1881 was in the box.

Had I not found the mauled case in the back yard dirt patch where Blu so loves to play and eat her ill-gotten food stuff, and the CPF miraculously safe and intact inside it, I can’t say what I would have done to the dog. Sweetness only goes so far. A man’s pipes are not to be messed with.

I’m sure everyone can appreciate my immediate overwhelming relief and forgiveness of Blu despite her terrible lapse in judgment.

PREVIEW

Part 3 of this series will describe the two years it took me to return an antique KB&B Blueline Bakelite billiard c. 1911 entrusted to me for a quick cleaning and restoration, and the unfortunate reasons for the…er, delay.

Part 4, taking a lesson from this restore, will go a touch further with my full restoration of an old First Quality meerschaum billiard with a wrecked inner shank, and the replacement of its tenon and stem.

SOURCES

http://pipephil.eu/logos/en/logo-c1.html

https://pipedia.org/wiki/Colossus_Pipe_Factory

https://www.invaluable.com/auction-lot/colossus-pipe-factory-african-calabash-sterling-109-c-13648cbbb7

https://rebornpipes.com/2013/04/14/some-reflection-on-the-historical-background-on-cpf-pipes/

https://www.onthisday.com/events/date/1881

https://norwoodspiperepair.com/index.html

https://rebornpipes.com/2017/09/14/on-bending-and-straightening-amber-stone-stems/

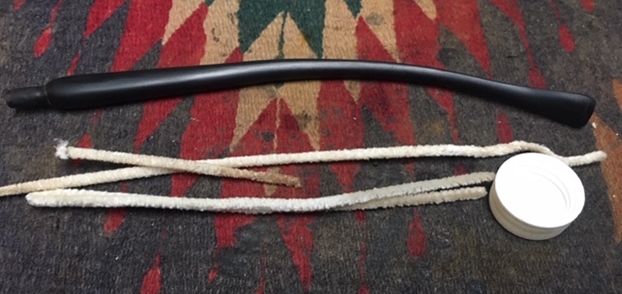

At first glance I thought that the tenon was broken off in the shank but as I examined it I came to believe it was even worse. It looked like someone had glued something in the shank and Gerry-rigged a connection to the stem. The photo below shows what I saw. What is not clear in the photo was a piece of metal in the centre of the mortise area. It looked like a tube but when I tried to push air through the shank it was absolutely plugged.

At first glance I thought that the tenon was broken off in the shank but as I examined it I came to believe it was even worse. It looked like someone had glued something in the shank and Gerry-rigged a connection to the stem. The photo below shows what I saw. What is not clear in the photo was a piece of metal in the centre of the mortise area. It looked like a tube but when I tried to push air through the shank it was absolutely plugged. I was going to have to try to drill out the shank but before I did that I examined the shank and stem more closely. The stem had been hacked pretty seriously so that the diameter was not even close to the diameter of the shank. In the centre of the mortise the metal tube turned out to be a 2 inch long finishing nail. It appears that the nail was used to keep the stem in place in the shank. For what? I don’t have an answer for that as it was utterly unsmokable. Once I removed the nail with a pair of needle nose pliers I was able to blow air through the shank. It was at least clear. I used a drill bit slightly larger than the mess in the shank and carefully drilled the shank. It did not work to clear out the shank! However, it was clear what was there – it was a tube made of masking or painters tape! I took a pen knife and twisted it into the mortise and was able to pull the tube free of the shank. The last photo shows everything that had been in the shank to hold the stem in place on the shank.

I was going to have to try to drill out the shank but before I did that I examined the shank and stem more closely. The stem had been hacked pretty seriously so that the diameter was not even close to the diameter of the shank. In the centre of the mortise the metal tube turned out to be a 2 inch long finishing nail. It appears that the nail was used to keep the stem in place in the shank. For what? I don’t have an answer for that as it was utterly unsmokable. Once I removed the nail with a pair of needle nose pliers I was able to blow air through the shank. It was at least clear. I used a drill bit slightly larger than the mess in the shank and carefully drilled the shank. It did not work to clear out the shank! However, it was clear what was there – it was a tube made of masking or painters tape! I took a pen knife and twisted it into the mortise and was able to pull the tube free of the shank. The last photo shows everything that had been in the shank to hold the stem in place on the shank.

I could surmise from the length of the stem what I would need for a replacement stem. I went through my can of stems and found one that had the right sized tenon and was the same length and width as the broken stem. It was a saddle stem instead of a taper but I liked the look of it on the pipe. I pushed it in place and took the following photos. I would need to reduce the diameter of the saddle, bend the stem and do a general cleanup, but it was a keeper.

I could surmise from the length of the stem what I would need for a replacement stem. I went through my can of stems and found one that had the right sized tenon and was the same length and width as the broken stem. It was a saddle stem instead of a taper but I liked the look of it on the pipe. I pushed it in place and took the following photos. I would need to reduce the diameter of the saddle, bend the stem and do a general cleanup, but it was a keeper.

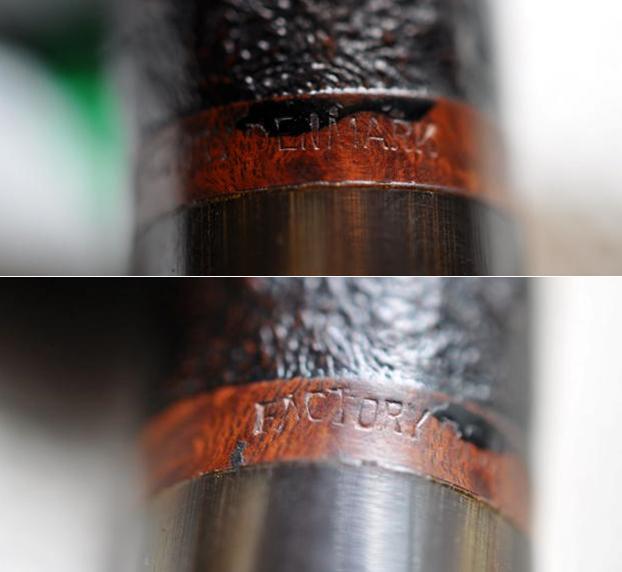

I took a photo of the stamping on the shank to show that it reads Kriswill. Underneath it says Hand Made in Denmark but that stamping is faint and only readable in a bright light or with a lens.

I took a photo of the stamping on the shank to show that it reads Kriswill. Underneath it says Hand Made in Denmark but that stamping is faint and only readable in a bright light or with a lens. With the stem chosen I set it aside to work on the bowl. I really hate working on dirty pipes! I can’t say enough how much I appreciate my brother Jeff doing the lion’s share of the reaming and cleaning before I even work on pipes… It is these few that I have to clean up that make me thankful and realize how much work he does before I get them here to restore. Thanks Jeff. The bowl had a thick cake and a heavy overflow of lava. It was obviously someone’s favourite pipe.

With the stem chosen I set it aside to work on the bowl. I really hate working on dirty pipes! I can’t say enough how much I appreciate my brother Jeff doing the lion’s share of the reaming and cleaning before I even work on pipes… It is these few that I have to clean up that make me thankful and realize how much work he does before I get them here to restore. Thanks Jeff. The bowl had a thick cake and a heavy overflow of lava. It was obviously someone’s favourite pipe. I reamed the bowl with a PipNet pipe reamer using the smallest cutting head. The bowl on these old Kriswill pipes is conical so the PipNet only goes so far down the inside. I reamed out the bowl as far as the reamer would reach and then used Savinelli Fitsall pipe knife to finish the project. I scraped the rim top with the pipe knife to remove the majority of the lava and could see that the rim edges and top were damaged with burn marks.

I reamed the bowl with a PipNet pipe reamer using the smallest cutting head. The bowl on these old Kriswill pipes is conical so the PipNet only goes so far down the inside. I reamed out the bowl as far as the reamer would reach and then used Savinelli Fitsall pipe knife to finish the project. I scraped the rim top with the pipe knife to remove the majority of the lava and could see that the rim edges and top were damaged with burn marks. To remove the damage to the top of the rim I topped it on a topping board with 220 grit sandpaper. I worked on it to remove the burned areas and the damage to the inner edge of the rim as much as possible. I am happy with how it turned out.

To remove the damage to the top of the rim I topped it on a topping board with 220 grit sandpaper. I worked on it to remove the burned areas and the damage to the inner edge of the rim as much as possible. I am happy with how it turned out. I lightly beveled the inner edge of the rim with a folded piece of 220 grit sandpaper to give it a cleaner look. The look of the bowl at this point is far better than when I started the rim clean up. I will still need to polish the rim and match the stain to the shank end smooth portion. Fortunately for me this old Kriswill originally had a smooth rim top so it will look like new.

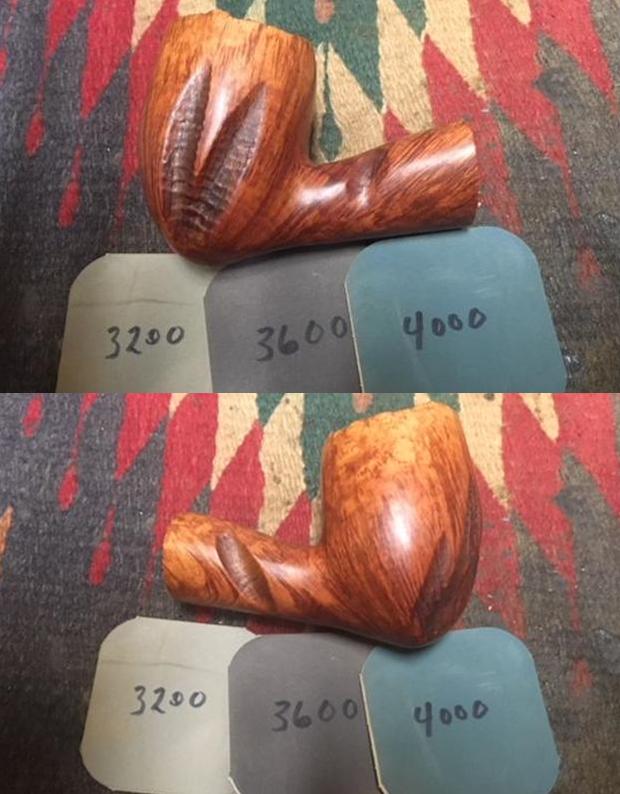

I lightly beveled the inner edge of the rim with a folded piece of 220 grit sandpaper to give it a cleaner look. The look of the bowl at this point is far better than when I started the rim clean up. I will still need to polish the rim and match the stain to the shank end smooth portion. Fortunately for me this old Kriswill originally had a smooth rim top so it will look like new. I polished the topped bowl rim with 3200-12000 grit micromesh sanding pads. With each successive grit of micromesh the grain stood out more and gave a good finished look to the pipe. I liked what I saw when I looked at it.

I polished the topped bowl rim with 3200-12000 grit micromesh sanding pads. With each successive grit of micromesh the grain stood out more and gave a good finished look to the pipe. I liked what I saw when I looked at it.

There was a little variation in stain colour between the rim top and the shank end so I decided to stain both to get a good blend. I used an Oak stain pen to match the colour of the shank and smooth spot where the stamping was. Once the stain had cured for that time I moved on to the next step in the process.

There was a little variation in stain colour between the rim top and the shank end so I decided to stain both to get a good blend. I used an Oak stain pen to match the colour of the shank and smooth spot where the stamping was. Once the stain had cured for that time I moved on to the next step in the process. It dawned on me at this point that I had been so intent on getting the plug out of the shank and topping the bowl that I forgot to clean out the shank! I normally do that right after reaming the bowl but forgot. It goes to show you that if you vary an habitual pattern even a bit you will leave steps out. I stopped the process and went back and cleaned out the shank and airway to the bowl with pipe cleaners, cotton swabs and isopropyl alcohol until the pipe was clean and smelled fresh.

It dawned on me at this point that I had been so intent on getting the plug out of the shank and topping the bowl that I forgot to clean out the shank! I normally do that right after reaming the bowl but forgot. It goes to show you that if you vary an habitual pattern even a bit you will leave steps out. I stopped the process and went back and cleaned out the shank and airway to the bowl with pipe cleaners, cotton swabs and isopropyl alcohol until the pipe was clean and smelled fresh. With the rim top and bowl polished and the shank and airway CLEAN, I worked some Before & After Restoration Balm into the surface of the briar with my fingertips to clean, enliven and protect it. I let the balm sit for a little while and then buffed with a cotton cloth to raise the shine. The following photos show the bowl at this point in the restoration process. The bowl and the rim top look really good and the darkening and lava are gone. The finish looks very good with the contrast between the rich, dark brown and the Oak stain on the rim and shank end. I am very happy with the results.

With the rim top and bowl polished and the shank and airway CLEAN, I worked some Before & After Restoration Balm into the surface of the briar with my fingertips to clean, enliven and protect it. I let the balm sit for a little while and then buffed with a cotton cloth to raise the shine. The following photos show the bowl at this point in the restoration process. The bowl and the rim top look really good and the darkening and lava are gone. The finish looks very good with the contrast between the rich, dark brown and the Oak stain on the rim and shank end. I am very happy with the results.

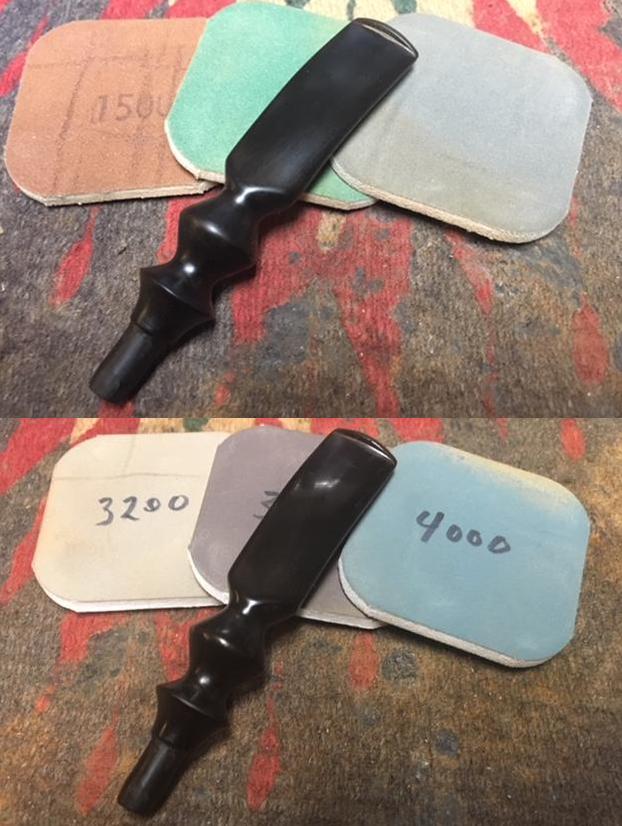

With the bowl finished I set it aside and turned my attention to the stem. I used a file and a folded piece of 220 grit sandpaper to shape the diameter of the saddle portion of the stem to fit the diameter of the shank. It took a lot of filing and sanding to get it to this point but there is a lot of fine tuning work to do.

With the bowl finished I set it aside and turned my attention to the stem. I used a file and a folded piece of 220 grit sandpaper to shape the diameter of the saddle portion of the stem to fit the diameter of the shank. It took a lot of filing and sanding to get it to this point but there is a lot of fine tuning work to do.

The shank is not round but it is more of a vertical oval in shape so the stem will need to match it to have a seamless fit. It is a lot of hand shaping work to get the two to match. I sanded the scratches and the tooth marks on the stem with 220 grit sandpaper to bring the shank and saddle portion into line.

The shank is not round but it is more of a vertical oval in shape so the stem will need to match it to have a seamless fit. It is a lot of hand shaping work to get the two to match. I sanded the scratches and the tooth marks on the stem with 220 grit sandpaper to bring the shank and saddle portion into line.

I further sanded and shape it with 400 grit sandpaper to remove the scratches. This is the beginning of the polishing process on the stem. I wiped the stem down with Obsidian Oil and put it back in the shank to take progress photos.

I further sanded and shape it with 400 grit sandpaper to remove the scratches. This is the beginning of the polishing process on the stem. I wiped the stem down with Obsidian Oil and put it back in the shank to take progress photos.

I polished the stem with micromesh sanding pads – wet sanding it with 1500-2400 grit pads and dry sanding it with 3200-12000 grit pads. I wiped the stem down with Obsidian Oil after each pad. I further polished it with Before & After Pipe Polish – both Fine and Extra Fine. I gave it a final coat of Obsidian Oil and set it aside to dry.

I polished the stem with micromesh sanding pads – wet sanding it with 1500-2400 grit pads and dry sanding it with 3200-12000 grit pads. I wiped the stem down with Obsidian Oil after each pad. I further polished it with Before & After Pipe Polish – both Fine and Extra Fine. I gave it a final coat of Obsidian Oil and set it aside to dry.

This pipe has had quite a journey to this point in time and space. It somehow traveled from Denmark where it was made to Mumbai, India. There is was found abandoned, binned and found by a rag picker who then sold it to Paresh in another region of India. From Paresh it traveled to me in Vancouver, Canada. In April it will travel to Nepal with me and back Paresh in India. I only wish that it could tell its story. All I know is that I have extended its life of usefulness and given its purpose back as it was intended.

This pipe has had quite a journey to this point in time and space. It somehow traveled from Denmark where it was made to Mumbai, India. There is was found abandoned, binned and found by a rag picker who then sold it to Paresh in another region of India. From Paresh it traveled to me in Vancouver, Canada. In April it will travel to Nepal with me and back Paresh in India. I only wish that it could tell its story. All I know is that I have extended its life of usefulness and given its purpose back as it was intended.