Blog by Steve Laug

This Dunhill Billiard was one of five other Billiards that came to us in the same lot as the 1922 Dunhill Bruyere Reading Pipe, a cracked shank 1962 Dunhill Shell Briar Pot and the 1905 BBB Calabash Reading Pipe and 1911 BBB Glokar Poker. It was a great looking Bruyere Billiard that had a Yello-Bole stem instead of the original Dunhill stem. The pipe is stamped on the left side of the shank with the letter A next to the bowl and the was followed by DUNHILL [over] LONDON. On the right side of the shank it was stamped MADE IN ENGLAND [over] PAT. NO 41757416 that is followed by the shape number 35.

This Dunhill Billiard was one of five other Billiards that came to us in the same lot as the 1922 Dunhill Bruyere Reading Pipe, a cracked shank 1962 Dunhill Shell Briar Pot and the 1905 BBB Calabash Reading Pipe and 1911 BBB Glokar Poker. It was a great looking Bruyere Billiard that had a Yello-Bole stem instead of the original Dunhill stem. The pipe is stamped on the left side of the shank with the letter A next to the bowl and the was followed by DUNHILL [over] LONDON. On the right side of the shank it was stamped MADE IN ENGLAND [over] PAT. NO 41757416 that is followed by the shape number 35.

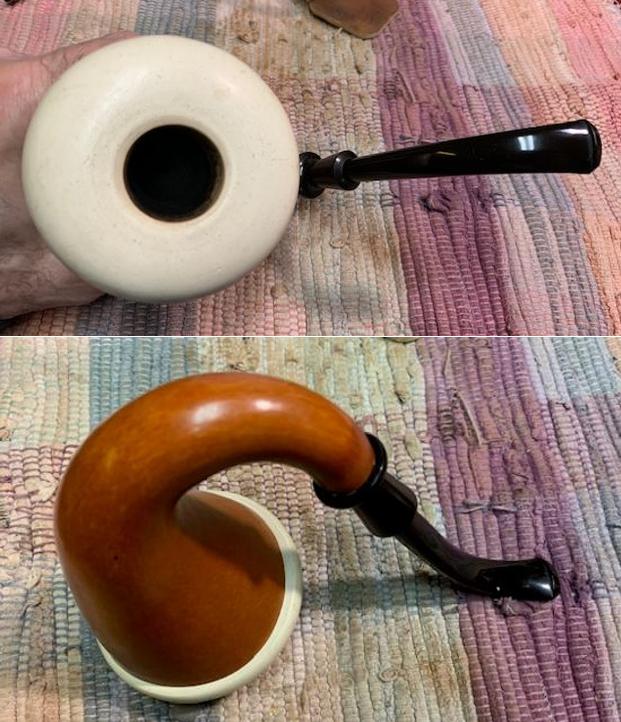

It was another filthy pipe with a thick cake in the bowl and a heavy lava overflow on the rim top. It looked like it had a shiny coat of varnish or shellac on the bowl that would need to be removed so I could work on the rim top and nicks in the bowl sides. The stem would need to be replaced so Jeff and I would look over what he had there in terms of stems we had set aside. Perhaps there would be one in the lot that would work. Jeff removed the Yello-Bole stem from the shank and took photos of the bowl before he did his clean up work.

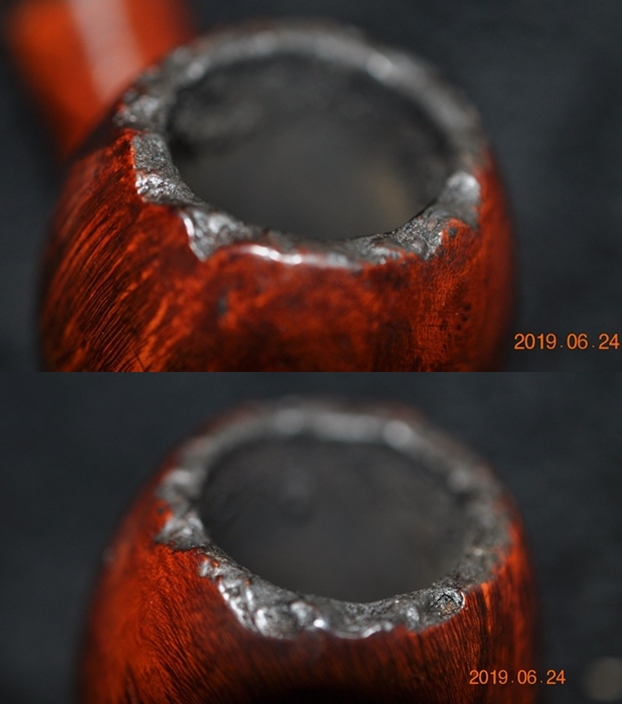

He took photos of the bowl and rim to give a picture of the thickness of the cake and lava on the rim top. This must have been a favourite pipe to have gone through a Dunhill stem and then pressing a Yello-Bole stem into service. I would need to find a Dunhill stem for it but it had promise even under the thick cake in the bowl.

He took photos of the bowl and rim to give a picture of the thickness of the cake and lava on the rim top. This must have been a favourite pipe to have gone through a Dunhill stem and then pressing a Yello-Bole stem into service. I would need to find a Dunhill stem for it but it had promise even under the thick cake in the bowl.

Jeff took photos of the stamping on the sides of the shank but they are quite blurry because of the refection of the shiny varnish/shellac coat. I am including them anyway here as the give a sense of where the stamp was on the shank sides.

Jeff took photos of the stamping on the sides of the shank but they are quite blurry because of the refection of the shiny varnish/shellac coat. I am including them anyway here as the give a sense of where the stamp was on the shank sides. I turned to Pipedia’s section on Dunhill Root Briar Pipes to get a bit of background on the Dunhill finishes (https://pipedia.org/wiki/Dunhill#Root_Briar). I quote:

I turned to Pipedia’s section on Dunhill Root Briar Pipes to get a bit of background on the Dunhill finishes (https://pipedia.org/wiki/Dunhill#Root_Briar). I quote:

Bruyere

The original finish produced (usually made using Calabrian briar), and a big part of developing and marketing the brand. It was the only finish from 1910 until 1917. A dark reddish-brown stain. Before the 1950s, there were three possible finishes for Dunhill pipes. The Bruyere was a smooth finish with a deep red stain, obtained through two coats, a brown understain followed by a deep red.

There was a link on the above site to a section specifically written regarding the Bruyere finish (https://pipedia.org/wiki/Dunhill_Bruyere). I turned there and have included the information from that short article below.

Initially, made from over century-old briar burls, classified by a “B” (denoted highest quality pipe); “DR” (denoted straight-grained) and an “A” (denoted first quality), until early 1915. After that, they became a high-end subset to the Dunhill ‘Bruyere’. The DR and B pipes, a limited production, they should be distinguished as hand-cut in London from burls as opposed to the Bruyere line which was generally finished from French turned bowls until 1917, when the Calabrian briar started to be used, but not completely. Only in 1920 Dunhill took the final step in its pipe making operation and began sourcing and cutting all of its own bowls, proudly announcing thereafter that “no French briar was employed”.

Bruyere pipes were usually made using Calabrian briar, a very dense and hardy briar that has a modest grain but does very well with the deep red stain.

“Before the 1950s, there were three possible finishes for Dunhill pipes. The Bruyere was a smooth finish with a deep red stain, obtained through two coats, a brown understain followed by a deep red. The Shell finish was the original sandblast with a near-black stain (though the degree to which it is truly black has varied over the years). Lastly, the Root finish was smooth also but with a light brown finish. Early Dunhill used different briars with different stains, resulting in more distinct and identifiable creations… Over the years, to these traditional styles were added four new finishes: Cumberland, Dress, Chestnut and Amber Root, plus some now-defunct finishes, such as County, Russet and Red Bark.”

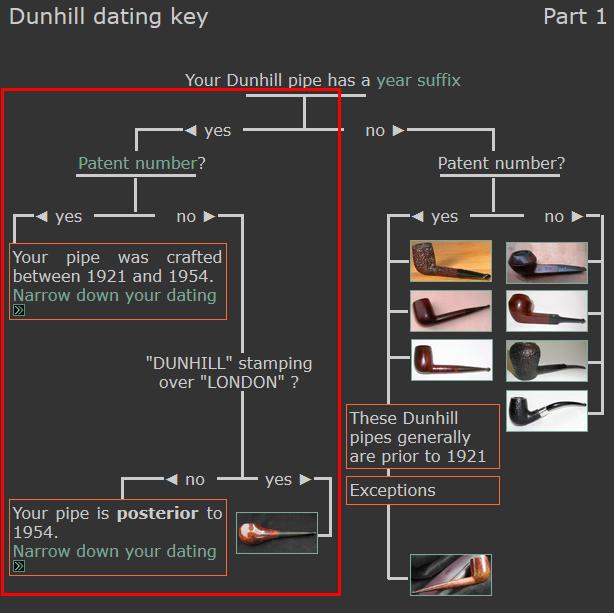

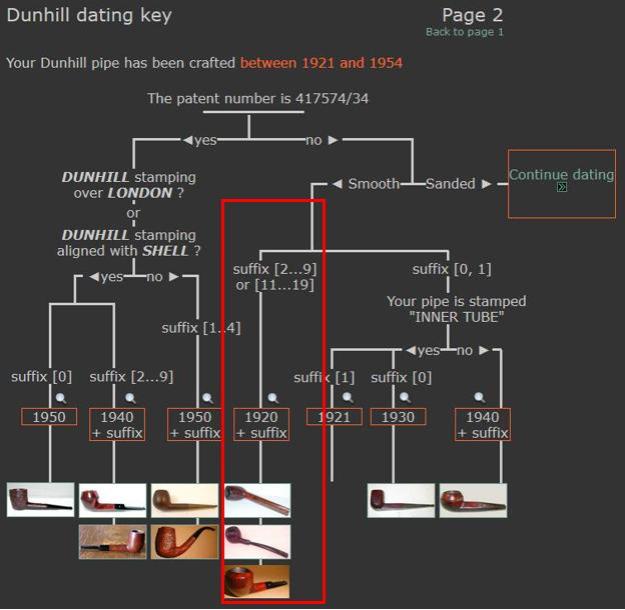

There was also a link to a catalogue page that gave examples and dates that the various finishes were introduced (https://pipedia.org/wiki/File:Dunnypipescatalog-1.png). I turned to Pipephil’s dating guide to show how I arrived at the date of manufacture for this pipe (http://www.pipephil.eu/logos/en/dunhill/cledat-en1.html). I am including two charts that are provided there for the dating a pipe. I have drawn a red box around the pertinent section in each chart. Since the pipe I am working on has a suffix 16 that is raised superscript it points to 1920+ 16 for a date of 1936 on the charts below.

I turned to Pipephil’s dating guide to show how I arrived at the date of manufacture for this pipe (http://www.pipephil.eu/logos/en/dunhill/cledat-en1.html). I am including two charts that are provided there for the dating a pipe. I have drawn a red box around the pertinent section in each chart. Since the pipe I am working on has a suffix 16 that is raised superscript it points to 1920+ 16 for a date of 1936 on the charts below.

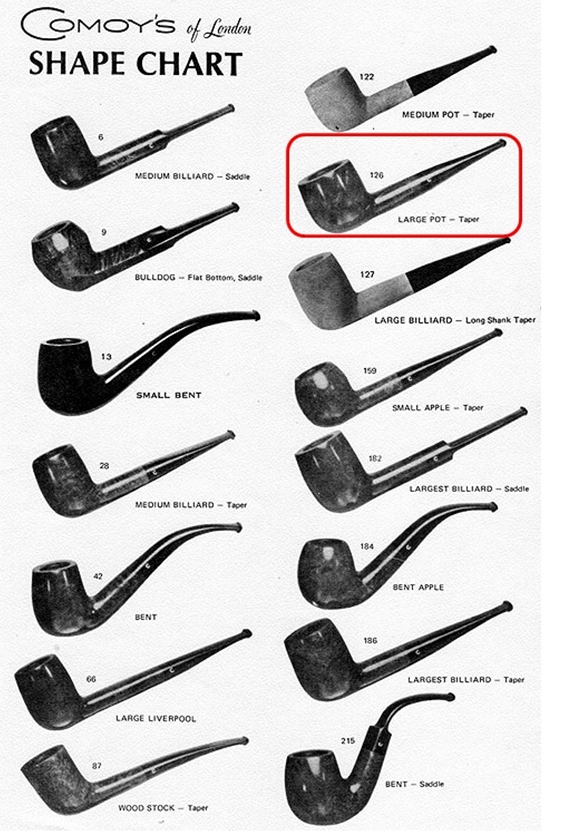

I now knew that I was working on a Bruyere that came out in 1936 because of the date stamp 16. The shape of the pipe was one of many Billiards that Dunhill put out and the #35 was a normal billiard shape with a taper stem. That helped me figure out the kind of stem I would need to restem the pipe.

I now knew that I was working on a Bruyere that came out in 1936 because of the date stamp 16. The shape of the pipe was one of many Billiards that Dunhill put out and the #35 was a normal billiard shape with a taper stem. That helped me figure out the kind of stem I would need to restem the pipe.

I turned to work on the pipe itself. Jeff had carried out his usual thorough cleanup of the pipe. He had reamed it with a PipNet reamer to remove the cake and cleaned the reaming up with a Savinelli Fitsall Pipe Knife. He scrubbed the internals of the bowl and stem with alcohol, cotton swabs and pipe cleaners. He scrubbed the externals with undiluted Murphy’s Oil Soap and rinsed the bowl off with running water. He had included a stem that we thought could work with the pipe and had soaked it in Before & After Deoxidizer and once it had soaked rinsed it off with warm water to remove the residual solution. He dried it off and scrubbed it down with Soft Scrub All-Purpose cleaner to remove any oxidation that was still on the stem. The biggest issue with the stem was the large chunk of vulcanite missing on the button on the underside but I thought we could make it work. The stem was from the wrong era and the button was the wrong shape but it would work until the proper stem was located. The pipe looked very clean when I received it. I took a photo of the bowl and the stem I was planning on using.  I sanded the tenon to slightly reduce the diameter and leave a snug fit in the shank. It did not take too much to get a nice fit. Note that the diameter of the stem is slightly larger than the shank and it is flattened on the bottom. Since it is larger the flatten portion will not be an issue and with a little work the stem will be a perfect fit. The fourth photo of the underside of the stem shows the damage to the button that will need to be repaired.

I sanded the tenon to slightly reduce the diameter and leave a snug fit in the shank. It did not take too much to get a nice fit. Note that the diameter of the stem is slightly larger than the shank and it is flattened on the bottom. Since it is larger the flatten portion will not be an issue and with a little work the stem will be a perfect fit. The fourth photo of the underside of the stem shows the damage to the button that will need to be repaired.

I took a photo of the rim top to show the condition. You can see the darkening, scratches and damage on the rim top. It is roughened and slightly out of round. The varnish/shellac coat is peeling on the top. The stem came out looking quite good. There are tooth marks and chatter on the top side near the button and a large chunk of the button missing on the underside.

I took a photo of the rim top to show the condition. You can see the darkening, scratches and damage on the rim top. It is roughened and slightly out of round. The varnish/shellac coat is peeling on the top. The stem came out looking quite good. There are tooth marks and chatter on the top side near the button and a large chunk of the button missing on the underside.

I took photos of the stamping on both sides of the shank to try to capture it better than the photos above. It is better and is readable it reads as noted above. Also not the variation in the diameter of the stem that will need to be addressed. It was time to work on the stem. I decided to tackle the repair to the missing part of the button on the underside of the stem first. I would also need to work on the diameter of the stem at the shank and the shape of the stem to match the year it was made. There was a lot of work to do on the stem.

It was time to work on the stem. I decided to tackle the repair to the missing part of the button on the underside of the stem first. I would also need to work on the diameter of the stem at the shank and the shape of the stem to match the year it was made. There was a lot of work to do on the stem.

I got the repair station set up. I use a piece of cardboard with two strips of packing tape to mix the putty. I used Loctite 380 rubberized Black CA glue and three capsules of charcoal powder. I made a cardboard wedge covered in packing tape to fit in the slot and keep me from filling the slot in with the mixture. I put a pool of the glue on the middle of the cardboard base so I could mix the charcoal powder into it. I mixed the powder and the glue together with a dental spatula. I stirred it until I got a thick putty like paste. I used the spatula to place the mixture on the top of the stem and fill in the missing chunk. I always overfill the area as I can easily remove the excess with the Dremel and files. I sprayed the repair with accelerator to harden the surface so I could remove the cardboard wedge. I took out the wedge and took a photo of the stem at this point in the process.

I mixed the powder and the glue together with a dental spatula. I stirred it until I got a thick putty like paste. I used the spatula to place the mixture on the top of the stem and fill in the missing chunk. I always overfill the area as I can easily remove the excess with the Dremel and files. I sprayed the repair with accelerator to harden the surface so I could remove the cardboard wedge. I took out the wedge and took a photo of the stem at this point in the process. I let the repair cure overnight and in the morning I used a rasp and file to begin to shape the stem surface and flatten the repair. It was a good solid repair and with a lot of shaping and sanding it would work well.

I let the repair cure overnight and in the morning I used a rasp and file to begin to shape the stem surface and flatten the repair. It was a good solid repair and with a lot of shaping and sanding it would work well. I continued to shape the stem surface with 220 grit sandpaper to the button and stem surface smooth. I also worked on the diameter of the stem and removed the flattened bottom. Lots more work to do but it is getting there.

I continued to shape the stem surface with 220 grit sandpaper to the button and stem surface smooth. I also worked on the diameter of the stem and removed the flattened bottom. Lots more work to do but it is getting there.

I knew that the 1936 stem would not have had the flared fishtail look but probably would have been more of a straight taper. I did a search on Google for a 1936 Dunhill Bruyere in a shape 35 to see if I could find one that would provide a pattern for the shaping of this replacement stem. I found one (https://www.worthpoint.com/worthopedia/1936-dunhill-bruyere-grade-billiard-490781280). I copied several of the photos to get a pattern to work with.

I knew that the 1936 stem would not have had the flared fishtail look but probably would have been more of a straight taper. I did a search on Google for a 1936 Dunhill Bruyere in a shape 35 to see if I could find one that would provide a pattern for the shaping of this replacement stem. I found one (https://www.worthpoint.com/worthopedia/1936-dunhill-bruyere-grade-billiard-490781280). I copied several of the photos to get a pattern to work with.

You can see from the photos to the left that the stem was significantly different in shape than the fishtail stem that I was working with. The taper on the sides from the shank to the button was far more gentle and almost straight. The taper on the top and bottom the stem is very similar to what I have. The biggest difference was in the last half inch of the stem and button. I would need to remove the horns or fish tail edges from the button and smooth out the transition on the button end so that it is not flared.

It took some work but I used the Dremel to roughly shape the stem like the sides of the stem and the button edges. I took off a lot of vulcanite and when I was done it was very close. I think the rest of the work would be done with sandpaper. I continued shaping it with 220 grit sandpaper. It is looking very good at this point. I still have work to do on the repair to take care of air bubbles but I am happy with how it is coming out so far.

I continued shaping it with 220 grit sandpaper. It is looking very good at this point. I still have work to do on the repair to take care of air bubbles but I am happy with how it is coming out so far. I filled in the air bubbles on the stem and button surfaces with black super glue and set the stem aside for the repairs to cure.

I filled in the air bubbles on the stem and button surfaces with black super glue and set the stem aside for the repairs to cure. I turned my attention to the bowl. I decided to start the restoration on it by working on the damage on the inner edge of the bowl. It had darkening and some damage to the edge. There were burn and reaming damage marks on the edge. I worked it over with a folded piece of 220 grit sandpaper to give the edge a light bevel and remove and minimize the damage on the edge. When I finished with it, the bowl and the rim top looked much better.

I turned my attention to the bowl. I decided to start the restoration on it by working on the damage on the inner edge of the bowl. It had darkening and some damage to the edge. There were burn and reaming damage marks on the edge. I worked it over with a folded piece of 220 grit sandpaper to give the edge a light bevel and remove and minimize the damage on the edge. When I finished with it, the bowl and the rim top looked much better. I wiped down the bowl with alcohol on a cotton pad to remove the shellac/varnish coat. It removed a lot of the shiny coat but the polishing with micromesh will remove the rest of it.

I wiped down the bowl with alcohol on a cotton pad to remove the shellac/varnish coat. It removed a lot of the shiny coat but the polishing with micromesh will remove the rest of it.

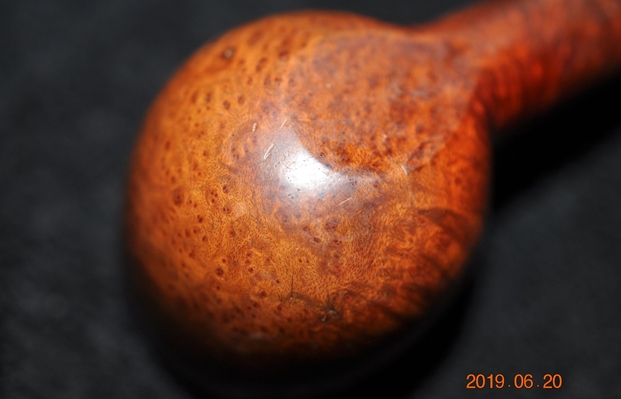

I polished the rim top and bowl with micromesh sanding pads – dry sanding with 1500-12000 grit sanding pads. I wiped the bowl down with a damp cloth after each sanding pad. The briar began to take on a shine.

I polished the rim top and bowl with micromesh sanding pads – dry sanding with 1500-12000 grit sanding pads. I wiped the bowl down with a damp cloth after each sanding pad. The briar began to take on a shine.

I paused the sanding with the micromesh to stain the rim top with a Mahogany Stain pen to match the colour around the bowl. Afterwards I picked up the micromesh pads 3200-12000 and completed the cycle to polish the bowl.

I paused the sanding with the micromesh to stain the rim top with a Mahogany Stain pen to match the colour around the bowl. Afterwards I picked up the micromesh pads 3200-12000 and completed the cycle to polish the bowl.

I rubbed the briar down with Before & After Restoration Balm. I worked it into the briar with my fingertips. The product works to clean, enliven and preserve the briar. I let it sit for 15 minutes while I worked on the stem. After the time passed I buffed it with a cotton cloth to deepen the shine. The briar really comes alive with the balm.

I rubbed the briar down with Before & After Restoration Balm. I worked it into the briar with my fingertips. The product works to clean, enliven and preserve the briar. I let it sit for 15 minutes while I worked on the stem. After the time passed I buffed it with a cotton cloth to deepen the shine. The briar really comes alive with the balm.

I was excited to be finishing this pipe. I still had work to do but thought I would take a look at the stem and pipe together. I put the stem in place and tried I tried to blow through it and only got read in the face. I tried to put a pipe cleaner through the button and it went into the area of the repair and stopped. I tried to push a wire through the blockage and it would not budge. My stem repair had sealed off the airway!!!!.

I was excited to be finishing this pipe. I still had work to do but thought I would take a look at the stem and pipe together. I put the stem in place and tried I tried to blow through it and only got read in the face. I tried to put a pipe cleaner through the button and it went into the area of the repair and stopped. I tried to push a wire through the blockage and it would not budge. My stem repair had sealed off the airway!!!!.  I usually do a stem repair with a folded greased pipe cleaner in the airway. This time I tried the cardboard wedge that both Dal and Paresh have used many times with no issues, thinking this stem would be a great candidate for that. I made a wedge and fit it in place but it must have had a small opening at the end that allowed the repair material to go past it. The airway was sealed tight and hard as a rock! I set the stem aside and went to the Post Office to mail a package. While I waited for the clerk I had an idea. When I got home I tried it. I put the smallest drill bit I had in the chuck of my cordless drill and carefully drilled it through. I up the bit to the second smallest one and the airway was clear! Whew… but even more amazing is that with all the drilling and fussing at the button lip the repair did not chip or loosen. The repair was solid. That at least was very good news in the midst of this mess.

I usually do a stem repair with a folded greased pipe cleaner in the airway. This time I tried the cardboard wedge that both Dal and Paresh have used many times with no issues, thinking this stem would be a great candidate for that. I made a wedge and fit it in place but it must have had a small opening at the end that allowed the repair material to go past it. The airway was sealed tight and hard as a rock! I set the stem aside and went to the Post Office to mail a package. While I waited for the clerk I had an idea. When I got home I tried it. I put the smallest drill bit I had in the chuck of my cordless drill and carefully drilled it through. I up the bit to the second smallest one and the airway was clear! Whew… but even more amazing is that with all the drilling and fussing at the button lip the repair did not chip or loosen. The repair was solid. That at least was very good news in the midst of this mess. I worked on the stem some more fine tuning the fit against the shank and the shape of the button and stem to get as close as possible to the pictures that I found and included above. I sanded and shaped and sanded and shaped… did I say sanded and shaped?? It seemed almost endless.

I worked on the stem some more fine tuning the fit against the shank and the shape of the button and stem to get as close as possible to the pictures that I found and included above. I sanded and shaped and sanded and shaped… did I say sanded and shaped?? It seemed almost endless.

I polished the vulcanite with micromesh sanding pads – 1500-12000 grit pads. I wiped it down with Obsidian Oil after each sanding pad. I used Before & After Pipe Polish – both Fine and Extra Fine to further polish the stem.

I polished the vulcanite with micromesh sanding pads – 1500-12000 grit pads. I wiped it down with Obsidian Oil after each sanding pad. I used Before & After Pipe Polish – both Fine and Extra Fine to further polish the stem.

This Dunhill A Bruyere 35 Patent Billiard from 1936 is a beautiful looking piece of briar that has a shape that follows grain. It is a great looking pipe that came out looking even better after the cleanup and restemming. The Bruyere is an early finish that Dunhill specialized in making. The finish on the pipe is in excellent condition. The red and brown stain on the bowl works well to highlight the grain. The polished black vulcanite taper stem that I repurposed to replace the Yello-Bole stem adds to the mix. It is not the 1936 stem but I reshaped it to a close approximation. It will work until I find the proper era stem. I put the stem back on the bowl and buffed the pipe with Blue Diamond on the buffing wheel being careful to not buff the stamping. I gave the bowl and the stem multiple coats of carnauba wax on the buffing wheel and followed that by buffing it with a clean buffing pad. I hand buffed the pipe with a microfiber cloth to deepen the shine.

This Dunhill A Bruyere 35 Patent Billiard from 1936 is a beautiful looking piece of briar that has a shape that follows grain. It is a great looking pipe that came out looking even better after the cleanup and restemming. The Bruyere is an early finish that Dunhill specialized in making. The finish on the pipe is in excellent condition. The red and brown stain on the bowl works well to highlight the grain. The polished black vulcanite taper stem that I repurposed to replace the Yello-Bole stem adds to the mix. It is not the 1936 stem but I reshaped it to a close approximation. It will work until I find the proper era stem. I put the stem back on the bowl and buffed the pipe with Blue Diamond on the buffing wheel being careful to not buff the stamping. I gave the bowl and the stem multiple coats of carnauba wax on the buffing wheel and followed that by buffing it with a clean buffing pad. I hand buffed the pipe with a microfiber cloth to deepen the shine.

The finished Bruyere 35 Billiard is quite nice and feels great in the hand. Give the finished pipe a look in the photos below. I can only tell you that like the other pipes I am working that it is much prettier in person than the photos capture. The dimensions of the pipe are Length: 5 ½ inches, Height: 1 ¾ inches, Outside diameter of the bowl: 1 ¼ inches, Chamber diameter: 5/8 of an inch. The weight of the pipe is 31grams/1.06oz. Thanks for walking through the restoration with me as I worked over another beautiful pipe. Remember we are not pipe owners; we are pipemen and women who hold our pipes in trust until they pass on into the trust of the next generation.