Blog by Paresh Deshpande

I have quite a few inherited Peterson’s System pipes ranging from the period 1915 to 1947 to present!!! I also have these pipes in System Standard, System 0 and System 3. So when Abha, my wife, sent me pictures of pipes that I had purchased from a Mumbai trash collector, I saw two distinct Peterson’s System pipes, one large and the other very small!! When Abha confirmed the COM stamping on both these pipes, I knew that I had Peterson’s System pipes from the 1930s-40s. Another two vintage Peterson’s System pipes added to my collection, I say. And I am not complaining, mind you readers!!

I was fortunate enough to have heeded the advice of my dear friend and mentor, Steve, and struck a deal with a junk collector from Mumbai. He did not know what he was selling and I did not know what I was buying as we reside in different cities!!!!! The argument that Mr. Steve presented was that if not anything, I shall at least have some spares and this was logical. I struck a deal and here are pictures of the pipes that I received in this lot.

This lot contains some very nice collectible pipes, a few well known brands and some mediocre brands. Overall, with seven Dunhill pipes, a Preben Holm #1 FH, a couple of “Made in England” Pete System pipes, a couple of Charatan’s Belvedere, Custom-Bilt, Stanwell and other assorted pipes, I would say that I had struck a decent haul!!! This is indeed my “Mumbai Bonanza”.

This lot contains some very nice collectible pipes, a few well known brands and some mediocre brands. Overall, with seven Dunhill pipes, a Preben Holm #1 FH, a couple of “Made in England” Pete System pipes, a couple of Charatan’s Belvedere, Custom-Bilt, Stanwell and other assorted pipes, I would say that I had struck a decent haul!!! This is indeed my “Mumbai Bonanza”.

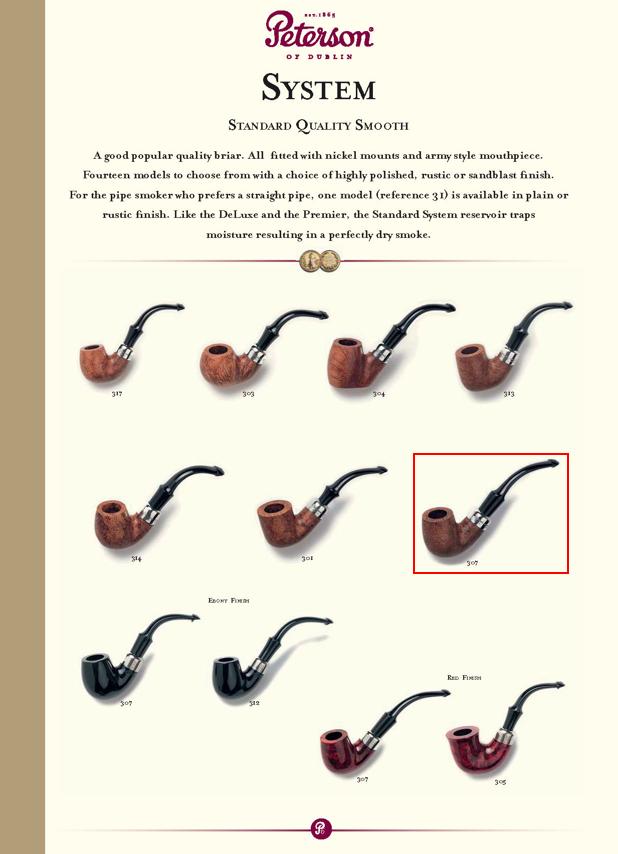

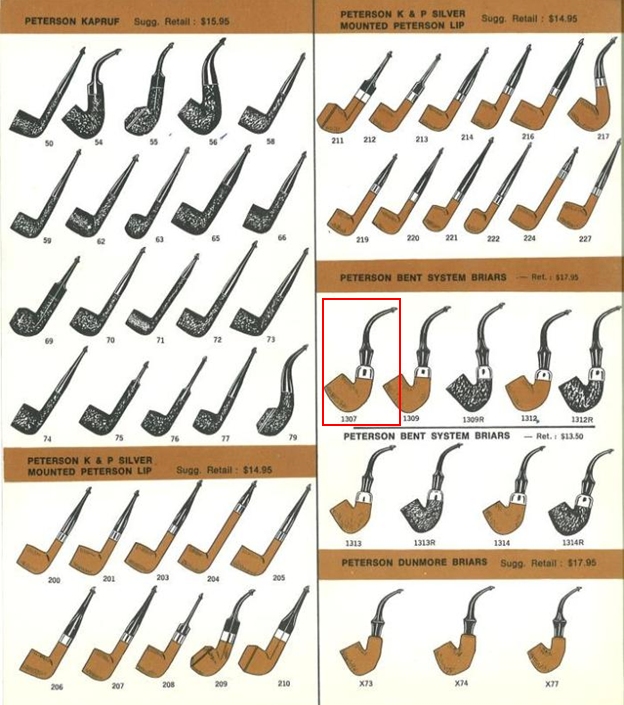

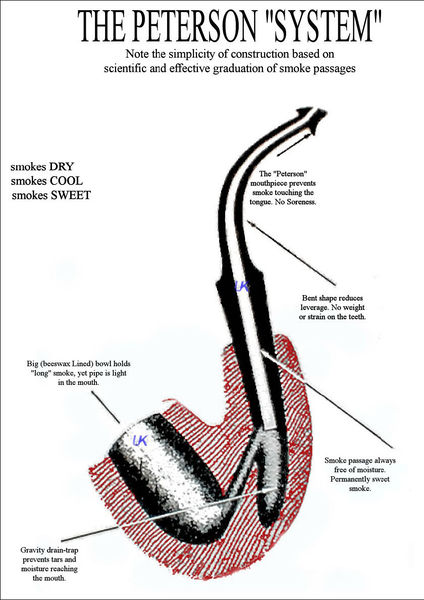

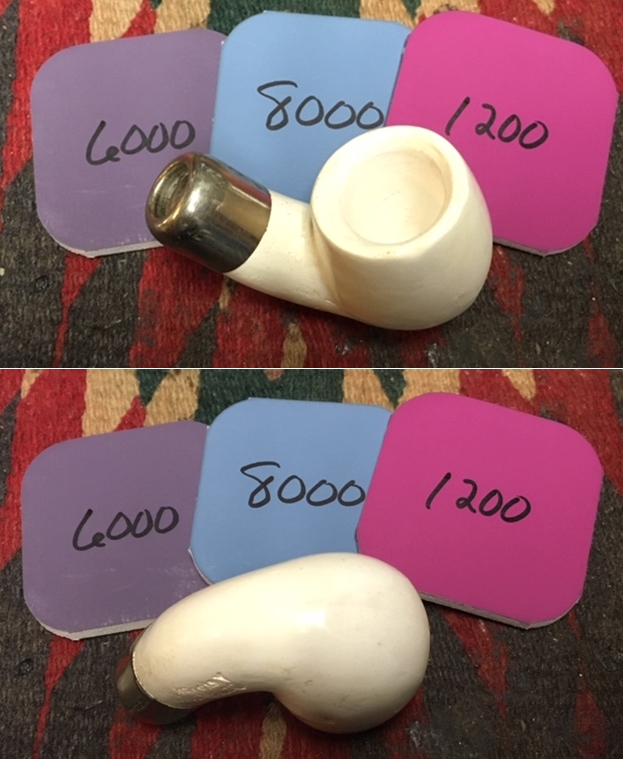

This 15th pipe that I decided to work on from this find is a large Peterson’s System 3 pipe with a nickel ferrule and is indicated in indigo color arrow. It is stamped on the left of the shank towards the shank end as “PETERSON’S” in an arch in block capital letters over arched “SYSTEM” in block capital over “# 3”. The tail of the P in Peterson’s is forked. The right side of the shank is stamped with COM stamp “MADE IN ENGLAND” in a circle format with “Made” and “England” in a circle with the “in” located in the center of the circle. Stamped at the bottom of the shank, very close to the ferrule is the shape number “357”. All the stampings are crisp and easily readable. The ferrule has the usual three cartouche with first having Shamrock, the second a Prone Fox and lastly a Stone Tower. Stamped above the cartouche are the letters “K & P” followed by “PETERSON’S” all in a straight line. The stem is devoid of any logo.

In my earlier restoration of my inherited Peterson’s System 31, I had extensively researched the dating of these old Peterson’s and I can say with certainty that this pipe is from the period 1938 to 1940/ 41. Also the forked tail of “P” in Peterson’s with the inward coiling upper part corroborates the vintage of this pipe.

In my earlier restoration of my inherited Peterson’s System 31, I had extensively researched the dating of these old Peterson’s and I can say with certainty that this pipe is from the period 1938 to 1940/ 41. Also the forked tail of “P” in Peterson’s with the inward coiling upper part corroborates the vintage of this pipe.

I reconfirmed and refreshed my learning by visiting pipedia.org and my memory has served me right. Here is the link to dating Peterson’s pipes: https://pipedia.org/wiki/A_Peterson_Dating_Guide;_A_Rule_of_Thumb

For further understanding of System Standard/ 0/ 3 etc, I referred to the main article on Peterson’s, but came out cropper. There is nothing substantive and clear information about this grading of these System pipes. Any source of information may please be shared with us on rebornpipes.com.

But nonetheless this is a Peterson’s System pipe from the 1938-40/41 vintage and sure is staying with me.

INITIAL VISUAL INSPECTION

The first and foremost thing that struck me as awful was that the smooth stummel is coated with a coat of lacquer!!! To top it, the coat has disintegrated in patches giving it a very sorry appearance. The icing on the cake is that half way up towards the rim, the stummel is stained black!! Why would they do that? Well, the long and short of the above is that both the lacquer and the black stain will be removed and whether the finish is to be kept natural or be stained will be decided later.

To be honest with you, being a grade 3 System pipe, there is nothing much to boast about the grains on the stummel. It has a smattering of cross grains and swirls all around the shank and stummel. The stummel surface is covered in grime giving the stummel a dirty appearance which is further accentuated by the patches of peeled lacquer coat. The stummel surface is peppered with a number of dents and ding on the foot and front of the stummel. A couple of fills are noticeable on either side near the shank and stummel junction and shown with yellow arrows. These will be clear when the stummel is cleaned of all the grime. In spite of all these flaws, the pipe has a nice size, heft and feel in the hand. It does have a quality which is seen on vintage pipes, but difficult to explain in words. And not to forget, this is nearly an 80 year old pipe!!

To be honest with you, being a grade 3 System pipe, there is nothing much to boast about the grains on the stummel. It has a smattering of cross grains and swirls all around the shank and stummel. The stummel surface is covered in grime giving the stummel a dirty appearance which is further accentuated by the patches of peeled lacquer coat. The stummel surface is peppered with a number of dents and ding on the foot and front of the stummel. A couple of fills are noticeable on either side near the shank and stummel junction and shown with yellow arrows. These will be clear when the stummel is cleaned of all the grime. In spite of all these flaws, the pipe has a nice size, heft and feel in the hand. It does have a quality which is seen on vintage pipes, but difficult to explain in words. And not to forget, this is nearly an 80 year old pipe!!

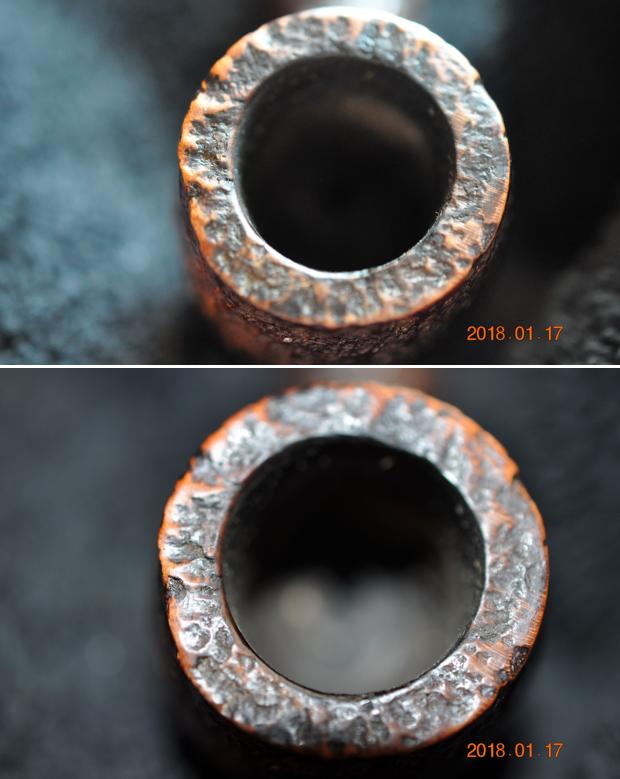

A thick and uneven layer of cake can be seen in the chamber. The rim top surface has suffered the maximum damage and is uneven. It is covered in thick overflow of lava, dirt, dust and grime. The condition of the inner walls of the chamber and rim top surface will be known once the cake has been taken down to bare briar and the rim top crud has been scraped off completely. The bowl is out of round with the left half being thinner than the rest of the rim top. The inner rim is uneven with suspected burn/ charred surfaces in 9 o’clock and 3 o’clock direction (marked in yellow circle). Only once the stummel has been thoroughly cleaned that I can be sure of my initial appreciation. The outer rim edge too has dents, chips and dings, but not very severe, likely caused due to knocking against the hard surface. In spite of the thick cake, the chamber odor is, surprisingly, not strong and should be addressed once the cake has been taken down to the bare briar and the shank internals have been thoroughly cleaned

A thick and uneven layer of cake can be seen in the chamber. The rim top surface has suffered the maximum damage and is uneven. It is covered in thick overflow of lava, dirt, dust and grime. The condition of the inner walls of the chamber and rim top surface will be known once the cake has been taken down to bare briar and the rim top crud has been scraped off completely. The bowl is out of round with the left half being thinner than the rest of the rim top. The inner rim is uneven with suspected burn/ charred surfaces in 9 o’clock and 3 o’clock direction (marked in yellow circle). Only once the stummel has been thoroughly cleaned that I can be sure of my initial appreciation. The outer rim edge too has dents, chips and dings, but not very severe, likely caused due to knocking against the hard surface. In spite of the thick cake, the chamber odor is, surprisingly, not strong and should be addressed once the cake has been taken down to the bare briar and the shank internals have been thoroughly cleaned

The shank end is adorned with a nickel ferrule. The ferrule has oxidized a fair bit but should polish up nicely. The sump shows a heavy deposition of accumulated dried gunk, adversely affecting the airflow.

The shank end is adorned with a nickel ferrule. The ferrule has oxidized a fair bit but should polish up nicely. The sump shows a heavy deposition of accumulated dried gunk, adversely affecting the airflow. The P-lip vulcanite stem is heavily oxidized and has calcification deposits towards the button end. There are deep tooth marks on the lower and upper stem surface in the bite zone and appears that the previous owner has literally chomped on the bite zone of the stem. The button edges also have bite marks, in fact, they are badly worn out. The tenon end has a major chunk missing and shows heavy accumulation of oils and tars. The part of the stem that seats in to the mortise is heavily scratched.

The P-lip vulcanite stem is heavily oxidized and has calcification deposits towards the button end. There are deep tooth marks on the lower and upper stem surface in the bite zone and appears that the previous owner has literally chomped on the bite zone of the stem. The button edges also have bite marks, in fact, they are badly worn out. The tenon end has a major chunk missing and shows heavy accumulation of oils and tars. The part of the stem that seats in to the mortise is heavily scratched.

Along with the stems of other pipes in line for restoration, I immersed the stem of this Peterson’s System 3 pipe in a mix of one part Hydrogen Peroxide 20% with one part hot water after I ran a couple of pipe cleaners dipped in alcohol through the stem air way. A couple of hours later, the stem oxidation on all these stems were raised to the surface.

Along with the stems of other pipes in line for restoration, I immersed the stem of this Peterson’s System 3 pipe in a mix of one part Hydrogen Peroxide 20% with one part hot water after I ran a couple of pipe cleaners dipped in alcohol through the stem air way. A couple of hours later, the stem oxidation on all these stems were raised to the surface. After I had fished out the stem from the Hydrogen Peroxide bath, I scrubbed it with Magiclean sponge and followed it up with a wipe of cotton swab and alcohol. I further scrubbed the stem surface with 0000 grade steel wool. The loosened and superficial layer of oxidation was easily removed and revealed the condition of the stem. There are deep bite marks in both the upper and lower bite zone. The bite marks are deep enough to cause significant thinning of the surface and complete disfigurement of the button edges. The deeper oxidation that was pulled to the surface would require more abrasive techniques.

After I had fished out the stem from the Hydrogen Peroxide bath, I scrubbed it with Magiclean sponge and followed it up with a wipe of cotton swab and alcohol. I further scrubbed the stem surface with 0000 grade steel wool. The loosened and superficial layer of oxidation was easily removed and revealed the condition of the stem. There are deep bite marks in both the upper and lower bite zone. The bite marks are deep enough to cause significant thinning of the surface and complete disfigurement of the button edges. The deeper oxidation that was pulled to the surface would require more abrasive techniques.

THE PROCESS

I started the restoration with the stem repairs as this would take the maximum of my time to clean, repair and spruce up the stem. I flamed the damaged button edge and the nicks and dents with the flame of a lighter. This helps the vulcanite to rise to the surface as it has an inherent property to regain its original shape when heated. At this stage, I could clearly make out the extent of damage to the lower surface and the extent of the crack in the bite zone. This was further accentuated due to heating with the flame of a lighter. The upper surface too has a couple of deep tooth marks. I cleaned the internals of the stem using hard and normal bristled pipe cleaners and isopropyl alcohol. The heap of pipe cleaners tells the sordid tale of the stem condition. With a pointed dental tool, I scraped out the entire dried gunk from the tenon end. I addressed the deeper oxidation by sanding the entire stem with a folded piece of 150 and followed by 220 grit sand paper. This also helps to address minor tooth chatter and prevents the fills turning brown once polished. Once the oxidation was completely removed, I wiped the surface clean with a cotton swab and alcohol and rubbed a little Extra Virgin Olive oil to hydrate the stem. Just for the information of statistically oriented reader, to get the stem to this stage it took better part of the afternoon and well past mid night!!

Continuing with the stem repair, I tightly wrapped a scotch tape around one end of a pipe cleaner so that I had achieved a snug fit of the pipe cleaner in the small rounded slot of the P-lip stem. At the tenon end, I folded a pipe cleaner till the fit was snug in to the wide tenon and after applying generous coat of petroleum jelly, I inserted it in to the tenon end of the stem. Both the scotch tape and petroleum jelly prevents the mix of charcoal and superglue from sticking over the pipe cleaners and keeps the slot and tenon open. Thereafter, I mixed superglue and activated charcoal powder and generously applied it over the bite zone on either side, including over the button, over the chipped tenon end and set it aside to cure.

Continuing with the stem repair, I tightly wrapped a scotch tape around one end of a pipe cleaner so that I had achieved a snug fit of the pipe cleaner in the small rounded slot of the P-lip stem. At the tenon end, I folded a pipe cleaner till the fit was snug in to the wide tenon and after applying generous coat of petroleum jelly, I inserted it in to the tenon end of the stem. Both the scotch tape and petroleum jelly prevents the mix of charcoal and superglue from sticking over the pipe cleaners and keeps the slot and tenon open. Thereafter, I mixed superglue and activated charcoal powder and generously applied it over the bite zone on either side, including over the button, over the chipped tenon end and set it aside to cure.

With the stem fill set aside to cure, I started with cleaning of the stummel as I was keen to know the condition of the walls of the chamber. With size 1 head followed by head size 2 and 3 of a PipNet pipe reamer, I took the cake down to bare briar. With my sharp fabricated knife, I removed the cake from the chamber where the reamer head could not reach and thereafter, using a folded piece of 180 grit sand paper, I sand out the last traces of cake and expose the walls of the chamber. I wiped the chamber with a cotton pad dipped in isopropyl alcohol to remove the carbon dust left behind by all the reaming and sanding process. Once the chamber walls were cleaned out, I was pleased to note a pristine chamber with no signs of heat fissures/ lines/ pits. With the same sharp knife, I gently scraped off the lava overflow from the rim top surface. The charred and uneven rim surface and damaged inner and outer rim edges is now clearly seen and should be addressed with simple topping of the bowl.

With the stem fill set aside to cure, I started with cleaning of the stummel as I was keen to know the condition of the walls of the chamber. With size 1 head followed by head size 2 and 3 of a PipNet pipe reamer, I took the cake down to bare briar. With my sharp fabricated knife, I removed the cake from the chamber where the reamer head could not reach and thereafter, using a folded piece of 180 grit sand paper, I sand out the last traces of cake and expose the walls of the chamber. I wiped the chamber with a cotton pad dipped in isopropyl alcohol to remove the carbon dust left behind by all the reaming and sanding process. Once the chamber walls were cleaned out, I was pleased to note a pristine chamber with no signs of heat fissures/ lines/ pits. With the same sharp knife, I gently scraped off the lava overflow from the rim top surface. The charred and uneven rim surface and damaged inner and outer rim edges is now clearly seen and should be addressed with simple topping of the bowl.

Next, I cleaned out the internals of the shank and mortise. Using my dental tool, I scraped out all the dried oils, tars and gunk that had accumulated in the draught hole, airway and sump. The amount of crud that was scrapped out and the condition of the pipe cleaners that were used leaves no surprise why air flow through it was restricted. I finished the cleaning by running a few pipe cleaners dipped in isopropyl alcohol. I also wiped the sump with cotton buds and alcohol. I gave a final cleaning to the sump with a paper napkin moistened with isopropyl alcohol. With this cleaning, all old smells in the pipe are history. The pipe now smells clean and fresh.

Next, I cleaned out the internals of the shank and mortise. Using my dental tool, I scraped out all the dried oils, tars and gunk that had accumulated in the draught hole, airway and sump. The amount of crud that was scrapped out and the condition of the pipe cleaners that were used leaves no surprise why air flow through it was restricted. I finished the cleaning by running a few pipe cleaners dipped in isopropyl alcohol. I also wiped the sump with cotton buds and alcohol. I gave a final cleaning to the sump with a paper napkin moistened with isopropyl alcohol. With this cleaning, all old smells in the pipe are history. The pipe now smells clean and fresh.  All this time that I was handling cleaning of the internals of this pipe, the patchy lacquer coating and the black stain to the upper half of the stummel was irritating me no end. The more I looked at it, the more convinced I was that this needs to be removed completely. Using cotton balls dipped in pure acetone; I worked the entire stummel and got rid of the lacquer as well as the black stain. The cleaned stummel revealed a couple of more flaws in the briar, but that is fine by me. I was prepared to handle a couple of fills and a couple more does not perturb me.

All this time that I was handling cleaning of the internals of this pipe, the patchy lacquer coating and the black stain to the upper half of the stummel was irritating me no end. The more I looked at it, the more convinced I was that this needs to be removed completely. Using cotton balls dipped in pure acetone; I worked the entire stummel and got rid of the lacquer as well as the black stain. The cleaned stummel revealed a couple of more flaws in the briar, but that is fine by me. I was prepared to handle a couple of fills and a couple more does not perturb me.

Next, I cleaned the external surface using a hard bristled toothbrush and Murphy’s Oil Soap. With a soft bristled brass wired brush, I removed the overflowing lava from the rim top surface and cleaned the internals of the shank with a shank brush and dish washing soap to remove what little crud remained in the shank. I rinsed it under running tap water and wiped the stummel dry with an absorbent soft cotton cloth.

Next, I cleaned the external surface using a hard bristled toothbrush and Murphy’s Oil Soap. With a soft bristled brass wired brush, I removed the overflowing lava from the rim top surface and cleaned the internals of the shank with a shank brush and dish washing soap to remove what little crud remained in the shank. I rinsed it under running tap water and wiped the stummel dry with an absorbent soft cotton cloth.

Once I had wiped the stummel dry with paper towels and soft cotton cloth, the exact extent of damage to the rim top and edges could be clearly gauged. Now I had a fair idea of the extent of topping the rim surface. I top the rim on a piece of 220 grit sand paper to even out the rim surface dents and dings and also to reduce the charred rim surface. I addressed the out of round inner edge by creating a light bevel to inner edge with a folded piece of 220 grit sand paper pinched between my thumb and index finger. With a folded piece of 220 grit sand paper, I sand the entire stummel surface and addressed the minor pits and flaws that were revealed when the lacquer coat was removed.

Once I had wiped the stummel dry with paper towels and soft cotton cloth, the exact extent of damage to the rim top and edges could be clearly gauged. Now I had a fair idea of the extent of topping the rim surface. I top the rim on a piece of 220 grit sand paper to even out the rim surface dents and dings and also to reduce the charred rim surface. I addressed the out of round inner edge by creating a light bevel to inner edge with a folded piece of 220 grit sand paper pinched between my thumb and index finger. With a folded piece of 220 grit sand paper, I sand the entire stummel surface and addressed the minor pits and flaws that were revealed when the lacquer coat was removed.

To further smooth out the scratches left behind by the abrasive 220 girt sand paper, I top the rim surface on a piece of 400 grit sand paper. I had hoped that further sanding with a 400 grit paper will address the minor dings that remained on the outer edge, but that was not to be. Thus, with a folded piece of 220 grit sand paper pinched between my thumb and index finger, I created a light bevel over the outer edge. I am very happy at the way the chamber and rim top surface appears at this in restoration.

To further smooth out the scratches left behind by the abrasive 220 girt sand paper, I top the rim surface on a piece of 400 grit sand paper. I had hoped that further sanding with a 400 grit paper will address the minor dings that remained on the outer edge, but that was not to be. Thus, with a folded piece of 220 grit sand paper pinched between my thumb and index finger, I created a light bevel over the outer edge. I am very happy at the way the chamber and rim top surface appears at this in restoration.

The old fills observed earlier during initial inspection and those revealed once the lacquer coat was removed, were next that I addressed. Very carefully and painstakingly, I completely removed the old fill with a pointed dental pick. I cleaned the fill of all the debris of old fill material, wiped it with alcohol and refreshed the fill with a mix of briar dust and CA superglue in each fill and set it aside to cure overnight.

The old fills observed earlier during initial inspection and those revealed once the lacquer coat was removed, were next that I addressed. Very carefully and painstakingly, I completely removed the old fill with a pointed dental pick. I cleaned the fill of all the debris of old fill material, wiped it with alcohol and refreshed the fill with a mix of briar dust and CA superglue in each fill and set it aside to cure overnight. By next day, the fill was nice, hard and well set. Using a flat head needle file, I sand these fills to achieve a rough match with the stummel surface. With a folded piece of 220 grit sand paper, I worked the fill till I had achieved a nice blend with the rest of the stummel surface. At this stage, the dreaded air pockets revealed itself (marked with red arrows) in one of the fills. I spot fill these air pockets with CA superglue. I repeated the sanding with a piece of 220 grit sand paper again once the glue had hardened. It turned out much better than I had anticipated. I further sand the entire stummel surface again with the same grit sand paper to further smooth the stummel surface in preparation for a polish by micromesh pads.

By next day, the fill was nice, hard and well set. Using a flat head needle file, I sand these fills to achieve a rough match with the stummel surface. With a folded piece of 220 grit sand paper, I worked the fill till I had achieved a nice blend with the rest of the stummel surface. At this stage, the dreaded air pockets revealed itself (marked with red arrows) in one of the fills. I spot fill these air pockets with CA superglue. I repeated the sanding with a piece of 220 grit sand paper again once the glue had hardened. It turned out much better than I had anticipated. I further sand the entire stummel surface again with the same grit sand paper to further smooth the stummel surface in preparation for a polish by micromesh pads.

I subjected the stummel to a complete cycle of micromesh polish, wet sanding with 1500 to 12000 grit pads. I paid greater attention to polish the rim top surface and the bevels created on the inner and outer rim edges. I wiped the stummel with a moist cloth after every grit pad to remove the sanding dust left behind by the pads. This also helps in monitoring the progress being made and provides an opportunity to take early corrective action, if required. I am happy with the progress being made till now.

I subjected the stummel to a complete cycle of micromesh polish, wet sanding with 1500 to 12000 grit pads. I paid greater attention to polish the rim top surface and the bevels created on the inner and outer rim edges. I wiped the stummel with a moist cloth after every grit pad to remove the sanding dust left behind by the pads. This also helps in monitoring the progress being made and provides an opportunity to take early corrective action, if required. I am happy with the progress being made till now.

Next, I rub a small quantity of “Before and After Restoration Balm” in to the briar with my finger tips and worked it deep in to the surface and let it rest for a few minutes. The balm almost immediately works its magic and the briar now has a nice vibrant appearance with the beautiful swirl grain patterns on full display. The contrast of the dark browns of the grain with the light hues of the rest of the stummel adds an interesting dimension to the appearance of the stummel. I further buffed it with a horse hair brush to further deepen the shine.

Next, I rub a small quantity of “Before and After Restoration Balm” in to the briar with my finger tips and worked it deep in to the surface and let it rest for a few minutes. The balm almost immediately works its magic and the briar now has a nice vibrant appearance with the beautiful swirl grain patterns on full display. The contrast of the dark browns of the grain with the light hues of the rest of the stummel adds an interesting dimension to the appearance of the stummel. I further buffed it with a horse hair brush to further deepen the shine.

Turning my attention to the stem repairs in my home stretch, using a flat head needle file, I reshaped the button and roughly matched the fills with the rest of the stem surface. I sand the tenon end on a piece of I sand the fill with a piece of folded 220 grit sandpaper to even it out. With a round needle file, I smooth out the jagged tenon opening. A sanding with a flat head needle file of the buttons and bite zone to achieve a rough match, revealed air pockets on the upper and lower portions of the P-lip. I painted these air pockets with a permanent marker and spot filled it with clear superglue. Once the fill had cured, I sand the fills with a piece of folded 220 grit sand paper and followed it up by further sanding the stem with 320, 600 and 800 grit sand papers to achieve a perfect blending of the fills with the stem surface and a build a crisp button edge on either side of the P-lip. The repairs look good and the stem should polish up nicely. In my exuberance to cross the finish line and start on the new project, I completely missed out on taking pictures of this last step in stem restoration. My sincere apologies for this miss….

Turning my attention to the stem repairs in my home stretch, using a flat head needle file, I reshaped the button and roughly matched the fills with the rest of the stem surface. I sand the tenon end on a piece of I sand the fill with a piece of folded 220 grit sandpaper to even it out. With a round needle file, I smooth out the jagged tenon opening. A sanding with a flat head needle file of the buttons and bite zone to achieve a rough match, revealed air pockets on the upper and lower portions of the P-lip. I painted these air pockets with a permanent marker and spot filled it with clear superglue. Once the fill had cured, I sand the fills with a piece of folded 220 grit sand paper and followed it up by further sanding the stem with 320, 600 and 800 grit sand papers to achieve a perfect blending of the fills with the stem surface and a build a crisp button edge on either side of the P-lip. The repairs look good and the stem should polish up nicely. In my exuberance to cross the finish line and start on the new project, I completely missed out on taking pictures of this last step in stem restoration. My sincere apologies for this miss….

Using the micromesh pads, I completed the polishing cycle by wet sanding the surface with 1500 to 3200 girt pads. I had read that White diamond polish is between 3600 and 4000 grit of micromesh pads and best used between these two. I decided to give this a try to see if there is any difference in the final stem finish. I mount a fresh cotton buffing wheel on to my hand held rotary tool and apply white diamond polish and buffed the stem. I wiped the stem with microfiber cloth and go through the remaining pads, dry sanding with 4000 to 12000 grit pads. The stem looks great with the fills nicely matched with the rest of the surface. I gave a final rub with “Before and After Extra Fine” stem polish compound from Mark to remove fine scratches from the stem surface. I rub a little quantity of Extra Virgin Olive oil in to the stem surface and set it aside to be absorbed by the vulcanite. The stem polished up nicely and appears as good as when new.

Using the micromesh pads, I completed the polishing cycle by wet sanding the surface with 1500 to 3200 girt pads. I had read that White diamond polish is between 3600 and 4000 grit of micromesh pads and best used between these two. I decided to give this a try to see if there is any difference in the final stem finish. I mount a fresh cotton buffing wheel on to my hand held rotary tool and apply white diamond polish and buffed the stem. I wiped the stem with microfiber cloth and go through the remaining pads, dry sanding with 4000 to 12000 grit pads. The stem looks great with the fills nicely matched with the rest of the surface. I gave a final rub with “Before and After Extra Fine” stem polish compound from Mark to remove fine scratches from the stem surface. I rub a little quantity of Extra Virgin Olive oil in to the stem surface and set it aside to be absorbed by the vulcanite. The stem polished up nicely and appears as good as when new.

To complete the restoration, I mount a cotton cloth buffing wheel on to my hand held rotary tool and applied several coats of carnauba wax. I finished the restoration by giving the entire pipe a rigorous hand buffing using a microfiber cloth to raise the shine further. I vigorously buff the nickel ferrule with a jeweler’s cloth and bring it to a nice shine.

To complete the restoration, I mount a cotton cloth buffing wheel on to my hand held rotary tool and applied several coats of carnauba wax. I finished the restoration by giving the entire pipe a rigorous hand buffing using a microfiber cloth to raise the shine further. I vigorously buff the nickel ferrule with a jeweler’s cloth and bring it to a nice shine. I mount a clean cotton cloth buffing wheel and give the entire pipe a once over buff. The finished pipe with a natural finish to the briar looks amazingly beautiful and is now ready for its long second innings with me. The dark spots of the fills, though visible, are not addressed as the pipe looks beautiful as it is. I only wish it could share with me its life story of the past years while I enjoy smoking my favorite Virginia blend in it or maybe an English blend!!

I mount a clean cotton cloth buffing wheel and give the entire pipe a once over buff. The finished pipe with a natural finish to the briar looks amazingly beautiful and is now ready for its long second innings with me. The dark spots of the fills, though visible, are not addressed as the pipe looks beautiful as it is. I only wish it could share with me its life story of the past years while I enjoy smoking my favorite Virginia blend in it or maybe an English blend!!

P.S. I earnestly would like to request all the readers to help me with information as to what does Standard/ 0/ 3 on these System pipes denote/ signify. The only thing that is confirmed is that this is definitely not one of the high grade System pipes from Peterson’s what with the fills that were seen on the stummel, but nevertheless, it’s a vintage Peterson’s!!

P.S. I earnestly would like to request all the readers to help me with information as to what does Standard/ 0/ 3 on these System pipes denote/ signify. The only thing that is confirmed is that this is definitely not one of the high grade System pipes from Peterson’s what with the fills that were seen on the stummel, but nevertheless, it’s a vintage Peterson’s!!

With this write up, I am through with all my pending works and look forward to work on my next project to restore a pipe which my dear friend and mentor, Steve, had sent me about a year back with the intention of providing me an opportunity to test my own skills. This pipe is close to my heart for other reasons too which I shall bring out in the write up after I have completed the restoration. Suffice to say at this point that this pipe is in a very very sad state and that it’s a DUNHILL!! I wish to thank each one for sparing their valuable time to read through this write up and sharing this journey with me.

Jeff captured the thick cake in the bowl and the heavy lava overflow onto the rim top in his photos. There really was no way of knowing what the edges looked like under the thick cake. You can also see the lava flowing down the sides of the bowl in the photos. The stem surface had a lot of tooth chatter and marks and was heavily oxidized and calcified.

Jeff captured the thick cake in the bowl and the heavy lava overflow onto the rim top in his photos. There really was no way of knowing what the edges looked like under the thick cake. You can also see the lava flowing down the sides of the bowl in the photos. The stem surface had a lot of tooth chatter and marks and was heavily oxidized and calcified.

He took photos of the sides and the heel of the bowl to show the interesting grain patterns in the briar. It was quite beautiful.

He took photos of the sides and the heel of the bowl to show the interesting grain patterns in the briar. It was quite beautiful.

He took photos of the stamping on the sides of the shank and on the ferrule and stem. It is readable but faint in places.

He took photos of the stamping on the sides of the shank and on the ferrule and stem. It is readable but faint in places.

I remembered that Paresh had restored a Peterson’s System Standard 314 earlier this year and as usual had done good work on the research. I turned to his blog and read through his work on the pipe (https://rebornpipes.com/2021/07/24/helping-a-fellow-piper-with-his-dream-pipea-petersons-system-pipe/). I quote below from the section on his blog regarding the dating of the pipe.

I remembered that Paresh had restored a Peterson’s System Standard 314 earlier this year and as usual had done good work on the research. I turned to his blog and read through his work on the pipe (https://rebornpipes.com/2021/07/24/helping-a-fellow-piper-with-his-dream-pipea-petersons-system-pipe/). I quote below from the section on his blog regarding the dating of the pipe.

I took photos of the rim top and bowl as well as the stem to give a sense of the condition of both. The rim top looked had some scratching on the top and some damage to the inner edge but over all it was in much better condition than I thought. The stem cleaned up well and the tooth marks on the top and underside ahead of the button are visible in the photos.

I took photos of the rim top and bowl as well as the stem to give a sense of the condition of both. The rim top looked had some scratching on the top and some damage to the inner edge but over all it was in much better condition than I thought. The stem cleaned up well and the tooth marks on the top and underside ahead of the button are visible in the photos. I took photos of the stamping on the shank sides. The are clear and readable as noted above. There is some faintness on parts of the stamping but it is still readable.

I took photos of the stamping on the shank sides. The are clear and readable as noted above. There is some faintness on parts of the stamping but it is still readable. I took the stem out of the shank and took a photo of the overall look of the pipe.

I took the stem out of the shank and took a photo of the overall look of the pipe. I decided to start my work on the pipe by addressing the damage on the inside edge of the bowl and the rim top. I used a folded piece of 220 grit sandpaper to smooth out the edge. I topped the bowl with 220 grit sandpaper on a topping board. I wiped it down with a damp cloth and the rim top damage and burn marks on the outer edges were gone.

I decided to start my work on the pipe by addressing the damage on the inside edge of the bowl and the rim top. I used a folded piece of 220 grit sandpaper to smooth out the edge. I topped the bowl with 220 grit sandpaper on a topping board. I wiped it down with a damp cloth and the rim top damage and burn marks on the outer edges were gone.

I polished the briar with micromesh sanding pads – dry sanding with 1500-12000 grit pads. I wiped the bowl down after each pad with a damp cloth.

I polished the briar with micromesh sanding pads – dry sanding with 1500-12000 grit pads. I wiped the bowl down after each pad with a damp cloth.

I restained the rim top and inner edges with a Walnut Stain Pen to blend it into the rest of the surrounding briar. The match was good.

I restained the rim top and inner edges with a Walnut Stain Pen to blend it into the rest of the surrounding briar. The match was good. I rubbed the bowl down with Before & After Restoration Balm. I worked it into the surface of the bowl sides and shank with my fingertips. The product works to clean, enliven and protect the briar. I let the balm sit for a little while and then buffed with a cotton cloth to raise the shine.

I rubbed the bowl down with Before & After Restoration Balm. I worked it into the surface of the bowl sides and shank with my fingertips. The product works to clean, enliven and protect the briar. I let the balm sit for a little while and then buffed with a cotton cloth to raise the shine.

I set the bowl aside and turned my attention to the stem. I “painted” the tooth marks on the surface with the flame of a lighter to lift them as much as possible. I was able to lift many of them but a few still remained. I filled in the remaining tooth marks with clear CA glue and set it aside to cure.

I set the bowl aside and turned my attention to the stem. I “painted” the tooth marks on the surface with the flame of a lighter to lift them as much as possible. I was able to lift many of them but a few still remained. I filled in the remaining tooth marks with clear CA glue and set it aside to cure.

I sanded the repairs smooth with a folded piece of 220 grit sandpaper to begin blending them into the stem surface. I started the polishing with some 400 grit wet dry sandpaper.

I sanded the repairs smooth with a folded piece of 220 grit sandpaper to begin blending them into the stem surface. I started the polishing with some 400 grit wet dry sandpaper. I touched up the “P” logo on the stem with white acrylic fingernail polish. I worked it into the tails on the “P” with a tooth pick and scraped off the excess with my fingernail and then buffed it with a soft cloth.

I touched up the “P” logo on the stem with white acrylic fingernail polish. I worked it into the tails on the “P” with a tooth pick and scraped off the excess with my fingernail and then buffed it with a soft cloth. I set the bowl aside and turned to work on the stem. I polished the stem with micromesh sanding pads – 1500-12000 grit pads. I wiped it down with Obsidian Oil after each sanding pad. I used Before & After Pipe Polish – both Fine and Extra Fine to further polish the stem.

I set the bowl aside and turned to work on the stem. I polished the stem with micromesh sanding pads – 1500-12000 grit pads. I wiped it down with Obsidian Oil after each sanding pad. I used Before & After Pipe Polish – both Fine and Extra Fine to further polish the stem.

This Republic Era Peterson’s System Standard 314 Bent Billiard with a vulcanite stem is a great looking pipe now that it has been restored. The beautiful grain that shines through the polished finish is stunning. As the pipe is smoked the patina should develop and look even better. I put the stem back on the bowl and carefully buffed the pipe with Blue Diamond on the buffing wheel. I gave the bowl and the stem multiple coats of carnauba wax on the buffing wheel and followed that by buffing the entire pipe with a clean buffing pad. I hand buffed the pipe with a microfiber cloth to deepen the shine. The finished Peterson’s System Standard 314 fits nicely in the hand and feels great. Give the finished pipe a look in the photos below. The dimensions of the pipe are Length: 5 inches, Height: 1 ½ inches, Outside diameter of the bowl: 1 1/8 inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 45grams/1.59oz. This one has been reserved for first refusal. If you are interested in being in the queue for this pipe send me a message or an email. Thanks for reading this blog and my reflections on the pipe while I worked on it. There are many more to come!

This Republic Era Peterson’s System Standard 314 Bent Billiard with a vulcanite stem is a great looking pipe now that it has been restored. The beautiful grain that shines through the polished finish is stunning. As the pipe is smoked the patina should develop and look even better. I put the stem back on the bowl and carefully buffed the pipe with Blue Diamond on the buffing wheel. I gave the bowl and the stem multiple coats of carnauba wax on the buffing wheel and followed that by buffing the entire pipe with a clean buffing pad. I hand buffed the pipe with a microfiber cloth to deepen the shine. The finished Peterson’s System Standard 314 fits nicely in the hand and feels great. Give the finished pipe a look in the photos below. The dimensions of the pipe are Length: 5 inches, Height: 1 ½ inches, Outside diameter of the bowl: 1 1/8 inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 45grams/1.59oz. This one has been reserved for first refusal. If you are interested in being in the queue for this pipe send me a message or an email. Thanks for reading this blog and my reflections on the pipe while I worked on it. There are many more to come!