Guest Blog by Robert M. Boughton

Member, North American Society of Pipe Collectors

http://www.roadrunnerpipes.com

http://about.me/boughtonrobert

Photos © the Author

“Life is really simple, but we insist on making it complicated.”

— Confucius (551-479 BC), Chinese philosopher, teacher, editor and politician

INTRODUCTION

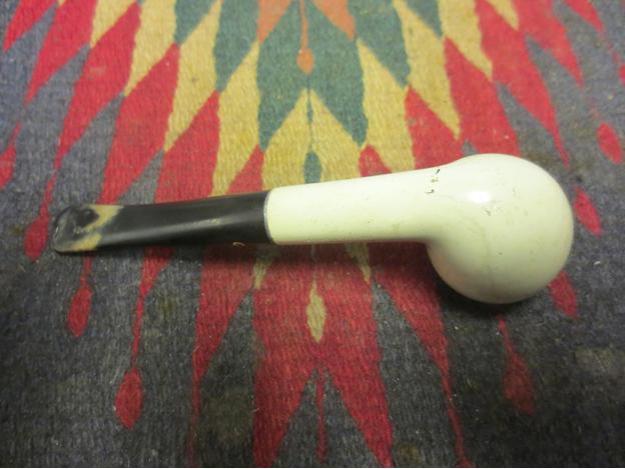

I had two main concerns when another pipe lot arrived in the mail and I turned one of the diverse examples in my hands: the head of a screw tightened flush with the draught end of the bottom of the shank, just before the chamber, and my serious doubts that whatever purpose a screw might serve could be legitimate. In other words, I was afraid to remove the thing for fear the pipe, which otherwise had potential for elegance, would fall to pieces if I did so. Before attempting to remove the ominous screw, I tried blowing through the open end of the shank, only to become red in the face and breathless with failure. Then I turned to running an alcohol-soaked pipe cleaner through the shank and found that it, also, was blocked, although the cleaner came out with only a light rusty color, a fact I told myself was promising. For the first time in my restoration experience, I had a structural problem with which to deal. I was elated.

Before attempting to remove the ominous screw, I tried blowing through the open end of the shank, only to become red in the face and breathless with failure. Then I turned to running an alcohol-soaked pipe cleaner through the shank and found that it, also, was blocked, although the cleaner came out with only a light rusty color, a fact I told myself was promising. For the first time in my restoration experience, I had a structural problem with which to deal. I was elated.

Now, don’t go and think I’m some sort of nut who gets his jollies working on broken things. For the most part I satisfy myself making old, abused or “well-used” pipes beautiful again. From upcoming photos, the need for this treatment on the bizarre Jenkins billiard this blog is about will be obvious. It’s just that until this pipe, the only kind of restoration I had done was of the basic variety. At last, I had an opportunity to tinker around and make adjustments to a pipe’s infrastructure, if you will. Hence, I felt the butterfly effect in my stomach.

Before touching whatever was screwed into the bottom of the pipe – I only describe the device this way now, as at the time I had no reason to suspect it might be anything but an average screw – I thought it advisable to see if I could find a Jenkins Pipe Co. or the like anywhere online. I started with pipephil.eu, my favorite first stop, but found no mention of the brand. And so I resorted to pipedia.com, which, as a user-generated source of information, can be more dubious in its reliability. Still I found no mention of the maker, despite the crisp, clear nomenclature including an elaborate brand stamp. Having spent two days using more than every word combination in Heaven and Earth than are dreamt of in my philosophy to track down the pipe’s origin, with both Google and Yahoo search engines, and finding everything but a plausible reference to the Jenkins who made this beautiful if weird pipe, my patience, wits and research skills (short of doing something crazy like going to the library) were exhausted. I must now hope for knowledgeable feedback from readers of this blog, or maybe our host.

Having spent two days using more than every word combination in Heaven and Earth than are dreamt of in my philosophy to track down the pipe’s origin, with both Google and Yahoo search engines, and finding everything but a plausible reference to the Jenkins who made this beautiful if weird pipe, my patience, wits and research skills (short of doing something crazy like going to the library) were exhausted. I must now hope for knowledgeable feedback from readers of this blog, or maybe our host.

The closest I came was a patent issued to one Eric G. Jenkins in 1959 for a wild but unique spring contraption to be used for tamping the spent ashes of pipe tobacco from the chamber into a suitable receptacle, without risking damage to the pipe or staining of the fingers, to which I gather pipe enjoyers back in the day had no other way to avoid. [See first hyperlink at the end of the blog. Thinking about it, the idea occurs to me that this is just the sort of Jenkins who could design the device used in the Ever Dry.

Remember, this was before the now ubiquitous three-piece pocket pipe tool was patented in the early 1970s.

RESTORATION

My routine in these blogs has been to take a linear path showing, with words and photos, what it was like, what happened, and what it is like now. But this restore was far more indirect, and so to guide me in my description of it I organized my photos to prompt my memory of just what it was I did, and when, to fix this Jenkins TrulyDry system pipe. That noted I will nevertheless begin with what it was like:

As some may have noticed in a few of the photos above, the stem and shank were uneven. In fact, I had to place the entire pipe in the refrigerator for close to an hour before I could even make the stem budge much less remove it. That feat came with more time in the cooler. The problem with the alignment, I soon learned, was remedied without trouble by cleaning off the buildup of some substance, with which I am not familiar, from the tenon.

As some may have noticed in a few of the photos above, the stem and shank were uneven. In fact, I had to place the entire pipe in the refrigerator for close to an hour before I could even make the stem budge much less remove it. That feat came with more time in the cooler. The problem with the alignment, I soon learned, was remedied without trouble by cleaning off the buildup of some substance, with which I am not familiar, from the tenon. Confident enough to continue with the removal of the screwy, old-fashioned tenon attachment-like gizmo that was over-tightened into the bottom of the shank, I did so with extreme care and slowness, listening all the while for something like a nut to come undone inside. But there was no such sound.

Confident enough to continue with the removal of the screwy, old-fashioned tenon attachment-like gizmo that was over-tightened into the bottom of the shank, I did so with extreme care and slowness, listening all the while for something like a nut to come undone inside. But there was no such sound. Right away, it was apparent that the object removed from the shank was not a regular screw employed in an ad lib repair but something designed for a purpose, however inexplicable. Able to blow through the shank, at least, I decided it was time to clean the pipe after reaming and sanding the chamber and using super fine steel wool on the rim to remove the blackness there.

Right away, it was apparent that the object removed from the shank was not a regular screw employed in an ad lib repair but something designed for a purpose, however inexplicable. Able to blow through the shank, at least, I decided it was time to clean the pipe after reaming and sanding the chamber and using super fine steel wool on the rim to remove the blackness there.

Without much hope that the pipe would have any draw on it when I replaced the screw, I was, therefore, not disappointed to find I was correct. But an idea came to me, and I loosened the screw just one full turn, allowing me to blow and inhale through the intact pipe. I removed the ventilator again and set it aside for the remaining work on the wood.

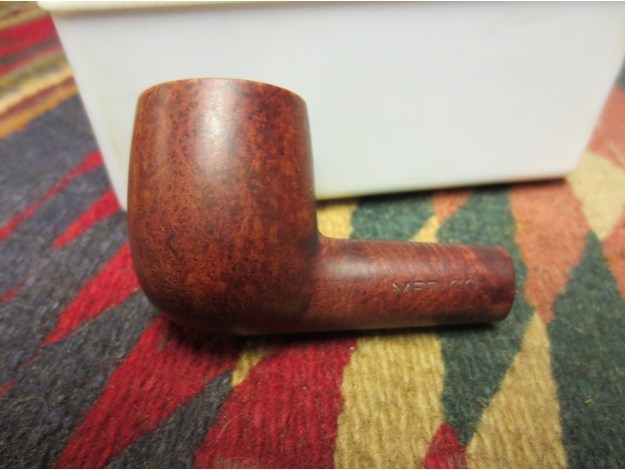

I cleaned up most of the scattered scratches either with 1500 micromesh or 400-grit paper and then rubbed the entire area of wood with the 1500 followed by 3600. The result was, as one reader of another recent blog commented, baby smooth. I also only had to re-stain a few small patches of the wood, not counting the rim. The stem required heavy sanding with 400-grit paper to fix all of the scratches, teeth chatter and uneven bit, followed by 1500 and then 3600 micromesh.

The stem required heavy sanding with 400-grit paper to fix all of the scratches, teeth chatter and uneven bit, followed by 1500 and then 3600 micromesh.

When I had prepped the pieces better than I had ever done before, the buffing brought out a brilliant, dark reddish luster.

CONCLUSION

CONCLUSION

I emailed my blog-in-progress to a retired engineer friend of mine, who looked over the text and photos and called me to arrange a meeting at McDonald’s the next morning. Armed with my laptop, an iced coffee and two printouts of the ash removal system patent that even I could see did not match the device used in the Ever Dry, I was relieved when I saw my friend walk through the door.

Confirming my conclusion concerning what the valve was not, my friend determined by the design and placement of the device that it was some sort of ventilator, however obtuse in planning and execution, that was intended to release heat and maybe even to collect moisture and small pieces of tobacco with the valve extended almost all the way. The engineer’s analysis made sense, and, happy to have an explanation of the atypical screw valve to present in this blog space, I embraced it.

At that time, I experienced another one of my moments of clarity. Seeing the intentional groove cut into the wood, I suggested that it would accommodate storage of the device with the valve retracted at times when the pipe was not being enjoyed. The engineer concurred.

Still later, while making the extensive but necessary revisions to my original version that had been debunked by the good engineer, I recalled an enlightening and lengthy online article concerning and titled “The Revolution of the System Pipe,” by Don Duco. The general knowledge and research behind the study of the evolution of system pipes around the globe is exhaustive.

I flashed on a description of the original Kirsten metal pipes with screw-on briar bowls and their inclusion of a closure system between the bowl and the shank that accomplished the same result of the screw valve on the Jenkins, and realized the design of the mechanism in the Jenkins pipe was nothing more than an adaptation of the early Kirsten, despite the newer, cruder method.

Still, whoever owned the Jenkins pipe brand must have been a frustrated engineer, if only by the aesthetic evidence, for being inspired by the notion of screwing something that, when the pipe is being enjoyed, dangles downward with an obvious and alarming attraction of attention. Besides, anyone, whether or not a connoisseur of pipes but not familiar with the Jenkins system, seeing one with the head of a screw in the bottom of it, would think it some sort of jury-rigged attempt to hold the pipe together.

As my father often pointed out, it takes all kinds.

WEBSITES TO VISIT

http://www.google.com/patents/US2886044 (Click on View as PDF for official USPTO document.)

http://www.pijpenkabinet.nl/Artikelen/Systeempijp/art-E-systeempijp.html