Blog by Steve Laug

I have been working through Bob Kerr’s estate for several weeks trying to finish up the remaining 12 pipes. I decided this morning that I needed a bit of a change of pace. I have been working on a lot of fine old briar pipes and thought a good meerschaum would be a change. I looked through the various cased figurals that I have to work and on and rejected each on as just not what I was looking for at this moment. I went back to some older pipes I have boxed here in the queue and found a black cased meer. From the case it looked like at least a ball/apple shaped pipe. I opened the case and immediately the pipe had my attention. It was exactly what I was looking for to work on next. It is an SMS Meerschaum ball with an amber coloured acrylic stem. Overall the pipe looked to be in decent condition. I wrote Jeff for the pre-cleanup photos and some history where it came from. Seems that pipe came to us from an auction in Albuquerque, New Mexico. It was a dirty pipe but not too badly scratched. There was a thick cake in the bowl for a meerschaum with some lava overflow on the inwardly beveled rim top. There was some good patina developing around the shank and bowl. The stem was pretty but had some tooth marks and chatter all around the button. The stem came off the tenon end leaving the tenon in the shank of the pipe. Not sure what was happening there. Jeff sent me the photos of the pipe in the case and out of the case before he started his cleanup work.

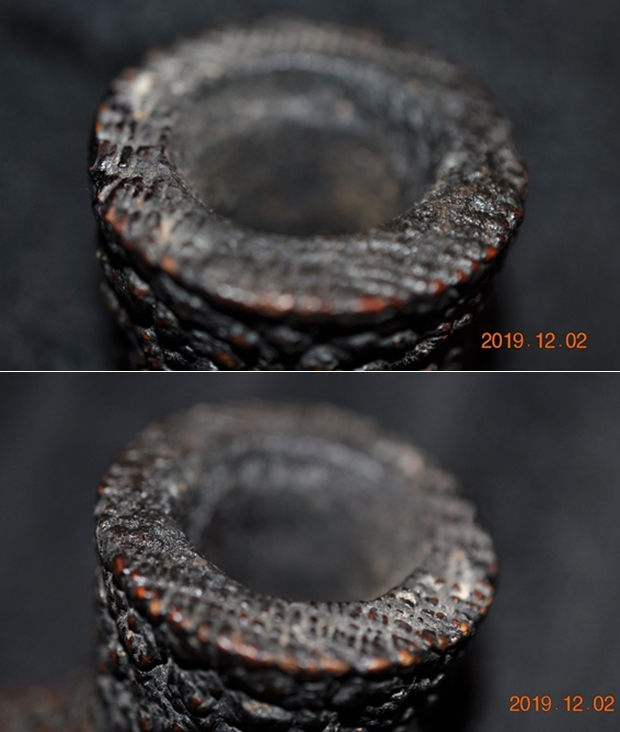

Jeff took a photo of the bowl and rim top to show the condition. It is hard to see the depth of the bowl but there as a cake lining the walls. The inwardly beveled rim top shows a thick lava coat and also some nicks and damage to the outer edge of the rim.

Jeff took a photo of the bowl and rim top to show the condition. It is hard to see the depth of the bowl but there as a cake lining the walls. The inwardly beveled rim top shows a thick lava coat and also some nicks and damage to the outer edge of the rim. He took some photos of the heel and sides of the bowl to show the developing patina as well as the dirty and grime on the bowl sides.

He took some photos of the heel and sides of the bowl to show the developing patina as well as the dirty and grime on the bowl sides.  The next two photos show the brand stamping on the inside cover of the case and in the round inlaid stem logo. It is made by SMS and is a Handcarved Meerschaum from Turkey.

The next two photos show the brand stamping on the inside cover of the case and in the round inlaid stem logo. It is made by SMS and is a Handcarved Meerschaum from Turkey. The next photos show the condition of the stem. You can see the tooth marks and chatter on both sides ahead of the button. It was rough to the touch.

The next photos show the condition of the stem. You can see the tooth marks and chatter on both sides ahead of the button. It was rough to the touch.  Jeff took a great photo of the tenon and stem connection. It appears that the tenon has come unglued from the stem end. I am not sure whether the tenon is a classic threaded tenon screwing into the shank or whether it is a push tenon. Once I work on it I will know.

Jeff took a great photo of the tenon and stem connection. It appears that the tenon has come unglued from the stem end. I am not sure whether the tenon is a classic threaded tenon screwing into the shank or whether it is a push tenon. Once I work on it I will know. I had some faint recall of the make but could not remember his name so I turned to pipephil’s site (http://www.pipephil.eu/logos/en/logo-s9.html) for some help. I found a quick note on the founding of the SMS brand which was the USA import brand for pipes made by Samil Sermet and his wife Beth. There was also a link there to the company website.

I had some faint recall of the make but could not remember his name so I turned to pipephil’s site (http://www.pipephil.eu/logos/en/logo-s9.html) for some help. I found a quick note on the founding of the SMS brand which was the USA import brand for pipes made by Samil Sermet and his wife Beth. There was also a link there to the company website. I clicked on the site link (http://www.smspipes.com/) to get a bigger picture of the brand and the makers. I quote the section of the site marked “About Us” and quote the following:

I clicked on the site link (http://www.smspipes.com/) to get a bigger picture of the brand and the makers. I quote the section of the site marked “About Us” and quote the following:

Welcome to SMS Pipes!!

We are proud to present a wide selection of premium smoking pipes. SMS Pipes features Turkish Block Meerschaum, supplied exclusively by SMS Meerschaums, and Italian Briar, supplied by Lorenzo of Italy. All the pipes offered by SMS Pipes meet or surpass our exacting “Standard of Excellence.”

Samil & Beth Sermet – SMS Pipes is family owned and operated extension of SMS Meerschaums, founded in 1980 by Samil Sermet and his wife, Beth. SMS Meerschaums is recognized nationwide as a trusted supplier by nearly 500 retail tobacconists. SMS Pipes promises to continue the philosophy embraced by SMS Meerschaums and provide premium smoking pipes that are:

Distinctive… each pipe is carefully selected for its uniqueness, quality and reliability.

Affordable… a wide range of prices makes owning a fine pipe possible for everyone.

Collectable… the timeless beauty of each pipe will be treasured for generations.

Key to the success of SMS Pipes is our dedicated staff. Based in the USA and Turkey, they maintain contact with our exceptionally talented pipe carvers and case makers and perform all the daily business activities described below:

Samil Sermet, a native of Turkey, is the buyer for SMS Meerschaums. His hometown is Eskisehir, Turkey, where a majority of the meerschaum pipe carvers live and have their shops. Samil makes a buying trip to Turkey each year and has a close working relationship with all the carvers. He is responsible for sales analysis and placing the orders necessary to maintain adequate stock in the warehouse. (samil@smspipes.com)

Beth Sermet, office manager of SMS Meerschaums, processes all orders. Even though Beth was born in Iowa, she is fluent in Turkish after living in Turkey for several years and knows all the carvers. The owners of Lorenzo Briars work closely with Beth to assure ample supply of their premium pipes. Beth also personally selects and photographs all the pipes shown on SMS Pipes. (beth@smspipes.com)

Mert Sermet, son of Samil and Beth, manages the daily operations of SMS Pipes. He is in charge of processing and shipping all orders. Mert has in-depth knowledge of every aspect of pipe manufacturing both in Turkey and Italy. He will personally respond to any comments, questions or concerns you may have about SMS Pipes by e-mail. (mert@smspipes.com)

Emel Sagtekin, Samil’s sister, is responsible for quality control and shipments of pipes to SMS Meerschaums from Turkey. Since 1988, Emel has personally checked thousands of pipes. She evaluates each pipe based on strict criteria set by SMS Meerschaums and selects only the pipes that meet or surpass our high standards.

SMS Pipes provides a wide variety of services for our customers. Although the inventory on SMS Pipes is reserved for Internet sale only, it is possible to have a selection of similar pipes sent “On Approval” to any tobacconist listed on the site. Membership in the SMS Collectors Society provides additional amenities for those interested in collecting our pipes. Our Master Carvers can be commissioned to carve custom pipe designs by special arrangement. We also offer repair and re-waxing services for all SMS Pipes.”

We are happy to have the opportunity to serve you. We hope your time spent with SMS Pipes is enjoyable and worthwhile.

Now I had a clearer picture of the brand and the makers. I knew that pipe was made after 1980 when the company began. Now it was time to work on the pipe itself.

Jeff cleaned the meerschaum with his usual penchant for thoroughness that I really appreciate. Once he finished he shipped it back to me with many of the other pipes that we have purchased or are working on for various estates. He reamed it with a PipNet pipe reamer and cleaned up the reaming with a Savinelli Fitsall Pipe Knife. He scrubbed out the internals with alcohol, pipe cleaners and cotton swabs until the pipe was clean. He scrubbed the exterior of the bowl with Murphy’s Oil Soap and a tooth brush to remove the grime and grit on the briar and the lava on the rim top. The finish looks very good with good looking grain around the bowl and shank. Jeff scrubbed the stem with Murphy’s Oil Soap to remove the grime on the exterior. When the pipe arrived here in Vancouver for the second stop of its restoration tour it looked a lot better. I took photos before I started my part of the work.

I took some close up photos of the rim top and stem to show the condition they were in when they arrived here. There was some slight darkening on the back edge as well as some scratching and nicks around the outer edges.

I took some close up photos of the rim top and stem to show the condition they were in when they arrived here. There was some slight darkening on the back edge as well as some scratching and nicks around the outer edges.  I took a photo of the pipe with the stem removed to show the overall look of the pipe. It is really a nice looking pipe. I will need to work on the tenon and see what is going on with it as a part of the restoration.

I took a photo of the pipe with the stem removed to show the overall look of the pipe. It is really a nice looking pipe. I will need to work on the tenon and see what is going on with it as a part of the restoration. I decided to work on the tenon first. I examined it with a bright light and a lens and could see that it had originally been glued in place in the stem. What I was not sure of at this point was whether it was a push tenon or a threaded one. I used a pair of needle nose pliers to check the connection. It did not wiggle like a push tenon and it turned so I had my answer – a threaded tenon. I unscrewed it from the shank and took a photo.

I decided to work on the tenon first. I examined it with a bright light and a lens and could see that it had originally been glued in place in the stem. What I was not sure of at this point was whether it was a push tenon or a threaded one. I used a pair of needle nose pliers to check the connection. It did not wiggle like a push tenon and it turned so I had my answer – a threaded tenon. I unscrewed it from the shank and took a photo. I roughened the smooth surface of the part of the tenon that would be glued in the stem with a needle file. Once it was sufficiently rough enough to provide some bite when glued into the stem I painted the end of the tenon with all-purpose white glue and inserted it in the stem. I ran a pipe cleaner through the airway to make sure it was clear and wiped off the excess glue around the threaded end of the tenon. I took a photo of the pipe with the proper tenon connection! Now it only needed to cure before I put it back together again.

I roughened the smooth surface of the part of the tenon that would be glued in the stem with a needle file. Once it was sufficiently rough enough to provide some bite when glued into the stem I painted the end of the tenon with all-purpose white glue and inserted it in the stem. I ran a pipe cleaner through the airway to make sure it was clear and wiped off the excess glue around the threaded end of the tenon. I took a photo of the pipe with the proper tenon connection! Now it only needed to cure before I put it back together again.

I set the stem aside and worked on the bowl and rim top while the glue cured in the tenon repair. I used a folded piece of 220 grit sandpaper to smooth out the damage to the outer edge of the rear part of the rim top and to minimize the darkening.

I set the stem aside and worked on the bowl and rim top while the glue cured in the tenon repair. I used a folded piece of 220 grit sandpaper to smooth out the damage to the outer edge of the rear part of the rim top and to minimize the darkening.  I polished the rim top and bowl with micromesh sanding pads – dry sanding it with 1500-12000 grit pads. I wiped the bowl down with a damp cloth after each grit of sanding pad. It is starting to really have a shine by the last sanding pads.

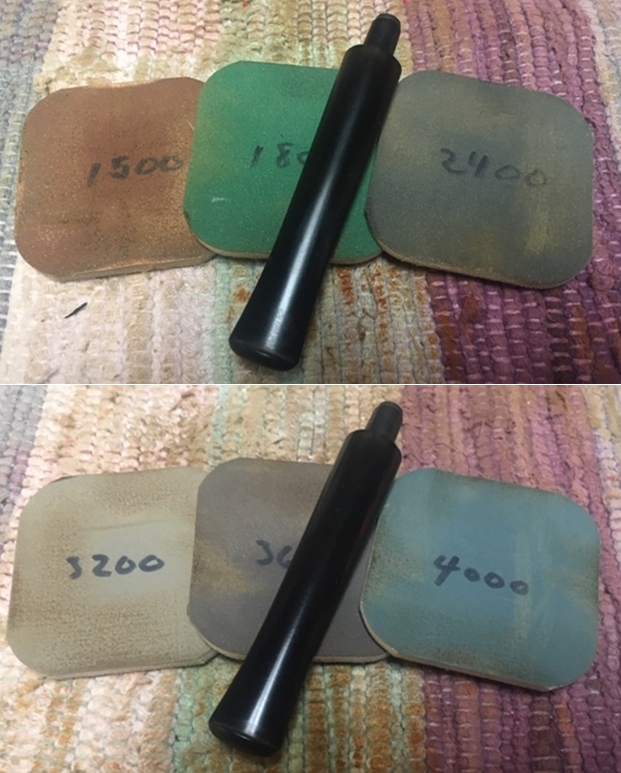

I polished the rim top and bowl with micromesh sanding pads – dry sanding it with 1500-12000 grit pads. I wiped the bowl down with a damp cloth after each grit of sanding pad. It is starting to really have a shine by the last sanding pads.

With the bowl polished it was time to wax the meerschaum. I heated it over a candle flame and rubbed it down with Clapham’s Beeswax Polish and let the wax sit and absorb into the meerschaum. Once it had cured I buffed it with a cotton towel and raised a rich shine in the surface of the meerschaum. The wax brought more of the patina to surface and the buffing highlighted.

With the bowl polished it was time to wax the meerschaum. I heated it over a candle flame and rubbed it down with Clapham’s Beeswax Polish and let the wax sit and absorb into the meerschaum. Once it had cured I buffed it with a cotton towel and raised a rich shine in the surface of the meerschaum. The wax brought more of the patina to surface and the buffing highlighted.

I filled in the deeper dents in the acrylic with clear super glue and set the stem aside to let it dry after a few moments I sprayed it with an accelerator to harden it. I sanded the repairs with 220 grit sandpaper to blend them into the surface and then started polishing the surface with 400 grit wet dry sandpaper.

I filled in the deeper dents in the acrylic with clear super glue and set the stem aside to let it dry after a few moments I sprayed it with an accelerator to harden it. I sanded the repairs with 220 grit sandpaper to blend them into the surface and then started polishing the surface with 400 grit wet dry sandpaper.

I polished the stem with micromesh sanding pads to remove the scratching in the acrylic stem. I wet sanded it with 1500-12000 grit pads and then gave it a buff with Before & After Pipe Stem polish – both Fine and Extra Fine. I buffed that off with a cotton pad. After each sanding pad and each polish I wiped the stem down with Obsidian Oil to preserve and protect the stem.

I polished the stem with micromesh sanding pads to remove the scratching in the acrylic stem. I wet sanded it with 1500-12000 grit pads and then gave it a buff with Before & After Pipe Stem polish – both Fine and Extra Fine. I buffed that off with a cotton pad. After each sanding pad and each polish I wiped the stem down with Obsidian Oil to preserve and protect the stem.

I put the pipe back together and gave it a buff on the wheel with Blue Diamond polish. I use a light touch on the acrylic as too heavy a touch can cause the heat to damage to acrylic. I gave the stem multiple coats of carnauba wax and buffed the pipe with a clean buffing pad to raise the shine. I hand buffed it with a soft cloth to deepen the shine. I put it back in the case and took a photo of the pipe in case.

I put the pipe back together and gave it a buff on the wheel with Blue Diamond polish. I use a light touch on the acrylic as too heavy a touch can cause the heat to damage to acrylic. I gave the stem multiple coats of carnauba wax and buffed the pipe with a clean buffing pad to raise the shine. I hand buffed it with a soft cloth to deepen the shine. I put it back in the case and took a photo of the pipe in case. I took photos of the finished pipe to show the shine and the patina around the bowl. The reddish amber acrylic stem looks very good with the deepening colour on the shank and the bottom of the bowl. With time the contrast will grow richer and deeper to a thing of beauty. The finished SMS Bent Ball fits nicely in the hand and I think it will feel great as it heats up with a good tobacco. Give the finished pipe a look in the photos below. The dimensions of the pipe are Length: 6 inches, Height: 2 ¼ inches, Outside diameter of the bowl: 1 ¾ inches, Chamber diameter: 7/8 of an inch. If you are interested in carrying on the legacy of this pipe it will be going on the rebornpipes store shortly. You can send me a message or an email to let know you are interested. Thanks for reading this blog and my reflections on the pipe while I worked on it. This is an interesting estate to bring back to life.

I took photos of the finished pipe to show the shine and the patina around the bowl. The reddish amber acrylic stem looks very good with the deepening colour on the shank and the bottom of the bowl. With time the contrast will grow richer and deeper to a thing of beauty. The finished SMS Bent Ball fits nicely in the hand and I think it will feel great as it heats up with a good tobacco. Give the finished pipe a look in the photos below. The dimensions of the pipe are Length: 6 inches, Height: 2 ¼ inches, Outside diameter of the bowl: 1 ¾ inches, Chamber diameter: 7/8 of an inch. If you are interested in carrying on the legacy of this pipe it will be going on the rebornpipes store shortly. You can send me a message or an email to let know you are interested. Thanks for reading this blog and my reflections on the pipe while I worked on it. This is an interesting estate to bring back to life.