Blog by Steve Laug

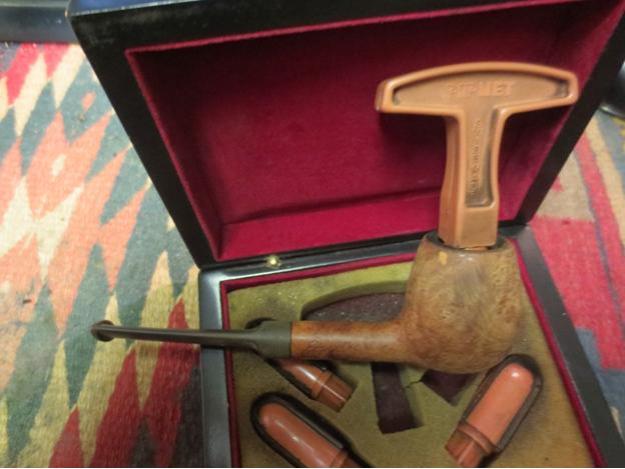

The next pipe on my work table a Danish looking Edwards Acorn shaped pipe. It is stamped Edwards in script on the left side of the shank. On the underside of the shank it is stamped with a 3. On the right side of the shank it is stamped Algerian Briar over the shape number 770 mid shank. The fancy saddle stem is stamped FRANCE on the underside of the saddle. The briar has a mix grain around the bowl and shank. There are a few small fills in the briar toward the front of the bowl on both sides. This pipe was bought from an online auction on March of 2019 in Wilkes Barre, Pennsylvania, USA. The finish was dirty but the grain shone through well. The rim top was clean but there was some darkening on the inner edge. There was a moderate cake in the bowl and some tobacco debris. The shank and stem airway was very dirty. The stem was lightly oxidized, calcified and had light tooth marks and chatter on both sides ahead of the button. Jeff took photos of the pipe before he started his clean up.

He took photos of the rim top and bowl to show the cake in the bowl, the darkening on the inner edge and the light lava on the rim top. The stem photos show the oxidation, calcification and tooth chatter and marks very well.

He took photos of the rim top and bowl to show the cake in the bowl, the darkening on the inner edge and the light lava on the rim top. The stem photos show the oxidation, calcification and tooth chatter and marks very well.

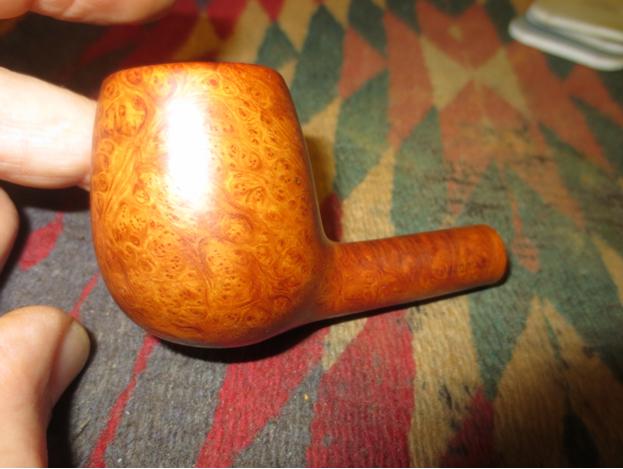

Jeff took photos of the sides of the bowl to highlight the grain around the bowl sides and base.

Jeff took photos of the sides of the bowl to highlight the grain around the bowl sides and base. He captured the stamping on the shank sides in the next photos. They are clean and readable as noted above.

He captured the stamping on the shank sides in the next photos. They are clean and readable as noted above.

I have worked on quite a few Edwards Algerian Briar pipes in the past so I turned to a blog on one of them to read the background on the brand and remind myself how to understand the stamping on the shank. Here is the link (https://rebornpipes.com/2020/03/21/refurbishing-an-edwards-unique-i-have-no-idea-what-to-call-the-shape/). I quote from the blog below rather than redo the research.

I have worked on quite a few Edwards Algerian Briar pipes in the past so I turned to a blog on one of them to read the background on the brand and remind myself how to understand the stamping on the shank. Here is the link (https://rebornpipes.com/2020/03/21/refurbishing-an-edwards-unique-i-have-no-idea-what-to-call-the-shape/). I quote from the blog below rather than redo the research.

Across the board they were all Algerian Briar and all were unstained waxed or oiled briar. I remember reading that actually oil curing was a feature of their pipes. I did a quick look on Pipedia (https://pipedia.org/wiki/Edward’s) and found that I was correct. I quote:

Edward’s pipes were originally produced in St. Claude France when France actually was a world-class pipe maker with longstanding business & political connections to Colonial Algeria that allowed them to obtain the finest briar.

During the tumultuous 1960’s, Edward’s created a business model to offer the finest briar available in both Classic and Freehand shapes – all at a fair price. They bought the company & equipment and cornered the market on the finest, choice Algerian Briar just before the supply vanished in political turmoil of Algeria’s independence. Edward’s packed up both machinery and briar-treasure to America, safely caching the essentials to create a new pipe-making dynasty. This was a coup, for the 70’s and 80’s were grim years for pipe smokers as quality briar all but disappeared.

All of Edward’s pipes are Algerian Briar – a fact very few pipe companies can claim, and all are oil-cured utilizing natural finishes – no strange concoctions are used to interfere in your tastebud’s dance with the briar. Algerian, Calabrian, Sardinian, Corsican – take your pick, but Algerian Briar is generally considered the finest smoking briar ever used. When combined with oil-curing, Algerian takes on a magical quality that even Alfred Dunhill recognized as far back as 1918 as the choice for both his Bruyere and Shell.

Jeff cleaned up the pipes with his usual thoroughness – reaming the bowl with a PipNet pipe reamer and cleaning up the reaming with a Savinelli Fitsall Pipe Knife. He scrubbed the internals of the shank and the stem with alcohol, cotton swabs and pipe cleaners. He scrubbed the exterior with Murphy’s Oil Soap to clean off the dust and grime on the finish. When he sent it the pipe was ready to restore. I could not believe how good the rim top looked in comparison to what it was when he started. I took photos of the pipe when I unpacked it. The briar was clean and the grain quite stunning. The finish looked dull and lifeless.

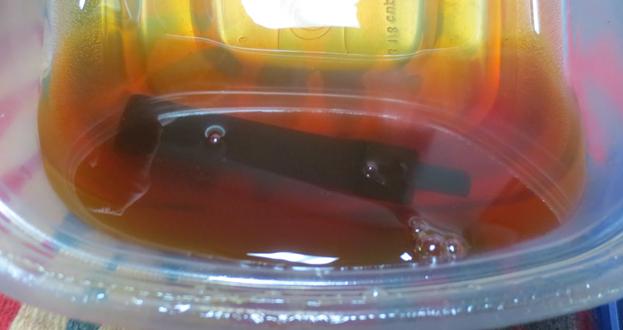

I took a close up photo of the bowl and rim top after Jeff had cleaned it up. The look of the rim top and edges is very good. He had been able to remove the cake and the lava very well. The bowl was spotless. The stem is also shown and was very clean. He had scrubbed it with Soft Scrub and then soaked it in Mark’s Before & After Deoxidizer. There was light tooth chatter and marks still remaining.

I took a close up photo of the bowl and rim top after Jeff had cleaned it up. The look of the rim top and edges is very good. He had been able to remove the cake and the lava very well. The bowl was spotless. The stem is also shown and was very clean. He had scrubbed it with Soft Scrub and then soaked it in Mark’s Before & After Deoxidizer. There was light tooth chatter and marks still remaining. I took some photos of the stamping on the shank sides. The first photo shows the Edwards cursive script stamp on the left side shank. The second shows the Algerian Briar [over] the shape number 770 on the right side. On the underside it is stamped with the number 3. All stamping is clear and readable.

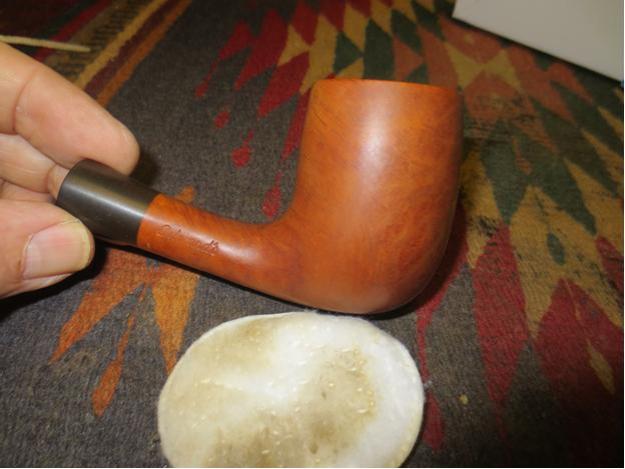

I took some photos of the stamping on the shank sides. The first photo shows the Edwards cursive script stamp on the left side shank. The second shows the Algerian Briar [over] the shape number 770 on the right side. On the underside it is stamped with the number 3. All stamping is clear and readable. I removed the stem from the shank and took a photo of the pipe to show the look of the pipe. It is a real beauty.

I removed the stem from the shank and took a photo of the pipe to show the look of the pipe. It is a real beauty. I polished the briar with micromesh sanding pads – dry sanding (carefully avoiding the stamping on the shank sides) with 1500-12000 grit pads. I wiped the bowl down with a damp cloth between each pad. The grain to take on a shine.

I polished the briar with micromesh sanding pads – dry sanding (carefully avoiding the stamping on the shank sides) with 1500-12000 grit pads. I wiped the bowl down with a damp cloth between each pad. The grain to take on a shine.

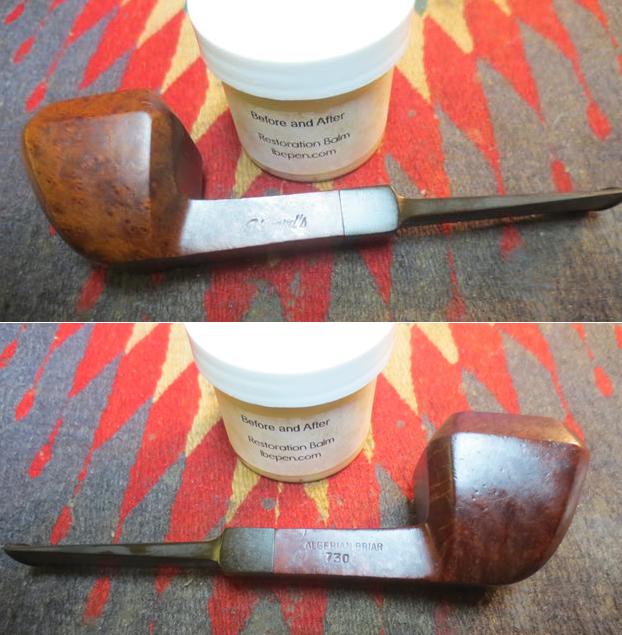

I rubbed the briar down with Before & After Restoration Balm. I worked it into the briar with my fingertips and let it do its magic. The product cleans, enlivens and preserves the briar. I let it sit for 10 minutes and then buffed it off with a cotton cloth. The bowl really is looking good at this point.

I rubbed the briar down with Before & After Restoration Balm. I worked it into the briar with my fingertips and let it do its magic. The product cleans, enlivens and preserves the briar. I let it sit for 10 minutes and then buffed it off with a cotton cloth. The bowl really is looking good at this point.

I set the bowl aside and turned my attention to the stem. I “painted” the tooth marks with the flame of a Bic Lighter. I was able to raise most of them. Those that remained I filled in with clear CA glue. I set the stem aside to let the repairs cure.

I set the bowl aside and turned my attention to the stem. I “painted” the tooth marks with the flame of a Bic Lighter. I was able to raise most of them. Those that remained I filled in with clear CA glue. I set the stem aside to let the repairs cure.

I smoothed out the repairs with a folded piece of 220 grit sandpaper. I started polishing it with 400 grit wet dry sandpaper.

I smoothed out the repairs with a folded piece of 220 grit sandpaper. I started polishing it with 400 grit wet dry sandpaper. I polished the stem with micromesh sanding pads – dry sanding with 1500-12000 grit pads. I wiped the stem down after each pad with a cloth impregnated with Obsidian Oil. I polished it with Before & After Stem Polish – both Fine and Extra Fine then gave it a final coat of Obsidian Oil and set it aside to dry.

I polished the stem with micromesh sanding pads – dry sanding with 1500-12000 grit pads. I wiped the stem down after each pad with a cloth impregnated with Obsidian Oil. I polished it with Before & After Stem Polish – both Fine and Extra Fine then gave it a final coat of Obsidian Oil and set it aside to dry.

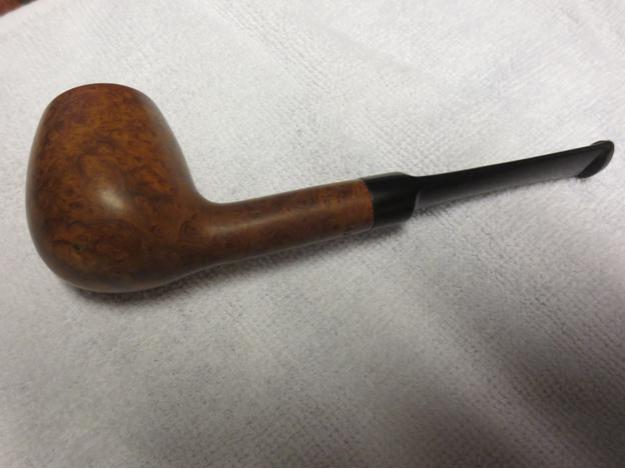

This is another beautiful pipe – this one is an Edwards Algerian Briar 770 Acorn 3. The oil cured Algerian Briar is very light weight and from my experience with other Edwards pipes, smokes very well. The grain on the pipe is quite nice and the few small fills are hidden in the finish. I put the stem on the shank and buffed the pipe with Blue Diamond on the wheel (being careful of the stamping so as not to damage that). I gave the bowl and stem multiple coats of carnauba wax and buffed the pipe with a clean buffing pad to raise the shine. I hand buffed it with a microfiber cloth to deepen the shine. The dimensions of this pipe are – Length: 6 inches, Height: 2 inches, Outside diameter of the bowl: 1 ¼ inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 1.16 ounces/33 grams. It is a great looking pipe and one that will be going on the rebornpipes store in the American Pipe Makers section. If you want to add it to your collection let me know via email to slaug@uniserve.com or by message. Thanks for walking through the restoration with me.

This is another beautiful pipe – this one is an Edwards Algerian Briar 770 Acorn 3. The oil cured Algerian Briar is very light weight and from my experience with other Edwards pipes, smokes very well. The grain on the pipe is quite nice and the few small fills are hidden in the finish. I put the stem on the shank and buffed the pipe with Blue Diamond on the wheel (being careful of the stamping so as not to damage that). I gave the bowl and stem multiple coats of carnauba wax and buffed the pipe with a clean buffing pad to raise the shine. I hand buffed it with a microfiber cloth to deepen the shine. The dimensions of this pipe are – Length: 6 inches, Height: 2 inches, Outside diameter of the bowl: 1 ¼ inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 1.16 ounces/33 grams. It is a great looking pipe and one that will be going on the rebornpipes store in the American Pipe Makers section. If you want to add it to your collection let me know via email to slaug@uniserve.com or by message. Thanks for walking through the restoration with me.