Blog by Steve Laug

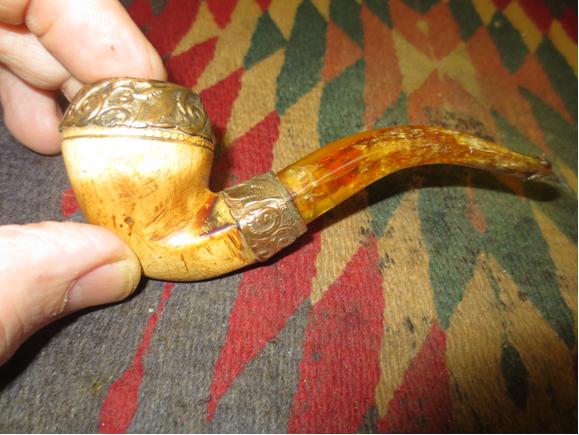

The next pipe I chose to work on from the lot of the lot of pipes my brother and I picked up on our virtual pipe hunt in Montana is a C.P.F. French Briar Silver Mount Billiard. It is a classic billiard shape, while the silver ferrule and cap on the stem end give it a feeling of elegance. The photos below show what it looked like before my brother did his clean up on it. It is another one from the lot of pipes my brother and I picked up on our virtual pipe hunt in Montana. I have written about several of the other CPF finds with the latest being a CPF horn stem bulldog and a CPF French Briar billiard. Just a reminder – CPF stands for Colossus Pipe Factory. The brand was made in the late 1880s and 1890s. Jeff took the above photos and those that follow to show the condition of the pipe before he cleaned it up. This little billiard comes from the same era as the other pipes in this find late 1880s – early 1890s. It was in worse condition in many ways than the previous pipes I had worked on from this lot. It was worn and was in rough condition. The finish was worn off and there were a lot of nicks, scratches around the outer rim of the bowl and top edge of the pipe. The outside of the bowl was covered with grime and grit. Once again there was a thick, crumbling cake buildup in the bowl and the lava from the bowl overflowed over the top of the rim. The damage to the outside of the rim made me think that the inner edge of the bowl was also damaged from the same kind of knife reaming. But I could not be certain until the cake was gone. The silver ferrule on the shank end was damaged and torn on end with what looked like small cracks in the silver. The tenon endcap was worn, scratched and some brass colour showed through the finish. The vulcanite stem had small tooth marks on the top and underside near the button and was oxidized.

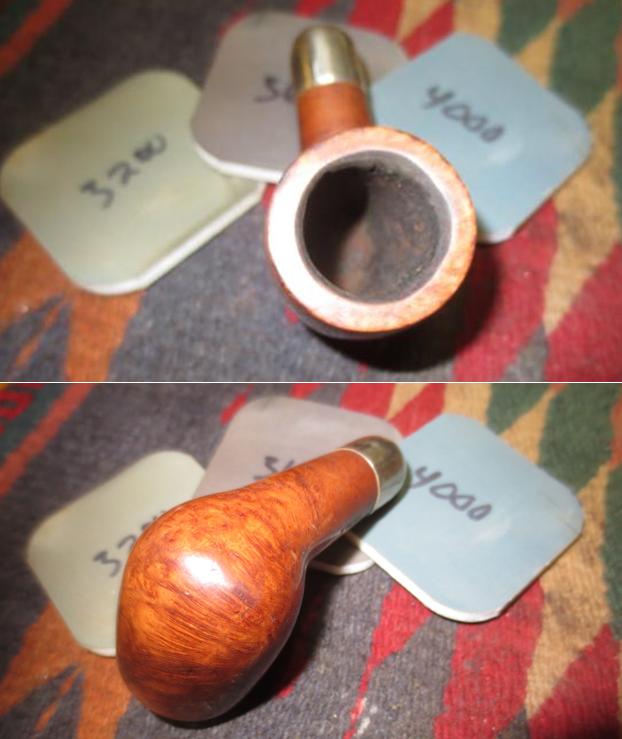

Jeff took the above photos and those that follow to show the condition of the pipe before he cleaned it up. This little billiard comes from the same era as the other pipes in this find late 1880s – early 1890s. It was in worse condition in many ways than the previous pipes I had worked on from this lot. It was worn and was in rough condition. The finish was worn off and there were a lot of nicks, scratches around the outer rim of the bowl and top edge of the pipe. The outside of the bowl was covered with grime and grit. Once again there was a thick, crumbling cake buildup in the bowl and the lava from the bowl overflowed over the top of the rim. The damage to the outside of the rim made me think that the inner edge of the bowl was also damaged from the same kind of knife reaming. But I could not be certain until the cake was gone. The silver ferrule on the shank end was damaged and torn on end with what looked like small cracks in the silver. The tenon endcap was worn, scratched and some brass colour showed through the finish. The vulcanite stem had small tooth marks on the top and underside near the button and was oxidized. Jeff took the next two close up photos of the rim top and bowl. You can see the thick cake in the bowl and the chipped overflow on the rim top. The damage to the inside edge and the chips on the outer edge are visible under the cake.

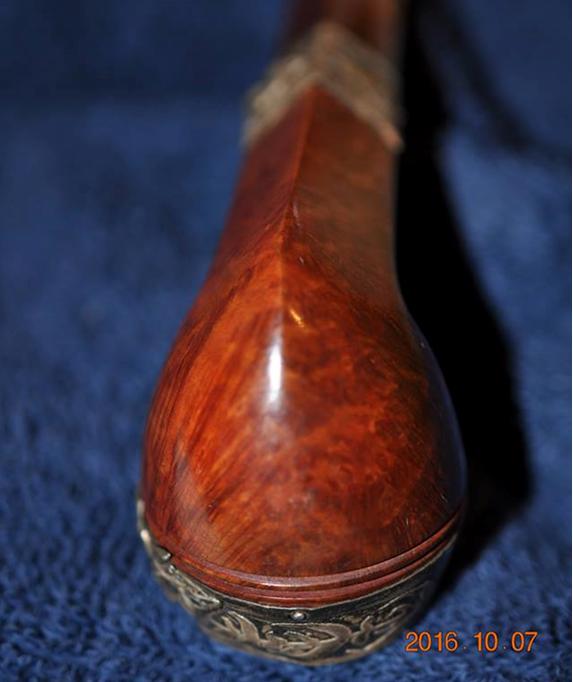

Jeff took the next two close up photos of the rim top and bowl. You can see the thick cake in the bowl and the chipped overflow on the rim top. The damage to the inside edge and the chips on the outer edge are visible under the cake.  The next three photos show the grain under the dirty and damaged finish on the bowl sides. There are also scratches and nicks in the bowl and around the rim.

The next three photos show the grain under the dirty and damaged finish on the bowl sides. There are also scratches and nicks in the bowl and around the rim.

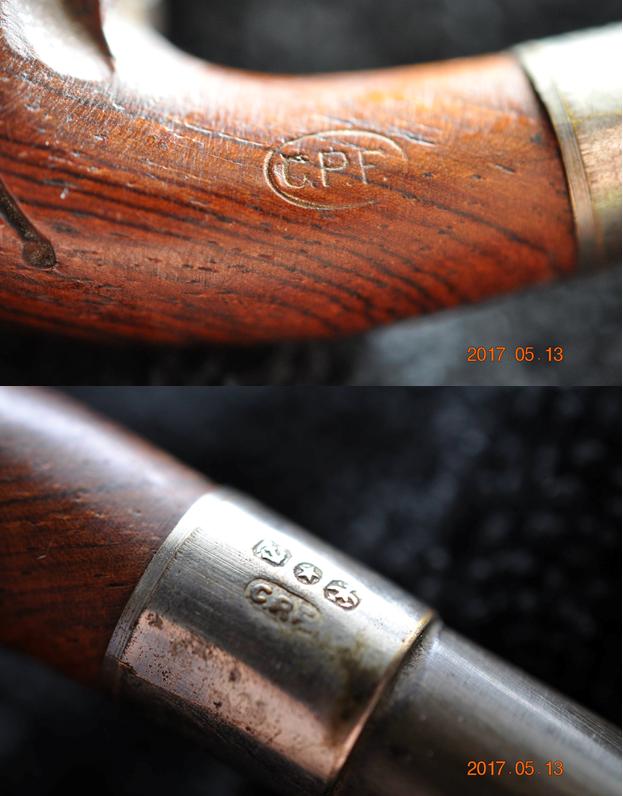

The stamping on the sides of the shank was very readable. The left side read The Remington and the right side read French Briar. The silver ferrule is stamped with three faux hallmarks and the logo of C.P.F. in an oval. Some of the cracks and tears on the ferrule are also visible in the third photo.

The stamping on the sides of the shank was very readable. The left side read The Remington and the right side read French Briar. The silver ferrule is stamped with three faux hallmarks and the logo of C.P.F. in an oval. Some of the cracks and tears on the ferrule are also visible in the third photo.

Jeff took photos of the condition and tears in the ferrule. It was in very rough shape and would take some work to repair and smooth out. But was it worth the effort.

Jeff took photos of the condition and tears in the ferrule. It was in very rough shape and would take some work to repair and smooth out. But was it worth the effort.

The bite marks, chatter and wear on the both the top and underside of the stem surface are visible in the next photos.

The bite marks, chatter and wear on the both the top and underside of the stem surface are visible in the next photos. Following his usual pattern, Jeff thoroughly cleaned the pipe. He reamed the bowl with a PipNet reamer and tidied up with a Savinelli Fitsall Pipe Knife. He scrubbed out the mortise and the airway in the shank and the stem with pipe cleaners, cotton swabs and alcohol. He scrubbed the exterior of the pipe with Murphy’s Oil Soap to remove the grime and grit on the bowl. He scrubbed the metal ferrule and stem end at the same time to clean it. I took photos of the pipe to show the condition it was in when it arrived in Vancouver. You can see the damaged rim top and edges and the fill on the right side of the bowl. The condition of the briar is rough and the stem is oxidized.

Following his usual pattern, Jeff thoroughly cleaned the pipe. He reamed the bowl with a PipNet reamer and tidied up with a Savinelli Fitsall Pipe Knife. He scrubbed out the mortise and the airway in the shank and the stem with pipe cleaners, cotton swabs and alcohol. He scrubbed the exterior of the pipe with Murphy’s Oil Soap to remove the grime and grit on the bowl. He scrubbed the metal ferrule and stem end at the same time to clean it. I took photos of the pipe to show the condition it was in when it arrived in Vancouver. You can see the damaged rim top and edges and the fill on the right side of the bowl. The condition of the briar is rough and the stem is oxidized.

Jeff had cleaned up the rim top and what was underneath was sad. The rim was chipped and damaged. The inner and outer edge of the bowl was badly damaged. The inner edge was out of round and the cuts in it seemed like they had been down when a previous owner had reamed the bowl with a knife. The outer edge was beat up with large chips and nicks going down the side of the bowl.

Jeff had cleaned up the rim top and what was underneath was sad. The rim was chipped and damaged. The inner and outer edge of the bowl was badly damaged. The inner edge was out of round and the cuts in it seemed like they had been down when a previous owner had reamed the bowl with a knife. The outer edge was beat up with large chips and nicks going down the side of the bowl. The next photos of the stem and end cap show the brass shining through and the oxidation on the surface of both sides. The tooth marks and chatter are also visible. Fortunately they do not appear to be deep.

The next photos of the stem and end cap show the brass shining through and the oxidation on the surface of both sides. The tooth marks and chatter are also visible. Fortunately they do not appear to be deep. I topped the bowl on the topping board using 220 grit sandpaper to remove the surface damage and clean up the edges from the top view. I did not have to top it too much to smooth out the rim. Topping the bowl also removed much of the damage to the edges as well.

I topped the bowl on the topping board using 220 grit sandpaper to remove the surface damage and clean up the edges from the top view. I did not have to top it too much to smooth out the rim. Topping the bowl also removed much of the damage to the edges as well. I used clear super glue and briar dust to repair the rough outer edge on the bowl top and the damaged fill on the back right side. I sanded the repairs smooth with 220 grit sandpaper to remove the excess repair and blend it into the surface of the briar.

I used clear super glue and briar dust to repair the rough outer edge on the bowl top and the damaged fill on the back right side. I sanded the repairs smooth with 220 grit sandpaper to remove the excess repair and blend it into the surface of the briar. I sanded the repairs smooth and repaired the light bevel to the inner edge of the rim with a folded piece of 220 grit sandpaper to repair the damages to the inner edge.

I sanded the repairs smooth and repaired the light bevel to the inner edge of the rim with a folded piece of 220 grit sandpaper to repair the damages to the inner edge. I polished the briar rim and the sides of the bowl with micromesh sanding pads – wet sanding with 1500-2400 grit and dry sanding with 3200-4000 grit pads. I wiped the bowl down after each pad with a damp cotton pad. The photos tell the story of the polishing process on the bowl.

I polished the briar rim and the sides of the bowl with micromesh sanding pads – wet sanding with 1500-2400 grit and dry sanding with 3200-4000 grit pads. I wiped the bowl down after each pad with a damp cotton pad. The photos tell the story of the polishing process on the bowl.

I heated the briar and stained it with dark brown aniline stain thinned by 50% with isopropyl alcohol. I flamed it to set it in the briar and repeated the process until the stain coverage was even all around the bowl.

I heated the briar and stained it with dark brown aniline stain thinned by 50% with isopropyl alcohol. I flamed it to set it in the briar and repeated the process until the stain coverage was even all around the bowl. Once the stain had dried I wiped it down with isopropyl alcohol to thin the stain and make it more transparent. When I finished wiping it down I buffed it with red Tripoli to reduce the stain even more. The pictures that follow show the process of reducing the opacity of the stain.

Once the stain had dried I wiped it down with isopropyl alcohol to thin the stain and make it more transparent. When I finished wiping it down I buffed it with red Tripoli to reduce the stain even more. The pictures that follow show the process of reducing the opacity of the stain.

I touched up the gold leaf on the stamping using European Gold Rub’n Buff. I applied it with a cotton swab and rubbed off the excess with a cotton pad. The repaired stamping is shown in the next two photos.

I touched up the gold leaf on the stamping using European Gold Rub’n Buff. I applied it with a cotton swab and rubbed off the excess with a cotton pad. The repaired stamping is shown in the next two photos. I decided to experiment with a repair to the tears in the ferrule using clear super glue. I had never tried this before but I had a hunch that the hardened glue would fill in the gaps and then I could sand it smooth. I applied the glue in layers until the edge was even with the end of the ferrule. I sanded the repairs after each application of glue until the surface of the repair matched the rest of the ferrule. While the glue is slightly visible it bound the tears together and I was able to sand it smooth and blend it into the silver. I polished the repair with micromesh sanding pads – wet sanding with1500-2400 grit pads and 3200-12000 grit pads. The following photos show the progress of the ferrule repair.

I decided to experiment with a repair to the tears in the ferrule using clear super glue. I had never tried this before but I had a hunch that the hardened glue would fill in the gaps and then I could sand it smooth. I applied the glue in layers until the edge was even with the end of the ferrule. I sanded the repairs after each application of glue until the surface of the repair matched the rest of the ferrule. While the glue is slightly visible it bound the tears together and I was able to sand it smooth and blend it into the silver. I polished the repair with micromesh sanding pads – wet sanding with1500-2400 grit pads and 3200-12000 grit pads. The following photos show the progress of the ferrule repair.

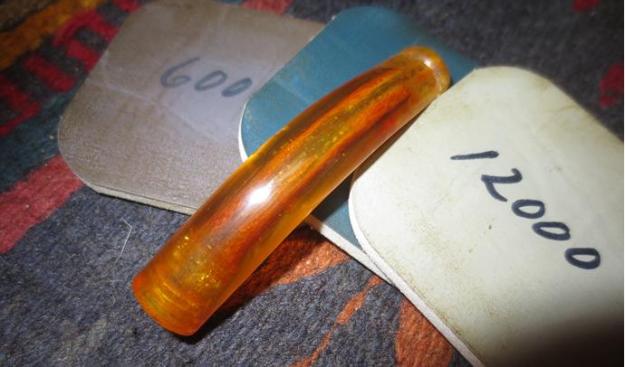

With the bowl and ferrule restored and functional I turned my attention to the stem. I polished the metal end cap with Blue Diamond on the buffing wheel. I polished the vulcanite with micromesh sanding pads – wet sanding with 1500-2400 grit pads and dry sanding with 3200-12000 grit pads. I rubbed the stem down with Obsidian Oil after each pad and after the final pad I set it aside to dry.

With the bowl and ferrule restored and functional I turned my attention to the stem. I polished the metal end cap with Blue Diamond on the buffing wheel. I polished the vulcanite with micromesh sanding pads – wet sanding with 1500-2400 grit pads and dry sanding with 3200-12000 grit pads. I rubbed the stem down with Obsidian Oil after each pad and after the final pad I set it aside to dry.

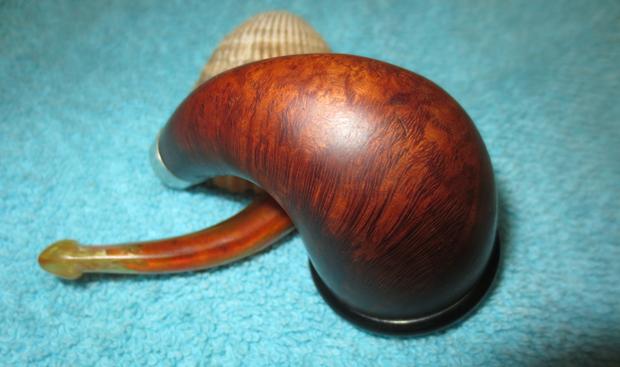

I buffed the pipe with Blue Diamond on the buffing wheel to polish the briar and the stem. I gave the bowl and stem multiple coats of carnauba wax and buffed it with a clean buffing pad to raise the shine on the pipe. I hand buffed it with a microfiber cloth to deepen the shine. The finished pipe is shown in the photos below. It has come a long way from the sad and damaged pipe that I started with when I began the restoration. What do you think? Was it worth the effort? Seems to me that it was more than worth it. Thanks for walking with me through this process.

I buffed the pipe with Blue Diamond on the buffing wheel to polish the briar and the stem. I gave the bowl and stem multiple coats of carnauba wax and buffed it with a clean buffing pad to raise the shine on the pipe. I hand buffed it with a microfiber cloth to deepen the shine. The finished pipe is shown in the photos below. It has come a long way from the sad and damaged pipe that I started with when I began the restoration. What do you think? Was it worth the effort? Seems to me that it was more than worth it. Thanks for walking with me through this process.