Blog by Steve Laug

The next pipe on the table is a mixed finish – both sandblast and smooth panels on a shape I would call a volcano. We are not sure where we picked this one up. I took in on a trade or else found on one of my long ago pipe hunts. I cannot remember to be honest with you all. Sometimes I just put the pipes in a box to work on at a later date and forget about them. Strange I know but it is the truth. The pipe had been reamed and cleaned as had the internals. The pipe is stamped on a smooth panel on the underside of the shank and reads Royal Danish [over] Made in Denmark. Next to the shank/stem union it was stamped with the shape number 970. The bowl had been reamed and cleaned somewhere along the way. The finish was clean but dull and lifeless. The stem was still lightly oxidized and there was some calcification on the underside that remained. The stem had light tooth marks or chatter. There was a gold crown logo on the topside of the taper stem. The pipe smelled clean but I would run some pipe cleaners through it for good measure. I took photos of the pipe before I started my cleanup work on it.

I took a close up photo of the bowl and rim top to show the cake in the bowl. The sandblasted rim edge were worn but looked good. The bowl was clean and the reaming nicely done. I took photos of the top and underside of the stem surface and button to show its general condition. It was lightly oxidized and had some calcification on the underside. There were some light tooth marks on the stem ahead of the button.

I took a close up photo of the bowl and rim top to show the cake in the bowl. The sandblasted rim edge were worn but looked good. The bowl was clean and the reaming nicely done. I took photos of the top and underside of the stem surface and button to show its general condition. It was lightly oxidized and had some calcification on the underside. There were some light tooth marks on the stem ahead of the button. The stamping is faint in parts but it readable as noted above. The stem had the Royal Danish logo on the stem top that was missing some of the gold stamping.

The stamping is faint in parts but it readable as noted above. The stem had the Royal Danish logo on the stem top that was missing some of the gold stamping. I removed the stem from the shank and took a photo to give a sense of the over all look of the pipe.

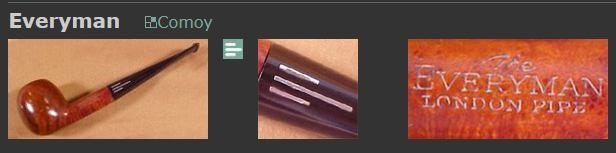

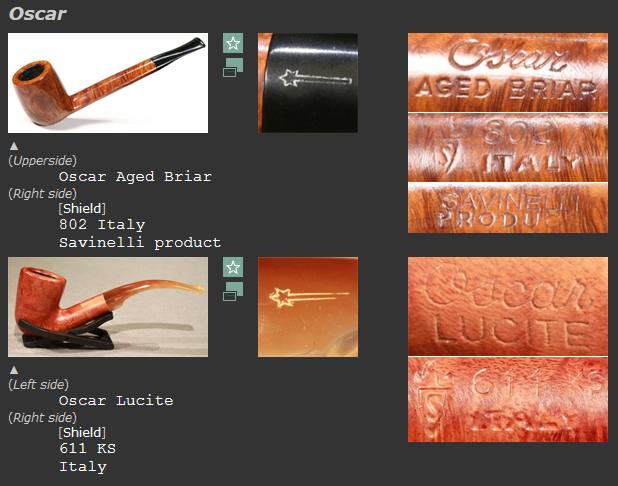

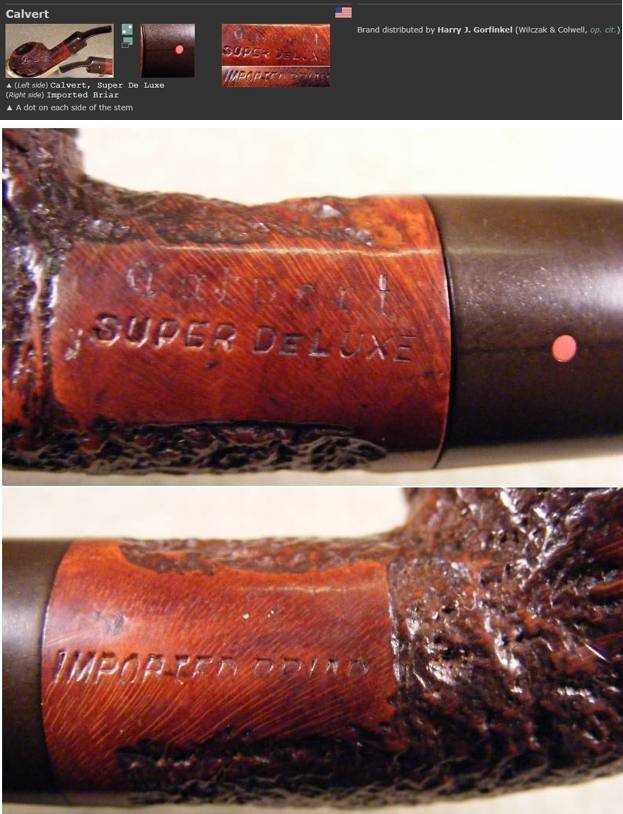

I removed the stem from the shank and took a photo to give a sense of the over all look of the pipe. I turned to Pipephil’s site (http://pipephil.eu/logos/en/logo-r6.html) to see what information I could garner that linked the brand to Stanwell like I assumed. It made the link definitive to the brand. I have included a screen capture of the information as well as the side bar information below.

I turned to Pipephil’s site (http://pipephil.eu/logos/en/logo-r6.html) to see what information I could garner that linked the brand to Stanwell like I assumed. It made the link definitive to the brand. I have included a screen capture of the information as well as the side bar information below. It gives a list of Stanwell seconds: Christian, Danish Natural, Danish Sovereign, Danske Club, Henley, Majestic, Royal Danish, Royal Guard, Scandia

It gives a list of Stanwell seconds: Christian, Danish Natural, Danish Sovereign, Danske Club, Henley, Majestic, Royal Danish, Royal Guard, Scandia

I turned also to Pipedia’s section regarding Royal Danish pipes to see what I could learn about it (https://pipedia.org/wiki/Royal_Danish). There was one short line that connects the brand to Stanwell as a second. You could also read the article on Stanwell pipes for history.

I knew I was dealing with a Stanwell made pipe in the shape number 970 – a mixed finish volcano shape.

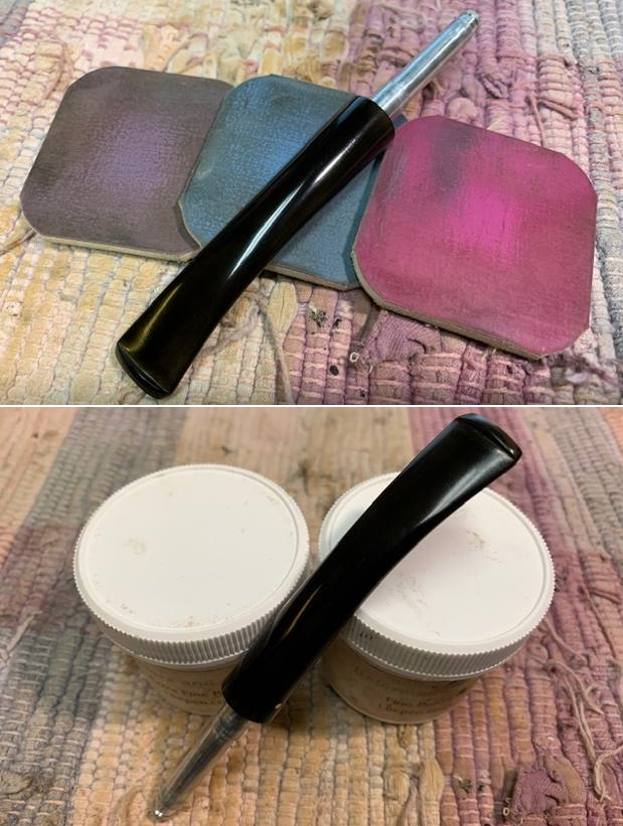

I began my work by polishing the edge of the rim top and the smooth panels on the bowl sides and the top of the shank. I used 1500-12000 grit sanding pads and wiped the bowl down with a damp cloth between each pad. It is a great looking pipe.

I worked some Before & After Restoration Balm into the surface of the briar with my fingertips and a horsehair shoe brush to clean, enliven and protect the briar. I let the balm sit for 15 minutes and then buffed with a cotton cloth to raise the shine. The photos show the bowl at this point in the restoration process.

I worked some Before & After Restoration Balm into the surface of the briar with my fingertips and a horsehair shoe brush to clean, enliven and protect the briar. I let the balm sit for 15 minutes and then buffed with a cotton cloth to raise the shine. The photos show the bowl at this point in the restoration process.

With that done the bowl was finished other than the final buffing. I set it aside and turned my attention to the stem. I “painted” the stem surface with the flame of a lighter and was able to lift all of the tooth marks on the surface. I sanded the stem surface smooth with 220 grit sandpaper to remove the small scratches and nicks in the stem surface. I started polishing it with 400 grit sandpaper.

With that done the bowl was finished other than the final buffing. I set it aside and turned my attention to the stem. I “painted” the stem surface with the flame of a lighter and was able to lift all of the tooth marks on the surface. I sanded the stem surface smooth with 220 grit sandpaper to remove the small scratches and nicks in the stem surface. I started polishing it with 400 grit sandpaper.

I paused and touched up the Gold Crown logo on the top of the stem with Rub’n Buff Antique Gold. I pressed it into the stamping and buffed off the excess with a soft cloth. While it was better it was not flawless.

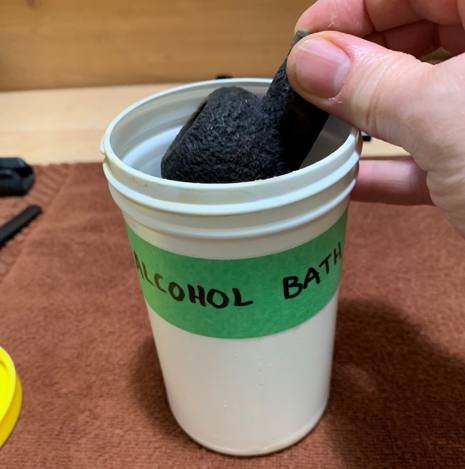

I paused and touched up the Gold Crown logo on the top of the stem with Rub’n Buff Antique Gold. I pressed it into the stamping and buffed off the excess with a soft cloth. While it was better it was not flawless. Though the pipe smelled and looked clean it had been sitting in a drawer here for quite a few years and I figured it would need a cleaning. I ran pipe cleaners and isopropyl alcohol through the shank, airway in the shank and stem. It cleaned up nicely. There was dust as well as stain that came out on the pipe cleaners.

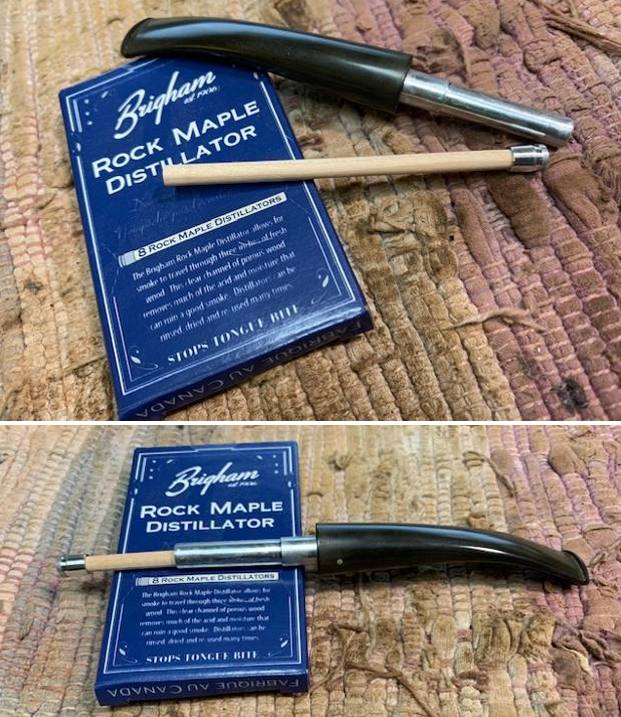

Though the pipe smelled and looked clean it had been sitting in a drawer here for quite a few years and I figured it would need a cleaning. I ran pipe cleaners and isopropyl alcohol through the shank, airway in the shank and stem. It cleaned up nicely. There was dust as well as stain that came out on the pipe cleaners. I polished the stem with micromesh sanding pads – wet sanding with 1500-12000 grit sanding pads. I wiped it down after each sanding pad with Obsidian Oil. I polished it with Before & After Pipe Stem Polish – both Fine and Extra Fine.

I polished the stem with micromesh sanding pads – wet sanding with 1500-12000 grit sanding pads. I wiped it down after each sanding pad with Obsidian Oil. I polished it with Before & After Pipe Stem Polish – both Fine and Extra Fine.

This Stanwell Made Royal Danish 970 Volcano is a really nice looking pipe. The finish is what I have found on 60s-70s era pipes – a mix of sandblast finish around the bowl and shank with smooth panels on the sides of the bowl and end of the shank. I put it back together and buffed it with Blue Diamond on the buffing wheel. I gave the bowl multiple coats of Conservator’s Wax and the stem multiple coats of carnauba wax. I buffed the pipe with a clean buffing pad on the wheel to raise the shine and hand buffed it with a microfiber cloth to deepen the shine. It is fun to see what the polished finish looks like with the polished black vulcanite stem. The pipe really is beautiful. This volcano shaped Royal Danish 970 Volcano is nice looking and the pipe feels great in my hand. It is light and well balanced. Have a look at it with the photos below. The dimensions are Length: 5 ½ inches, Height: 1 ½ inches, Outside diameter of the bowl: 1 1/8 inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 42 grams/1.48 ounces. It is a beautiful pipe and one that will soon be on the rebornpipes store in the Danish Pipemaking Company section. If you are interested in adding it to your collection let me know. Thanks for walking through the restoration with me as I worked over this pipe. Please we are not pipe owners; we hold our pipes in trust until they pass on into the trust of the next in line.

This Stanwell Made Royal Danish 970 Volcano is a really nice looking pipe. The finish is what I have found on 60s-70s era pipes – a mix of sandblast finish around the bowl and shank with smooth panels on the sides of the bowl and end of the shank. I put it back together and buffed it with Blue Diamond on the buffing wheel. I gave the bowl multiple coats of Conservator’s Wax and the stem multiple coats of carnauba wax. I buffed the pipe with a clean buffing pad on the wheel to raise the shine and hand buffed it with a microfiber cloth to deepen the shine. It is fun to see what the polished finish looks like with the polished black vulcanite stem. The pipe really is beautiful. This volcano shaped Royal Danish 970 Volcano is nice looking and the pipe feels great in my hand. It is light and well balanced. Have a look at it with the photos below. The dimensions are Length: 5 ½ inches, Height: 1 ½ inches, Outside diameter of the bowl: 1 1/8 inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 42 grams/1.48 ounces. It is a beautiful pipe and one that will soon be on the rebornpipes store in the Danish Pipemaking Company section. If you are interested in adding it to your collection let me know. Thanks for walking through the restoration with me as I worked over this pipe. Please we are not pipe owners; we hold our pipes in trust until they pass on into the trust of the next in line.