Blog by Kenneth Lieblich

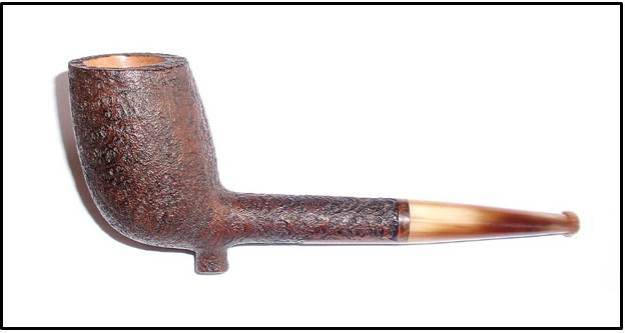

Next on the chopping block is a beautiful Danish pipe from Scandia. This terrific pipe came to me from an antique shop in the Fraser Valley (an area to the east of Vancouver). The price was reasonable, so I had to have it. The pipe is beautiful and a great example of Danish pipe-making.

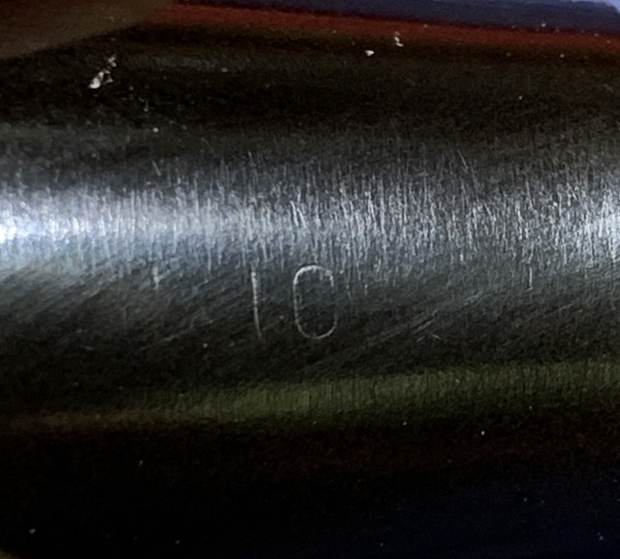

The pipe is a Danish pickaxe pipe by Scandia, produced from the esteemed pipemaker, Stanwell. The pickaxe is a very attractive shape and this one is no exception. It really makes an impression. It has beautiful, sandblasted briar from the bowl, down the shank and transitions into the vulcanite ferrule. It also has a fantastic push stem. The underside of the shank reads Scandia [over] Made in Denmark. There is a faint marking on the ferrule, which appears to show “10” or possibly “1C”. I don’t think this is a shape number, for reasons I will explain momentarily. Finally, the stem’s top also has the SC, indicating the Scandia make.

The pipe is a Danish pickaxe pipe by Scandia, produced from the esteemed pipemaker, Stanwell. The pickaxe is a very attractive shape and this one is no exception. It really makes an impression. It has beautiful, sandblasted briar from the bowl, down the shank and transitions into the vulcanite ferrule. It also has a fantastic push stem. The underside of the shank reads Scandia [over] Made in Denmark. There is a faint marking on the ferrule, which appears to show “10” or possibly “1C”. I don’t think this is a shape number, for reasons I will explain momentarily. Finally, the stem’s top also has the SC, indicating the Scandia make.

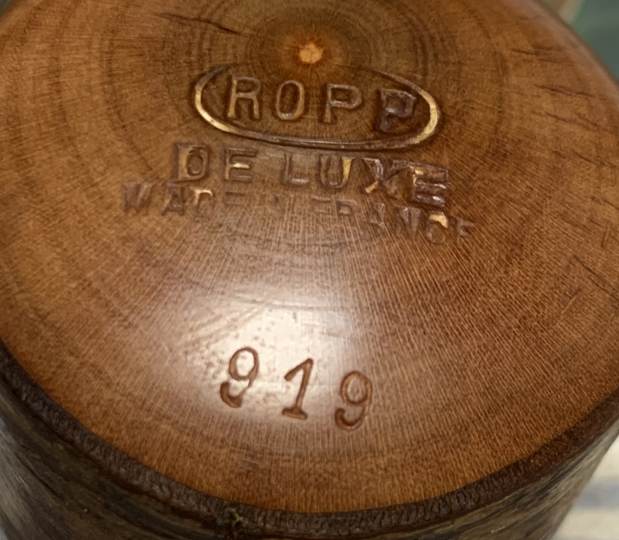

Both Pipedia and Pipephil list Scandia as being a Stanwell sub-brand or second (and not much else), as per the photo below.

Both Pipedia and Pipephil list Scandia as being a Stanwell sub-brand or second (and not much else), as per the photo below. Meanwhile, Pipedia has a good amount of information on the Stanwell brand and its history. I certainly recommend looking it over: https://pipedia.org/wiki/Stanwell.

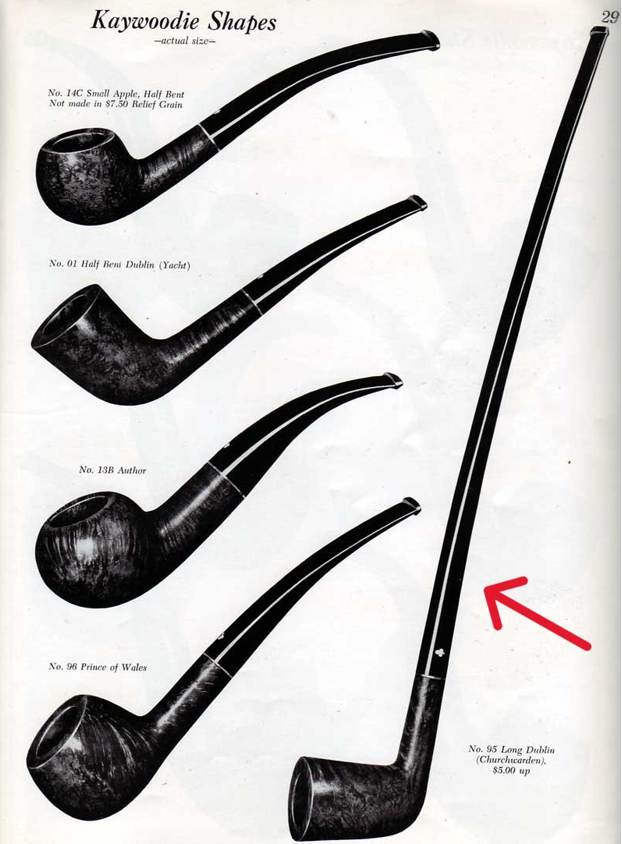

Meanwhile, Pipedia has a good amount of information on the Stanwell brand and its history. I certainly recommend looking it over: https://pipedia.org/wiki/Stanwell. Despite the (possible) number 10 on the ferrule, I went to check the list of Stanwell shapes, here on Reborn Pipes, and I found that this definitely did not match. However, I did find something that was a match! Shape 1b is listed as “Freehand, Pick Ax, push mouthpiece, by Sixten Ivarsson. (1975)”. To further confirm this, here is a page from an old 70s or 80s Stanwell catalogue which clearly shows the same shape of pipe with the matching shape number. I think we can safely assume that this is a pickaxe, designed by the legendary Sixten Ivarsson.

Despite the (possible) number 10 on the ferrule, I went to check the list of Stanwell shapes, here on Reborn Pipes, and I found that this definitely did not match. However, I did find something that was a match! Shape 1b is listed as “Freehand, Pick Ax, push mouthpiece, by Sixten Ivarsson. (1975)”. To further confirm this, here is a page from an old 70s or 80s Stanwell catalogue which clearly shows the same shape of pipe with the matching shape number. I think we can safely assume that this is a pickaxe, designed by the legendary Sixten Ivarsson. Anyway, this really is a good-looking pipe. No major issues to resolve – just a few minor ones. The stem was dirty, and some small scratches. There were a couple of significant bite marks, as well as some oxidation and calcification on the vulcanite.

Anyway, this really is a good-looking pipe. No major issues to resolve – just a few minor ones. The stem was dirty, and some small scratches. There were a couple of significant bite marks, as well as some oxidation and calcification on the vulcanite.

The rim on the stummel was blackened and burnt – that would need to be addressed. The insides were fairly dirty and would need some work to clean out. There was also a small nick along the inside edge of the rim.

The rim on the stummel was blackened and burnt – that would need to be addressed. The insides were fairly dirty and would need some work to clean out. There was also a small nick along the inside edge of the rim.

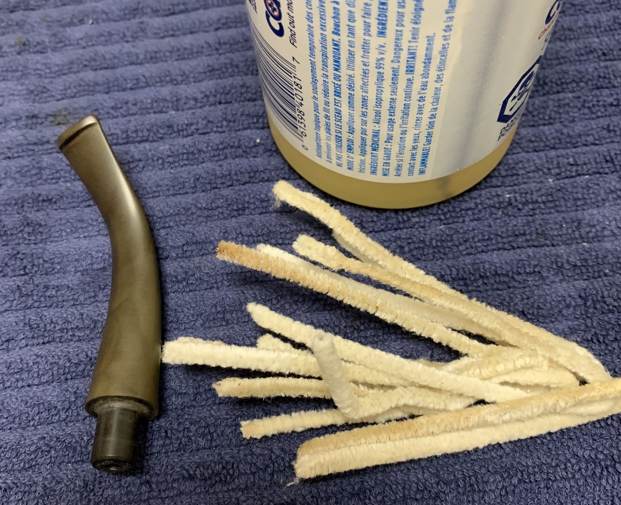

The stem was first on my list. I wiped down the outside of the stem with Murphy’s Oil Soap on some cotton pads. I also took a BIC lighter and ‘painted’ the stem with its flame in order to lift the bite marks and dents. Unfortunately, this didn’t really work, but I have ways of sorting this out. Then, I cleaned out the insides of the stem with pipe cleaners and isopropyl alcohol.

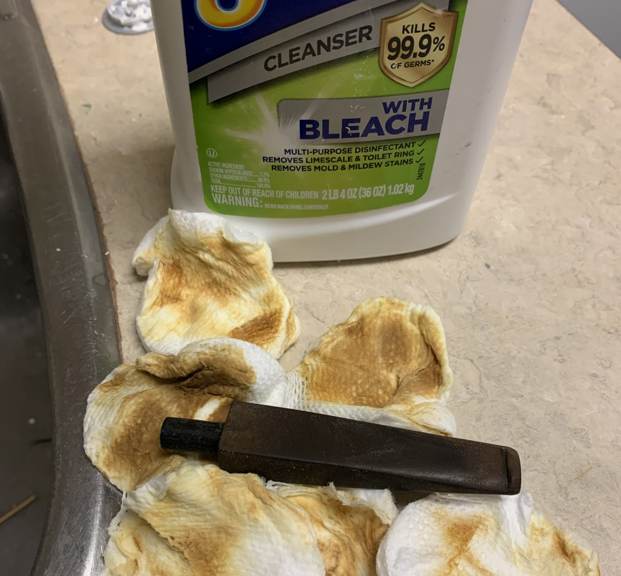

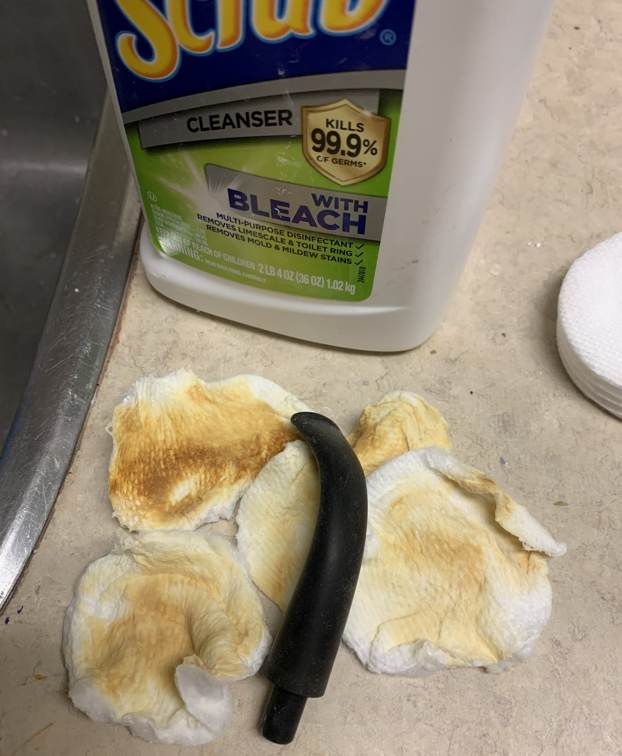

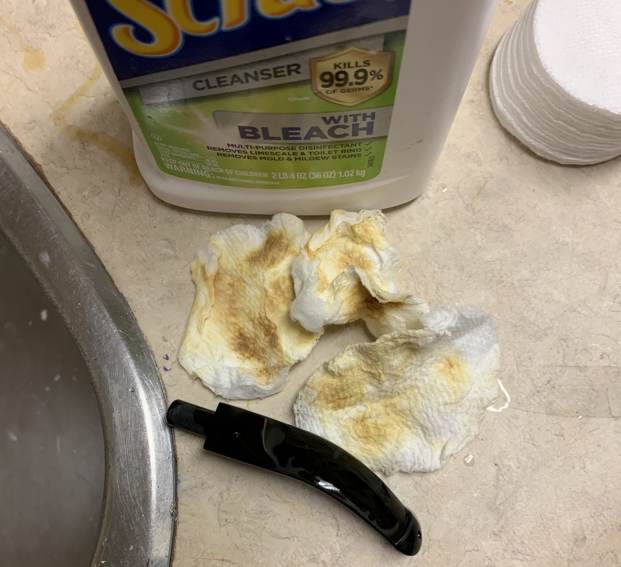

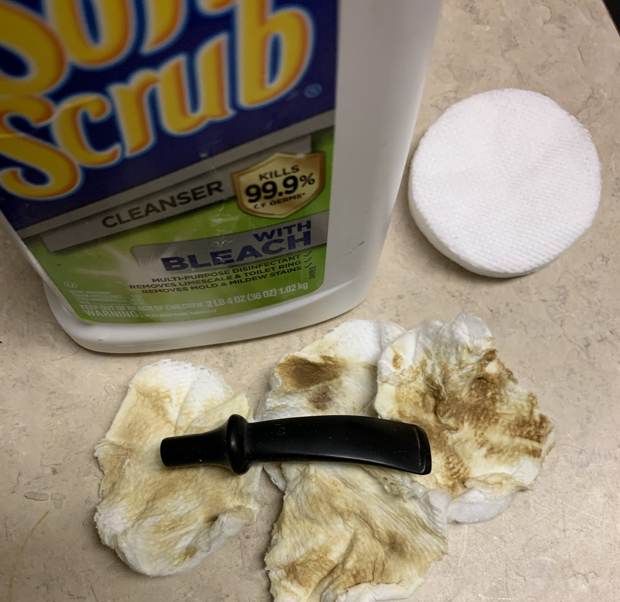

The stem was first on my list. I wiped down the outside of the stem with Murphy’s Oil Soap on some cotton pads. I also took a BIC lighter and ‘painted’ the stem with its flame in order to lift the bite marks and dents. Unfortunately, this didn’t really work, but I have ways of sorting this out. Then, I cleaned out the insides of the stem with pipe cleaners and isopropyl alcohol. Once this process was done, I used SoftScrub and cotton pads to wipe down the stem before throwing it in the Pipe Stem Oxidation Remover overnight. The following day, I cleaned all of the de-oxidizing mess and again scrubbed with SoftScrub on some cotton pads to remove the leftover oxidation. This worked well.

Once this process was done, I used SoftScrub and cotton pads to wipe down the stem before throwing it in the Pipe Stem Oxidation Remover overnight. The following day, I cleaned all of the de-oxidizing mess and again scrubbed with SoftScrub on some cotton pads to remove the leftover oxidation. This worked well.

I used some nail polish to restore the letters SC on the stem. I painted the area carefully and let it fully set before proceeding. These letters were too worn to be fully restored, but they definitely looked better after I worked on them.

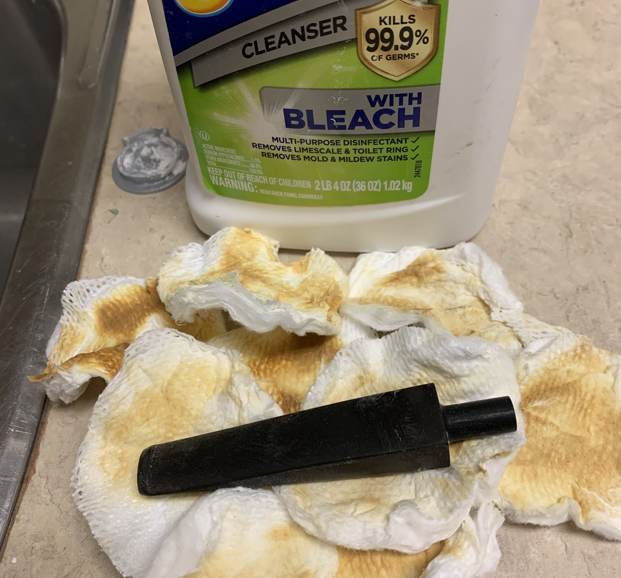

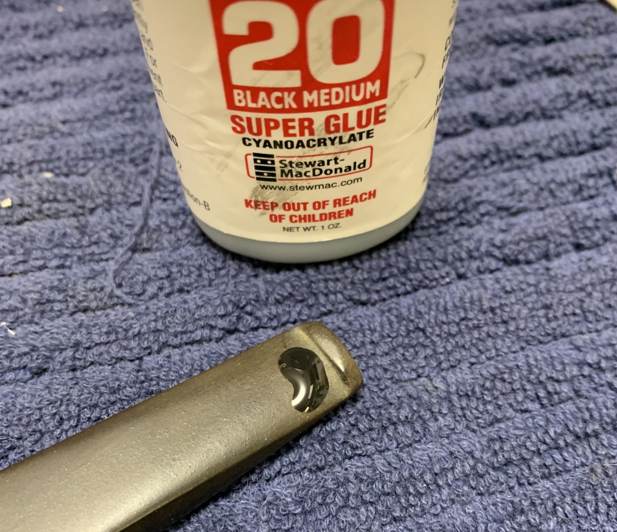

I used some nail polish to restore the letters SC on the stem. I painted the area carefully and let it fully set before proceeding. These letters were too worn to be fully restored, but they definitely looked better after I worked on them. Before I moved on to the Micromesh pads, I built up the dents on the stem with cyanoacrylate adhesive and let them fully cure.

Before I moved on to the Micromesh pads, I built up the dents on the stem with cyanoacrylate adhesive and let them fully cure. I used my miniature files to ensure that the repairs keep the shape and look like they should. I then sanded the stem down with 220-, 400-, and 600-grit sandpapers to meld seamlessly into the stem. I did the same to the remaining tooth marks. I then used all nine Micromesh pads (1,500 through 12,000 grit) to bring out the lovely black lustre on the stem. I also used Obsidian Pipe Stem Oil in between each pad scrubbing.

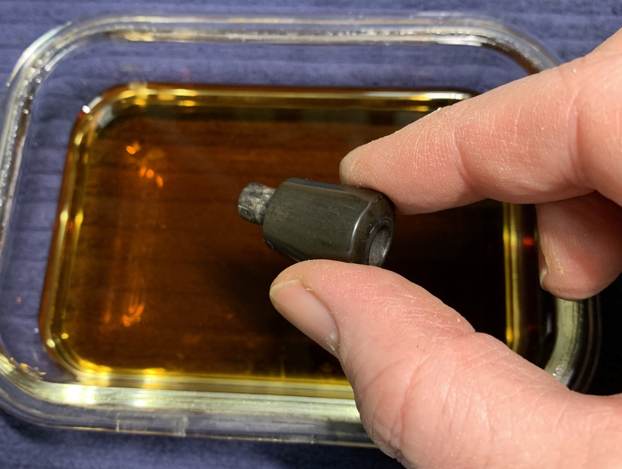

I used my miniature files to ensure that the repairs keep the shape and look like they should. I then sanded the stem down with 220-, 400-, and 600-grit sandpapers to meld seamlessly into the stem. I did the same to the remaining tooth marks. I then used all nine Micromesh pads (1,500 through 12,000 grit) to bring out the lovely black lustre on the stem. I also used Obsidian Pipe Stem Oil in between each pad scrubbing. I repeated all of the above procedures for the vulcanite ferule, which only came off the stummel after applying heat and some gentle force.

I repeated all of the above procedures for the vulcanite ferule, which only came off the stummel after applying heat and some gentle force.

On to the stummel, and the usual cleaning procedures were in order for this pipe. I used both the PipNet Reamer and the KleenReem to remove the built-up cake and take the bowl down to bare briar, as I wanted to ensure there were no hidden flaws in the walls of the bowl. Fortunately, there were none.

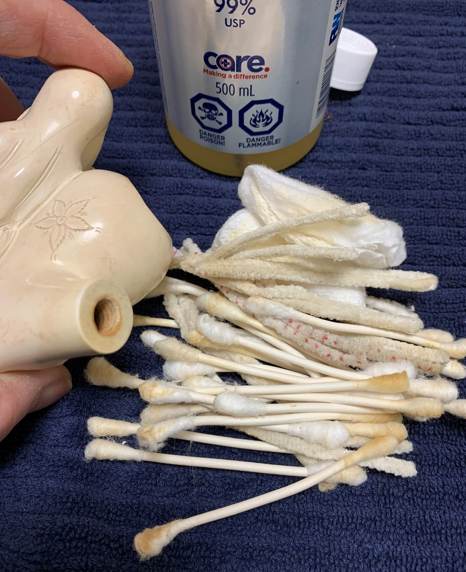

On to the stummel, and the usual cleaning procedures were in order for this pipe. I used both the PipNet Reamer and the KleenReem to remove the built-up cake and take the bowl down to bare briar, as I wanted to ensure there were no hidden flaws in the walls of the bowl. Fortunately, there were none. I then proceeded to clean out the insides of the shank with Q-tips, pipe cleaners, and isopropyl alcohol. There was lots of filth inside this stummel, and it took a good number of pipe cleaners etc. to sort that out. I followed that up by cleaning the insides with some dish soap and tube brushes. I then moved on to cleaning the outside of the stummel with Murphy’s Oil Soap and some cotton pads. That removed any latent dirt.

I then proceeded to clean out the insides of the shank with Q-tips, pipe cleaners, and isopropyl alcohol. There was lots of filth inside this stummel, and it took a good number of pipe cleaners etc. to sort that out. I followed that up by cleaning the insides with some dish soap and tube brushes. I then moved on to cleaning the outside of the stummel with Murphy’s Oil Soap and some cotton pads. That removed any latent dirt.

I decided to de-ghost the pipe in order to remove any lingering smells of the past. I thrust cotton balls into the bowl and the shank and saturated them with 99% isopropyl alcohol. I let the stummel sit overnight. This caused any remaining oils, tars and smells to leach out into the cotton. The bowl was nice and clean after this.

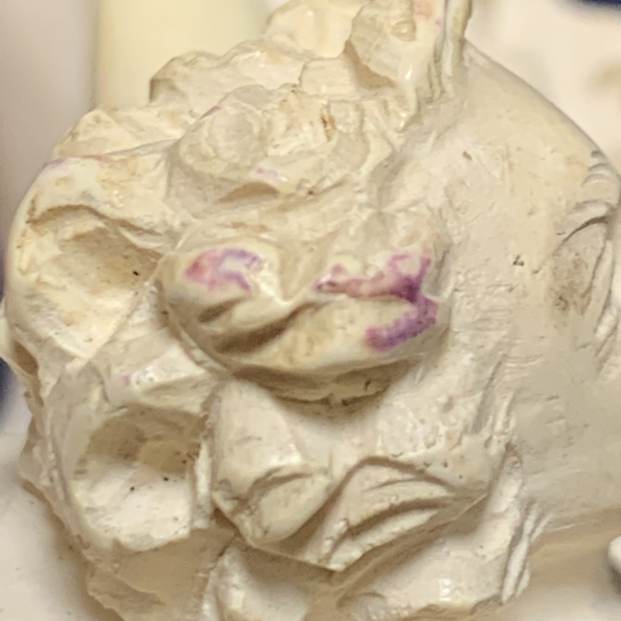

I decided to de-ghost the pipe in order to remove any lingering smells of the past. I thrust cotton balls into the bowl and the shank and saturated them with 99% isopropyl alcohol. I let the stummel sit overnight. This caused any remaining oils, tars and smells to leach out into the cotton. The bowl was nice and clean after this. As I mentioned earlier, there were some small burn marks on the rim of the stummel that also needed to be addressed. Some of this was removed by the Murphy’s. For the burns that remained, I took some oxalic acid on a Q-tip and rubbed and rubbed. As you will see, the treatment worked reasonably well and the rim was improved. Some would remain, but that is part of the history of this pipe. I completed this step by gently sanding the interior rim edge to remove any remnants that remained.

As I mentioned earlier, there were some small burn marks on the rim of the stummel that also needed to be addressed. Some of this was removed by the Murphy’s. For the burns that remained, I took some oxalic acid on a Q-tip and rubbed and rubbed. As you will see, the treatment worked reasonably well and the rim was improved. Some would remain, but that is part of the history of this pipe. I completed this step by gently sanding the interior rim edge to remove any remnants that remained.

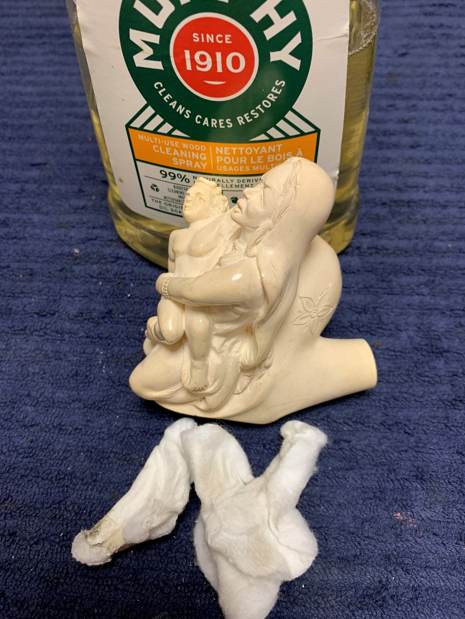

Then I addressed the nick on the rim by filling it with cyanoacrylate adhesive and briar dust. I sanded it down and made it look great. After this, the entire stummel was treated to a rub-down with all nine Micromesh pads (1,500 through 12,000 grit). A light application of Before & After Restoration Balm brought out the best in the stummel’s sandblast. There is some beautiful wood on this Danish pipe!

Then I addressed the nick on the rim by filling it with cyanoacrylate adhesive and briar dust. I sanded it down and made it look great. After this, the entire stummel was treated to a rub-down with all nine Micromesh pads (1,500 through 12,000 grit). A light application of Before & After Restoration Balm brought out the best in the stummel’s sandblast. There is some beautiful wood on this Danish pipe!

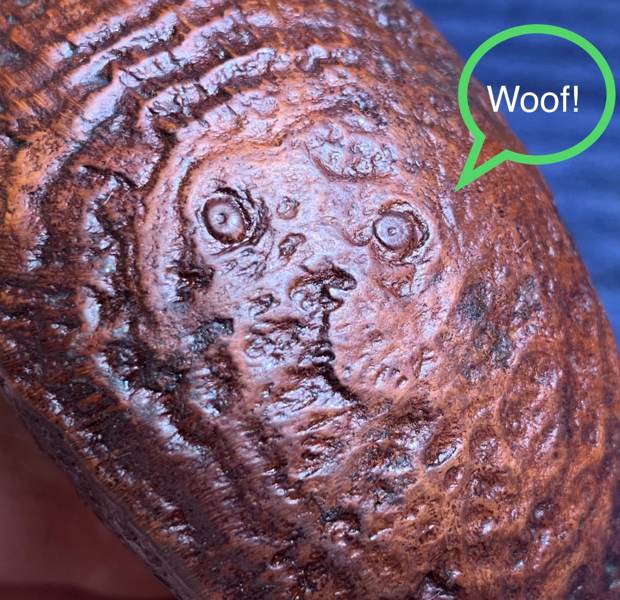

In fact, as I was working, my youngest child came to watch me for a bit and said, “Is that a doggy?” I wasn’t sure what she meant, but she grabbed the stummel and pointed this out. That’s pretty funny!

In fact, as I was working, my youngest child came to watch me for a bit and said, “Is that a doggy?” I wasn’t sure what she meant, but she grabbed the stummel and pointed this out. That’s pretty funny! I glued the ferrule back I place and then it was off for a trip to the buffer. A dose of White Diamond and a few coats of conservator’s wax were just what this pipe needed. I had to be especially careful with the bench polisher, since the edges had a tendency to catch on the buffing wheels.

I glued the ferrule back I place and then it was off for a trip to the buffer. A dose of White Diamond and a few coats of conservator’s wax were just what this pipe needed. I had to be especially careful with the bench polisher, since the edges had a tendency to catch on the buffing wheels.

This pipe was a delight from the start and its beauty only increased through the restoration process. This pipe is elegant, light, and incredibly comfortable to hold. Finally, I am pleased to announce that this pipe is for sale! If you are interested in acquiring it for your collection, please have a look in the ‘Danish’ pipe section of the store here on Steve’s website. You can also email me directly at kenneth@knightsofthepipe.com. The approximate dimensions of the Stanwell are as follows: length 5½ in. (140 mm); height 2½ in. (64 mm); bowl diameter 1⅝ in. (41 mm); chamber diameter ¾ in. (19 mm). The weight of the pipe is 1⅝ oz. (47 g). I hope you enjoyed reading the story of this restoration as much as I enjoyed restoring it. If you are interested in more of my work, please follow me here on Steve’s website or send me an email. Thank you very much for reading and, as always, I welcome and encourage your comments.

This pipe was a delight from the start and its beauty only increased through the restoration process. This pipe is elegant, light, and incredibly comfortable to hold. Finally, I am pleased to announce that this pipe is for sale! If you are interested in acquiring it for your collection, please have a look in the ‘Danish’ pipe section of the store here on Steve’s website. You can also email me directly at kenneth@knightsofthepipe.com. The approximate dimensions of the Stanwell are as follows: length 5½ in. (140 mm); height 2½ in. (64 mm); bowl diameter 1⅝ in. (41 mm); chamber diameter ¾ in. (19 mm). The weight of the pipe is 1⅝ oz. (47 g). I hope you enjoyed reading the story of this restoration as much as I enjoyed restoring it. If you are interested in more of my work, please follow me here on Steve’s website or send me an email. Thank you very much for reading and, as always, I welcome and encourage your comments.