Blog by Steve Laug

The next pipe I have chosen is smooth finished Peterson’s Billiard pipe. This one is a smooth Billiard that has a rich coloured finish around the bowl sides and shank. It came to us recently from an estate of a pipeman in Idaho, USA. The contrast of the brown stains makes the grain really pop. It was stamped on the left side of the shank and read Peterson’s [over] “Kildare”. It was stamped to the right of the shank and reads Made in the Republic of Ireland (3 lines) with the shape number 6 next to the bowl. It came to us quite clean, just some dust and debris and little bit of oxidation. The bowl was very clean and I am pretty sure it was either lightly smoked or unsmoked. There is no smell of tobacco in the bowl. The rim top and the inner edge of the bowl looked good. There is one spot on the inner edge on the right front of the bowl that is slightly darkened that makes me wonder if it had been smoked. The mortise was also clean with no oils or tars darkening it. The stem was lightly oxidized but there were not any tooth marks or chatter on the top and underside on and near the button. I took photos of the pipe before I started my cleanup work. They tell the story and give a glimpse of the promise that we see in this pipe.

I took photos of the rim top and stem to show the general condition of the pipe. The bowl is very clean other than dust and the rim top and edges look good. Though, there appears to be a little darkening on the right front inner edge. The stem is lightly oxidized but there are no tooth marks on the surface or the button.

I took photos of the rim top and stem to show the general condition of the pipe. The bowl is very clean other than dust and the rim top and edges look good. Though, there appears to be a little darkening on the right front inner edge. The stem is lightly oxidized but there are no tooth marks on the surface or the button.  I took photos of the sides of the shank to show the stamping. The stamping is readable in the photos below and is as noted above. I removed the stem and took a photo of the bowl and stem to give a sense of proportion for the pipe. It is a beauty.

I took photos of the sides of the shank to show the stamping. The stamping is readable in the photos below and is as noted above. I removed the stem and took a photo of the bowl and stem to give a sense of proportion for the pipe. It is a beauty.

I am including the link to the Pipedia’s article on Peterson pipes. It is a great read in terms of the history of the brand (https://pipedia.org/wiki/Peterson).

I am including the link to the Pipedia’s article on Peterson pipes. It is a great read in terms of the history of the brand (https://pipedia.org/wiki/Peterson).

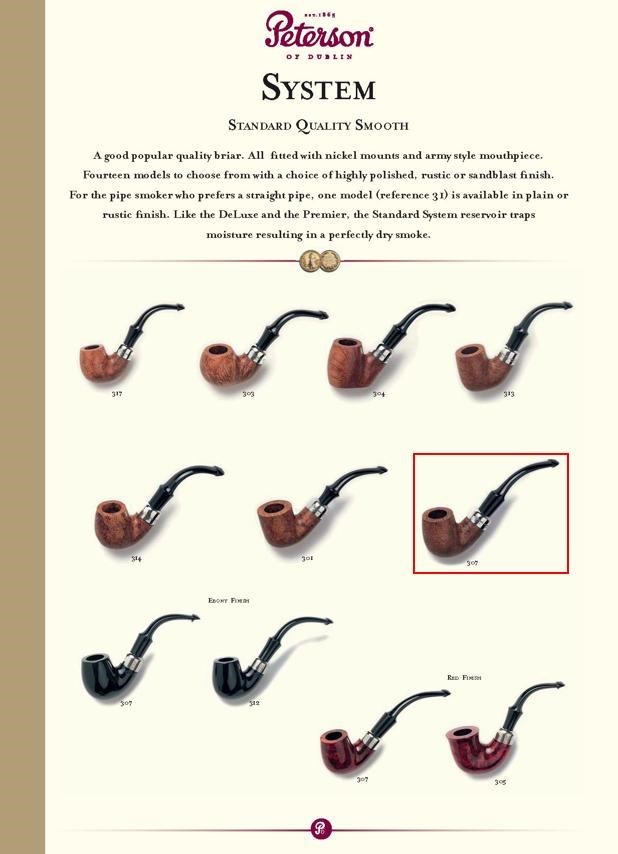

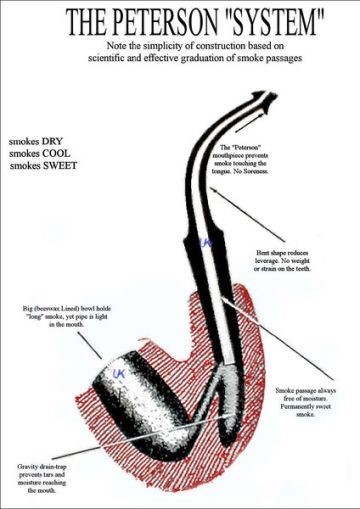

I turned to “The Peterson Pipe” by Mark Irwin and Gary Malmberg to get some background on the Peterson’s System Line. On page 314 it had the following information.

Kildare (1965-) First issue of line with matte-finish in Classic Range shapes, P-Lip and fishtail mouthpiece. Second issue C.1979 as Kildare Patch, with rusticated patches on pipe surface. Third issue 2010, matte-brown, P-Lip or fishtail mouthpiece, no band. Fourth issue 2011-, burgundy sandblast finish, nickel army mount, fishtail mouthpiece, exclusive to Smokingpipes.com.

Judging from the description above I believe that I am working on a First Issue of the line in the time period of 1965-1979. It is a late Republic Era Classic Shaped pipe with a matte-finish and a P-Lip stem. Now it was time to work on the pipe.

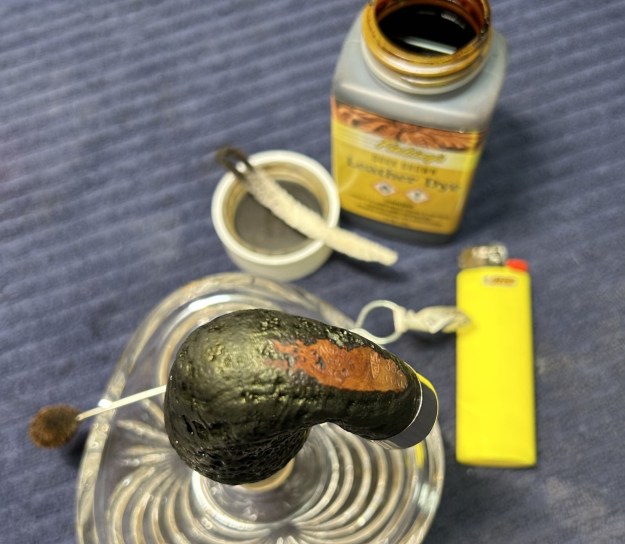

I decided to address the darkening on the front inner edge of the bowl first. I used a folded piece of 220 grit sandpaper to give the inner edge of the bowl a slight bevel to minimize the darkening and blend it into the surrounding briar. It looked much better at this point. I polished the briar with micromesh sanding pads to remove the scratches in the briar – dry sanding with 1500-12000 grit sanding pads. I wiped the bowl down with a damp cloth after each sanding pad.

I polished the briar with micromesh sanding pads to remove the scratches in the briar – dry sanding with 1500-12000 grit sanding pads. I wiped the bowl down with a damp cloth after each sanding pad.

I worked some Before & After Restoration Balm into the surface of the briar with my fingertips to clean, enliven and protect the briar. I let the balm sit for 15 minutes and then buffed with a cotton cloth to raise the shine. The photos show the bowl at this point in the restoration process.

I worked some Before & After Restoration Balm into the surface of the briar with my fingertips to clean, enliven and protect the briar. I let the balm sit for 15 minutes and then buffed with a cotton cloth to raise the shine. The photos show the bowl at this point in the restoration process.

I set the bowl aside and turned my attention to the stem. I polished the stem with micromesh sanding pads – wet sanding with 1500-12000 grit sanding pads. I wiped it down after each sanding pad with Obsidian Oil.

I set the bowl aside and turned my attention to the stem. I polished the stem with micromesh sanding pads – wet sanding with 1500-12000 grit sanding pads. I wiped it down after each sanding pad with Obsidian Oil.

I polished it with Before & After Pipe Stem Polish – both Fine and Extra Fine. I wiped it down with another coat of Obsidian Oil and set it aside to cure.

I polished it with Before & After Pipe Stem Polish – both Fine and Extra Fine. I wiped it down with another coat of Obsidian Oil and set it aside to cure.  I am excited to finish this Peterson’s “Kildare” 6 Straight Billiard. I put the pipe back together and buffed it with Blue Diamond on the buffing wheel. I gave the bowl and the stem multiple coats of carnauba wax. I hand buffed the pipe with a clean buffing pad to raise the shine. It is fun to see what the polished bowl looks like with beautiful flame grain all around it. Added to that the polished Sterling Silver band and the black vulcanite stem was beautiful. This smooth Classic Peterson’s “Kildare” 6 Billiard is great looking and the pipe feels great in my hand. It is light and well balanced. Have a look at it with the photos below. The dimensions are Length: 6 inches, Height: 1 ¾ inches, Outside diameter of the bowl: 1 ¼ inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 38 grams/1.34 ounces. It is a beautiful pipe and one that I will be putting on the rebornpipes store in the Irish Pipe Makers Section. If you want to add it to your collection you can send me a message or an email to slaug@uniserve.com. Thanks for walking through the restoration with me as I worked over this pipe. Thanks to each of you who are reading this blog.

I am excited to finish this Peterson’s “Kildare” 6 Straight Billiard. I put the pipe back together and buffed it with Blue Diamond on the buffing wheel. I gave the bowl and the stem multiple coats of carnauba wax. I hand buffed the pipe with a clean buffing pad to raise the shine. It is fun to see what the polished bowl looks like with beautiful flame grain all around it. Added to that the polished Sterling Silver band and the black vulcanite stem was beautiful. This smooth Classic Peterson’s “Kildare” 6 Billiard is great looking and the pipe feels great in my hand. It is light and well balanced. Have a look at it with the photos below. The dimensions are Length: 6 inches, Height: 1 ¾ inches, Outside diameter of the bowl: 1 ¼ inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 38 grams/1.34 ounces. It is a beautiful pipe and one that I will be putting on the rebornpipes store in the Irish Pipe Makers Section. If you want to add it to your collection you can send me a message or an email to slaug@uniserve.com. Thanks for walking through the restoration with me as I worked over this pipe. Thanks to each of you who are reading this blog.