When Kirk Fitzgerald posted this step by step tutorial on Smokers Forums I thought it would be great to have it on the blog. I asked Kirk if I could post it on the blog and he granted his permission. So without further introduction here is his rustication process. Kirk is the founder of the Pipe Smokers Cubby Web Forum http://www.pipesmokerscubby.com/cubby.php

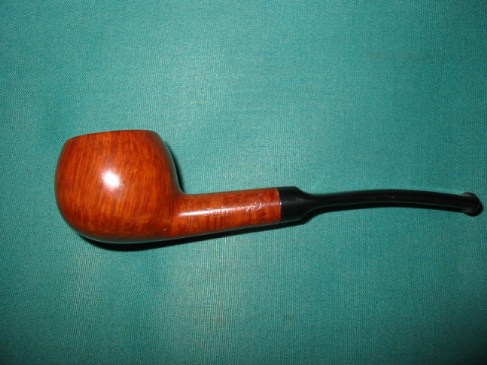

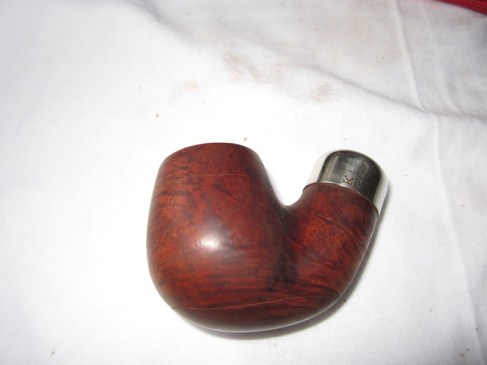

I was asked if I would do a step-by-step rundown on my own rustication process, so I have rusticated my own Peterson bent bowl for this purpose.

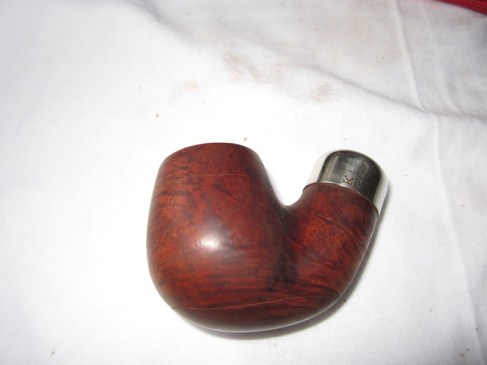

So before we get going, let’s see what the process will do to the bowl of the pipe

The pipe’s bowl, the two chisels I use, my crappy pencil and the knife I use to perma-line the boundaries for the areas to be rusticated

Here we mark the rustication boundaries in pencil

Here we perma-mark the boundaries using a sharp knife to scratch out the lines

Notched out the shank boundary lines

Here’s me notching the bowl rim boundaries

Notched the bowl rim boundary

Here I have started notching the bowl top

Here’s the bowl top notched

Start of the base boundary notches

The base boundary notches are now done

This is where we are so far, getting there

Start to notch the bowl rim edge

Finished notching the bowl rim edge

Here I have now notched the bowl top rim

Notching the bulk of the base interior

Here I have notched out the bulk of the bowl top rim interior

Here I have notched the remainder of the base interior

Here I am starting to remove the remaining surface finish with 180 wet and dry

Here the remaining finish is now removed; note I have made sure it looks distressed

Here I have now sanded the bowl smooth using 400, 600, 1200 grit wet and dry sand paper, note the effect is looking distressed

Here I have applied a dark brown stain, note it is a full and generous application

Here I have applied a dark red stain, again note the fullness of the coating

Now I have applied the final stain, a mid-brown, coverage is not so important with this one, a quick cover would do but I have opted for a full and generous application.

Now I have given the bowl an alcohol rub-down using a clean cloth and Isopropyl alcohol, note I have almost wiped the stains away, but only ‘almost’

I have now applied 2 very generous applications of Tripoli using the buffer wheels, this stage is vital to the finish of the bowl

This is after I have brutalised the bowl on the buffer wheels to remove some staining to distress the bowl further

Here I have used White Diamond on the buffer wheels to remove the Tripoli much and shine the surface a little before the wax

Here I have applied the first coat of wax and carnauba

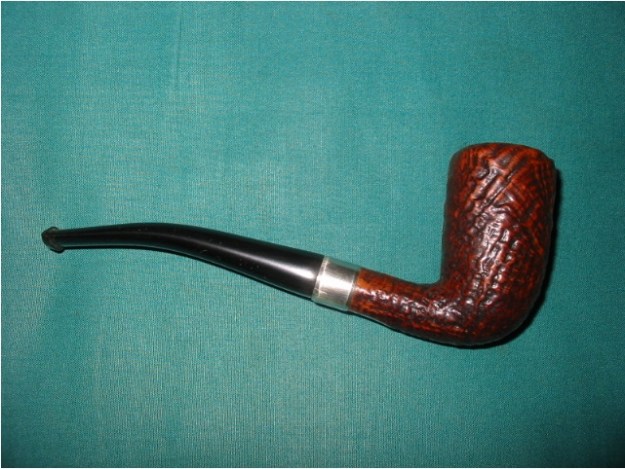

All done now, here is the final bowl re-attached to its polished stem.