by Steve Laug

The next pipe on the table is one that we picked up in the lot from a seller in Barrington, Rhode Island, USA on 08/22/2024. The classic Charatan Dublin shape caught our eye and we bought it along with some other pipes. It is stamped on the underside of the shank and reads C (cursive in a circle) [followed by] Charatan’s Make [over] London, England [followed by] the shape number 90X. It has a Dark Tan to Medium Brown stain on the sandblast finish that is a stark contrast to the vulcanite saddle stem with the CP stamp on the left side of the saddle. The bowl had been recently reamed and cleaned. The seller told us that he had cleaned it before selling it to us. The inner edge and the top look good. The stem is oxidized. It shows some light tooth marks or chatter on the top and underside ahead of the button and damage on the button edge on both sides. Jeff took some photos of the pipe to show the general condition of the pipe before he started his clean up.

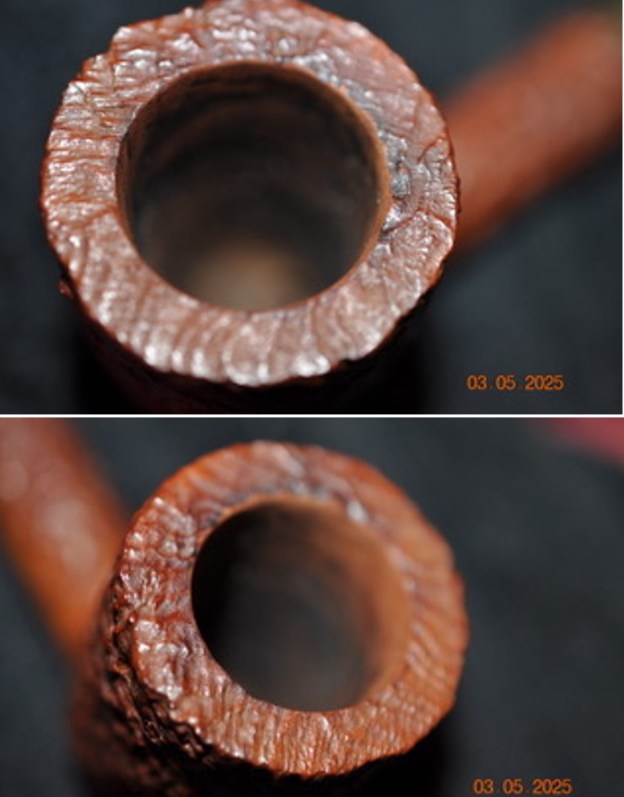

He took some photos of the rim top and bowl from various angles to give me a clear picture of the condition of the rim top and bowl. The outside of the bowl and rim is quite clean and the inside of the bowl is very clean. He included photos that show the top and underside of the stem. It is as described above.

He took some photos of the rim top and bowl from various angles to give me a clear picture of the condition of the rim top and bowl. The outside of the bowl and rim is quite clean and the inside of the bowl is very clean. He included photos that show the top and underside of the stem. It is as described above.

Jeff took some photos of the sides and heel of the bowl to show the condition of the finish on the pipe. The photos showed some great grain showing through the deep sandblast around the bowl and shank. It is a great looking piece of briar.

Jeff took some photos of the sides and heel of the bowl to show the condition of the finish on the pipe. The photos showed some great grain showing through the deep sandblast around the bowl and shank. It is a great looking piece of briar.

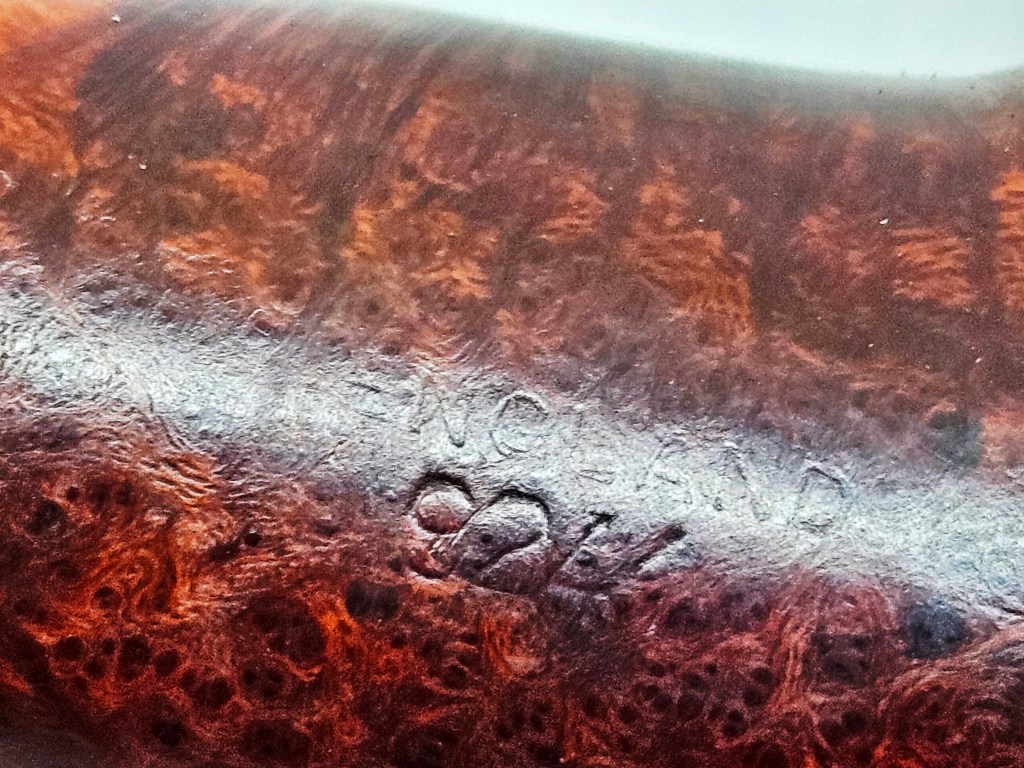

He took photos of the stamping on the underside of the shank. The stamping was clear and readable as noted above.

He took photos of the stamping on the underside of the shank. The stamping was clear and readable as noted above.  An added part of pipe restoration for me is to try to gather as much background on a brand and maker as I can find. With Charatan that is an enjoyable web to untangle. There is a lot of information and it can lead to understanding what era a pipe was made in. To try to figure out the era of the Charatan’s pipe I was working on I turned to the Pipephil website, Logos and Stampings (http://www.pipephil.eu/logos/en/logo-charatan.html). There is some really helpful information on each of the lines of Charatan’s Make pipes that entered the market. There was not a sandblast stamped like the one in hand. The site did give a short history of the brand. I quote the portion that is most pertinent.

An added part of pipe restoration for me is to try to gather as much background on a brand and maker as I can find. With Charatan that is an enjoyable web to untangle. There is a lot of information and it can lead to understanding what era a pipe was made in. To try to figure out the era of the Charatan’s pipe I was working on I turned to the Pipephil website, Logos and Stampings (http://www.pipephil.eu/logos/en/logo-charatan.html). There is some really helpful information on each of the lines of Charatan’s Make pipes that entered the market. There was not a sandblast stamped like the one in hand. The site did give a short history of the brand. I quote the portion that is most pertinent. The brand was founded in 1863 by Frederik Charatan. When his father retired in 1910, Reuben Charatan took over the family business. All the pipes were handmade until 1973. The brand name has been overtaken by Dunhill in 1978 and sold in 1988 to James B. Russell Inc.(NJ, USA). During the period 1988-2002 Charatans were crafted by Butz Choquin in St Claude (France). Dunhill re-purchased Charatan brand name in 2002 and Colin Fromm (Invicta Briars, Castleford) followed up on freehand production.

The brand was founded in 1863 by Frederik Charatan. When his father retired in 1910, Reuben Charatan took over the family business. All the pipes were handmade until 1973. The brand name has been overtaken by Dunhill in 1978 and sold in 1988 to James B. Russell Inc.(NJ, USA). During the period 1988-2002 Charatans were crafted by Butz Choquin in St Claude (France). Dunhill re-purchased Charatan brand name in 2002 and Colin Fromm (Invicta Briars, Castleford) followed up on freehand production.

Next, I turned to Pipedia to see if I could find more information on the brand and possibly a link to a sandblast finished Dublin (https://pipedia.org/wiki/Charatan) but once again in the general article it was not listed. It did give a little more historical information. I quote the pertinent parts that give information on this particular pipe. In 1950 Herman G. Lane, striving to expand his business in Great Britain, made contacts with the Charatan family. Apparently, Lane got a certain influence soon, but it was not until 1955 that Lane Ltd. became the sole distributor for Charatan’s in the United States superseding Wally Frank. This can be documented in a “biography” written for Herman G. Lane titled “Leaves from a Tobaccoman’s Log”.

Thanks to Herman G. Lane’s dedicated labor Charatan became hugely popular in the States. As reported by Ken Barnes in an interview with Rick Newcombe, Reuben Charatan passed away in 1962, and his widow sold the firm to Herman Lane 1 or 2 years after his death.[1] In the early 1960s Charatan pipes were the first to overstep the $100 Dollar line in US pipe sales. In 1978 Lane’s heirs sold the Charatan company to Dunhill. The Prescot Street factory was closed in March 1982. Thereafter the fame and quality of the make declined.

The pre-Lane period (prior to 1955) and the Lane era pipes (1955 to until sometime between 1979 – 1984) are of primary interest the collector. The Lane era is often quoted as beginning about 1950.

Charatan records are almost non-existent before Lane due to a factory fire, making it difficult to date pre-Lane pipes. Charatan used 4 basic grades prior to 1950: Supreme, Selected, Executive, and Belvedere. After 1950 Herman Lane’s influence began, and the grades started to expand. In 1955 Lane took over sole distributorship of Charatan in the US. In 1957 he introduced the Supreme S. Most of his other introductions were from the 1960s and early 1970s.

From this I am fairly certain I am dealing with a Lane pipe made after 1955. There is also a circle L script mark that is a Lane stampings on the pipe which also supports this.

I continued digging further into the dating of the pipe, but what I had found above was a good start for me. If some of you would like to try your hand at dating it more accurately as to the time period it came out you might want to check out the article on Pipedia on Dating Charatans (https://pipedia.org/wiki/Dating_of_Charatans).

I also reread the article on Pipedia by the Italian fellow who contributed some really helpful information on the brand (https://pipedia.org/wiki/Charatan_-_Milan_2014). I quote the section on the Second period: Reuben Charatan 1910 – c. 1962. I have highlighted a portion of the section on the shank in red to point out some more helpful dating information.

– In 1962 Herman Lane took over the business from the Charatan family, although he had already influenced production from the 1950s.

– The pipes were mostly larger than the previous ones and corresponded in size to Dunhill group 5. These are slightly less rare, but still difficult to find.

– Stem: Usually in ebonite, saddle shaped or tapered, bearing a fine “CP” stamp, underbore system (see below) used when necessary.

– Shank: The shape code is stamped on it together with the nomenclature “CHARATAN’S MAKE LONDON ENGLAND” arranged in two lines. From 1955 onward on the models marketed for the USA there is also a serif and circled capital “L” (but not all models bear this) which resembles the pound sterling symbol. The “L” is for Lane, the importer.

From 1958, Lane changed the nomenclature for models marketed for the US to clarify the message: “MADE BY HAND”. In this period the underbore was introduced. Its manufacturing period ranged between 1920 and c.1930. This model was equipped with a duralumin plunger trap fitted in the stem, which served to clean the residue more easily. This particular model bore a special stamp on the stem, and also had its own catalogue…

QUALITY GRADES…The stem did not only display the stamps mentioned above. Another stamp that can help dating is the one referring to the quality of the pipe. Until Herman Lane arrived on the scene there were four quality grades. Starting with the lowest: Belvedere, Executive, Selected, and Supreme. Lane went on to add higher grades from time to time: Supreme S, Supreme S100, S150, S200, S250, S300, Coronation, Royal Achievement, Crown Achievement, and Summa Cum Laude; these last three are extremely rare and almost impossible to find. He also invented other, different grades, even changing the previous pipe classification standards. We will not go into detail here, but it means that if we find an S100 or Coronation the pipe was manufactured following Herman Lane’s acquisition. In particular, the FH mark, or Freehand pipe was commissioned to the famous Danish craftsman, Preben Holm.

Nomenclature – The Lane Trademark serif and circled L indicates the pipe is from the “Lane Era” (approx. 1955 to 1979 -1984?), however it appears that both the English factory or Lane themselves sometimes, or perhaps even often forget to stamp the L on a pipe. The Charatan factory was known for inconsistencies, especially in stampings. Therefore, although an L on the pipe definitely defines it as a Lane Era pipe, the lack of it could simply mean the pipe missed receiving the stamp from the factory. The lack of the trademark could also mean the pipe was destined for the European market.

Charatan pipes were not well distributed prior to the Lane Era, so very few pre-Lane pipes exist today. Herman Lane greatly grew the brand in the U.S., which caused corresponding growth in Europe.

Generally, when the pipe is stamped with the BLOCK letters “MADE BY HAND” it means the pipe was probably made between 1958 and 1965”

Generally, block letters “MADE BY HAND” and some of the other nomenclature in script (i.e. City of London or Extra Large next to the MADE BY HAND) means the pipe was made sometime between 1965 and the mid 1970s. The total script nomenclature “Made by Hand in City of London” evolved over this period of time, so many pipes had variants, such as Made By Hand in block letters and City of London in script, or some other variation of the terms or stampings.

It is believed the FH was used on Charatan pipes between 1957 and 1967-68. Three different sizes were used. The Charatan Logo (CP) on the pipe bit was changed over the year

Now I knew I was working on Lane pipe which actually means it was between 1955 and 1988 as shown by the stamping.

Armed with that information I turned to work on the pipe itself. Jeff had done a great job cleaning up the pipe as usual. He cleaned up the inside of the bowl with a Savinelli Fitsall Pipe Knife. The rim top and the inner edge of the bowl are in excellent condition. The bowl walls looked very good. He scrubbed the interior of the bowl and shank with shank brushes, pipe cleaners, cotton swabs and alcohol to remove the tars and oils. He scrubbed the exterior of the pipe with Murphy’s Oil Soap and a tooth brush to remove the grime from the finish. He scrubbed the inside of the stem with alcohol and pipe cleaners. He scrubbed the exterior with Soft Scrub and then soaked it in Briarville’s Pipe Stem Deoxidizer. He washed it off with warm water to remove the deoxidizer. The stem looked very good. I took photos of the pipe before I started working on it.

I took close up photos of the bowl, rim top and stem to show how clean the pipe was. The bowl was clean and the rim top and the inner edge look beautiful. The stem was clean and showed light tooth marks or chatter.

I took close up photos of the bowl, rim top and stem to show how clean the pipe was. The bowl was clean and the rim top and the inner edge look beautiful. The stem was clean and showed light tooth marks or chatter. I took a photo of the stamping on the side of the shank. It is very clear and readable and read as noted above. I also removed the stem from the shank and took photos of the pipe to show the look of the parts.

I took a photo of the stamping on the side of the shank. It is very clear and readable and read as noted above. I also removed the stem from the shank and took photos of the pipe to show the look of the parts.  I worked some Before & After Restoration Balm into the briar with my finger tips and a shoe brush to get in the nooks and crannies of the sandblast. I let it sit on the bowl for 10 minutes and then buffed it off with a paper towel and soft cloth. The product is a great addition to the restoration work. It enlivens, enriches and protects the briar while giving it a deep glow. It is a product I use on every pipe I restore.

I worked some Before & After Restoration Balm into the briar with my finger tips and a shoe brush to get in the nooks and crannies of the sandblast. I let it sit on the bowl for 10 minutes and then buffed it off with a paper towel and soft cloth. The product is a great addition to the restoration work. It enlivens, enriches and protects the briar while giving it a deep glow. It is a product I use on every pipe I restore.

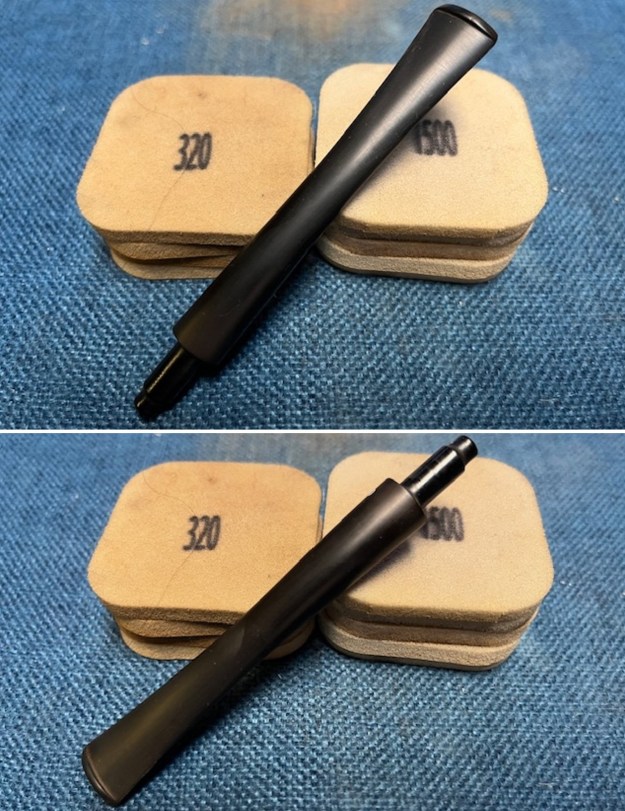

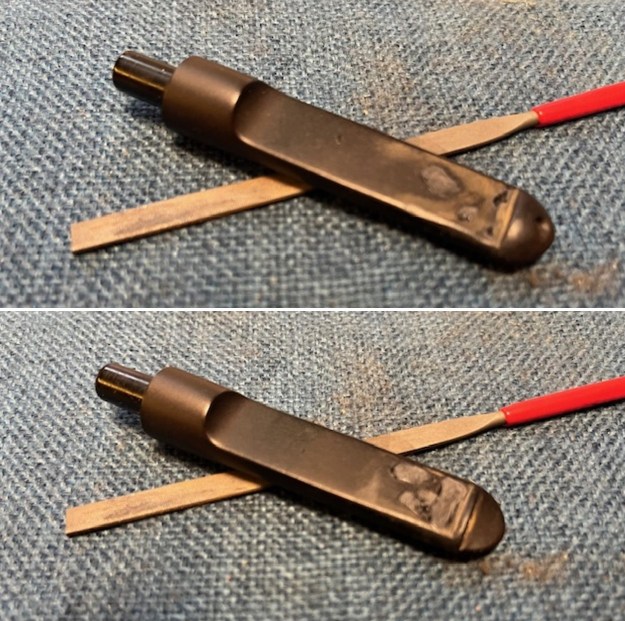

I set the bowl aside and turned my attention to the stem. I touched up the Charatan logo CP stamp on the left side of the saddle stem with white acrylic fingernail polish. I scraped the excess when it had cured. I removed more of the excess with a worn 1500 grit micromesh sanding pad. It looked very good.

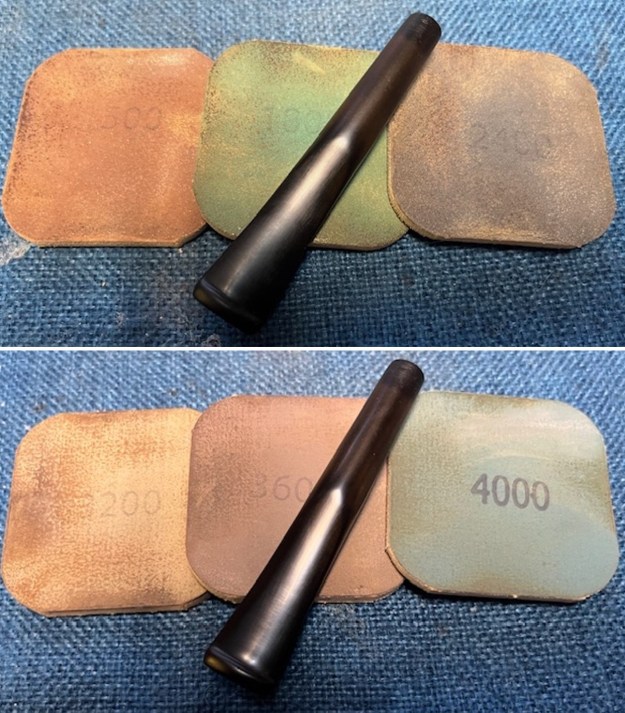

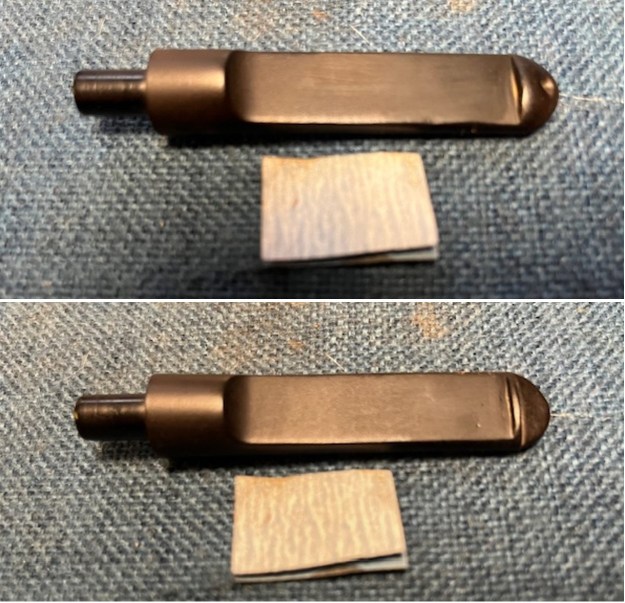

I set the bowl aside and turned my attention to the stem. I touched up the Charatan logo CP stamp on the left side of the saddle stem with white acrylic fingernail polish. I scraped the excess when it had cured. I removed more of the excess with a worn 1500 grit micromesh sanding pad. It looked very good. It was ready for the next step. I polished it with micromesh sanding pads – dry sanding with 1500-12000 grit pads and wiping the surface down with Obsidian Oil after each sanding pad. It is really shining. I polished it further with Before & After Stem Polish – both Fine and Extra Fine. I gave it another coat of Obsidian Oil to finish this step.

It was ready for the next step. I polished it with micromesh sanding pads – dry sanding with 1500-12000 grit pads and wiping the surface down with Obsidian Oil after each sanding pad. It is really shining. I polished it further with Before & After Stem Polish – both Fine and Extra Fine. I gave it another coat of Obsidian Oil to finish this step.

It was great to finish this Charatan’s Make 90X Saddle Stem Dublin. I put the pipe back together and buffed it with Blue Diamond on the buffing wheel. I gave the bowl multiple coats of carnauba wax. I buffed the pipe with a clean buffing pad to raise the shine. I hand buffed the pipe with a microfiber cloth to deepen the shine. It is fun to see what the polished bowl looks like with deep sandblast all around it. Added to that the polished black, vulcanite, saddle stem was beautiful. This Charatan’s Make 90X Dublin is great looking and the pipe feels great in my hand. It is light and well balanced. Have a look at it with the photos below. The dimensions are Length: 5 ½ inches, Height: 2 inches, Outside diameter of the bowl: 1 ½ inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 42 grams/1.48 ounces. It is a beautiful pipe and one that will soon be on the rebornpipes store in the British Pipe Makers Section. If you want to add it to your collection let me know. Thanks for walking through the restoration with me as I worked over this pipe.

It was great to finish this Charatan’s Make 90X Saddle Stem Dublin. I put the pipe back together and buffed it with Blue Diamond on the buffing wheel. I gave the bowl multiple coats of carnauba wax. I buffed the pipe with a clean buffing pad to raise the shine. I hand buffed the pipe with a microfiber cloth to deepen the shine. It is fun to see what the polished bowl looks like with deep sandblast all around it. Added to that the polished black, vulcanite, saddle stem was beautiful. This Charatan’s Make 90X Dublin is great looking and the pipe feels great in my hand. It is light and well balanced. Have a look at it with the photos below. The dimensions are Length: 5 ½ inches, Height: 2 inches, Outside diameter of the bowl: 1 ½ inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 42 grams/1.48 ounces. It is a beautiful pipe and one that will soon be on the rebornpipes store in the British Pipe Makers Section. If you want to add it to your collection let me know. Thanks for walking through the restoration with me as I worked over this pipe.

As always, I encourage your questions and comments as you read the blog. Thanks to each of you who are reading this blog. Remember we are not pipe owners; we are pipe men and women who hold our pipes in trust until they pass on into the trust of those who follow us.

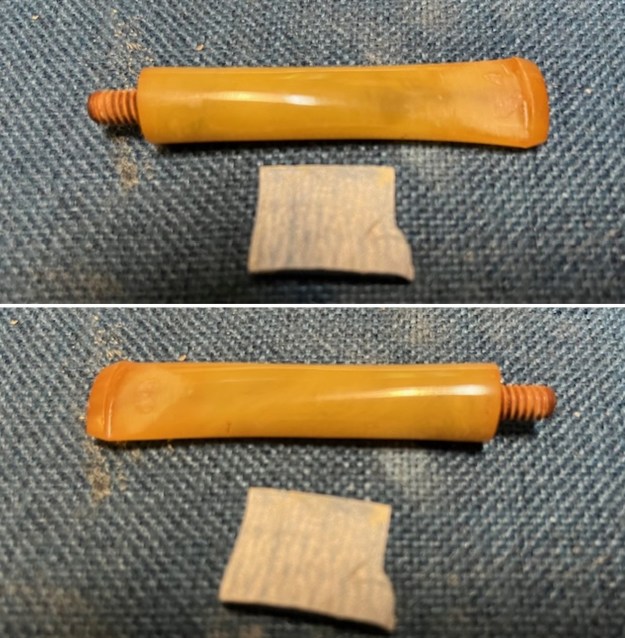

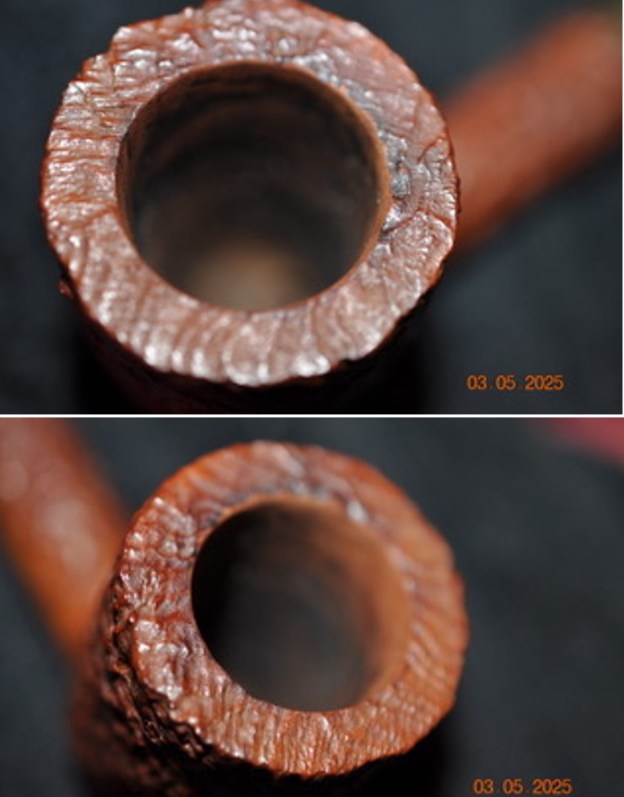

I took photos of the rim top and the stem to show the condition of the pipe when I brought it to the worktable. You can see the cake in the bowl and the build up of lava and debris on the edge and top of the rim top. It is another dirty pipe but still a charmer. The yellow/butterscotch acrylic saddle stem has light chatter and tooth marks on both sides near the button.

I took photos of the rim top and the stem to show the condition of the pipe when I brought it to the worktable. You can see the cake in the bowl and the build up of lava and debris on the edge and top of the rim top. It is another dirty pipe but still a charmer. The yellow/butterscotch acrylic saddle stem has light chatter and tooth marks on both sides near the button.  I removed the stem from the shank and took a photo of the parts. It is a beautiful pipe and the developing patina is very nice.

I removed the stem from the shank and took a photo of the parts. It is a beautiful pipe and the developing patina is very nice.  I started my work on the bowl by reaming the thick cake out of the bowl. I started with a PipNet reamer and the 2nd and 3rd cutting heads to take back the cake to the walls of the bowl. I cleaned up the reaming with a Savinelli Fitsall Pipe Knife. I sanded the bowl walls with a piece of dowel wrapped with 220 grit sandpaper. Once finished it looked very good.

I started my work on the bowl by reaming the thick cake out of the bowl. I started with a PipNet reamer and the 2nd and 3rd cutting heads to take back the cake to the walls of the bowl. I cleaned up the reaming with a Savinelli Fitsall Pipe Knife. I sanded the bowl walls with a piece of dowel wrapped with 220 grit sandpaper. Once finished it looked very good.

I cleaned out the airway in the shank and mortise as well as in the new stem with pipe cleaners (both bristle and regular). It was not as dirty as I expected considering the cake in the bowl. IT came out very clean.

I cleaned out the airway in the shank and mortise as well as in the new stem with pipe cleaners (both bristle and regular). It was not as dirty as I expected considering the cake in the bowl. IT came out very clean. I scrubbed the exterior of the bowl with undiluted Murphy’s Oil Soap and a tooth brush to remove the grime. I rinsed it with warm water and repeated the process until the surface was clean. I dried it off with a soft cloth. It is greatly improved.

I scrubbed the exterior of the bowl with undiluted Murphy’s Oil Soap and a tooth brush to remove the grime. I rinsed it with warm water and repeated the process until the surface was clean. I dried it off with a soft cloth. It is greatly improved.

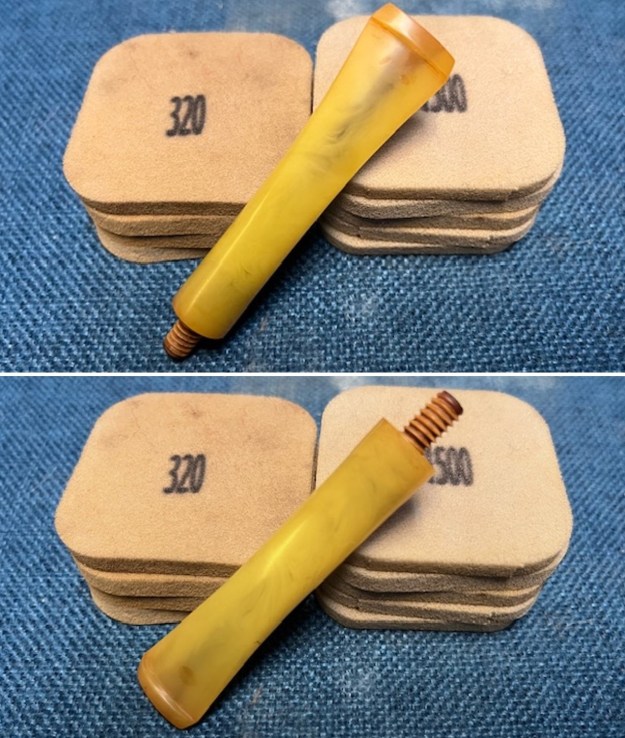

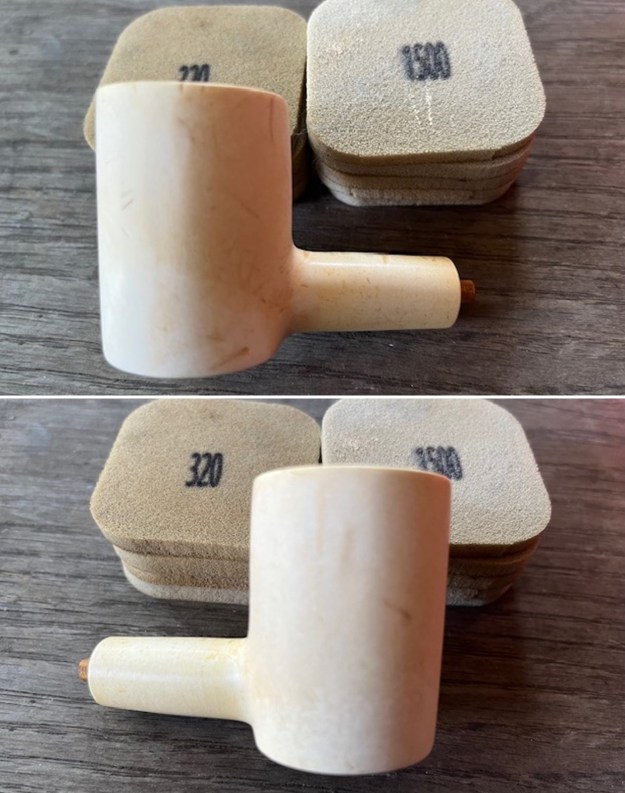

Now it was time to work on the scratches on the bowl and rim top. I sat on the front porch in the sun and started my work by sanding the bowl with 320-3500 grit 2×2 inch sanding pads. It smoothed out the scratches and revealed more and more of the patina around the bowl and shank. It is a beautiful looking pipe.

Now it was time to work on the scratches on the bowl and rim top. I sat on the front porch in the sun and started my work by sanding the bowl with 320-3500 grit 2×2 inch sanding pads. It smoothed out the scratches and revealed more and more of the patina around the bowl and shank. It is a beautiful looking pipe.

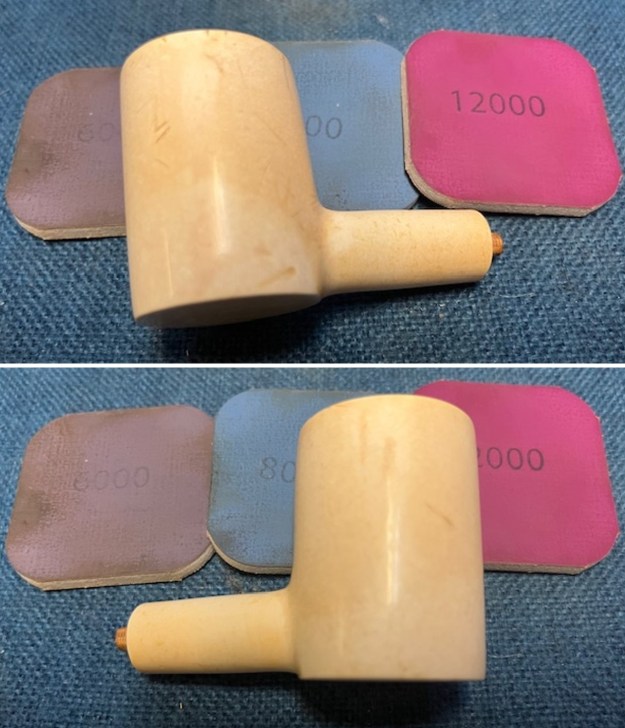

I polished the meerschaum with micromesh sanding pads – dry sanding with 1500-12000 grit pads. I wiped the bowl down after each pad with a damp cotton cloth. The bowl took on a shine by the last pads.

I polished the meerschaum with micromesh sanding pads – dry sanding with 1500-12000 grit pads. I wiped the bowl down after each pad with a damp cotton cloth. The bowl took on a shine by the last pads.

I gave the bowl multiple coats of Clapham’s Wax that blends both carnauba and beeswax in a soft wax. I rubbed the wax on the bowl sides and the shank end with my fingers and set it aside to dry. Once the wax cured I buffed the bowl with a clean buffing pad and then with a soft microfibre cloth. The bowl has a rich glow.

I gave the bowl multiple coats of Clapham’s Wax that blends both carnauba and beeswax in a soft wax. I rubbed the wax on the bowl sides and the shank end with my fingers and set it aside to dry. Once the wax cured I buffed the bowl with a clean buffing pad and then with a soft microfibre cloth. The bowl has a rich glow.

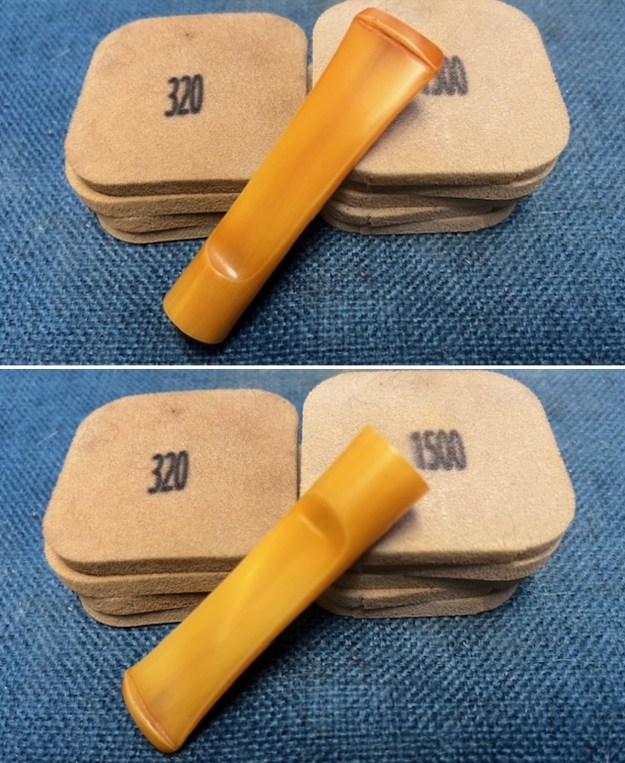

I set the bowl aside and turned my attention to the stem. I sanded the stem surface with 320-3500 grit 2×2 inch sanding pads to blend the light marks and chatter into the stem surface. I wiped the stem down after each pad with a damp pad to remove the debris. By the end it was quite shiny and ready for polishing.

I set the bowl aside and turned my attention to the stem. I sanded the stem surface with 320-3500 grit 2×2 inch sanding pads to blend the light marks and chatter into the stem surface. I wiped the stem down after each pad with a damp pad to remove the debris. By the end it was quite shiny and ready for polishing. I polished the stem with micromesh sanding pads – wet sanding it 1500-12000 pads. I wiped it down with a damp cloth after each pad to protect it and preserve it. I polished it with Before After Pipe Polish – both Fine and Extra Fine.

I polished the stem with micromesh sanding pads – wet sanding it 1500-12000 pads. I wiped it down with a damp cloth after each pad to protect it and preserve it. I polished it with Before After Pipe Polish – both Fine and Extra Fine.

I am really happy with the way that this Block Meerschaum Cherrywood Pipe with the butterscotch amber like acrylic stem turned out. It really is a beautiful looking pipe with a unique shape and smooth meerschaum bowl. The amberlike acrylic taper stem is really nice. The rich patina on the meerschaum came alive with waxing and buffing. I put the stem back on the bowl and carefully buffed the pipe with Blue Diamond on the buffing wheel. I gave the bowl and the stem multiple coats of beeswax/carnauba wax and buffed the pipe with a clean buffing pad to raise the shine. I hand buffed the pipe with a microfiber cloth to deepen the shine. The finished Meerschaum Cherrywood really is a beauty and feels great in the hand and looks very good. Give the finished pipe a look in the photos below. The dimensions of the pipe are Length: 5 ½ inches, Height: 2 inches, Outside diameter of the bowl: 1 ¼ inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 43 grams/ 1.52 ounces. The pipe will be going on the rebornpipes store soon. It will be in the Ceramic and Meerschaum Pipes Section if you would like to add it to your collection. Thanks for reading this blog and my reflections on the pipe while I worked on it. It was a fun one to work on!

I am really happy with the way that this Block Meerschaum Cherrywood Pipe with the butterscotch amber like acrylic stem turned out. It really is a beautiful looking pipe with a unique shape and smooth meerschaum bowl. The amberlike acrylic taper stem is really nice. The rich patina on the meerschaum came alive with waxing and buffing. I put the stem back on the bowl and carefully buffed the pipe with Blue Diamond on the buffing wheel. I gave the bowl and the stem multiple coats of beeswax/carnauba wax and buffed the pipe with a clean buffing pad to raise the shine. I hand buffed the pipe with a microfiber cloth to deepen the shine. The finished Meerschaum Cherrywood really is a beauty and feels great in the hand and looks very good. Give the finished pipe a look in the photos below. The dimensions of the pipe are Length: 5 ½ inches, Height: 2 inches, Outside diameter of the bowl: 1 ¼ inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 43 grams/ 1.52 ounces. The pipe will be going on the rebornpipes store soon. It will be in the Ceramic and Meerschaum Pipes Section if you would like to add it to your collection. Thanks for reading this blog and my reflections on the pipe while I worked on it. It was a fun one to work on!