by Steve Laug

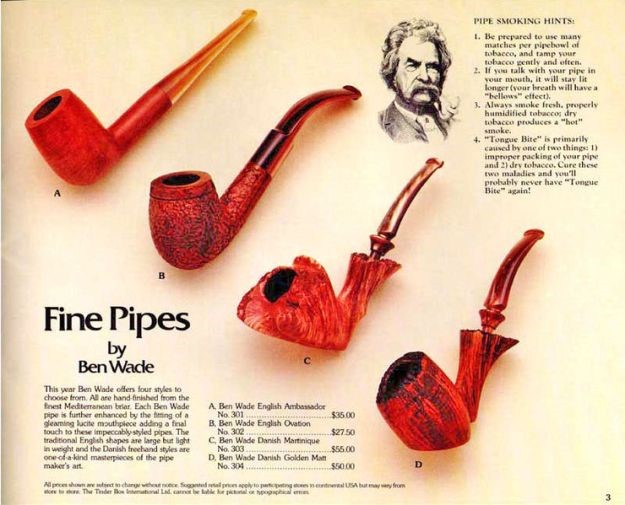

The next pipe on the work table is Peterson’s 999 Rhodesian pipe that we purchased from and our connection in Los Angeles, California, USA on 04/11/2023. It was stamped Peterson’s [over] “Kildare” on the left side of the shank. On the right it is stamped with Made in the Republic of Ireland (in three lines) followed by the shape number 999. It is a classic Peterson’s Rhodesian shape that has a smooth finish with great grain around the bowl and shank that is covered with a lot of oils, debris and grime. There was a thick cake in the bowl with remnants of tobacco stuck on the walls. There was a heavy lava overflow on the rim top and edges. The top and edges of the rim were well hidden under the tars and lava but I was hoping they were protected. There was a very beautiful pipe underneath all of the buildup of years of use. The stem was a Peterson’s P-lip stem with the P logo in white on the left side of the taper. It was oxidized and calcified toward the end with some tooth marks and chatter on both sides ahead of the button. Jeff took photos of the pipe before he started his cleanup work on it.

Jeff took photos of the bowl and rim top to show the thick, hard cake in the bowl with remnants of tobacco stuck on the walls of the bowl. There was a lava build up on the top of the rim and the edges of the bowl. The rim top looked pretty good but it was hard to know for sure if there was damage under the thick lava. Only clean up would tell the full story. Jeff took photos of the top and underside of the stem showing the tooth marks, chatter, scratching, calcification and oxidation on the stem surface.

Jeff took photos of the bowl and rim top to show the thick, hard cake in the bowl with remnants of tobacco stuck on the walls of the bowl. There was a lava build up on the top of the rim and the edges of the bowl. The rim top looked pretty good but it was hard to know for sure if there was damage under the thick lava. Only clean up would tell the full story. Jeff took photos of the top and underside of the stem showing the tooth marks, chatter, scratching, calcification and oxidation on the stem surface.

Jeff took photos of the sides and heel of the bowl to show the condition of the finish. You can see the grime around the sides of the bowl and shank. Even under the dirt and debris of the years it looked very good.

Jeff took photos of the sides and heel of the bowl to show the condition of the finish. You can see the grime around the sides of the bowl and shank. Even under the dirt and debris of the years it looked very good.

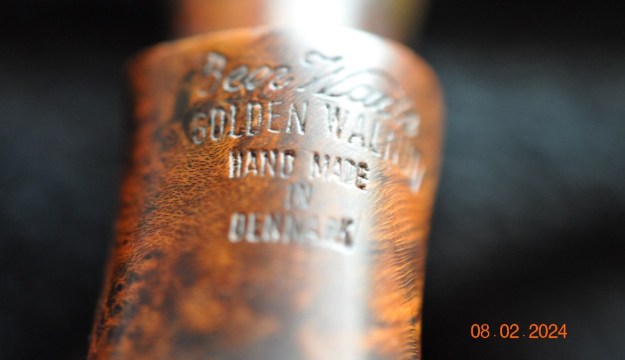

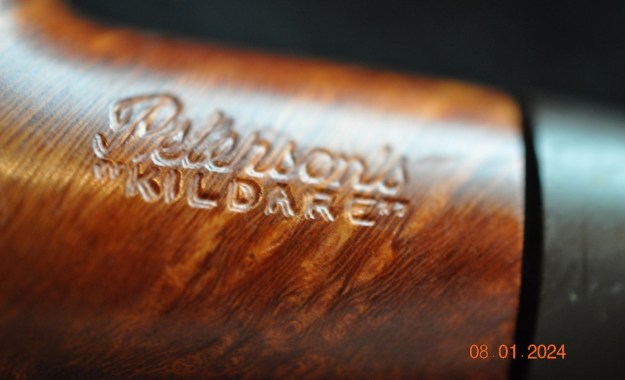

Jeff took photos of the stamping on the sides of the shank. The stamping was readable as you can see from the photos. It read as noted above.

Jeff took photos of the stamping on the sides of the shank. The stamping was readable as you can see from the photos. It read as noted above.

Before I started working on the pipe I turned to “The Peterson’s Pipe” by Mark Irwin and Gary Malmberg to see what it had to say on the “Kildare” line. On page 306 it says:

Before I started working on the pipe I turned to “The Peterson’s Pipe” by Mark Irwin and Gary Malmberg to see what it had to say on the “Kildare” line. On page 306 it says:

Kildare (1965-) First issue of the line with matte-finish in Classic Range shapes. P-lip and fishtail mouthpiece. Second issue c.1979 as Kildare Patch, with rusticated patches on the pipe surface. Third issue 2010, matte brown, P-lip or fishtail mouthpiece, no band. Fourth issue 2011-burgundy sandblast finish, nickel army mount, fishtail mouthpiece, exclusive to Smokingpipes.com.

I believe that the pipe I am working on is a First Issue of the line. It has a Matte-finish in a Classic shape and a P-lip mouthpiece. That would make the pipe one issued between 1965 and 1978. It has a bit of age on it and it is in excellent condition.

Jeff had cleaned it thoroughly. He had reamed it with a PipNet reamer and cleaned that up with a Savinelli Fitsall Pipe Knife. He had scrubbed the exterior of the briar with undiluted Murphy’s Oil Soap. He cleaned out the interior of the shank, sump and airway in the shank and stem with alcohol, pipe cleaners, shank brushes and cotton swabs. He scrubbed the stem with Soft Scrub to remove the oxidation and calcification on the surface. He soaked it in Briarville’s Pipe Stem Deoxidizer to remove the oxidation. He removed it from the Deoxidizer and rinsed it off with warm water. I took some photos of the pipe before I started my part of the work.

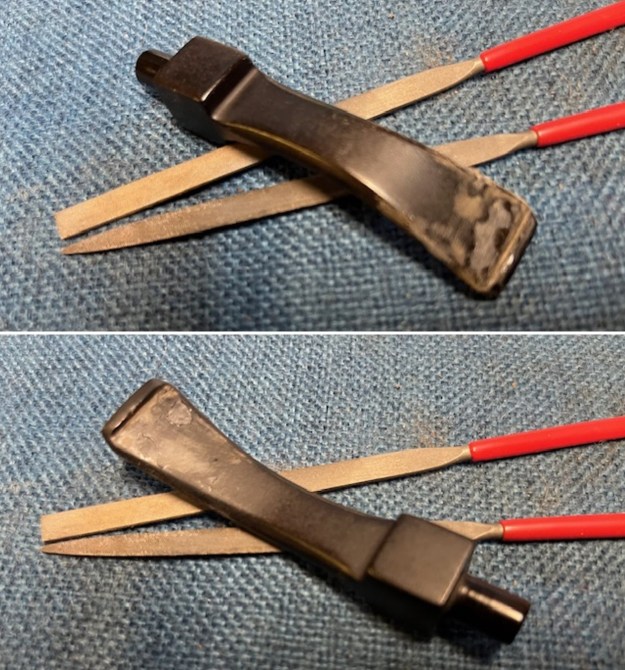

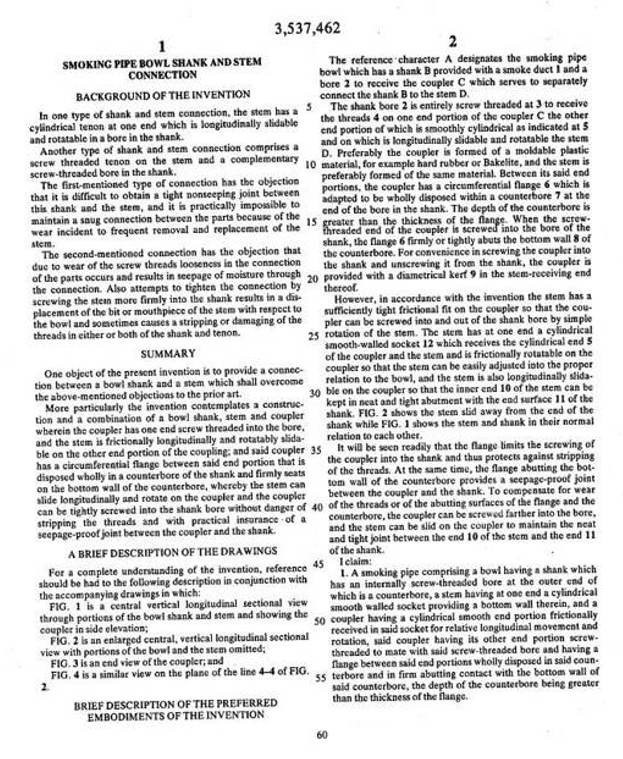

I took some close up photos of the rim top and the stem surface. I wanted to show what an amazing job Jeff did in the cleanup of the rim top. The rim top and inner edge looked very good. There was some light damage to the inner edge on the front left side of the bowl. I took close up photos of the stem to show the condition of the vulcanite. It was quite clean and there were light tooth marks and chatter barely visible in the photos.

I took some close up photos of the rim top and the stem surface. I wanted to show what an amazing job Jeff did in the cleanup of the rim top. The rim top and inner edge looked very good. There was some light damage to the inner edge on the front left side of the bowl. I took close up photos of the stem to show the condition of the vulcanite. It was quite clean and there were light tooth marks and chatter barely visible in the photos. One of the things I appreciate about Jeff’s cleanup is that he works to protect and preserve the nomenclature on the shank of the pipes that he works on. He was able to preserve and maintain its condition in the process. I took some photos to show the clarity of the stamping. I have noticed that many restorers are not careful to protect the stamping in their cleaning process and often by the end of the restoration the nomenclature is almost destroyed. I would like to encourage all of us to be careful in our work to preserve this as it is a critical piece of pipe restoration! I took the stem off the shank and took a photo of the pipe.

One of the things I appreciate about Jeff’s cleanup is that he works to protect and preserve the nomenclature on the shank of the pipes that he works on. He was able to preserve and maintain its condition in the process. I took some photos to show the clarity of the stamping. I have noticed that many restorers are not careful to protect the stamping in their cleaning process and often by the end of the restoration the nomenclature is almost destroyed. I would like to encourage all of us to be careful in our work to preserve this as it is a critical piece of pipe restoration! I took the stem off the shank and took a photo of the pipe.

I decided to start my work on the pipe by cleaning up the damage to the inner edge on the front left side of the bowl. I worked over the edge with a folded piece of 220 grit sandpaper. Once finished the edge looked very good.

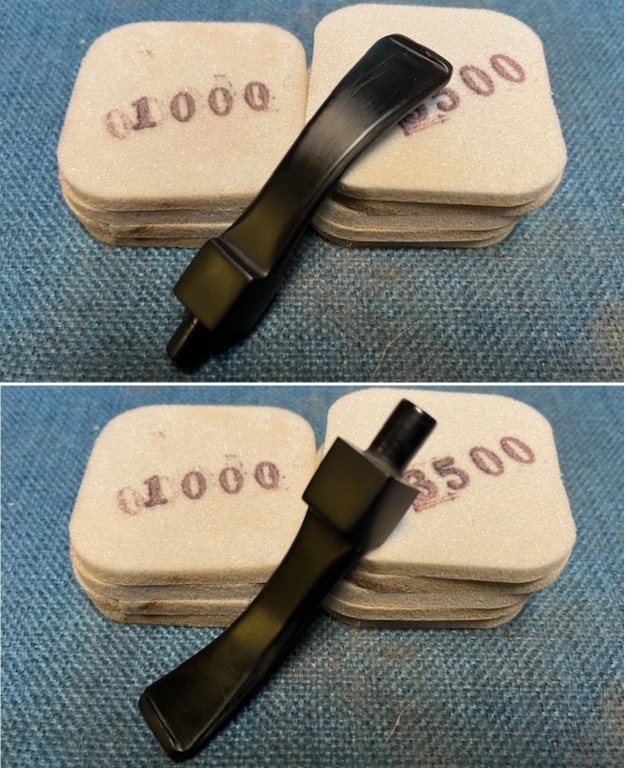

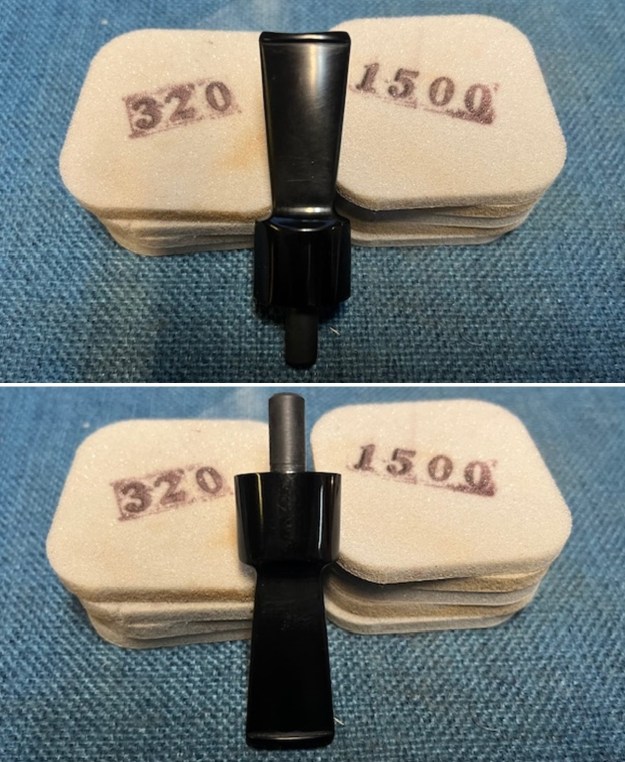

I decided to start my work on the pipe by cleaning up the damage to the inner edge on the front left side of the bowl. I worked over the edge with a folded piece of 220 grit sandpaper. Once finished the edge looked very good. I polished the briar with micromesh sanding pads – dry sanding it with 1500-12000 grit sanding pads. I wiped it down with a damp cloth after each sanding pad to remove the dust. The rim top, edges and bowl were really shining by the final pad.

I polished the briar with micromesh sanding pads – dry sanding it with 1500-12000 grit sanding pads. I wiped it down with a damp cloth after each sanding pad to remove the dust. The rim top, edges and bowl were really shining by the final pad.

I rubbed the bowl and rim down with Before & After Restoration Balm. I worked it into the surface of the briar with my fingertips and into the twin rings around the cap with a shoe brush to clean, enliven and protect it. I let the balm sit for 10 minutes and then buffed with a cotton cloth to raise the shine. I really like watching the Balm do its magic and bring the briar alive.

I rubbed the bowl and rim down with Before & After Restoration Balm. I worked it into the surface of the briar with my fingertips and into the twin rings around the cap with a shoe brush to clean, enliven and protect it. I let the balm sit for 10 minutes and then buffed with a cotton cloth to raise the shine. I really like watching the Balm do its magic and bring the briar alive.

I set the bowl aside and turned my attention to the stem. The stem was in such good condition that I decided to just do some preliminary work on it before polishing it. I touched up the “P” logo on the left side of the stem with white acrylic fingernail polish. I let it dry then polished off the excess with a worn 1500 grit micromesh sanding pad. Once the excess was removed the stamp looked much better. There were some weak spots on the curve of the “P” stamp but overall it looked very good.

I set the bowl aside and turned my attention to the stem. The stem was in such good condition that I decided to just do some preliminary work on it before polishing it. I touched up the “P” logo on the left side of the stem with white acrylic fingernail polish. I let it dry then polished off the excess with a worn 1500 grit micromesh sanding pad. Once the excess was removed the stamp looked much better. There were some weak spots on the curve of the “P” stamp but overall it looked very good. I polished the stem with micromesh sanding pads – dry sanding with 1500-12000 grit pads. I wiped the stem down after each sanding pad with Obsidian Oil. I polished it further with Before & After Pipe Stem Polish – both Fine and Extra Fine, I rubbed it on with my finger and buffed it off with a cloth. I gave the stem a final coat of Obsidian Oil and set it aside to let the oil be absorbed.

I polished the stem with micromesh sanding pads – dry sanding with 1500-12000 grit pads. I wiped the stem down after each sanding pad with Obsidian Oil. I polished it further with Before & After Pipe Stem Polish – both Fine and Extra Fine, I rubbed it on with my finger and buffed it off with a cloth. I gave the stem a final coat of Obsidian Oil and set it aside to let the oil be absorbed.

Once again at this point in the restoration process I am excited to be on the homestretch. I look forward to the final look when the Peterson’s “Kildare” 999 Rhodesian with a taper stem is put back together, polished and waxed. I put the bowl and stem back together. I lightly polished the bowl and stem with Blue Diamond to polish out the scratches in the briar and the vulcanite. I gave the bowl and the stem multiple coats of carnauba wax. I buffed the pipe with a clean buffing pad to raise the shine. I hand buffed it with a microfiber cloth to deepen the shine. The pipe polished up pretty nicely and the beautiful grain really popped with the wax and polish. The shiny black vulcanite stem is a beautiful contrast to the browns of the bowl and thick shank. This Republic Era Peterson’s “Kildare” 999 Rhodesian was another fun pipe to work on. It really is a quite stunning piece of briar whose shape follows the flow of the briar. The pipe feels great in the hand will be better when warmed up while smoking. The finished pipe is shown in the photos below. The dimensions of the pipe are Length: 5 ½ inches, Height: 1 ½ inches, Outside diameter of the bowl: 1 ¼ inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 1.76 ounces/50 grams. I will be putting it on the rebornpipes store in the Irish Pipemakers Section if you would like to add it to your rack and carry on the previous pipeman’s legacy. This is an interesting estate to bring back to life.

Once again at this point in the restoration process I am excited to be on the homestretch. I look forward to the final look when the Peterson’s “Kildare” 999 Rhodesian with a taper stem is put back together, polished and waxed. I put the bowl and stem back together. I lightly polished the bowl and stem with Blue Diamond to polish out the scratches in the briar and the vulcanite. I gave the bowl and the stem multiple coats of carnauba wax. I buffed the pipe with a clean buffing pad to raise the shine. I hand buffed it with a microfiber cloth to deepen the shine. The pipe polished up pretty nicely and the beautiful grain really popped with the wax and polish. The shiny black vulcanite stem is a beautiful contrast to the browns of the bowl and thick shank. This Republic Era Peterson’s “Kildare” 999 Rhodesian was another fun pipe to work on. It really is a quite stunning piece of briar whose shape follows the flow of the briar. The pipe feels great in the hand will be better when warmed up while smoking. The finished pipe is shown in the photos below. The dimensions of the pipe are Length: 5 ½ inches, Height: 1 ½ inches, Outside diameter of the bowl: 1 ¼ inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 1.76 ounces/50 grams. I will be putting it on the rebornpipes store in the Irish Pipemakers Section if you would like to add it to your rack and carry on the previous pipeman’s legacy. This is an interesting estate to bring back to life.

As always, I encourage your questions and comments as you read the blog. Thanks to each of you who are reading this blog. Remember we are not pipe owners; we are pipe men and women who hold our pipes in trust until they pass on into the trust of those who follow us.