Blog by Kenneth Lieblich

Next on the chopping block, we have a unique and large, carved, meerschaum figural pipe. As I’m sure you know, meerschaum is a German word which literally means “sea foam” (meer = sea and schaum = foam). Incidentally, schaum is also where we get the English word scum from. But where did the Germans get the meerschaum word from? Obviously, meerschaum is so called because it is white and light, but the Oxford Dictionary of Etymology further explains that the term is itself a translation of the Persian word kef-i-daryā – literally meaning “foam of sea”. Now you can impress friends at your next cocktail party.

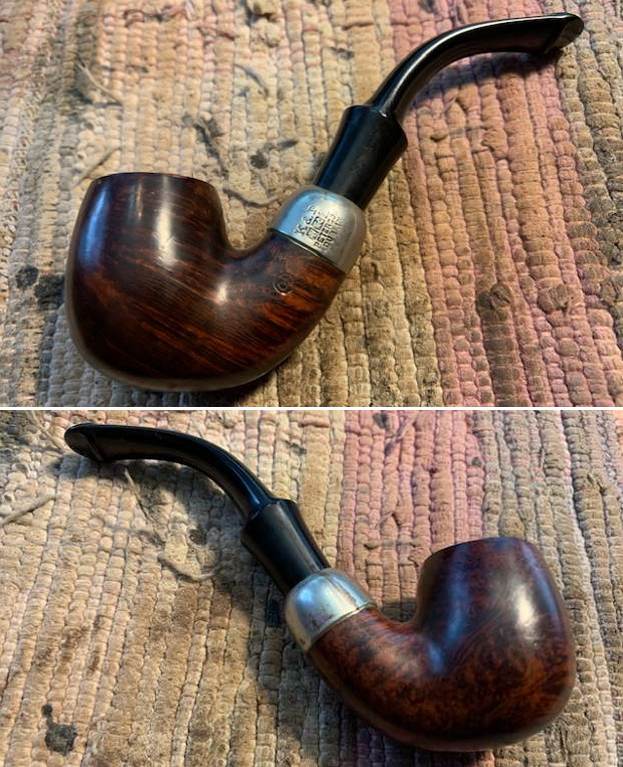

I acquired this pipe in a large lot in the summertime. This meerschaum pipe was notable as its stem had been lost in the mists of time, on its way from Asia Minor. I searched through the lot of pipes that it came in, but there was no sign of it. Fortunately, Steve kindly supplied me with a suitable stem which worked perfectly.

I acquired this pipe in a large lot in the summertime. This meerschaum pipe was notable as its stem had been lost in the mists of time, on its way from Asia Minor. I searched through the lot of pipes that it came in, but there was no sign of it. Fortunately, Steve kindly supplied me with a suitable stem which worked perfectly.

The pipe is a large piece of block meerschaum, presumably from Turkey, although it has no markings of any sort. However, it has all the hallmarks of Eskişehir, so I feel confident in saying it’s Turkish.

The pipe is a large piece of block meerschaum, presumably from Turkey, although it has no markings of any sort. However, it has all the hallmarks of Eskişehir, so I feel confident in saying it’s Turkish.

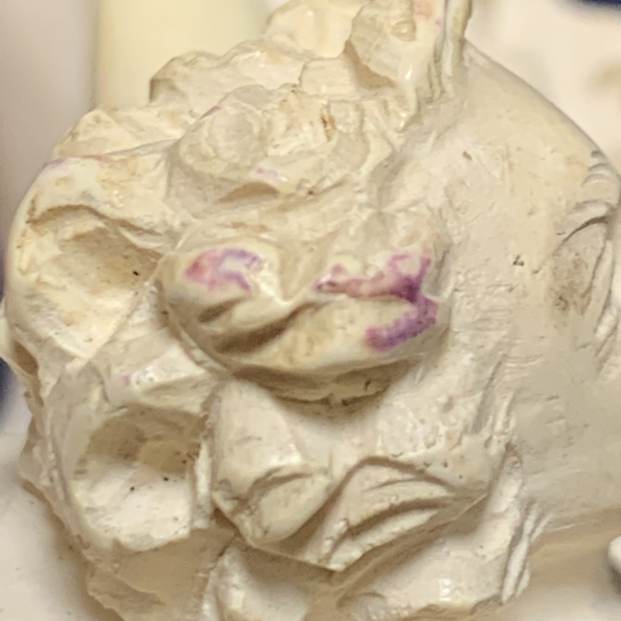

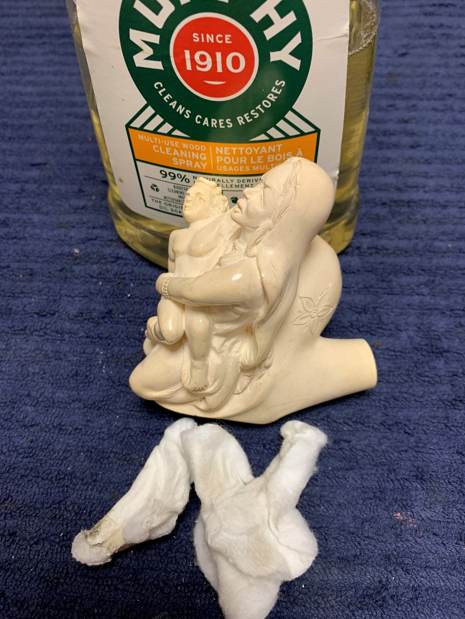

As for the carving, I’m not totally sure what it is meant to be. I can’t tell if it’s intended to be an image of the Virgin and Child, people from an ancient Anatolian myth, or some historical characters with which I am unfamiliar. Steve didn’t recognize them either, so if you have some idea who these people are, please feel free to clear up the mystery with a comment below.

As for the carving, I’m not totally sure what it is meant to be. I can’t tell if it’s intended to be an image of the Virgin and Child, people from an ancient Anatolian myth, or some historical characters with which I am unfamiliar. Steve didn’t recognize them either, so if you have some idea who these people are, please feel free to clear up the mystery with a comment below.

The pipe was in very nice condition, though a bit dirty. There was dust and debris in the grooves and even on the smooth surfaces. It had been smoked, though not heavily. The main part of the pipe was in good condition, without any notable damage. There was a tenon left in the shank that was broken and would need replacement. There was also a meerschaum shank extension which was dirty, but otherwise in good shape too.

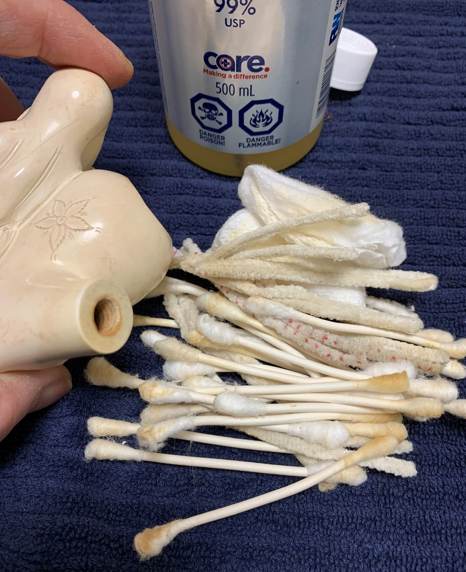

To work! I began by removing the tenon in the shank with a pair of needle-nose pliers. Meerschaum is too fragile for a proper reamer, so I used 220-grit sandpaper on the end of a wooden dowel to clean out the bowl and it turned out very nicely. I then cleaned the shank with lemon-infused isopropyl alcohol, pipe cleaners and Q-tips. One of the frustrations of cleaning meerschaum is that once smoked, the stains never go away. However, I did what I could and cleaned the shank extension in a similar manner.

To work! I began by removing the tenon in the shank with a pair of needle-nose pliers. Meerschaum is too fragile for a proper reamer, so I used 220-grit sandpaper on the end of a wooden dowel to clean out the bowl and it turned out very nicely. I then cleaned the shank with lemon-infused isopropyl alcohol, pipe cleaners and Q-tips. One of the frustrations of cleaning meerschaum is that once smoked, the stains never go away. However, I did what I could and cleaned the shank extension in a similar manner.

There were some unusual purple stains on parts of the meerschaum. I don’t know what they were, but I took a good-quality eraser and they came off with ease, fortunately. Then I took Murphy’s Oil Soap on some cotton rounds (and Q-tips) and cleaned the meerschaum. It’s important to be cautious in one’s use of fluids around meerschaum. Allowing it to soak in a liquid causes it to soften. I also used a soft bristle toothbrush with the Murphy’s in some of the nooks and crannies.

There were some unusual purple stains on parts of the meerschaum. I don’t know what they were, but I took a good-quality eraser and they came off with ease, fortunately. Then I took Murphy’s Oil Soap on some cotton rounds (and Q-tips) and cleaned the meerschaum. It’s important to be cautious in one’s use of fluids around meerschaum. Allowing it to soak in a liquid causes it to soften. I also used a soft bristle toothbrush with the Murphy’s in some of the nooks and crannies.

Now that the figural was all clean, I set about using my MicroMesh sanding pads to polish up the meerschaum. I didn’t use the coarser grits over the entire pipe – only in the areas that required it – as I didn’t want to risk any damage. I neglected to take pictures, but I also rubbed some Clapham’s Beeswax into the meerschaum. In fact, I used Q-tips as well to get it into the nooks and crannies. Then I let it sit for 15-20 minutes, buffed it with a microfiber cloth and then repeated the beeswax process. Worked like a charm!

Now that the figural was all clean, I set about using my MicroMesh sanding pads to polish up the meerschaum. I didn’t use the coarser grits over the entire pipe – only in the areas that required it – as I didn’t want to risk any damage. I neglected to take pictures, but I also rubbed some Clapham’s Beeswax into the meerschaum. In fact, I used Q-tips as well to get it into the nooks and crannies. Then I let it sit for 15-20 minutes, buffed it with a microfiber cloth and then repeated the beeswax process. Worked like a charm!

As I mentioned, Steve was kind enough to give me an acrylic stem which came with its own push-tenon. He also gave me a handful of other plastic, bone and metal tenons so I could find the right fit for the pipe in question. The stem was terrific, but it had been used and was plenty dirty.

As I mentioned, Steve was kind enough to give me an acrylic stem which came with its own push-tenon. He also gave me a handful of other plastic, bone and metal tenons so I could find the right fit for the pipe in question. The stem was terrific, but it had been used and was plenty dirty. First, I removed the push-tenon by heating it lightly with my heat gun. That allowed it to unscrew without much trouble. I then cleaned out the stem and tenon with the usual lemon-infused isopropyl alcohol, cotton pads, Q-tips etc. Just like meerschaum, acrylic tends to stain after smoking, no matter how dutiful you are with your cleaning. However, I put in a lot of elbow grease to sterilize the stem and tenon as much as I could. I even used some Castile soap and tube brushes. There were a couple of very small nicks on the stem, which I repaired with cyanoacrylate adhesive. However, I forgot to take pictures of that.

First, I removed the push-tenon by heating it lightly with my heat gun. That allowed it to unscrew without much trouble. I then cleaned out the stem and tenon with the usual lemon-infused isopropyl alcohol, cotton pads, Q-tips etc. Just like meerschaum, acrylic tends to stain after smoking, no matter how dutiful you are with your cleaning. However, I put in a lot of elbow grease to sterilize the stem and tenon as much as I could. I even used some Castile soap and tube brushes. There were a couple of very small nicks on the stem, which I repaired with cyanoacrylate adhesive. However, I forgot to take pictures of that.

I then used all nine MicroMesh pads (1,500 through 12,000 grit) and some Obsidian Pipe Stem Oil in between each pad scrubbing. Once that was done, I fitted a new bone tenon for the shank extension and a new mortise for the push-tenon.

I then used all nine MicroMesh pads (1,500 through 12,000 grit) and some Obsidian Pipe Stem Oil in between each pad scrubbing. Once that was done, I fitted a new bone tenon for the shank extension and a new mortise for the push-tenon.  Finally, as meerschaum pipes don’t do well on a bench-polisher, I buffed the pipe by hand with a microfibre cloth. And that’s that! This big meerschaum looks fantastic and is ready to be enjoyed again by the next owner. I am pleased to announce that this pipe is for sale! If you are interested in acquiring it for your collection, please have a look in the “Meerschaum” section of the store here on Steve’s website. You can also email me directly at kenneth@knightsofthepipe.com. The approximate dimensions of the pipe are as follows: length 7½ in. (190 mm); height 3½ in. (89 mm); bowl diameter 1½ in. (38 mm); chamber diameter ¾ in. (20 mm). The weight of the pipe is 4 oz. (114 g). I hope you enjoyed reading the story of this pipe’s restoration as much as I did restoring it. If you are interested in more of my work, please follow me here on Steve’s website or send me an email. Thank you very much for reading and, as always, I welcome and encourage your comments.

Finally, as meerschaum pipes don’t do well on a bench-polisher, I buffed the pipe by hand with a microfibre cloth. And that’s that! This big meerschaum looks fantastic and is ready to be enjoyed again by the next owner. I am pleased to announce that this pipe is for sale! If you are interested in acquiring it for your collection, please have a look in the “Meerschaum” section of the store here on Steve’s website. You can also email me directly at kenneth@knightsofthepipe.com. The approximate dimensions of the pipe are as follows: length 7½ in. (190 mm); height 3½ in. (89 mm); bowl diameter 1½ in. (38 mm); chamber diameter ¾ in. (20 mm). The weight of the pipe is 4 oz. (114 g). I hope you enjoyed reading the story of this pipe’s restoration as much as I did restoring it. If you are interested in more of my work, please follow me here on Steve’s website or send me an email. Thank you very much for reading and, as always, I welcome and encourage your comments.