Moving one of my own – a Pre-Republic Peterson’s System 0, Made in Ireland 317 Bent Billiard

Blog by Steve Laug

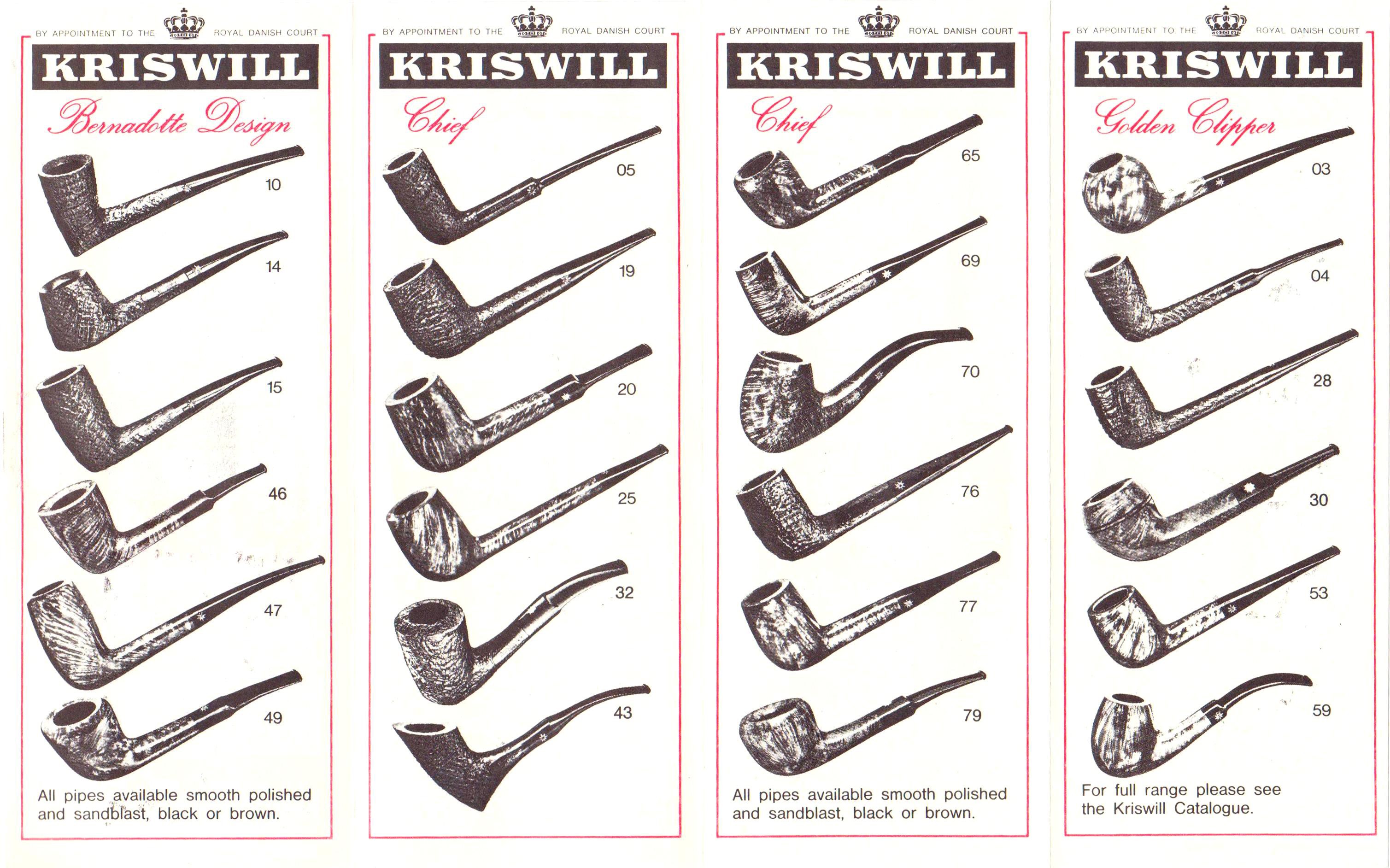

This is another pipe that I have taken out of my personal collection as I just do not use it too much. It is a classic Peterson’s Bent Billiard shaped pipe with some nice grain around the bowl and a nickel ferrule. It is another pipe that I smoked solely Virginia tobaccos in so it is very clean. The airway in the shank and the mortise were quite clean. The smooth rim top and edges were in excellent condition. The smooth finish was very clean but dull and quite lifeless. There were a few small fills the bowl sides. The grain is mixed but still quite nice around the bowl and shank. It is stamped on the left side of the shank and reads Peterson’s [arched over] System [arched over] 0. On the right side of the shank it is stamped Made in Ireland in a circle with the “In” mid circle. There is a faintly stamped number above that which seems to read 317. The nickel ferrule is stamped K&P [over] faux hallmarks (a clover leaf, an Irish wolfhound laying down and a tower). Next to that it reads Peterson’s. The bowl was quite clean with light damage to the inner edge and the front outer edge of the bowl. The nickel ferrule was in great condition and was dull looking. I took photos of the pipe before I did my clean up work on it.

I took a photo of the bowl and rim top to verify the description above. I also took photos of the stem surface showing that there were no tooth marks on either side.

I took a photo of the bowl and rim top to verify the description above. I also took photos of the stem surface showing that there were no tooth marks on either side.

I took photos of the stamping on the sides of the shank. It is faint but readable as noted above. The stamping on the ferrule is also very readable.

I took photos of the stamping on the sides of the shank. It is faint but readable as noted above. The stamping on the ferrule is also very readable. I took the stem off the bowl and took a photo of the pipe to give a sense of proportion of the pipe. It is a beauty.

I took the stem off the bowl and took a photo of the pipe to give a sense of proportion of the pipe. It is a beauty. I turned to Pipedia (https://pipedia.org/wiki/Peterson) and read through the article there. I found an interesting note in the middle of the page. I quote the pertinent section below and have highlights some important information in red below.

I turned to Pipedia (https://pipedia.org/wiki/Peterson) and read through the article there. I found an interesting note in the middle of the page. I quote the pertinent section below and have highlights some important information in red below.

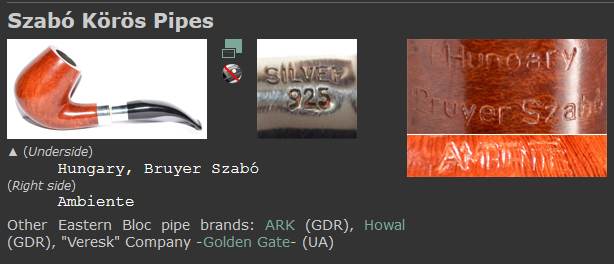

As usual when trying to get accurate facts in regard to Peterson history, something will jump up and get in the way. They are missing many of their records. The following is the best that we can do for a guide to the myriad markings during the period 1922 – 1949. Prior to 1920 it was rare for a country of origin to be stamped on the pipe, just Peterson’s Dublin on the band. After 1921/22, if it is stamped “MADE IN IRELAND” and the “Made in” is stacked over “Ireland” or “MADE IN EIRE” or several other forms, it was made between 1922 and 1938. A considerable number of Peterson pipes were stamped “Irish Free State”. From about 1930 to 1949, most of the pipes (those which were stamped) were stamped “Made in Ireland”.” If the stamp reads “MADE IN IRELAND” in a circle, the pipe was made between 1939 and 1948. These are all “pre-republic” pipes. I can tell you that the mark “Irish Free State” was adopted in 1922;and replaced by “Eire” in 1937 and then by “Republic of Ireland” in 1949.

I turned to “The Peterson Pipe” by Mark Irwin and Gary Malmberg to get some background on the Peterson’s System 0 Made in Ireland stamp. On page 126 it had the following information.

The stamp reads IRISH over FREE STATE, in small letters, usually perpendicular to the line of the shank, very close to and parallel to the seam where the shank meets the mouth piece. On banded pipe, this often hidden under the band itself. At the same time, they issued a smaller number of pipes stamped MADE IN over IRELAND. Today’s collector may encounter specimens of these with mountings hallmarked for every year from 1922-1937.

On page 301 of the above book I found a listing on System pipes that referred to the 0 stamp. I quote:

System Pipes (1937-59) The 1937 catalog only slightly changed the grading hierarchy for System pipes. The De Luxe model, described as “the finished possible quality obtainable” would be assigned no grading subscript, but neither would the First Quality. Below these were 0 Grade, 2nd Grade and 3rd Grade, all stamped with numbers and PETERSON’S over SYSTEM or PETERSON’S over DUBLIN. Grades 0 and 2nd were fitted with sterling mounts, 3rd grade with nickel. Each of these grades were sometimes stamped below and sometimes to the right of the model name. Sometimes these numbers were circled, sometimes not. The location of the number and whether it was circled or not was rather random from the onset of its use until discontinued in 1959, and by itself only indicates that a given pipe was made between ’37 and ’59.

On page 302 there was a listing on the nickel mounted markings. I quote:

Nickel-Mount Markings. Often called faux hallmarks or faux marks by Peterson collectors, this set of three little images of a shamrock, an Irish wolfhound and a round tower appear within rectangular shapes as decorations on nickel mountings. Very early nickel mounts (1891-c. 1920) had no such decorations, only the same stamps used on sterling but without the hallmarks. As a stamp, the set of decorations began to appear at the beginning of the Irish Free State era, sometimes alone but often under K&P and over block lettered PETERSON over DUBLIN, although the three emblems appeared on K&P’s Irish Carving Shamrocks pipes since 1896. The stamp was used until about 1963, when hand soldered nickel bands and ferrules were replaced by pressed ferrules and premade bands…The shamrock is the emblem of Ireland; the Irish wolfhound has long been used for both hunting and protection, and is an emblem of strength; the round tower a symbol of Ireland’s early religious power. These decorations were stamped at the factory on non-sterling mounts only, and the assay office has nothing to do with…

The information was very helpful. I have highlighted the pertinent reference to regarding the stamping, the shape 0 number and the faux hallmarks above. I knew that I was dealing with a Pre-Republic period pipes stamped Made in Ireland in a circle made between 1939-1948.

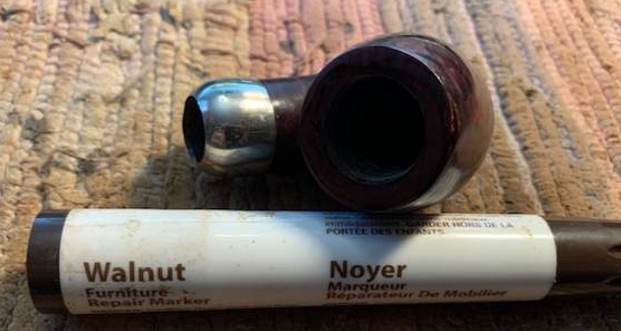

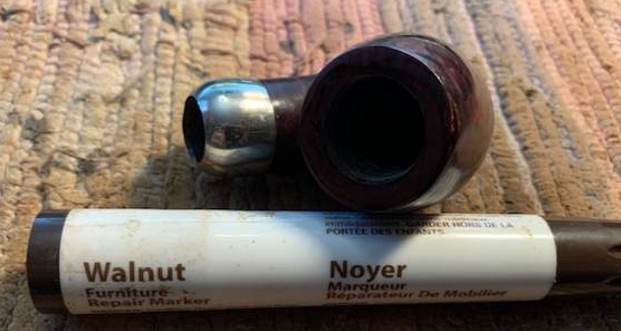

Now it was time to work on the pipe. I started working on the pipe with a folded piece of 220 grit sandpaper to smooth out the nicks in the inner edge. It did not take too much work to get it round again. I also used the sandpaper to smooth out the outer edge of the bowl. I rebuilt the front outer edge of the bowl with clear CA glue and briar dust to remove damaged area that was a flattened angle on the top bowl front. Once the repair cured I flattened it with a small flat file and then topped the bowl with a topping board and 220 grit sandpaper. I sanded the repair with a folded piece of 220 grit sandpaper to smooth it out. I wiped down the bowl sides and top with isopropyl alcohol on a cotton pad. I touched up the sanded rim top and the repaired area on the front of the bowl with a Walnut stain pen to match the surrounding briar on the bowl and the shank.

I rebuilt the front outer edge of the bowl with clear CA glue and briar dust to remove damaged area that was a flattened angle on the top bowl front. Once the repair cured I flattened it with a small flat file and then topped the bowl with a topping board and 220 grit sandpaper. I sanded the repair with a folded piece of 220 grit sandpaper to smooth it out. I wiped down the bowl sides and top with isopropyl alcohol on a cotton pad. I touched up the sanded rim top and the repaired area on the front of the bowl with a Walnut stain pen to match the surrounding briar on the bowl and the shank.

I cleaned up the light cake in the bowl with a Savinelli Fitsall Pipe Knife. I sanded the bowl walls with a piece of dowel wrapped in 220 grit sandpaper.

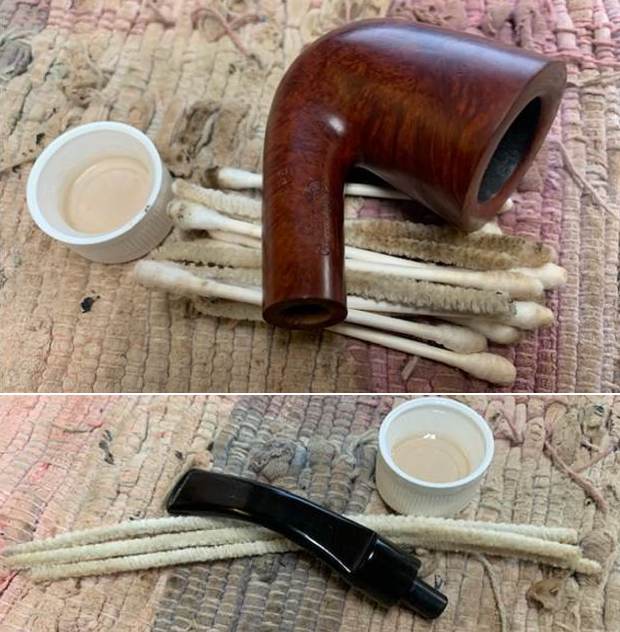

I cleaned up the light cake in the bowl with a Savinelli Fitsall Pipe Knife. I sanded the bowl walls with a piece of dowel wrapped in 220 grit sandpaper. I cleaned the shank and sump in the shank with cotton swabs, pipe cleaners and isopropyl alcohol to remove the debris and tars from my smoking. You can see that it was not too bad as I tend to keep my pipes clean.

I cleaned the shank and sump in the shank with cotton swabs, pipe cleaners and isopropyl alcohol to remove the debris and tars from my smoking. You can see that it was not too bad as I tend to keep my pipes clean. I polished the briar with micromesh sanding pads – dry sanding with 1500-12000 grit sanding pads. I wiped the bowl down with a damp cloth after each sanding pad.

I polished the briar with micromesh sanding pads – dry sanding with 1500-12000 grit sanding pads. I wiped the bowl down with a damp cloth after each sanding pad.

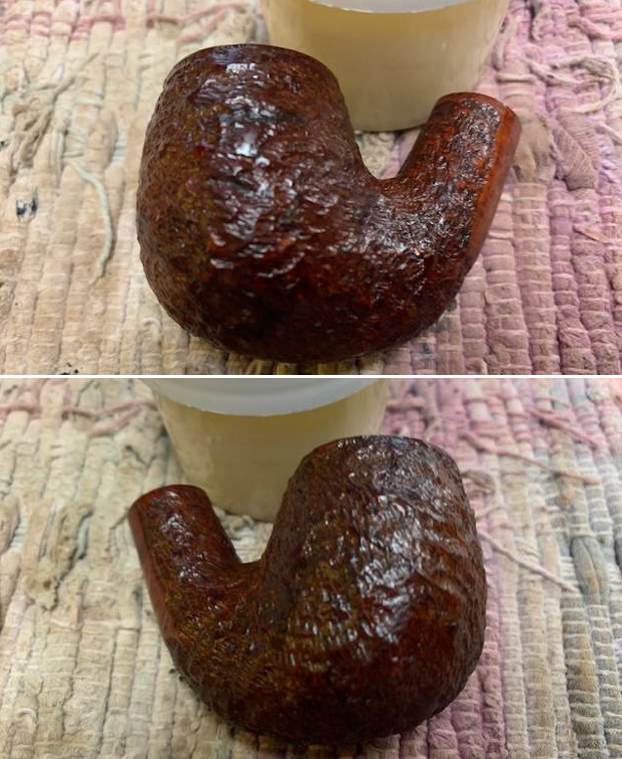

I worked some Before & After Restoration Balm into the surface of the briar with my fingertips to clean, enliven and protect the briar. I let the balm sit for 15 minutes and then buffed with a cotton cloth to raise the shine. The photos show the bowl at this point in the restoration process.

I worked some Before & After Restoration Balm into the surface of the briar with my fingertips to clean, enliven and protect the briar. I let the balm sit for 15 minutes and then buffed with a cotton cloth to raise the shine. The photos show the bowl at this point in the restoration process.

I polished the nickel domed ferrule with a jeweler’s cloth to raise the shine and give it some pop. It looked much better after the polishing.

I polished the nickel domed ferrule with a jeweler’s cloth to raise the shine and give it some pop. It looked much better after the polishing.

Since the stem was in new condition I rubbed it down with some Obsidian Oil and buffed it off. It is a beautiful stem.

Since the stem was in new condition I rubbed it down with some Obsidian Oil and buffed it off. It is a beautiful stem.  I am excited to put the final touches on this Pre-Republic, Made in Ireland Peterson’s System 0 Bent. I put the pipe back together and buffed it with Blue Diamond on the buffing wheel. I gave the bowl and the stem multiple coats of carnauba wax. I hand buffed the pipe with a clean buffing pad to raise the shine. It is fun to see what the polished bowl looks like with beautiful mixed grain all around it. Added to that the polished black vulcanite stem and nickel ferrule combined with the bowl and made a stunning pipe. This smooth Classic Older Peterson’s System 0 Bent is great looking and the pipe feels great in my hand. It is light and well balanced. Have a look at it with the photos below. The dimensions are Length: 5 ½ inches, Height: 1 ¾ inches, Outside diameter of the bowl: 1 ¼ inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 47 grams/1.66 ounces. It is a beautiful pipe that I will soon be putting on the rebornpipes store in the Irish Pipe Makers section. If you are interested in adding it to your collection send me an email or a message. Thanks for walking through the restoration with me as I worked over this pipe. Thanks to each of you who are reading this blog.

I am excited to put the final touches on this Pre-Republic, Made in Ireland Peterson’s System 0 Bent. I put the pipe back together and buffed it with Blue Diamond on the buffing wheel. I gave the bowl and the stem multiple coats of carnauba wax. I hand buffed the pipe with a clean buffing pad to raise the shine. It is fun to see what the polished bowl looks like with beautiful mixed grain all around it. Added to that the polished black vulcanite stem and nickel ferrule combined with the bowl and made a stunning pipe. This smooth Classic Older Peterson’s System 0 Bent is great looking and the pipe feels great in my hand. It is light and well balanced. Have a look at it with the photos below. The dimensions are Length: 5 ½ inches, Height: 1 ¾ inches, Outside diameter of the bowl: 1 ¼ inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 47 grams/1.66 ounces. It is a beautiful pipe that I will soon be putting on the rebornpipes store in the Irish Pipe Makers section. If you are interested in adding it to your collection send me an email or a message. Thanks for walking through the restoration with me as I worked over this pipe. Thanks to each of you who are reading this blog.

I took a photo of the bowl and rim top to verify the description above. I also took photos of the stem surface showing the light chatter and tooth marks on both side.

I took a photo of the bowl and rim top to verify the description above. I also took photos of the stem surface showing the light chatter and tooth marks on both side.  I took a photo of the stamping on the sides of the shank. It is clear and readable as noted above.

I took a photo of the stamping on the sides of the shank. It is clear and readable as noted above.  I took the stem off the bowl and took a photo of the pipe to give a sense of proportion of the pipe. You can also see the deep and rugged rustication on the briar and it is a beauty.

I took the stem off the bowl and took a photo of the pipe to give a sense of proportion of the pipe. You can also see the deep and rugged rustication on the briar and it is a beauty. Now it was time to work on the pipe. I worked on the inner edge of the bowl 220 grit sandpaper to give the inner edge a slight bevel and clean up the damage that was present there. The rim came out looking quite good.

Now it was time to work on the pipe. I worked on the inner edge of the bowl 220 grit sandpaper to give the inner edge a slight bevel and clean up the damage that was present there. The rim came out looking quite good.  I cleaned the mortise and airways in the shank and stem with cotton swabs, pipe cleaners and isopropyl alcohol to remove the debris and tars from my smoking. You can see that it was not too bad as I tend to keep my pipes clean.

I cleaned the mortise and airways in the shank and stem with cotton swabs, pipe cleaners and isopropyl alcohol to remove the debris and tars from my smoking. You can see that it was not too bad as I tend to keep my pipes clean.  I polished the rim top and the briar with micromesh sanding pads – dry sanding with 1500-12000 grit pads. I wiped the bowl down with a damp cloth after each sanding pad to remove the dust and debris. The rim top polished out and matched the oil cured look of the bowl and shank.

I polished the rim top and the briar with micromesh sanding pads – dry sanding with 1500-12000 grit pads. I wiped the bowl down with a damp cloth after each sanding pad to remove the dust and debris. The rim top polished out and matched the oil cured look of the bowl and shank.

The bowl was in such good condition that decided to give the bowl and shank a coating of Before & After Restoration Balm. I worked it into the surface of the briar with my fingertips and a horsehair shoe brush to clean, enliven and protect the briar. I let the balm sit for 15 minutes and then buffed with a cotton cloth to raise the shine. The photos show the bowl at this point in the restoration process.

The bowl was in such good condition that decided to give the bowl and shank a coating of Before & After Restoration Balm. I worked it into the surface of the briar with my fingertips and a horsehair shoe brush to clean, enliven and protect the briar. I let the balm sit for 15 minutes and then buffed with a cotton cloth to raise the shine. The photos show the bowl at this point in the restoration process.

I set the bowl aside and sanded out the tooth marks and chatter on the stem surface and button with 220 grit sandpaper. I was able to smooth out the marks on the surface of both sides.

I set the bowl aside and sanded out the tooth marks and chatter on the stem surface and button with 220 grit sandpaper. I was able to smooth out the marks on the surface of both sides. I scrubbed the oxidized portions of the stem from the shank end back almost an inch using some Soft Scrub cleanser. I was able to remove the oxidation from the vulcanite. It was quite dirty and the majority of it was gone.

I scrubbed the oxidized portions of the stem from the shank end back almost an inch using some Soft Scrub cleanser. I was able to remove the oxidation from the vulcanite. It was quite dirty and the majority of it was gone.  I polished the stem with micromesh sanding pads – dry sanding with 1500-12000 grit pads. I rubbed it down between pads with Obsidian Oil. I polished it with Before & After Fine and Extra Fine Pipe Stem Polish. I wiped it down with some Obsidian Oil and buffed it off. It is a beautiful stem.

I polished the stem with micromesh sanding pads – dry sanding with 1500-12000 grit pads. I rubbed it down between pads with Obsidian Oil. I polished it with Before & After Fine and Extra Fine Pipe Stem Polish. I wiped it down with some Obsidian Oil and buffed it off. It is a beautiful stem.

I am excited to put the final touches on this great looking Churchill Matt Grain ¼ Bent Pot I put the pipe back together and buffed the stem with Blue Diamond on the buffing wheel. I gave the bowl and the stem multiple coats of carnauba wax. I hand buffed the pipe with a clean buffing pad to raise the shine. It is fun to see what the polished bowl looks like with the beautiful grain and the polished vulcanite taper stem. This smooth Churchill Matt Grain Pot is great looking and the pipe feels great in my hand. It is light and well balanced. Have a look at it with the photos below. The dimensions are Length: 6 inches, Height: 1 ½ inches, Outside diameter of the bowl: 1 ½ inches, Chamber diameter: 1 inch. The weight of the pipe is 44 grams/1.55 ounces. It is a beautiful pipe that I will soon be putting on the rebornpipes store in the English Pipe Makers Section. If you are interested in adding it to your collection send me an email or a message. Thanks for walking through the restoration with me as I worked over this pipe. Thanks to each of you who are reading this blog.

I am excited to put the final touches on this great looking Churchill Matt Grain ¼ Bent Pot I put the pipe back together and buffed the stem with Blue Diamond on the buffing wheel. I gave the bowl and the stem multiple coats of carnauba wax. I hand buffed the pipe with a clean buffing pad to raise the shine. It is fun to see what the polished bowl looks like with the beautiful grain and the polished vulcanite taper stem. This smooth Churchill Matt Grain Pot is great looking and the pipe feels great in my hand. It is light and well balanced. Have a look at it with the photos below. The dimensions are Length: 6 inches, Height: 1 ½ inches, Outside diameter of the bowl: 1 ½ inches, Chamber diameter: 1 inch. The weight of the pipe is 44 grams/1.55 ounces. It is a beautiful pipe that I will soon be putting on the rebornpipes store in the English Pipe Makers Section. If you are interested in adding it to your collection send me an email or a message. Thanks for walking through the restoration with me as I worked over this pipe. Thanks to each of you who are reading this blog.