Blog by Paresh Deshpande

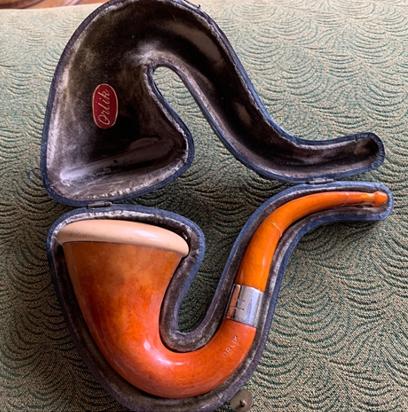

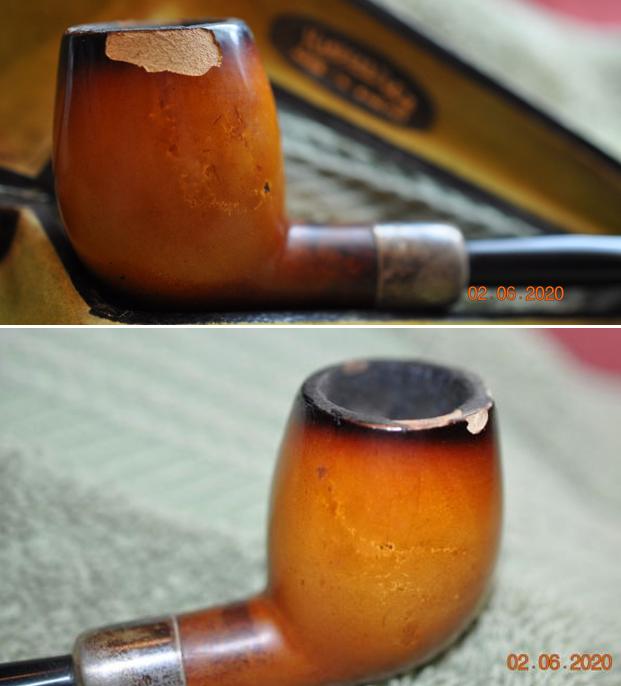

While surfing eBay for estate pipe lots, I came across a job lot that contained four estate pipes. The seller had not included any description for the item other than a simple statement that read “The lot is being sold as is. Pictures are part of description” or words to that effect. The worst part was that there were only two pictures that were posted by the seller!! Here are the pictures that were posted by the seller…

I could make out one Orlik with dental stem, a Hardcastle’s Bulldog, one Comoy’s Lovat, and the last one was unidentifiable but appeared to be fitted with a horn stem. The pipes appeared to be in a decent condition and included some nice brand names. Soon the pipes reached Abha at my home town. I had restored the pipe with horn stem and it turned out to be a gem from an old and reputable maker “Salmon (Barnett) & Gluckstein” from the period 1894 (guesstimated). Here is the link to the write up that was posted on rebornpipes;

I could make out one Orlik with dental stem, a Hardcastle’s Bulldog, one Comoy’s Lovat, and the last one was unidentifiable but appeared to be fitted with a horn stem. The pipes appeared to be in a decent condition and included some nice brand names. Soon the pipes reached Abha at my home town. I had restored the pipe with horn stem and it turned out to be a gem from an old and reputable maker “Salmon (Barnett) & Gluckstein” from the period 1894 (guesstimated). Here is the link to the write up that was posted on rebornpipes;

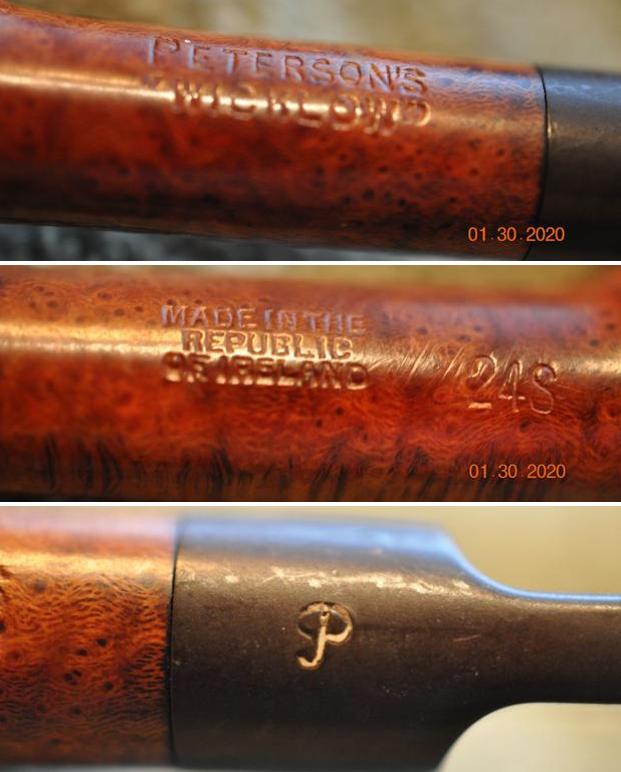

The 2nd pipe that I selected to work on from this lot is the Hardcastle’s Bulldog and is indicated with indigo blue arrow. The pipe is a classic Bent Bulldog with a diamond shank and a saddle vulcanite stem with a push-fit tenon. It is a medium sized pipe with a nice hand feel and a nice heft to it. The pipe may not have fantastic flame grains to boast, but has a beautiful mix of bird’s eye and straight grains scattered around the stummel surface and is without a single fill. The briar piece used to carve this pipe is of top quality and the construction and finish of the stummel and mouthpiece feels top notch too. It is stamped on the left shank panel as underlined “HARDCASTLE’S” in an arch in capital letters over “BRITISH MADE” over “DRAWEL” in an opposite arch forming a rugby ball shaped stamping. The right shank panel bears the shape code # 27 in the centre. The high quality saddle stem bears the trademark logo “H” on the left face of the saddle. The stampings are crisp and easily readable and shown below.

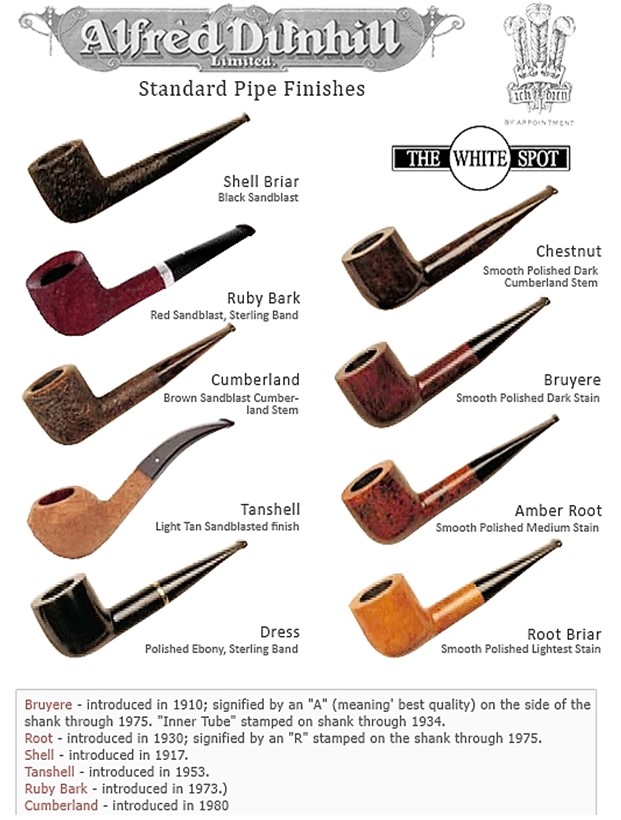

The pipe is a classic Bent Bulldog with a diamond shank and a saddle vulcanite stem with a push-fit tenon. It is a medium sized pipe with a nice hand feel and a nice heft to it. The pipe may not have fantastic flame grains to boast, but has a beautiful mix of bird’s eye and straight grains scattered around the stummel surface and is without a single fill. The briar piece used to carve this pipe is of top quality and the construction and finish of the stummel and mouthpiece feels top notch too. It is stamped on the left shank panel as underlined “HARDCASTLE’S” in an arch in capital letters over “BRITISH MADE” over “DRAWEL” in an opposite arch forming a rugby ball shaped stamping. The right shank panel bears the shape code # 27 in the centre. The high quality saddle stem bears the trademark logo “H” on the left face of the saddle. The stampings are crisp and easily readable and shown below. I had cleaned up a Hardcastle’s Royal Windsor, a quaint lightweight sandblasted straight billiards with ring grains all round even before I started posting my work on rebornpipes and had read about the marquee. I remembered the brand to be British that was taken over by Dunhill and eventually relegated to being a seconds brand to even Parker, also taken over by Dunhill. To refresh my memory and relive the painful demise of a classic quality pipe maker from Britain, I visited pipedia.org. I have reproduced the snippets of relevant information for easy referencing of the esteemed readers.

I had cleaned up a Hardcastle’s Royal Windsor, a quaint lightweight sandblasted straight billiards with ring grains all round even before I started posting my work on rebornpipes and had read about the marquee. I remembered the brand to be British that was taken over by Dunhill and eventually relegated to being a seconds brand to even Parker, also taken over by Dunhill. To refresh my memory and relive the painful demise of a classic quality pipe maker from Britain, I visited pipedia.org. I have reproduced the snippets of relevant information for easy referencing of the esteemed readers.

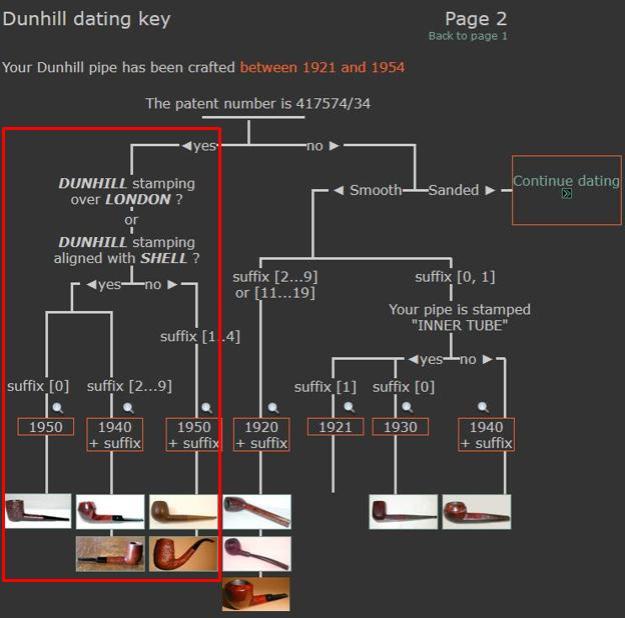

Hardcastle was founded in 1908 by Edmund Hardcastle and built itself a good reputation among the numerous British mid-graders. In 1935 Dunhill started to build a factory next door to Hardcastle in Forest Road, Walthamstow, London E17. The family owned Hardcastle Pipes Limited sold 49% of its equity to Dunhill In 1936.

Along with closing down its pipe factory in Notting Hill in 1946 Dunhill bought the remaining shares, turning Hardcastle into a 100% Dunhill subsidiary. As members of the Hardcastle family continued as executives in the company’s management Hardcastle retained a certain independence.

This ended in 1967. Dunhill merged Hardcastle with Parker (100% Dunhill as well). The new Parker Hardcastle Limited also absorbed the former Masta Patent Pipe Company. Hardcastle’s Forest Road plant was immediately given up and the production of Hardcastle pipes was shifted to Parker’s nearby St. Andrews Road factory – now consequently called Parker-Hardcastle factory.

In fact this put a definite end to Hardcastle as an own-standing pipe brand, and none other than Edwin Hardcastle, the last of the family executives, spoke frankly and loudly of Hardcastle pipes being degenerated to an inferior Dunhill second.

Today Hardcastle pipes use funneled down bowls that are not deemed suitable to bear the Dunhill or even the Parker name (as well as obtaining briar from other sources).

Timeline

- 1903: Edmund Hardcastle establishes the brand

- 1936: Family sells 49% of the Hardcastle Pipes Limited shares to Dunhill

- 1946: Dunhill buys the remaining shares, but the family continues to manage the company

- 1967: Dunhill merges Hardcastle with Parker. The new Parker-Hardcastle Limited company absorbs the Masta Patent Pipe Company also.

- After 1967 it is speculated that Hardcastle became the brand for “Parker Seconds”

John Loring states in “The Dunhill Briar Pipe – ‘the patent years and after'” that in the absence of sales receipts, or other items of provenance, Hardcastles cannot be accurately dated. Loring further states that he knows of no way to distinguish the briar source when looking at Hardcastle, Parker, or Parker-Hardcastle pipes.

Models & Grades

Family Period

Straight Grain, Supergrain, Leweard, Nut Bruyere, De Luxe, Royal Windsor Sandhewn, Royal Crown, The Crown, Phito Dental, Old Bruyere, Jack O’London, Dental Briar, Phito, Dental, Dryconomy, Drawel, Phithu, Telebirar, Camden, Lightweight, The Table, Dovetail, Dental, Crescent Extra, Lonsdale, Welard De Luxe

Thus from the above, it is evident that the pipe on my work table is from the family era and made prior to 1967 when Hardcastle became the brand for “Parker Seconds”.

Initial Visual Inspection

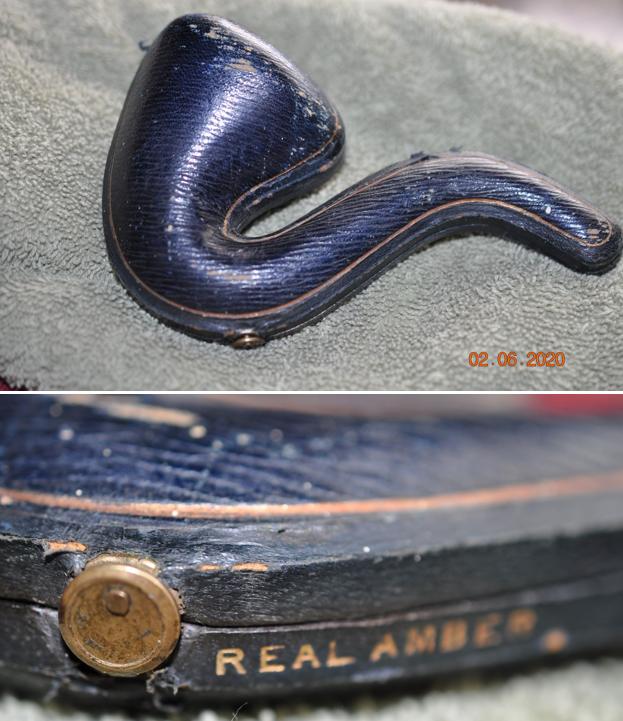

This pipe has the classic Bent Bulldog shape with a diamond shank and a medium sized bowl. The stummel boasts of some beautiful bird’s eye and cross grains all over the bowl and shank. The stummel surface is covered in dirt and grime of the overflowed lava. There is not a single fill in the briar which speaks of high quality selection of the briar. There is a thick layer of cake in the chamber. The saddle vulcanite stem is heavily oxidized with tooth chatter and light tooth indentations on either surface in the bite zone. The stem does not seat flush with the shank face. The set of pictures below shows the condition of the pipe when it had reached us.

Detailed Inspection Of The Pipe And Observations

Detailed Inspection Of The Pipe And Observations

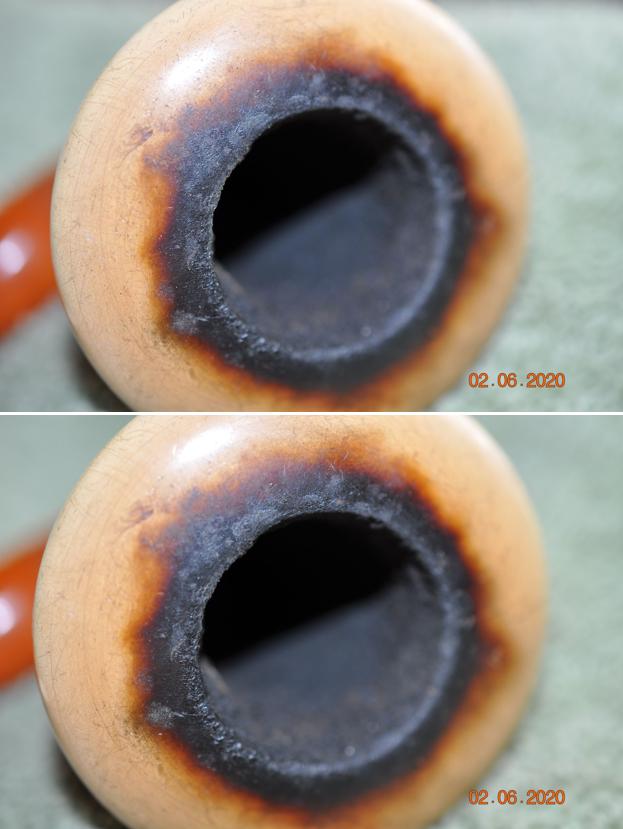

The chamber has an even layer of thick cake. The smooth rim top surface shows a couple of dents/ dings (indicated with blue arrows) and is covered in lava overflow, dirt and grime from previous usage. The outer rim edge has a charred spot in 10 o’clock direction (encircled in yellow) and has suffered a few blows on a hard surface resulting in a few chipped edge surfaces in 12 o’ clock direction (encircled in green). The inner edge appears to be in decent condition. The condition of the inner walls of the chamber can be commented upon after the cake has been taken down to the bare briar. The chamber exudes a very strong odor of old tobacco. The draught hole is dead center at the bottom of the chamber and that makes me believe that it should be a great smoke and the thick cake in the chamber lends credence to this observation. The stummel appears solid to the touch all around and hence I do not foresee any serious damage to the walls in the form of a burnout/ deep heat fissures/ lines or pits. To address the damage to outer rim edge, I shall create a slight bevel over the rim edge. Topping the rim surface should address the dents and dings over the rim top surface. The reaming and subsequent cleaning of the chamber and mortise should reduce the ghost smells from the chamber. The smooth stummel surface is covered in lava overflow that has attracted a lot of dust and dirt. The natural hued briar has taken on a layer of aged patina through which one can make out the beautiful cross grains that adorns most of the stummel surface and Bird’s eye grain at the foot and bottom of the shank. There are a few dents and chipped areas over the bowl cap (encircled in yellow), probably due to falls and or rough, uncared for handling of the pipe. Close observation of the stummel surface under magnification has revealed three very minute fills, two at the front of the bowl and one on the shank (indicated by red arrows) in the entire stummel. The double ring that separates the cap from the rest of the bowl is uneven but intact; however, it is filled with dust, dirt and grime. The briar looks lifeless and bone dry and has taken on dull dark hues. The mortise shows heavy accumulation of oils, tars and gunk and due to which the air flow is not full and smooth. Thorough cleaning of the stummel surface and rinsing it under warm water should highlight the grain patterns. This cleaning will further reveal any other damage to the stummel surface. In all probability, I shall let the minor fills in the stummel surface remain and avoid the process of refreshing these fills. The dents and dings to the bowl cap and the rest of the stummel will be addressed to an extent once the stummel is sanded and polished using micromesh pads.

The smooth stummel surface is covered in lava overflow that has attracted a lot of dust and dirt. The natural hued briar has taken on a layer of aged patina through which one can make out the beautiful cross grains that adorns most of the stummel surface and Bird’s eye grain at the foot and bottom of the shank. There are a few dents and chipped areas over the bowl cap (encircled in yellow), probably due to falls and or rough, uncared for handling of the pipe. Close observation of the stummel surface under magnification has revealed three very minute fills, two at the front of the bowl and one on the shank (indicated by red arrows) in the entire stummel. The double ring that separates the cap from the rest of the bowl is uneven but intact; however, it is filled with dust, dirt and grime. The briar looks lifeless and bone dry and has taken on dull dark hues. The mortise shows heavy accumulation of oils, tars and gunk and due to which the air flow is not full and smooth. Thorough cleaning of the stummel surface and rinsing it under warm water should highlight the grain patterns. This cleaning will further reveal any other damage to the stummel surface. In all probability, I shall let the minor fills in the stummel surface remain and avoid the process of refreshing these fills. The dents and dings to the bowl cap and the rest of the stummel will be addressed to an extent once the stummel is sanded and polished using micromesh pads.

The seating of the stem tenon into the mortise is not flush. The most probable reason for this could be the accumulated gunk in the mortise. Thorough cleaning of the mortise should address this issue. The minor fill in the shank described above, is indicated with a red arrow.

The seating of the stem tenon into the mortise is not flush. The most probable reason for this could be the accumulated gunk in the mortise. Thorough cleaning of the mortise should address this issue. The minor fill in the shank described above, is indicated with a red arrow.  The vulcanite saddle stem is heavily oxidized. The bite zone has tooth chatter on either surface. The lower stem surface has deep tooth indentation that, in all probability, would need to be filled. The button edges on both surfaces have minor bite marks and would need to be sharpened. The tenon is smeared in oils and tars and grime and so is the horizontal slot. The high quality saddle stem bears the trademark logo “H” on the left face of the saddle and would need to be refreshed/ highlighted. Overall, the stem is in a decent condition and the high quality of the vulcanite means that it should take on a nice shine readily.

The vulcanite saddle stem is heavily oxidized. The bite zone has tooth chatter on either surface. The lower stem surface has deep tooth indentation that, in all probability, would need to be filled. The button edges on both surfaces have minor bite marks and would need to be sharpened. The tenon is smeared in oils and tars and grime and so is the horizontal slot. The high quality saddle stem bears the trademark logo “H” on the left face of the saddle and would need to be refreshed/ highlighted. Overall, the stem is in a decent condition and the high quality of the vulcanite means that it should take on a nice shine readily. The Process

The Process

I started the restoration of this pipe by reaming the chamber with size 1 and 2 heads of the` Castleford reamer. With my fabricated knife, I further scraped the chamber walls to remove the remaining carbon deposits and also scraped out the lava overflow from the rim top surface. Once the cake was reamed back to the bare briar, I used a 220 grit sand paper to remove all the traces of remaining cake and also to smooth out the inner walls of the chamber surface. Finally, to remove the residual carbon dust, I wiped the chamber with a cotton pad wetted with 99.9% pure isopropyl alcohol. The chamber walls are in pristine condition with no signs of heat lines/ fissures. The beveled inner rim edge shows signs of minor charring in the 10 ‘O’ clock direction which will be addressed by light sanding along the beveled edge. This charring further extends to the outer rim edge as well and will be addressed while topping the rim top. The rim top surface itself is peppered with dents/ dings and scratches which will be smoothed by topping. The problem of the chipped outer edge will be resolved during the topping of rim surface followed by creating a slight bevel, if need be. The ghost smells are still very strong and may further reduce after the shank/ mortise are thoroughly cleaned.  This was followed by cleaning the mortise with cue tips, pipe cleaners and shank brush dipped in isopropyl alcohol. I scraped the walls of the mortise with my fabricated knife to remove the dried oils and tars. The mortise was a bear to clean and the heap of pipe cleaners, q-tips that were used and the pile of scraped out gunk is an indication of how dirty the shank internals were. The old smells of the tobacco are still strong and would need more invasive methods to get rid of these odors.

This was followed by cleaning the mortise with cue tips, pipe cleaners and shank brush dipped in isopropyl alcohol. I scraped the walls of the mortise with my fabricated knife to remove the dried oils and tars. The mortise was a bear to clean and the heap of pipe cleaners, q-tips that were used and the pile of scraped out gunk is an indication of how dirty the shank internals were. The old smells of the tobacco are still strong and would need more invasive methods to get rid of these odors. With the bowl internals clean, I moved to clean the exterior of the stummel. I used a hard bristled tooth brush and Briar Cleaner, a product that has been developed by Mark Hoover, to scrub the stummel and rim top. I set the stummel aside for 10 minutes for the product to draw out all the grime from the briar surface. After 10 minutes, I washed the stummel under running warm water with anti oil dish washing detergent till the stummel surface was clean and dried it using paper towels and a soft cotton cloth. I simultaneously cleaned the shank internals with the detergent and hard bristled shank brush and set the stummel aside to dry out naturally. I diligently cleaned the grooves between the bowl rings that separated the bowl cap from rest of the stummel surface. The stummel surface, including the rim top has cleaned up nicely with the beautiful grain patterns on full display. The lower edge of the bowl cap has chipped areas that were exposed during the cleaning of the grooves. I shall try to even it out by sanding in between the grooves with a folded piece of 220 grit sandpaper. The three very small fills that I had noticed under magnification, are all solid and refreshing them is not required. I shall subject the chamber to cotton and alcohol treatment to eliminate the ghost smells completely as the smell is still very strong.

With the bowl internals clean, I moved to clean the exterior of the stummel. I used a hard bristled tooth brush and Briar Cleaner, a product that has been developed by Mark Hoover, to scrub the stummel and rim top. I set the stummel aside for 10 minutes for the product to draw out all the grime from the briar surface. After 10 minutes, I washed the stummel under running warm water with anti oil dish washing detergent till the stummel surface was clean and dried it using paper towels and a soft cotton cloth. I simultaneously cleaned the shank internals with the detergent and hard bristled shank brush and set the stummel aside to dry out naturally. I diligently cleaned the grooves between the bowl rings that separated the bowl cap from rest of the stummel surface. The stummel surface, including the rim top has cleaned up nicely with the beautiful grain patterns on full display. The lower edge of the bowl cap has chipped areas that were exposed during the cleaning of the grooves. I shall try to even it out by sanding in between the grooves with a folded piece of 220 grit sandpaper. The three very small fills that I had noticed under magnification, are all solid and refreshing them is not required. I shall subject the chamber to cotton and alcohol treatment to eliminate the ghost smells completely as the smell is still very strong.

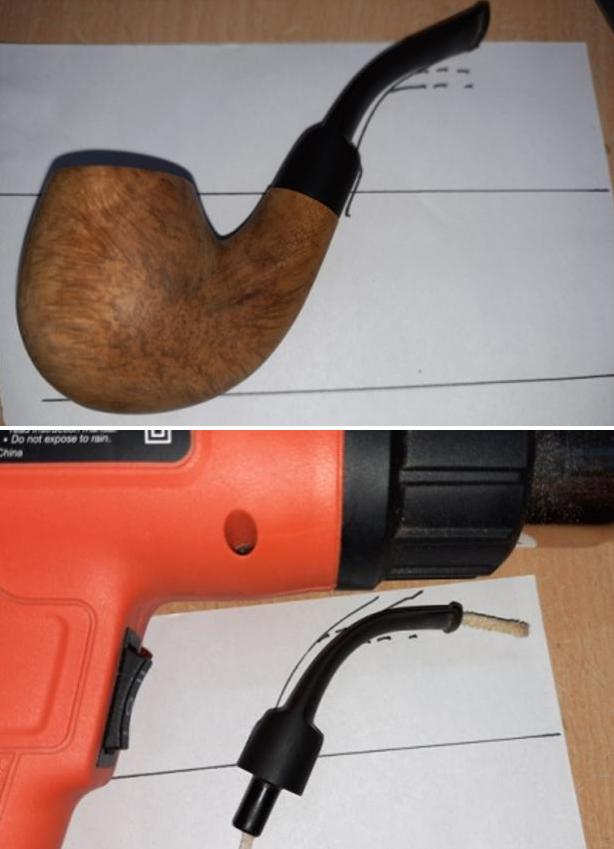

Next I cleaned the internals of the stem with bristled pipe cleaners and 99.9% pure isopropyl alcohol. With my fabricated knife, I gently scraped out the dried gunk from the tenon end and the horizontal slot. I further cleaned out the stem internals with a shank brush and dish washing liquid soap. Once the stem internals were cleaned, I sanded the entire stem surface with a 220 grit sand paper in preparation for dunking the stem in Before and After Deoxidizer solution.

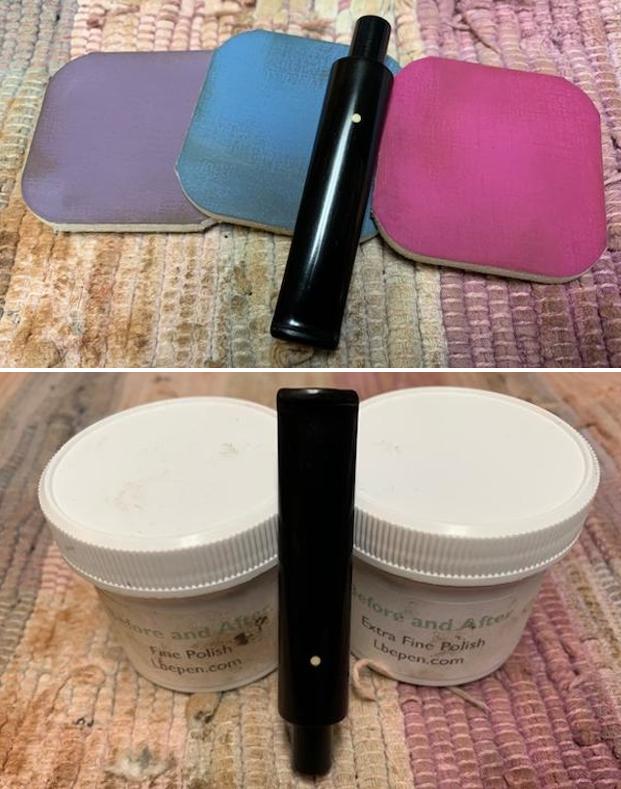

Next I cleaned the internals of the stem with bristled pipe cleaners and 99.9% pure isopropyl alcohol. With my fabricated knife, I gently scraped out the dried gunk from the tenon end and the horizontal slot. I further cleaned out the stem internals with a shank brush and dish washing liquid soap. Once the stem internals were cleaned, I sanded the entire stem surface with a 220 grit sand paper in preparation for dunking the stem in Before and After Deoxidizer solution. I thereafter, dropped the stem in to “Before and After Deoxidizer” solution developed by my friend Mark Hoover. The solution helps to draw out heavy oxidation to the surface, making it’s further removal a breeze, while the minor oxidation is eliminated to a very great extent. The initial sanding helps to draw out the complete oxidation as the sanding opens up the stem surface that has been initially covered with oxidation. I usually dunk stems of the pipes that are in-line for restoration and this pipe is marked in a pastel blue arrow. I generally allow the stems to soak overnight for the solution to do its work.

I thereafter, dropped the stem in to “Before and After Deoxidizer” solution developed by my friend Mark Hoover. The solution helps to draw out heavy oxidation to the surface, making it’s further removal a breeze, while the minor oxidation is eliminated to a very great extent. The initial sanding helps to draw out the complete oxidation as the sanding opens up the stem surface that has been initially covered with oxidation. I usually dunk stems of the pipes that are in-line for restoration and this pipe is marked in a pastel blue arrow. I generally allow the stems to soak overnight for the solution to do its work. While the stem was soaking in the deoxidizer solution, I continued the cleaning of the chamber and shank internals with a salt and alcohol bath. I used cotton balls which is an at par substitute as I have realized over the years. I drew out a wick from the cotton and along with a folded regular pipe cleaner; inserted it into the mortise and through the draught hole into the chamber. Thereafter, I packed the chamber with cotton balls to about quarter of an inch below the inner rim edge and soaked the cotton balls with isopropyl alcohol up to the brim. About half an hour later, the level of alcohol had gone down, having being absorbed by the cotton. I topped it up once again and set it aside overnight. By the next morning, the cotton and alcohol had drawn out all the remaining oils and tars from the chamber and mortise, fulfilling its intended task. I removed the cotton balls and ran pipe cleaners through the mortise to clean out all the loosened tars and gunk and further cleaned it with alcohol and q-tips. The chamber now smells clean and fresh. I set the stummel aside to dry out naturally.

While the stem was soaking in the deoxidizer solution, I continued the cleaning of the chamber and shank internals with a salt and alcohol bath. I used cotton balls which is an at par substitute as I have realized over the years. I drew out a wick from the cotton and along with a folded regular pipe cleaner; inserted it into the mortise and through the draught hole into the chamber. Thereafter, I packed the chamber with cotton balls to about quarter of an inch below the inner rim edge and soaked the cotton balls with isopropyl alcohol up to the brim. About half an hour later, the level of alcohol had gone down, having being absorbed by the cotton. I topped it up once again and set it aside overnight. By the next morning, the cotton and alcohol had drawn out all the remaining oils and tars from the chamber and mortise, fulfilling its intended task. I removed the cotton balls and ran pipe cleaners through the mortise to clean out all the loosened tars and gunk and further cleaned it with alcohol and q-tips. The chamber now smells clean and fresh. I set the stummel aside to dry out naturally. The next morning, after I had cleaned the chamber and shank, I removed the stem that had been soaking in the deoxidizer solution overnight. I cleaned the stem and the stem airway under running warm water and scrubbed the raised oxidation from the stem surface using a Magic Eraser pad followed by Scotch Brite pad and the airway with a thin shank brush. I further removed the oxidation by scrubbing the stem with 0000 grade steel wool and applied a little EVO to rehydrate the stem. This now gives a clearer picture of the extent of depth of the bite marks as can be seen in the pictures below. These will definitely require a fill even after I have heated and raised the vulcanite. I need to rebuild the entire button edges on both the upper and lower surface of the stem. Traces of stubborn deep seated oxidation can be seen, especially on the saddle portion of the stem that would need to be eliminated before polishing the stem.

The next morning, after I had cleaned the chamber and shank, I removed the stem that had been soaking in the deoxidizer solution overnight. I cleaned the stem and the stem airway under running warm water and scrubbed the raised oxidation from the stem surface using a Magic Eraser pad followed by Scotch Brite pad and the airway with a thin shank brush. I further removed the oxidation by scrubbing the stem with 0000 grade steel wool and applied a little EVO to rehydrate the stem. This now gives a clearer picture of the extent of depth of the bite marks as can be seen in the pictures below. These will definitely require a fill even after I have heated and raised the vulcanite. I need to rebuild the entire button edges on both the upper and lower surface of the stem. Traces of stubborn deep seated oxidation can be seen, especially on the saddle portion of the stem that would need to be eliminated before polishing the stem. To begin repairs to the stem, I sanded the entire stem surface with a folded piece of 220 grit sand paper till the complete oxidation was eliminated from the stem and saddle portion in particular. I cleaned the entire stem and areas in the bite zone with cotton swab and alcohol. Next, I filled the tooth indentations in the lower surface with a mix of clear CA superglue and activated charcoal and set it aside to cure. After the glue had partially hardened on the lower surface, likewise, I filled the upper surface tooth marks and set the stem aside for the superglue to harden completely. Once the fill has hardened, I shall file and sand the fills to reconstruct the bite zone and the buttons on either surfaces and subsequently match it with the surface of the stem.

To begin repairs to the stem, I sanded the entire stem surface with a folded piece of 220 grit sand paper till the complete oxidation was eliminated from the stem and saddle portion in particular. I cleaned the entire stem and areas in the bite zone with cotton swab and alcohol. Next, I filled the tooth indentations in the lower surface with a mix of clear CA superglue and activated charcoal and set it aside to cure. After the glue had partially hardened on the lower surface, likewise, I filled the upper surface tooth marks and set the stem aside for the superglue to harden completely. Once the fill has hardened, I shall file and sand the fills to reconstruct the bite zone and the buttons on either surfaces and subsequently match it with the surface of the stem. I turned my attention to address the damage to the stummel. I next decided to smooth the rim top surface dents/dings and the charred surface in 10 o’clock direction extending from inner to outer rim edge. I topped the rim top surface on a piece of 220 grit sand paper, checking frequently for the progress being made as I hate to loose briar estate any more than absolutely necessary. The darkened rim top extending from inner to outer edges can still be seen, though much greatly reduced. With a folded piece of a 220 grit sand paper pinched between my thumb and forefinger, I cleaned the bevel on the inner edge of the rim top surface to minimize the darkening. This helps to mask and address the minor dents and dings that had remained on the rim edges after topping. I am careful so as not to alter the profile of the stummel by excessive topping or creation of the bevels. I am pretty pleased with the appearance of the rim top and edges at this stage. The following pictures show the progress being made and improvements to the inner and outer rim edges.

I turned my attention to address the damage to the stummel. I next decided to smooth the rim top surface dents/dings and the charred surface in 10 o’clock direction extending from inner to outer rim edge. I topped the rim top surface on a piece of 220 grit sand paper, checking frequently for the progress being made as I hate to loose briar estate any more than absolutely necessary. The darkened rim top extending from inner to outer edges can still be seen, though much greatly reduced. With a folded piece of a 220 grit sand paper pinched between my thumb and forefinger, I cleaned the bevel on the inner edge of the rim top surface to minimize the darkening. This helps to mask and address the minor dents and dings that had remained on the rim edges after topping. I am careful so as not to alter the profile of the stummel by excessive topping or creation of the bevels. I am pretty pleased with the appearance of the rim top and edges at this stage. The following pictures show the progress being made and improvements to the inner and outer rim edges. I followed it by wet sanding the stummel with 1500 to 2000 wet & dry sand paper and further with 3200 to 12000 grit micromesh pads, wiping frequently with a moist cloth to check the progress. The minor outer rim damage was repaired to a very large extent and so was the darkening during this process. I really like the looks of the stummel at this point in restoration. The grain and the clean classic lines of this pipe are worthy of appreciation.

I followed it by wet sanding the stummel with 1500 to 2000 wet & dry sand paper and further with 3200 to 12000 grit micromesh pads, wiping frequently with a moist cloth to check the progress. The minor outer rim damage was repaired to a very large extent and so was the darkening during this process. I really like the looks of the stummel at this point in restoration. The grain and the clean classic lines of this pipe are worthy of appreciation.

At this point in the restoration, I remembered that I had to even out the lower edge of the bowl ring. I firstly cleaned the debris that was lodged in between the rings with a sharp knife after the sanding and polishing process. I folded a piece of 220 grit sand paper and inserting it into the grooves, evened out the edges.

At this point in the restoration, I remembered that I had to even out the lower edge of the bowl ring. I firstly cleaned the debris that was lodged in between the rings with a sharp knife after the sanding and polishing process. I folded a piece of 220 grit sand paper and inserting it into the grooves, evened out the edges. Next, I rubbed a small quantity of “Before and After Restoration Balm” deep in to the briar with my finger tips and let it rest for a few minutes. The balm almost immediately works it’s magic and the briar now has a nice vibrant appearance with the beautiful grain patterns displayed in their complete splendor. I further buffed it with a horse hair brush. The contrast of the dark browns of the Bird’s eye and cross grains with the natural patina of the rest of the stummel adds an interesting dimension to the appearance of the stummel which may be insufficiently described in words and be rather seen in person.

Next, I rubbed a small quantity of “Before and After Restoration Balm” deep in to the briar with my finger tips and let it rest for a few minutes. The balm almost immediately works it’s magic and the briar now has a nice vibrant appearance with the beautiful grain patterns displayed in their complete splendor. I further buffed it with a horse hair brush. The contrast of the dark browns of the Bird’s eye and cross grains with the natural patina of the rest of the stummel adds an interesting dimension to the appearance of the stummel which may be insufficiently described in words and be rather seen in person.

With the stummel rejuvenation almost complete, save for the final wax polish, I worked the stem. The fill had cured and with a flat head needle file, I worked on the filling till I had achieved a rough match with the surrounding surface and had sufficiently sharpened the button edges. To bring a deep shine to the stem, I went through the complete set of micromesh pads, wet sanding with 1500 to 2000 wet & dry sand paper and further with 3200 to 12000 grit micromesh pads. I wiped the stem with moist cloth after each pad and rubbed it down with Extra Virgin Olive oil to rejuvenate the vulcanite. I am pretty happy with the way the stem repairs have shaped up and also the buttons have a nice delicate shape to them. The finished stem is shown below.

With the stummel rejuvenation almost complete, save for the final wax polish, I worked the stem. The fill had cured and with a flat head needle file, I worked on the filling till I had achieved a rough match with the surrounding surface and had sufficiently sharpened the button edges. To bring a deep shine to the stem, I went through the complete set of micromesh pads, wet sanding with 1500 to 2000 wet & dry sand paper and further with 3200 to 12000 grit micromesh pads. I wiped the stem with moist cloth after each pad and rubbed it down with Extra Virgin Olive oil to rejuvenate the vulcanite. I am pretty happy with the way the stem repairs have shaped up and also the buttons have a nice delicate shape to them. The finished stem is shown below.  I used a white correction pen to highlight the stem logo. I smeared the correction ink over the logo and once dried, I gently wiped out the excess ink. The stem logo “H” is now prominently visible.

I used a white correction pen to highlight the stem logo. I smeared the correction ink over the logo and once dried, I gently wiped out the excess ink. The stem logo “H” is now prominently visible. I have now reached the homestretch in this restoration project. To complete the restoration, I mounted a cotton cloth buffing wheel onto my hand held rotary tool and polished the stummel and stem with Blue Diamond compound. This compound helps to remove the minor scratch marks that remain from the sanding. I mounted another cotton buffing wheel that I have earmarked for carnauba wax and applied several coats of the wax. I finished the restoration by giving the entire pipe a rigorous hand buffing using a microfiber cloth to raise the shine further. The finished pipe looks amazingly beautiful and is ready to join my collection of other Hardcastle’s pipes that I have inherited. I only wish it could share with me it’s story of the past years while I enjoy smoking my favorite Virginia blend in it or maybe an English blend or maybe just keep admiring it!! A big thank you to all the readers who have joined me on this path by reading this write up as I restored and completed this project.

I have now reached the homestretch in this restoration project. To complete the restoration, I mounted a cotton cloth buffing wheel onto my hand held rotary tool and polished the stummel and stem with Blue Diamond compound. This compound helps to remove the minor scratch marks that remain from the sanding. I mounted another cotton buffing wheel that I have earmarked for carnauba wax and applied several coats of the wax. I finished the restoration by giving the entire pipe a rigorous hand buffing using a microfiber cloth to raise the shine further. The finished pipe looks amazingly beautiful and is ready to join my collection of other Hardcastle’s pipes that I have inherited. I only wish it could share with me it’s story of the past years while I enjoy smoking my favorite Virginia blend in it or maybe an English blend or maybe just keep admiring it!! A big thank you to all the readers who have joined me on this path by reading this write up as I restored and completed this project.