Blog by Robert M. Boughton, P.I.

Copyright © Reborn Pipes and the Author except as cited

Copyright © Reborn Pipes and the Author except as cited

https://www.roadrunnerpipes2k.com/

https://www.facebook.com/roadrunnerpipes/

Member, North American Society of Pipe Collectors

O hell! what have we here?

A carrion Death, within whose empty eye

There is a written scroll! I’ll read the writing.

‘All that glisters is not gold;

Often have you heard that told:

Many a man his life hath sold

But my outside to behold:

Gilded tombs do worms enfold.

Had you been as wise as bold,

Young in limbs, in judgment old,

Your answer had not been inscroll’d:

Fare you well; your suit is cold –

Cold indeed, and labor lost.’

— Shakespeare, The Merchant of Venice, Act 2, Scene 7, 1596 (original editions)

INTRODUCTION

An English historian of pipes in general and Alfred Dunhill Ltd. of London in particular, the late John C. Loring, dated the beginning of estate pipe collecting to 1976. That was the year Dunhill acquired Lane Ltd., which included Charatan pipes. It also marked the first noticeable blip, on the pipe world radar, of avid collectors in the U.S. starting to seek older, used English pipes that were rarer and could be repaired for reborn enjoyment. The birth of estate pipe collecting, with its attendant lust for uncommon and valuable specimens, created a market that was susceptible to fraud on a new, sophisticated level.

Thus arrived on the scene the simultaneous phenomena of collectors who recognized the potential value of estate pipes and the intrepid craft folks who filled the need for independent, skilled workers, or pipe restorers, as they came to call themselves, to repair and clean all of the old pipes being snatched up in more and more amazing numbers. Of course there were also the scam artists and other opportunistic ne’er-do-wells, that ubiquitous element of every business enterprise, who found in the appetite for used but “collectible” pipes an abundance of buyers ignorant of the knowledge needed to distinguish the legitimate from the fakes.

Limited at first to pipes from England due to their perceived superiority to those from other countries, in time the used pipe craze spread to estates from around the world. The trend saw its heyday in the first decade, continuing into the mid second, of the new millennium.

Aristotle is often cited as the first person to expound the notion that nature abhors a vacuum, when in fact he was a plenist, or a believer that there can be no occurrence of a vacuum in nature. His basic reasoning was that space is filled with bodies, even if most of them are molecular, and therefore can have no empty area. The great Greek philosopher and polymath was so contemptuous of the idea of a natural vacuum that he made a deliberate joke, in Physics, Book IV, Part 8: “But even if we consider it on its own merits the so-called vacuum will be found to be really vacuous.” LOL! Modern physics recognizes that nature indeed cannot tolerate a vacuum – but only so far as to force whatever happens to be nearby any such anomaly to be sucked in to fill it the same instant. In that sense, old Aristotle was half right, considering that an empty space appearing in nature must be filled in less than a nanosecond. At any rate, pipe restorers, qualified or otherwise, as well as forgers, filled the new figurative vacuum made by the Great Estate Pipe Rush.

THE BIRTH OF ESTATE PIPES

The blooming of the estate pipe collecting hobby mushroomed into a full-blown industry that epitomized certain aspects of capitalism as contemplated in An Inquiry into the Nature and Causes of the Wealth of Nations, published 200 years earlier just two months before the Declaration of Independence. There was then and remains the principle of supply and demand with its buyers, sellers and middlemen. The prices were set only by the depths of the pockets of the buyers and their much shallower knowledge of what constituted a rare Dunhill.

Loring, whose research into the darkest hour of estate pipe history identified the birth of used pipe collecting, died October 7, 2009 in Chicago. In a memorial on PipesMagazine.com, Kevin Godbee wrote that Loring possessed “an encyclopedic knowledge of Dunhill Pipes and other tobacciana.” In “The 1980s Fake Dunhill,” first published in the Winter-Spring 2005 issue of The Pipe Smoker’s Ephemeris, Loring wrote of how, while Dunhill acquired Lane and Charatan:

“…on the other side of the Atlantic a strange new hobby was developing, ‘used briar pipe collecting,’ with Dunhill pipes the crown jewels of those pioneer American collections. Soon there were pipe shows, mail order lists, evenings on the telephone in ‘hot pursuit’ and even excursions to England to salvage previously smoked pipes from the dustbins. Hundreds, even thousands of dollars were paid for used, quickly renamed ‘Estate’ Dunhills with premium prices being paid for the largest and oldest.”

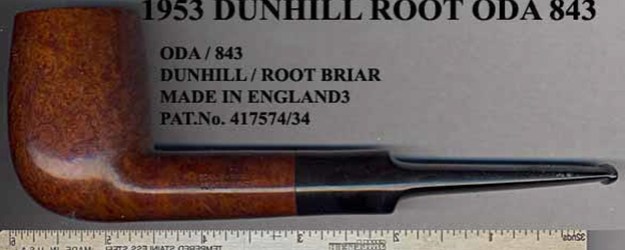

Note that Loring splits the popularity of estate pipes in two parts, large and old, but emphasizes the bigger ones by nature of the definite if understated order of the above reference, which lumps both together as rare. Even if Loring were not a good enough writer for the placement of his modifiers to be significant, he goes on to explain the special nature of “oversized” pipes. “Magnums were viewed as ‘one of a kind’ rarities that could be counted on one hand, maybe two at best,” Loring wrote. The ODA shown here from Loring’s personal collection that sold at auction after his death, with its exquisite bird’s-eye, is a fine example of a magnum.

THE RISE OF COUNTERFEITS

With the Lane-Charatan takeover, some of the pipe makers from the two manufacturers consumed by Dunhill lost their jobs. During the early 1980s, as the factories of the three companies were consolidated into one, many more layoffs were made. The market for estate Dunhills in the U.S. continued to escalate. A few unemployed and bitter pipe makers in England, able and willing to abscond with tools of all kinds – including those used for shaping, finishing and stamping nomenclature on the completed products, as well as stummels abandoned for flaws or left unfinished and even raw briar blocks – did so.

“And at work’s-end,” Loring wrote, “employed and unemployed still met at the pub to dwell on the injustice of it all.” These conditions – angry, jobless pipe carvers on one side of the Atlantic and wealthy collectors on the other – created what Loring called “our own perfect storm.”

Dunhills have never been easy to date much less make it through the rest of the Byzantine nomenclature. Even Loring admits the task can be impossible for anyone, no matter how knowledgeable of Dunhill markings. Then there’s the fact that back in the day, meaning the 1980s, early Dunhill catalogs were not as available as they later became, which was never on par with Sears or LL Bean. And of course, the World Wide Web was not up and running until the following decade, although the ARPA net allowed computers to connect to each other with a virtual “handshake” and transmit batches of data using Transmission Control Protocol/Internet Protocol (TCP/IP) machine language. In other words, identifying a fake pipe, in particular one made by a disgruntled former Dunhill carver using real Dunhill wood and tools but changing or fabricating certain nomenclature to make them appear almost priceless, was beyond the means of most serious collectors of the day.

As it happened, one of those very leading collectors, an American whose name is remembered by some old-timers of our society who refuse to utter or record it in print, highlighted the top British pipe show of 1984 with his collection of 30 stunning examples. Loring recorded that they included “four near magnum sized Shells bearing extremely rare or previously unknown shape numbers; three smooth finished “LC” shapes, two Roots and a Bruyere, one bearing a previously unknown shape number; three extremely rare un-smoked ODAs , a Bruyere and a Shell 844 and an 824 Shell; a number of sought after ODA shapes in a variety of finishes, many unsmoked; and two awesome supposedly pre-WWII Canadians both upwards of 9 inches long with 5¾ inch shanks, a Bruyere with a small, 1¾ inch tall bowl and a Shell with a magnum sized, 2¾ inch tall bowl.”

To cut to the chase, most of these pipes, if not all of them, were bogus in that they were not made by Dunhill but rather were tweaked as far as the nomenclature was concerned or cobbled together using spare parts, as it were, however skillful or “authentic” the cobbling.

The suspicions of some collectors were piqued by the too good to be true aspects of the fabulous forgeries. Consider Loring’s repeated references to “extremely rare or previously unknown shape numbers” and “unsmoked” pipes. Had avarice not gotten the better of the collectors who fell victim to the scam, “Thousands upon thousands of dollars and pipes” would not have been exchanged during the infamous incident that took place over a period of only two or three days.

It is important to remember about the 1980s fake Dunhills that of the 50-75 total pipes involved in the overall debacle on both sides of the Pond in which, by Loring’s estimation, perhaps hundreds of thousands of dollars were paid for technically bogus pipes, “in almost all cases,” they were excellent in terms of craftsmanship and were “akin to top quality 1980s English Dunhill alternatives such as Ashton or Upshall.” The photo below from Loring’s collection shows two supposed World War II-era pipes, both magnums about eight inches long and each a beautiful Dunhill pipe – if only each had been manufactured in the Dunhill factory and not stamped with outrageous nomenclature. The shape codes HB and HP have come to be known as existing only on fakes.

“In short,” Loring cautions with classic, subdued British humor and style, “if on the way to writing a two thousand dollar check you find that the shape stamped on the pipe you are fondling doesn’t comport to catalog examples or is otherwise unknown, stay your pen for further examination.”

“In short,” Loring cautions with classic, subdued British humor and style, “if on the way to writing a two thousand dollar check you find that the shape stamped on the pipe you are fondling doesn’t comport to catalog examples or is otherwise unknown, stay your pen for further examination.”

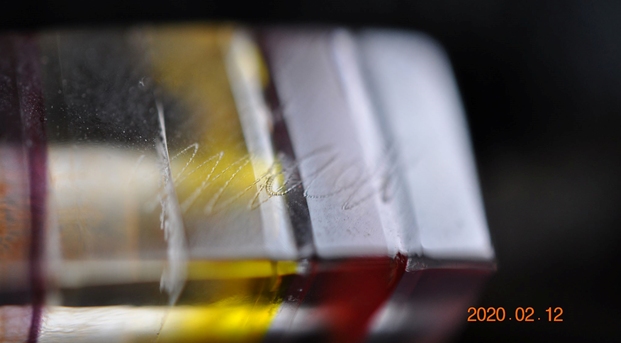

Another way to identify pipe forgeries is the nomenclature, no matter how subtle the discrepancy may seem. Loring’s most basic rules of thumb in spotting a fake are to be discerning of every detail and to trust your instincts. The following examples are brilliant. The problem with the two pipes in the one photo is harder to spot, and I took the liberty of editing the very bluish original from the web page so that it appears closer to natural pipe brown. The issue in this picture is not the HLP on the top and the HB on the bottom (well, those are no-nos, to be sure), but the uneven stamp marks, as the un-removable type suggests. Otherwise the two lines of markings are perfect for WWII-era pipes and indicate that the stamp used may have been “lifted” from Dunhill. The egregious error in the other pic should be apparent to anyone who is at all familiar with Dunhill. Take a look and see if you can spot the sign of serious trouble that should set off bells and whistles in the shot of the lone stamp. All done? Everything considered, the only glaring annoyance is the word SHELL on a smooth finish pipe. Loring identified three examples including the one above that appear to have been marked with a real Dunhill pre-1937 stamp “in the hands of an illiterate.” ROFL.

All done? Everything considered, the only glaring annoyance is the word SHELL on a smooth finish pipe. Loring identified three examples including the one above that appear to have been marked with a real Dunhill pre-1937 stamp “in the hands of an illiterate.” ROFL.

The absence of the World Wide Web at the time of the 1980s Dunhill fiasco explains in some small part how experts were misled by imitations. So how has the Web made things worse for everyone else in the intervening 30-plus years?

THE SPINNING OF A WEB OF FRAUD

I will begin this section with the bottom line: Internet fraud, intentional or otherwise – and whether or not it will ever become a crime that can be prosecuted in a viable, systemic manner, much less eradicated – is here to stay for the foreseeable future. The solution, therefore, would seem to fall in educating consumers as to the dangers that exist on a very real and frequent basis.

By way of an example of fake pipes that can be found on the internet, the cautionary tale of an alleged Dunhill “Bijou” 401 pot, Patent Number 417574/34, will illustrate how the Dunhill scandal still haunts us and also provide a smooth transition into the modern phase of pipe forgeries. I came across this one, offered on consignment for just under $1,000, on a very respected and reputable online site a while back. The seller alleged the pipe dated to the 1920s or ’30s, as I recall. I’m sure if the gentleman reads this he won’t mind that I omitted his credit for the following photos. From a distance, even without the White Spot that appears to be on the top of the stem in closer shots, the pipe looks OK, at least.

But something struck me as – well – just plain off with the first look, and in particular the name, Bijou, which rang a bell, although not yet any whistles. I had to save the pics provided to my computer to view them in large enough format for air raid sirens to go off. Everything was wrong with this so-called little jewel, from downright cheesy and double stamping to the runny stain job and, as Loring warned, an off-round, somewhat fuzzy White Spot.

But something struck me as – well – just plain off with the first look, and in particular the name, Bijou, which rang a bell, although not yet any whistles. I had to save the pics provided to my computer to view them in large enough format for air raid sirens to go off. Everything was wrong with this so-called little jewel, from downright cheesy and double stamping to the runny stain job and, as Loring warned, an off-round, somewhat fuzzy White Spot. Furthermore, although in some rare instances the given patent number could have traced as far back as the 1920s, without a DUNHILL over LONDON stamp, the raised 4 after ENGLAND signifies the pipe would have been made in 1964, had Dunhill been involved at all in the manufacture of this knockoff. (See Pipephil in Sources below.)

Furthermore, although in some rare instances the given patent number could have traced as far back as the 1920s, without a DUNHILL over LONDON stamp, the raised 4 after ENGLAND signifies the pipe would have been made in 1964, had Dunhill been involved at all in the manufacture of this knockoff. (See Pipephil in Sources below.)

At last I remembered where I had heard of Bijou in relation to Dunhill. It was Alfred Dunhill’s invention of the first handheld thumb-flick lighter in the late 1920s, which he called the Bijou. I could find no strong evidence of any Dunhill Bijou pipe ever being made. The letters GT in the photo below are the original owner’s monogram.

I emailed my concerns to the address listed for the site and to my surprise heard back immediately from the owner that he was looking into the matter. Within 24 hours, experts confirmed that Dunhill never made a Bijou line, and the pipe indeed was a forgery. It was removed from the website, and the pipe’s owner was notified of its true nature.The owner of the Bijou provided ample photos of the pipe for its proper identification, and there is no reason to suspect he intended to pass it off as a genuine Dunhill with any disingenuousness. Here is another, lighter, shinier version of the same pipe, this one called a Dunhill 401 Root Briar Patent Number 417574/34 pot, found on eBay, with only the one picture and nothing but a distant angle on the White Spot to assume its authenticity. This and the Bijou are the only 401 shapes I can find. Now, indulge me with a final Dunhill photo showing two pipes. Both are supposed to be very rare #848 ODA magnums, but only one is the real thing. The other appears to date back to the 1980s scandal, demonstrating how that scourge is not yet behind us. Can you tell which is which? Dunhill experts will have no trouble, but if you found the fake on eBay as the knowing buyer in this case did, would you? The answer is here,* but I recommend the first Youtube video in the Sources for the full story.

Now, indulge me with a final Dunhill photo showing two pipes. Both are supposed to be very rare #848 ODA magnums, but only one is the real thing. The other appears to date back to the 1980s scandal, demonstrating how that scourge is not yet behind us. Can you tell which is which? Dunhill experts will have no trouble, but if you found the fake on eBay as the knowing buyer in this case did, would you? The answer is here,* but I recommend the first Youtube video in the Sources for the full story.

Courtesy Pipehub, YoutubeBen Rapaport, a respected U.S. antiquities historian and columnist, wrote a comprehensive article about the history of pipe counterfeiting, called “The Age of Steal,” for Pipes and Tobaccos Magazine online. Rapaport prefaced his detailed reporting of fraudulent activities in the pipe world with a note that they may not be “classified as theft in the literal sense [but] are, in my opinion, theft in the figurative sense.”

With the beginning of eBay’s real success as an online auction site in the mid-1990s, Rapaport claimed, “there suddenly appeared a pixel-and-byte tsunami, or maybe a torrent, of instant tobacco treasures for sale.”

The fraudulent cyber pipe business is now out of control, running the gamut from established old name brands, antique or otherwise, to contemporary makers and even artisan carvers. The vast majority of pipes I’ve bought on eBay over the years have been more or less just what they were represented to be, with only two exceptions, one of which was supposed to be a KB&B Rocky Briar salesman sample. Salesman samples were miniature, scale versions of regular sized pipes carried by – you guessed it, salesmen – in the early 20th century to show prospective buyers an idea of what they would get. By nature of the time period in which they were used, salesman samples are now antiques or near the mark. When I opened the package that arrived in the mail and removed the pipe, even taking into consideration its tininess, I found a corruption of pipe making that seemed to be crafted of balsa. Examining the little monstrosity, I was at once alarmed by its color, which I call Chinese red, and the tacky (as in sticky and uneven) looking coat of stain, or whatever was used to cover the cheap, ultra-light wood I later concluded was something along the lines of paulawney. A closer look revealed just plain sloppy nomenclature, regardless of age, in particular an uneven Reg. US Pat. No. 298978. Since there were two each of the numbers 8 and 9, I examined them, and they didn’t match, as shown in the following photo which is compared to one of Steve Laug’s that shows a real, crisp Rocky Briar imprint.

Examining the little monstrosity, I was at once alarmed by its color, which I call Chinese red, and the tacky (as in sticky and uneven) looking coat of stain, or whatever was used to cover the cheap, ultra-light wood I later concluded was something along the lines of paulawney. A closer look revealed just plain sloppy nomenclature, regardless of age, in particular an uneven Reg. US Pat. No. 298978. Since there were two each of the numbers 8 and 9, I examined them, and they didn’t match, as shown in the following photo which is compared to one of Steve Laug’s that shows a real, crisp Rocky Briar imprint. As if there were any doubt as to the pipe’s fraudulence, it lacks the shape number on the right side of the shank.

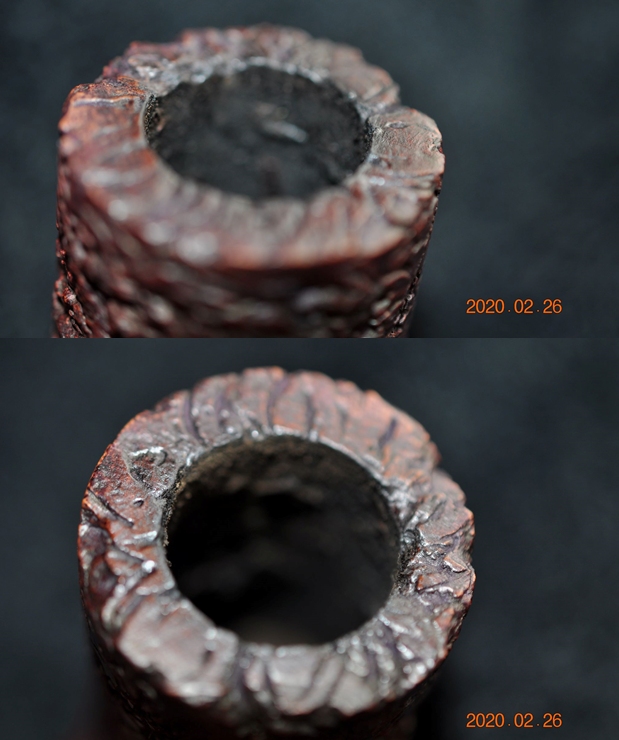

As if there were any doubt as to the pipe’s fraudulence, it lacks the shape number on the right side of the shank. The other fake pipe was a CPF Globe Mount, a recent eBay purchase. The wood is also very light and soft, but more substantial than the KB&B Rocky Briar. Based on the light color of the shank opening and scratches, and the reddish tinge of the sanded chamber, I suspect it’s Chinese red cedar. The stem, an obvious mismatch, is plastic.

The other fake pipe was a CPF Globe Mount, a recent eBay purchase. The wood is also very light and soft, but more substantial than the KB&B Rocky Briar. Based on the light color of the shank opening and scratches, and the reddish tinge of the sanded chamber, I suspect it’s Chinese red cedar. The stem, an obvious mismatch, is plastic.

Each of these pipes cost the same or less than return postage would be, and so I kept them. But it’s important to be sure that returns of online estate pipe purchases are guaranteed by the seller, especially if it’s a substantial investment. Both of the above pipes were so protected, if I wanted to punish the sellers at my expense!

Each of these pipes cost the same or less than return postage would be, and so I kept them. But it’s important to be sure that returns of online estate pipe purchases are guaranteed by the seller, especially if it’s a substantial investment. Both of the above pipes were so protected, if I wanted to punish the sellers at my expense!

Capitello was founded in Italy by Enzo Galluzzo, the former official carver for Caminetto who had worked at Castello and Ascorti. Although the business lasted only from c. 1982-1991, Galluzzo produced some of the most astounding, creative pipes in a short but brilliant run. I have an interesting story about some shameful Capitello counterfeits I discovered on eBay and did my best to have removed. To understand why the fakes were so preposterous, it is important to see a few real Capitello pipes. Following are, in order, a wax drip Gotico from Pipephil, a rustic Gotico courtesy of a reputable eBay seller, an Airecchio from Haddock’s Pipes and a Jonico from my own collection.

Now, have a gander at the best of the counterfeits.

Now, have a gander at the best of the counterfeits. The very small, bland billiard is supposed to be new and unsmoked, a rarity, but note the absence of the genuine stem mark, and the use of all caps in the name Capitello, among other problems that a simple check of Pipephil would illuminate for anyone not familiar with the brand.

The very small, bland billiard is supposed to be new and unsmoked, a rarity, but note the absence of the genuine stem mark, and the use of all caps in the name Capitello, among other problems that a simple check of Pipephil would illuminate for anyone not familiar with the brand. There are more, hideous black “dress” style pipes that Capitello never made, with the same ridiculous nomenclature, but here is the worst offender, something that doesn’t even pretend to have Capitello nomenclature. Capitello also never used metal bands, even good ones.

There are more, hideous black “dress” style pipes that Capitello never made, with the same ridiculous nomenclature, but here is the worst offender, something that doesn’t even pretend to have Capitello nomenclature. Capitello also never used metal bands, even good ones. In light of the brazen fraud, I gave the seller, who was registered in the UK, a friendly chance to retract the offers. When he replied with a rude note, a friend and I reported him to eBay, and I went so far as to file an online criminal complaint with Scotland Yard. I never heard how that turned out, but I hope they at least rattled his cage. I learned that the seller has a terrible reputation and is named in the second Youtube video in my Sources. I recommend it as an excellent guide to spotting big name forgeries.

In light of the brazen fraud, I gave the seller, who was registered in the UK, a friendly chance to retract the offers. When he replied with a rude note, a friend and I reported him to eBay, and I went so far as to file an online criminal complaint with Scotland Yard. I never heard how that turned out, but I hope they at least rattled his cage. I learned that the seller has a terrible reputation and is named in the second Youtube video in my Sources. I recommend it as an excellent guide to spotting big name forgeries.

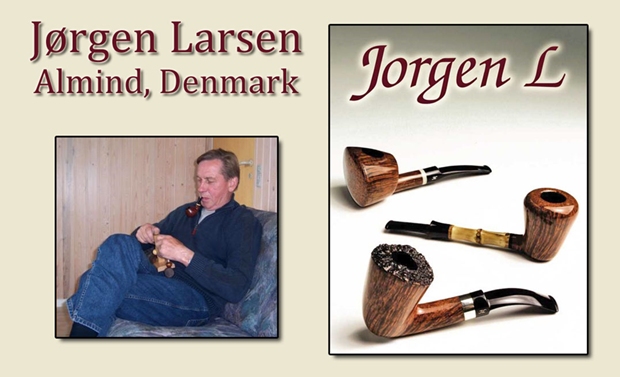

To end this section, I’ll show a couple of fake artisan pipes, both by Tom Eltang, the respected Danish carver. I don’t have more than one photo each of the pipes or details of what is wrong with them, but they demonstrate how careful we need to be when buying anything online. * The top, chestnut-colored pipe is the fake. Real Dunhill ODA pipes had lighter Root or Bruyere finishes.

* The top, chestnut-colored pipe is the fake. Real Dunhill ODA pipes had lighter Root or Bruyere finishes.

CONCLUSION

To be sure, the great majority of online sellers, eBay or elsewhere, are not frauds. The biggest abuse now is the outrageous over-pricing, mostly for Medicos and Dr. Grabows, which sellers seem to regard as the Holy Grail. I remember the good old days when I had multiple lots of nine-12 pipes coming in the mail all the time, and all of them had good pipes as well as some little treasures in them. While it was only natural that sellers would catch on, they seem to have over-reacted to the point where they are now paying their sources so much for garbage, more or less, that they are willing to go without selling their pipes at all unless they recoup their investments that were idiotic in the first place. Not being collectors or restorers themselves, for the most part, they don’t understand what goes into repairing and sanitizing pipes for a business and being able to make a living, or even a reasonable extra income.

This blog is supposed to be more about the dangers of buying fake high-end pipes that are expensive as opposed to some lower-priced examples I showed by way of illustrating how far forgers will go to defraud collectors for a buck, so to speak. The big names in pipe forgeries, other than Dunhill, include Radice, Sasieni, Peterson, Comoy’s and on and on. Check out the second Youtube video in the Sources for an excellent guide on that subject. For purposes of a summary, I’ve made some notes on how to avoid the snares these scoundrels will set.

- Don’t be an easy mark. Take advantage of the wealth of information available online and at your local tobacconist!

- Watch out for rare/unsmoked Not many collectors buy pipes to put them on the shelf and not enjoy them.

- Scrutinize the nomenclature, and compare it to online sites like Pipephil.com. This means everything about the stampings on the pipe: the positioning, size, crispness and shape number.

- Look at the finish. Is it the same style and color as examples of the real thing you find elsewhere online, e.g., smooth/rustic and light or dark brown? Is the stain even and not tacky or runny?

- Be sure the seller has an excellent history of top feedback.

- Be sure there are plenty of pictures showing every angle and all of the nomenclature clearly. Don’t be afraid to ask the seller for more if you need them, and if he doesn’t provide them, don’t bid on the pipe!

- Be absolutely sure returns are accepted.

- Are there many bidders already? If not, why?

- TRUST YOUR INSTINCTS! IF THE DEAL SEEMS TOO GOOD TO BE TRUE, IT PROBABLY IS!

Concerning newer estate pipes that are still in production and not rare, always check at sites such as Smokingpipes.com to see if you can find one that’s identical or similar but brand-new for the same price or less.

There is much resistance in the pipe world to the idea of counterfeits. I believe I have presented, in this relatively outline form, enough evidence to dispel the notion that they don’t exist. Books could be written on the subject.

In recent years, I have noticed a marked decrease in estate pipe sales by those who buy and restore them for resale, not just my own but those of friends. The unfortunate fact is that the few crooks – or in some cases simple fools – who take advantage of buyers’ ignorance give the estate pipe business a bad name. In most cases, great deals for used pipes that are hard to come by and have been restored to excellent condition – and sanitized for immediate use – can be found, if you only look for them.

SOURCES

http://loringpage.com/pipearticles/80s%20Fakes.htm

http://classics.mit.edu/Aristotle/physics.4.iv.html

https://pipesmagazine.com/blog/pipe-news/john-c-loring-legend-in-the-pipe-collecting-world-dies/

https://pipedia.org/wiki/John_C._Loring

https://pipedia.org/wiki/Loring%27s_Dunhill_Collection

http://www.pipephil.eu/logos/en/dunhill/cledat-en1a.html

https://www.youtube.com/watch?v=-M0-DlI6D3o

https://www.youtube.com/watch?v=0JNnjSS4x64

https://rebornpipes.com/2017/09/26/the-brief-shining-history-behind-an-italian-dublin-and-its-easier-than-usual-refurbish/

https://pipesandtobaccosmagazine.com/2011/06/the-age-of-steal/

https://www.archaeologicalconservancy.org/wpfb-file/8-3fall04singleslr-pdf/

Free PDF download available