Blog by Fred Bass

The following was an article that Fred Bass sent me to hold in my files for him. The idea was that he was going to use it some time in the near future for a book he was working on Meerschaum pipes. Sadly that book was not completed to my understanding. It is an interesting short article that also became the base of a discussion on Smoker’s Forum All thing meerschaum group. RIP Fred, you are missed. Give the article a read!

February 1, 2009

This is about general considerations that have served me in decisions about purchases. It’s not an exhaustive guide, but more a line of thought brought by Buyer’s experience in the Meerschaum trades. I buy Pipes to smoke, so I don’t buy antiques.

I’ll start with new Turkish Block Pipes. Going from the starting point of looking at the works of favored Carvers, I’ll look at Pipes until one calls me. The best Carvers use the best block, which is the most important point of judging a Pipe’s quality. High grade Turkish Meerschaum is light in weight, is very porous, has no inclusions or deficits and has a pearl like translucent quality. It does not look like chalk. High grade Block will provide a cool and dry smoke, in addition to coloring well. Lesser grades will produce smoking experiences of less quality…, which is not to say that this is bad since a cheapie Meer will provide a better smoke than many other materials.

You are more likely to encounter Pressed Meerschaum (a composite of Meerschaum chips & epoxy) with No Name Meers and products of disreputable Carvers & Name Brands. High Grade Carver specific Pipes cost more, but you will have a Pipe that the Carver will take care of, should anything go wrong. This is an important consideration since Meerschaum is a product of nature and can possess flaws that become noticed only after the Pipe is smoked. These are Pipes that mean less to the Carver than the importance of his reputation, so you get a Pipe that is the best the Carver can produce. Bad news travels fast and reputation is everything in this cottage industry.

Other considerations, such as size, artistic merit and how well the Pipe fits into your world are worth consideration. The established Carvers will want premium price for their work, but there is never a question of quality. It’s a good idea to confirm that the picture you see is that of the Pipe that you want and whether a Case exists or is yet to be made. If the Pipe & Case are yet to be made, then determine how long it will take to be shipped to you. These same issues are best understood by both Buyer & Seller on commissioned Pipes as well. You can establish the quality of the Block and the color & material of the bit prior to payment.

When I’m evaluating a Pipe from an upcoming Carver, an estate Pipe or from a Retailer that I’ve not dealt with before, I first try to establish dialogue. No dialogue, no deal. If the estate Pipe Seller has little knowledge about his/her Pipe, I’ll still try and get information on the Pipe’s condition, type of connector joint and dimensions. The estate Seller should discuss the Pipe in the pre-sale encounter or I don’t bid. Sometimes, I discover that the Seller doesn’t know that the Pipe is a fraud, which is frequently the case with ‘Andreas Bauer’ and ‘Paul Fischer’ Pipes, in my experience. If you watch the Meerschaum markets, you will find promising Carvers who have yet to become well known. These Carvers will discuss their art with you and the prices can be very reasonable, as many will have just severed ties with Retailers and have started selling direct to Buyers. If there is something that you don’t see, then ask questions. Since I buy Meerschaums from the internet,

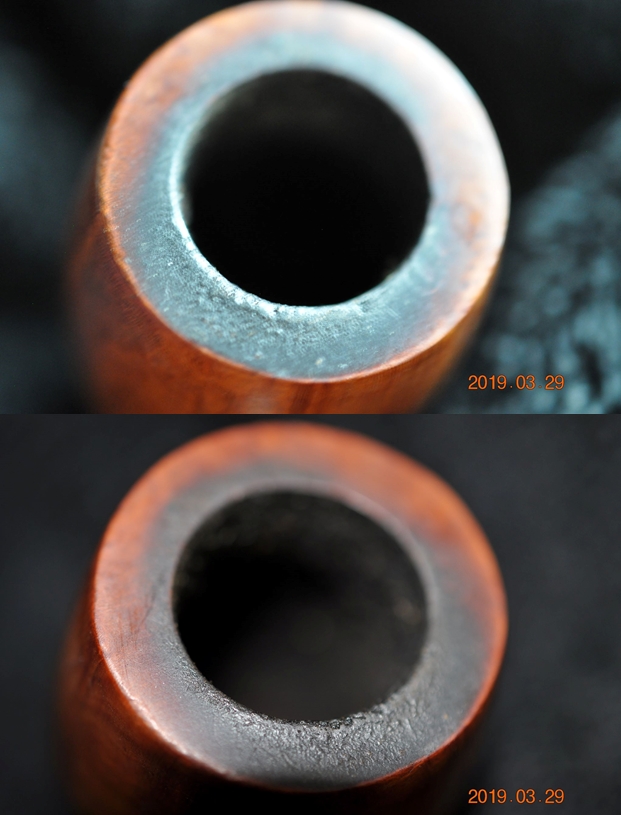

I ask a lot of questions. If the photos are poor quality and/or the Seller’s not answering your questions, then don’t put the coin down. I’ve touched on some of the major considerations involved in my own experiences, which are not offered as expert information. Instead, I’ve started this dialogue for all to share and participate in. I know little about the Antique market and just a bit about the African Block Pipes.

Another aspect of purchasing new Meerschaum Pipes, where some real bargains can be found, is the upcoming source of new Carvers. These are artisans that have been selling to Retailers and have established a degree of excellence, that promises to continue improving with time. At some point, they decide to break out on their own and start selling direct. They are trying to create a name for themselves and will use top quality Block as they attempt to establish a reputation with their art. The Pipes that are posted for sale will be the best effort that the Carver can produce and the prices will be lower, as there is no middleman to pay. Customer satisfaction will be the primary concern for these Carvers as they attempt to increase their market. This is a good time to get in on the action, since in time, as their work becomes more widely acknowledged for it’s superior quality, the prices will increase. This market is apparent to those who follow the Meerschaum trades. For the inexperienced, it is best to seek direction from more seasoned Pipesters and those that have access to the current markets. If you know what to look for, you can find some outstanding quality Pipes that appeal to your individual tastes, at very reasonable prices.

The Estate Meerschaum market is related to this in many ways, but there are differences. The first consideration that should be taken into account is the Pipe’s condition, and how much $$ it will cost to bring it into a smokable condition. This is not about Antiques, as they are more for Collectors than they are for those who buy Pipes to smoke. You should consider the cost of repair as the hidden total cost of the Pipe. If repairs have already been done on the Pipe, are they professional quality (?) and are they effective (?) are questions you should find out prior to purchase. Does the Seller know the Pipe’s legacy. Is the Pipe indeed what the brand designation on the case claims it to be, or is it a mediocre Pipe that has been put in a case of known reputation, in order to sell it for a higher price? If your plan is to continue to develop the Pipe’s Patina, does it look like the Pipe has been taken care of or did Uncle Charley use a blow torch to light it? Abused Meerschaums can be brought back to part of their former glory, but this takes time and the Patina is the most difficult to preserve and/or restore.

These are the basics, but by no means are they the whole story of either the Estate market or the newly initiated Carver direct seller. It is a good start on these issues and leaves room for the contributions of others, which is welcome.