Blog by Dal Stanton

I think the reason this Kaywoodie stood out to Jen as she was rummaging through my baskets and boxes of ‘Help Me!’ pipes, was the ‘fancy stem’ and the strong, full look of the stummel. The grain is impressive and it will clean up nicely. Jen is leaving Bulgaria soon after working with us for a few years. She’s taking a trove of pipes back to the US to give to the men in her family. For her too, is the fact that each pipe she purchases will benefit our work with the Daughters of Bulgaria – helping women and girls who have been trafficked in Europe and sexually exploited. This is the second Kaywoodie she has chosen. The first was a beautiful Kaywoodie Author (See: LINK) that needed extensive rim repair. The Kaywoodie now on the work table got my attention too, on the eBay auction block from a seller in North Carolina. After Jenny rescued it from the basket, I take some pictures of the Kaywoodie she chose.

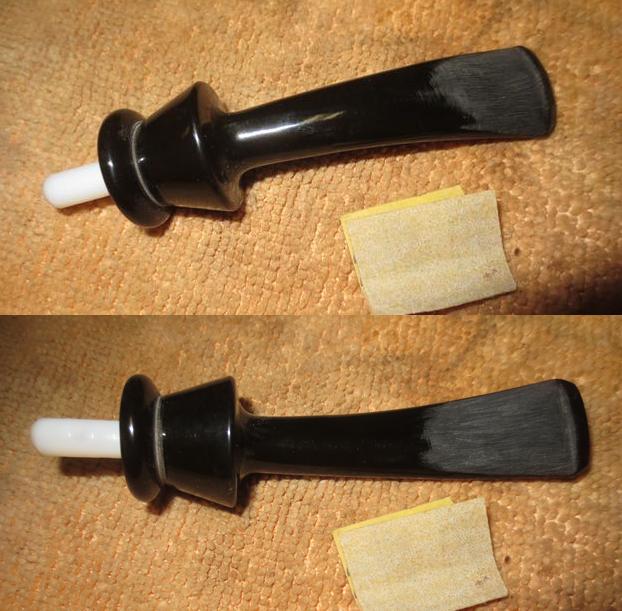

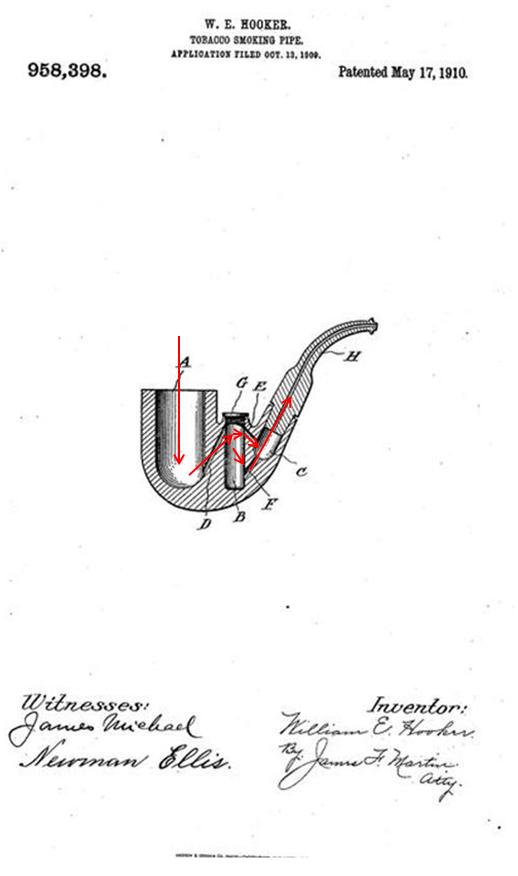

Generally, the pipe is in pretty good shape other than normal time wear and tear issues, but the stem bit might need some work. The rim and fire chamber are both in good shape, but in need of cleaning and the removal the light carbon cake to bring it to fresh briar for a new start. In the picture immediately above shows two fills – one filled and one emptied. The hole looks like a drill hole and I first suspected it was part of a cracked shank repair, but no cracks are evident. Only these two fills on the stummel will need to be refilled and I’ll see if the other needs to be replaced. The ‘Fancy Stem’ (I spent time trying to find a name for this type of stem and this is what I came up with via Steve’s assistance!) has serious tooth dents on the upper button lip and a significant dent and chatter on the lower bit. I also detected that the classic Kaywoodie Synchro-Stem threaded tenon is underclocked a bit – which over time, I discovered, is a normal happening with metal threaded tenons (See from Reborn Pipes: About Stem/Bit Shapes).

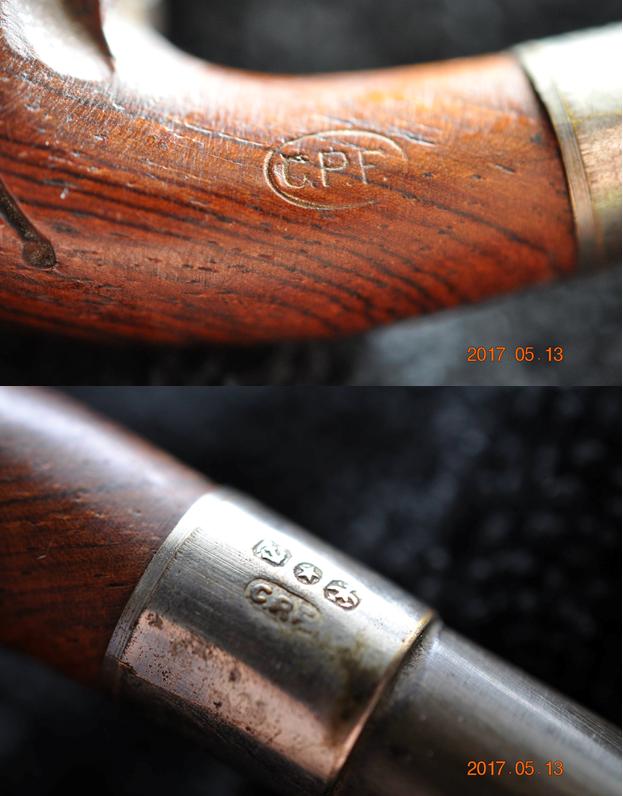

Generally, the pipe is in pretty good shape other than normal time wear and tear issues, but the stem bit might need some work. The rim and fire chamber are both in good shape, but in need of cleaning and the removal the light carbon cake to bring it to fresh briar for a new start. In the picture immediately above shows two fills – one filled and one emptied. The hole looks like a drill hole and I first suspected it was part of a cracked shank repair, but no cracks are evident. Only these two fills on the stummel will need to be refilled and I’ll see if the other needs to be replaced. The ‘Fancy Stem’ (I spent time trying to find a name for this type of stem and this is what I came up with via Steve’s assistance!) has serious tooth dents on the upper button lip and a significant dent and chatter on the lower bit. I also detected that the classic Kaywoodie Synchro-Stem threaded tenon is underclocked a bit – which over time, I discovered, is a normal happening with metal threaded tenons (See from Reborn Pipes: About Stem/Bit Shapes). The nomenclature on the sides of the shank are in bad shape – almost warn off and beyond history’s grasp. I had to take several looks at the stamping with a magnifying glass at different angles of light – lamp light and sunlight outside on my ‘Man Cave’ balcony on the 10th floor of our former Communist Blok apartment building. What I can decipher with much effort, is a phantom “Kaywoodie” [over] “***in” offset to the far right of the Kaywoodie stamping above it (under the ‘-die’). On the shank’s right side, I make a guess at ‘11’ which is a shape number. These two pictures try to show what I can barely see! I mark with yellow pen where the ‘K’ starts of Kaywoodie and I underline the ‘***in’ and the 11 in the second picture.

The nomenclature on the sides of the shank are in bad shape – almost warn off and beyond history’s grasp. I had to take several looks at the stamping with a magnifying glass at different angles of light – lamp light and sunlight outside on my ‘Man Cave’ balcony on the 10th floor of our former Communist Blok apartment building. What I can decipher with much effort, is a phantom “Kaywoodie” [over] “***in” offset to the far right of the Kaywoodie stamping above it (under the ‘-die’). On the shank’s right side, I make a guess at ‘11’ which is a shape number. These two pictures try to show what I can barely see! I mark with yellow pen where the ‘K’ starts of Kaywoodie and I underline the ‘***in’ and the 11 in the second picture. With a passion to understand as much as I can about the provenance of the pipes I restore, I know that I’m on a steep learning curve with this only being my second Kaywoodie. I’ve benefited much from Troy’s expertise, of Baccy Pipes, with Kaywoodie pipes and his help on this Kaywoodie. I’ve picked up some of the markers that help establish a Kaywoodie’s identity. The first thing to look at is, what is the “***in” refer to? Identifying the Kaywoodie line, at least partially, can help place a pipe. It did not take long as I search Pipedia for a listing of the names of the Kaywoodie lines (see LINK). What I found is that throughout the years, Kaywoodie has put forward several lines with the word “Grain” making sense of my mystery “***in”: Straight Grain, Super Grain, Flame Grain, Bird’s Eye Grain, Relief Grain, and Custom Grain – were the Kaywoodie lines that I cataloged from Pipedia. My next step was to go to the Kaywoodie section of Pipe Phil’s inventory of examples and to see if I could find an example of what appears to be the same script style for the ‘Kaywoodie’ [over] ‘*** Grain’ in cursive, simply to visualize. The only example I found of the same script for both ‘Kaywoodie’ and ‘Grain’ was this Flame Grain, Meerschaum from the 1947 catalogue that Kaywoodie produced. A close look of the script follows in picture two. I think this is a pretty good visual match of the nomenclature style.

With a passion to understand as much as I can about the provenance of the pipes I restore, I know that I’m on a steep learning curve with this only being my second Kaywoodie. I’ve benefited much from Troy’s expertise, of Baccy Pipes, with Kaywoodie pipes and his help on this Kaywoodie. I’ve picked up some of the markers that help establish a Kaywoodie’s identity. The first thing to look at is, what is the “***in” refer to? Identifying the Kaywoodie line, at least partially, can help place a pipe. It did not take long as I search Pipedia for a listing of the names of the Kaywoodie lines (see LINK). What I found is that throughout the years, Kaywoodie has put forward several lines with the word “Grain” making sense of my mystery “***in”: Straight Grain, Super Grain, Flame Grain, Bird’s Eye Grain, Relief Grain, and Custom Grain – were the Kaywoodie lines that I cataloged from Pipedia. My next step was to go to the Kaywoodie section of Pipe Phil’s inventory of examples and to see if I could find an example of what appears to be the same script style for the ‘Kaywoodie’ [over] ‘*** Grain’ in cursive, simply to visualize. The only example I found of the same script for both ‘Kaywoodie’ and ‘Grain’ was this Flame Grain, Meerschaum from the 1947 catalogue that Kaywoodie produced. A close look of the script follows in picture two. I think this is a pretty good visual match of the nomenclature style. So, I think it’s safe to say that the Kaywoodie before me was a line suffixed by ‘Grain’. I don’t know how rare or common the use of the cursive script was with Kaywoodie ‘Grain’ lines, but it could possibly help in identification if one knew. Another concrete marker I identified was the shape number, ‘11’ which is identified as a ‘Large Billiard’ in the Pipedia Kaywoodie Shapes Guide. This description seems to be right on with the Kaywoodie before me – a handful of wonderful Billiard briar! The other marker that I was aware of was the iconic Kaywoodie stem shamrock or club. From PipePhil.eu, I found this concise description that indicates that the black shamrock in the white dot started to emerge on pipes since 1937:

So, I think it’s safe to say that the Kaywoodie before me was a line suffixed by ‘Grain’. I don’t know how rare or common the use of the cursive script was with Kaywoodie ‘Grain’ lines, but it could possibly help in identification if one knew. Another concrete marker I identified was the shape number, ‘11’ which is identified as a ‘Large Billiard’ in the Pipedia Kaywoodie Shapes Guide. This description seems to be right on with the Kaywoodie before me – a handful of wonderful Billiard briar! The other marker that I was aware of was the iconic Kaywoodie stem shamrock or club. From PipePhil.eu, I found this concise description that indicates that the black shamrock in the white dot started to emerge on pipes since 1937:

The cloverleaf logo: the round logo (black cloverleaf in white circle or white cloverleaf in black circle) was first used in 1937. Up until the late 40’s this logo was used on all of the upper grades pipes. The concomitant use of the plain white cloverleaf and the disk inlaid logo continued until the early 80’s.

Up until the late 1940’s/early 50’s, the logo was on top of the stem. After that the logo was moved to the side of the stem (exceptions exist).

The other solid marker that I investigated was the No. ‘11’ shape number. In Pipedia’s Kaywoodie Shapes Number section, shape number 11 is described:

| Shape # |

Description |

Years Produced |

| 11 |

Large billiard |

1935-1972 |

Troy later sent me another helpful link from Kaywoodie My Free Forum that allowed me to see all the Kaywoodie Billiard offerings with the comparison of 2 and 3-digit shape numbers. From the same Forum article, the center column reflects the 2-digit system employed from 1927 to 1972, when the system was changed to a 3-digit system when pipe production (for Kaywoodie, Yello-Bole and Medico) was moved to the Medico factory in Richmond Hill Queens NY as plans for new plant were in process. The left-hand column above was the 3 digit numbers used during this period for all Kaywoodie and Medico pipes, from 1972 to 1980. The same article indicated that the 2-digit numbers were only for Kaywoodies produced in the US – that Kaywoodie of London to Cadogan had their own three-digit system.

From the same Forum article, the center column reflects the 2-digit system employed from 1927 to 1972, when the system was changed to a 3-digit system when pipe production (for Kaywoodie, Yello-Bole and Medico) was moved to the Medico factory in Richmond Hill Queens NY as plans for new plant were in process. The left-hand column above was the 3 digit numbers used during this period for all Kaywoodie and Medico pipes, from 1972 to 1980. The same article indicated that the 2-digit numbers were only for Kaywoodies produced in the US – that Kaywoodie of London to Cadogan had their own three-digit system.

I took my search for a Kaywoodie ‘Something Grain’, shape #11 to the latest Kaywoodie Catalog that would have a representation of the #11 Billiard at Chris’ Pipe Pages that is consistent with the older Kaywoodie catalogues leading up to it (See: LINK). See the 5th pipe down on the left: That is the Large Billiard stummel on my work table. There is one thing that doesn’t line up. The Fancy Stem. I spend extensive time trying to find the No. 11 with a fancy stem flipping through all the Kaywoodie catalogs (referenced above) and found no specimen – not even on another shape. During this exploration, I sent my forensic findings and some pictures to Troy whose experience with Kaywoodies is extensive. I wanted to know what I might be missing. After an enjoyable time of communicating back and forth – pipe restorers’ cyber fellowship, Troy’s experience with Kaywoodie pipes cut through my fog quickly. Regarding the nomenclature of the Kaywoodie Jenny chose as part of her trove, I’ll let Troy’s observations conclude this Kaywoodie origins adventure! Thanks Troy!

That is the Large Billiard stummel on my work table. There is one thing that doesn’t line up. The Fancy Stem. I spend extensive time trying to find the No. 11 with a fancy stem flipping through all the Kaywoodie catalogs (referenced above) and found no specimen – not even on another shape. During this exploration, I sent my forensic findings and some pictures to Troy whose experience with Kaywoodies is extensive. I wanted to know what I might be missing. After an enjoyable time of communicating back and forth – pipe restorers’ cyber fellowship, Troy’s experience with Kaywoodie pipes cut through my fog quickly. Regarding the nomenclature of the Kaywoodie Jenny chose as part of her trove, I’ll let Troy’s observations conclude this Kaywoodie origins adventure! Thanks Troy!

…if the shank is straight then the only thing I can think of is someone took a pre-1972 #11 and re-stemmed it with a 1970’s type quarter bent stem. If that is the case then it’s a 1955-1972 #11 Flame Grain with a different stem…. Or it could be a Super Grain (1955-1972) with a later Flame Grain type stem.

With a better understanding of this Kaywoodie in front of me, I start the restoration by reaming the fire chamber. Since the cake is so thin, I use the Savinelli Pipe Knife to do the job. After spreading out paper towel to catch the carbon, I employ the knife and it makes short work of the cake. I follow by sanding the fire chamber with a coarse 120 grade paper, then a 240 grade paper – in both cases wrapped around a Sharpie Pen. I finish by wiping the bowl with cotton wetted with isopropyl 95% to remove the residue carbon dust. The pictures show the initial clean up.

Next, using undiluted Murphy’s Oil Soap I address the grime on the stummel using cotton cloth pads. After scrubbing, I rinse the soap off the stummel with cool tap water, not allowing water in the internals. While the stummel is still wet, I probe the fill on the left side of the shank to see if it had softened and might come out. It was solid. The pictures show the progress.

Next, using undiluted Murphy’s Oil Soap I address the grime on the stummel using cotton cloth pads. After scrubbing, I rinse the soap off the stummel with cool tap water, not allowing water in the internals. While the stummel is still wet, I probe the fill on the left side of the shank to see if it had softened and might come out. It was solid. The pictures show the progress.

I now turn to cleaning the stummel internals because I like working on clean pipes. Using pipe cleaners and cotton swabs dipped in isopropyl 95%, I go to work. The internal gunk is thick – I use a curved, spaded dental probe to scrape the sides of the mortise and I remove a lot of old tars and oil built up.

I now turn to cleaning the stummel internals because I like working on clean pipes. Using pipe cleaners and cotton swabs dipped in isopropyl 95%, I go to work. The internal gunk is thick – I use a curved, spaded dental probe to scrape the sides of the mortise and I remove a lot of old tars and oil built up.  After some time working like this, I decide to switch tactics and use a retort to clean the internals and make more efficient headway! After setting up the system, putting a cotton ball in the bowl, and lighting a candle to heat the alcohol in the capped test tube, the alcohol heats and eventually boils. When it boils, the expansion forces the hot fluid into the stummel. Much of the alcohol is initially absorbed into cotton ball so I replenish the alcohol and continue the process. The rhythm of boil, expansion and then removing from the flame and tipping the stummel so that the expanded alcohol runs back into the test tube, is repeated several times.

After some time working like this, I decide to switch tactics and use a retort to clean the internals and make more efficient headway! After setting up the system, putting a cotton ball in the bowl, and lighting a candle to heat the alcohol in the capped test tube, the alcohol heats and eventually boils. When it boils, the expansion forces the hot fluid into the stummel. Much of the alcohol is initially absorbed into cotton ball so I replenish the alcohol and continue the process. The rhythm of boil, expansion and then removing from the flame and tipping the stummel so that the expanded alcohol runs back into the test tube, is repeated several times.  I pour off the first cycle into a Lord of the Rings commemorative shot glass to compare. I refill the test tube with alcohol, and continue several more cycles, pouring out the expended alcohol in another shot glass and refilling with fresh alcohol for a 3rd and final cycle. There is a gradual lightening of the expended alcohol as I picture all three for comparison. After finishing use of the retort, I finish up again using pipe cleaners and cotton swabs. The pictures show the progress.

I pour off the first cycle into a Lord of the Rings commemorative shot glass to compare. I refill the test tube with alcohol, and continue several more cycles, pouring out the expended alcohol in another shot glass and refilling with fresh alcohol for a 3rd and final cycle. There is a gradual lightening of the expended alcohol as I picture all three for comparison. After finishing use of the retort, I finish up again using pipe cleaners and cotton swabs. The pictures show the progress.

Looking at the stummel surface, the old finish does not look uniform so I use cotton pads and wipe down the stummel with acetone to remove vestiges of the old finish. The acetone worked very quickly. I again look at the suspect fill on the left side of the shank, and this time I detect a gap on the edge of it. I use the sharp dental probe to remove the old fill.

Looking at the stummel surface, the old finish does not look uniform so I use cotton pads and wipe down the stummel with acetone to remove vestiges of the old finish. The acetone worked very quickly. I again look at the suspect fill on the left side of the shank, and this time I detect a gap on the edge of it. I use the sharp dental probe to remove the old fill.  Looking now more closely at the rim, there is a dark ring around the external edge simply indicating wear. I take a picture of the right side of the rim that shows more wear. To freshen the rim lines, I decide to lightly top the KW Billiard. Using a chopping board topped with 240 grit paper I evenly rotate the inverted stummel, checking to make sure I’m staying true. After making sufficient progress with the 240, I switch to 600 grade to smooth further the top surface. The pictures show the topping progress.

Looking now more closely at the rim, there is a dark ring around the external edge simply indicating wear. I take a picture of the right side of the rim that shows more wear. To freshen the rim lines, I decide to lightly top the KW Billiard. Using a chopping board topped with 240 grit paper I evenly rotate the inverted stummel, checking to make sure I’m staying true. After making sufficient progress with the 240, I switch to 600 grade to smooth further the top surface. The pictures show the topping progress.

With the topping completed, I fine tune the rim freshening by beveling the internal edge of the rim. I use 120 grit paper rolled tightly to cut the initial angle of the bevel. I follow the 120 with a rolled piece of 240, then 600. To me an internal bevel adds class to a stummel. This #11 Large Billiard stummel looks good. I also lightly sand around the edge external rim. This softens the lines. The pictures show this rim fine-tuning process.

With the topping completed, I fine tune the rim freshening by beveling the internal edge of the rim. I use 120 grit paper rolled tightly to cut the initial angle of the bevel. I follow the 120 with a rolled piece of 240, then 600. To me an internal bevel adds class to a stummel. This #11 Large Billiard stummel looks good. I also lightly sand around the edge external rim. This softens the lines. The pictures show this rim fine-tuning process. To address the small holes on the left side of the shank, using a toothpick, I drop fill the holes using HOT STUFF Special ‘T’ – thick CA glue. I put a little CA glue on close to the end of the toothpick and allow gravity to run it to the tip to allow a surgical application of the glue. After applying the thick CA glue, I spray it with an accelerator to cure it more rapidly. In a few minutes, using a flat needle file then a rolled-up piece of 240 grit paper, I bring the CA patch mound down to the briar surface. I finish by using a rolled-up piece of 600 grit paper to smooth the patches more and blend. The pictures show the process.

To address the small holes on the left side of the shank, using a toothpick, I drop fill the holes using HOT STUFF Special ‘T’ – thick CA glue. I put a little CA glue on close to the end of the toothpick and allow gravity to run it to the tip to allow a surgical application of the glue. After applying the thick CA glue, I spray it with an accelerator to cure it more rapidly. In a few minutes, using a flat needle file then a rolled-up piece of 240 grit paper, I bring the CA patch mound down to the briar surface. I finish by using a rolled-up piece of 600 grit paper to smooth the patches more and blend. The pictures show the process.

To prepare the stummel for sanding, to preserve what is the precious little of this Kaywoodie’s nomenclature, I cut small pieces of masking tape to cover the remnants. First using a medium grade sanding sponge, I sand the stummel gently removing very small nicks and pits to smooth the stummel. I follow with a light weight sanding sponge. Using strategically placed thumb and fingers the masking tape guards did the job.

To prepare the stummel for sanding, to preserve what is the precious little of this Kaywoodie’s nomenclature, I cut small pieces of masking tape to cover the remnants. First using a medium grade sanding sponge, I sand the stummel gently removing very small nicks and pits to smooth the stummel. I follow with a light weight sanding sponge. Using strategically placed thumb and fingers the masking tape guards did the job.

Now to the micromesh pad cycles to bring out the grain on this already attractive Kaywoodie Large Billiard. Using pads 1500 to 2400 I wet sand the stummel, followed by dry sanding with 3200 to 4000 and then 6000 to 12000 – throughout, guarding the nomenclature. I am impressed by the quality of the briar grain emerging in the Kaywoodie Large Billiard. The pictures show what I’m seeing.

Now to the micromesh pad cycles to bring out the grain on this already attractive Kaywoodie Large Billiard. Using pads 1500 to 2400 I wet sand the stummel, followed by dry sanding with 3200 to 4000 and then 6000 to 12000 – throughout, guarding the nomenclature. I am impressed by the quality of the briar grain emerging in the Kaywoodie Large Billiard. The pictures show what I’m seeing.

Putting the stummel aside, it’s time to tackle the Fancy Stem. Using pipe cleaners dipped in isopropyl 95% I work on the internals. I also employ the use of long wired brushes that more easily work up into the Kaywoodie 3-hole stinger/tenon system. Following this, I use a brass bristle brush on the exterior of the stinger/tenon and finish with shining it with 0000 steel wool.

Putting the stummel aside, it’s time to tackle the Fancy Stem. Using pipe cleaners dipped in isopropyl 95% I work on the internals. I also employ the use of long wired brushes that more easily work up into the Kaywoodie 3-hole stinger/tenon system. Following this, I use a brass bristle brush on the exterior of the stinger/tenon and finish with shining it with 0000 steel wool.

With stem internals clean, I look again at the work needed on the upper and lower bit. The upper button area has tooth chatter but more significant is the compression on the button lip that may need rebuilding. Looking at the upper lip from the slot side, the lip has a dent that compresses toward the slot. The lower bit has a significant tooth dent and chatter. The lower button lip is in better shape. I take some pictures to mark the problem areas.

With stem internals clean, I look again at the work needed on the upper and lower bit. The upper button area has tooth chatter but more significant is the compression on the button lip that may need rebuilding. Looking at the upper lip from the slot side, the lip has a dent that compresses toward the slot. The lower bit has a significant tooth dent and chatter. The lower button lip is in better shape. I take some pictures to mark the problem areas.

I decide to use the heating method first to see if this will minimize the damage. By heating the vulcanite over a flame, the expansion of the rubber will seek out its original shape – at least in part. I’ll give it a try, then move to sanding and filling. With a candle lit, I pass the button area over the flame – back and forth several times. The technique helps on the lower bit but not sufficiently. The upper bit, button repair was not helped much. So, using 240 grit paper, I work on the lower and upper bit. Using a flat needle file, I also try to remove dents from the upper button lip. Pictures show the progress.

I decide to use the heating method first to see if this will minimize the damage. By heating the vulcanite over a flame, the expansion of the rubber will seek out its original shape – at least in part. I’ll give it a try, then move to sanding and filling. With a candle lit, I pass the button area over the flame – back and forth several times. The technique helps on the lower bit but not sufficiently. The upper bit, button repair was not helped much. So, using 240 grit paper, I work on the lower and upper bit. Using a flat needle file, I also try to remove dents from the upper button lip. Pictures show the progress.

The first pictures below show the sanding/filing progress on the upper lip. I’m not satisfied with the results as I will need to remove more of the button than I want to remove the dents. I wanted to see if I could repair the lip without rebuilding the lip, but this will not be possible. I’ll need to mix activated charcoal powder with CA glue to rebuild the upper button lip and fill the dent on the lower bit.

The first pictures below show the sanding/filing progress on the upper lip. I’m not satisfied with the results as I will need to remove more of the button than I want to remove the dents. I wanted to see if I could repair the lip without rebuilding the lip, but this will not be possible. I’ll need to mix activated charcoal powder with CA glue to rebuild the upper button lip and fill the dent on the lower bit. I open one capsule of activated charcoal and mix it with Hot Stuff Special ‘T’ CA glue. This CA glue is extra thick. After cleaning the patch areas with a cotton ball and isopropyl 95%, I place a small puddle of ‘T’ CA glue on an index card, and use a toothpick as a mixer and trowel. After reaching a molasses-like viscosity with the mixture, I apply the mixture to the dent and the upper button lip. I apply more mixture than necessary to enable later sanding down, shaping and blending the patches. To shorten the curing time for the patches, I spray each with an accelerator. The pictures show the progress.

I open one capsule of activated charcoal and mix it with Hot Stuff Special ‘T’ CA glue. This CA glue is extra thick. After cleaning the patch areas with a cotton ball and isopropyl 95%, I place a small puddle of ‘T’ CA glue on an index card, and use a toothpick as a mixer and trowel. After reaching a molasses-like viscosity with the mixture, I apply the mixture to the dent and the upper button lip. I apply more mixture than necessary to enable later sanding down, shaping and blending the patches. To shorten the curing time for the patches, I spray each with an accelerator. The pictures show the progress.

Back to filing and sanding. Using a flat needle file, I file the patches down. I follow by using 240 grit paper to fine tune bringing the lower bit dent patch down to surface level. I blend the patch further using 600 grit paper. I do the same with the lower button lip. After shaping the bit with the flat needle file, I use 240, 600 grit papers. The process with the button is a gradual filing, sanding and shaping until the button emerges and looks balanced. Pictures show the progress.

Back to filing and sanding. Using a flat needle file, I file the patches down. I follow by using 240 grit paper to fine tune bringing the lower bit dent patch down to surface level. I blend the patch further using 600 grit paper. I do the same with the lower button lip. After shaping the bit with the flat needle file, I use 240, 600 grit papers. The process with the button is a gradual filing, sanding and shaping until the button emerges and looks balanced. Pictures show the progress.

Above the slot, during the sanding, I notice a pinhole – what appears to be a small air pocket. There are also very small air pockets on the upper button lip repair. This is normal and I use a toothpick and drop-fill the hole with CA glue. I then paint a thin coat of CA glue over the button lip to fill the air holes. I quickly spray the glue with an accelerator to shorten the curing. I then finish the button sanding out the air pocket fills. I complete this phase of repair by using 0000 steel wool to the upper and lower bit. The lower bit patch will blend more as I polish the stem. The button looks good. The pictures show progress.

Above the slot, during the sanding, I notice a pinhole – what appears to be a small air pocket. There are also very small air pockets on the upper button lip repair. This is normal and I use a toothpick and drop-fill the hole with CA glue. I then paint a thin coat of CA glue over the button lip to fill the air holes. I quickly spray the glue with an accelerator to shorten the curing. I then finish the button sanding out the air pocket fills. I complete this phase of repair by using 0000 steel wool to the upper and lower bit. The lower bit patch will blend more as I polish the stem. The button looks good. The pictures show progress.

With the repair to the bit completed, I now turn to the Fancy Stem. Even though there is no oxidation, I use 0000 steel wool to buff the entire stem to remove many small nicks and scratches on the surface. I then begin the micromesh pad process by wet sanding with pads 1500 to 2400. I follow by dry sanding with pads 3200 to 4000 then 6000 to 12000. After each cycle, I apply Obsidian Oil to revitalize the vulcanite. The Fancy Stem is looking good. The pictures show the progress.

With the repair to the bit completed, I now turn to the Fancy Stem. Even though there is no oxidation, I use 0000 steel wool to buff the entire stem to remove many small nicks and scratches on the surface. I then begin the micromesh pad process by wet sanding with pads 1500 to 2400. I follow by dry sanding with pads 3200 to 4000 then 6000 to 12000. After each cycle, I apply Obsidian Oil to revitalize the vulcanite. The Fancy Stem is looking good. The pictures show the progress.

I again take the stummel after completing the stem sanding. During the stem work, I had in the back of my mind the consideration of the next step working with the Kaywoodie ‘Flame/Super Grain’ stummel. The stummel’s natural briar color is dark and rich with grain flow – horizontal, bird’s eye and flame. My idea is to add some pop to the grain by staining the stummel with a light brown dye. This will not darken the stummel, but perhaps it will lighten the softer wood grains. We’ll see! I take a few pictures of the stummel to mark the progress. Using a cotton pad wetted with isopropyl 95%, I wipe the stummel down to assure it’s clean. I use a cork inserted into the bowl to use as a handle and I warm the stummel using the heat gun to warm and expand the grain helping it to be more receptive to the dye. I then apply a generous amount of Fiebing’s Light Brown Leather Dye to the stummel using a folded pipe cleaner. When covered thoroughly with dye, I ‘flame’ the stummel with a lit candle which immediately burns off the alcohol in the aniline based dye. This sets the hue in the grain. After a few minutes, I repeat the process again and then set the stummel aside to rest. The pictures show the process.

I again take the stummel after completing the stem sanding. During the stem work, I had in the back of my mind the consideration of the next step working with the Kaywoodie ‘Flame/Super Grain’ stummel. The stummel’s natural briar color is dark and rich with grain flow – horizontal, bird’s eye and flame. My idea is to add some pop to the grain by staining the stummel with a light brown dye. This will not darken the stummel, but perhaps it will lighten the softer wood grains. We’ll see! I take a few pictures of the stummel to mark the progress. Using a cotton pad wetted with isopropyl 95%, I wipe the stummel down to assure it’s clean. I use a cork inserted into the bowl to use as a handle and I warm the stummel using the heat gun to warm and expand the grain helping it to be more receptive to the dye. I then apply a generous amount of Fiebing’s Light Brown Leather Dye to the stummel using a folded pipe cleaner. When covered thoroughly with dye, I ‘flame’ the stummel with a lit candle which immediately burns off the alcohol in the aniline based dye. This sets the hue in the grain. After a few minutes, I repeat the process again and then set the stummel aside to rest. The pictures show the process.

After several hours, the stummel is ready to ‘unwrap’. Using the Dremel, mounting a felt buffing wheel, at the slowest speed, I apply Tripoli compound to the surface to remove the fired crust. I take a picture to show the contrast from the crust, and the emerging grain. After the Tripoli, I lightly wipe the stummel with a cotton pad wetted with isopropyl 95% to blend the dye further. After this, using a cotton cloth buffing wheel mounted on the Dremel, and notching up the speed to ‘2’ (fastest is 5), I apply the slightly less abrasive compound, Blue Diamond. I love to see the rich tones of the briar grain emerge during this process.

After several hours, the stummel is ready to ‘unwrap’. Using the Dremel, mounting a felt buffing wheel, at the slowest speed, I apply Tripoli compound to the surface to remove the fired crust. I take a picture to show the contrast from the crust, and the emerging grain. After the Tripoli, I lightly wipe the stummel with a cotton pad wetted with isopropyl 95% to blend the dye further. After this, using a cotton cloth buffing wheel mounted on the Dremel, and notching up the speed to ‘2’ (fastest is 5), I apply the slightly less abrasive compound, Blue Diamond. I love to see the rich tones of the briar grain emerge during this process.  Before I apply the carnauba wax to the stummel, I have a couple of corrections to apply. The first is to correct the under-clocked stem. Using a lit candle, I heat the metal tenon so that the vulcanite loosens its grip and I quickly screw the tenon in until it tightens and I apply pressure carefully to advance the stem. I repeated the heating process a few times until I reached the desired stem position. The pictures show the process.

Before I apply the carnauba wax to the stummel, I have a couple of corrections to apply. The first is to correct the under-clocked stem. Using a lit candle, I heat the metal tenon so that the vulcanite loosens its grip and I quickly screw the tenon in until it tightens and I apply pressure carefully to advance the stem. I repeated the heating process a few times until I reached the desired stem position. The pictures show the process.

The second thing I wanted to do before applying the carnauba wax was to coat the fire chamber with pipe mud. I have this tutorial bookmarked on Reborn Pipes here: LINK. I noticed minor heat fissures in fire chamber earlier which is shown in the first picture below. Applying a coat of pipe mud will simply coat the chamber, filling the fissures, and provide the foundation for a new cake to develop. To create the pipe mud, I use a mixture of cigar ash (thanks to my colleague, Gary!) and water. I make sure that the cigar ash is finely ground using the flat end of a pipe nail and I remove any solid debris. I put ash in a shot glass and water in a small bottle and I add water using a large eye-dropper and mix with the pipe nail until I achieve a paste like viscosity. I then use a pipe cleaner to paint the mud to the chamber wall and tamp it using the spoon end of the pipe nail tool. I’ll wait about an hour for the mud to fully set up. The pictures show the process.

The second thing I wanted to do before applying the carnauba wax was to coat the fire chamber with pipe mud. I have this tutorial bookmarked on Reborn Pipes here: LINK. I noticed minor heat fissures in fire chamber earlier which is shown in the first picture below. Applying a coat of pipe mud will simply coat the chamber, filling the fissures, and provide the foundation for a new cake to develop. To create the pipe mud, I use a mixture of cigar ash (thanks to my colleague, Gary!) and water. I make sure that the cigar ash is finely ground using the flat end of a pipe nail and I remove any solid debris. I put ash in a shot glass and water in a small bottle and I add water using a large eye-dropper and mix with the pipe nail until I achieve a paste like viscosity. I then use a pipe cleaner to paint the mud to the chamber wall and tamp it using the spoon end of the pipe nail tool. I’ll wait about an hour for the mud to fully set up. The pictures show the process.

Now for the home stretch. With stummel and stem reconnected, I apply several coats of carnauba wax to the Large Billiard stummel of this Kaywoodie Flame/Super Grain. I use a cotton cloth buffing wheel mounted on the Dremel at the same speed (2) and methodically apply the carnauba using the sheen reflection on the surface to guide my application. After applying carnauba, I change to a clean cotton cloth buffing wheel and go over the surface again to bring out the shine and more fully blend the wax. Finally, I hand buff the pipe with a microfiber cloth to raise the shine more.

Now for the home stretch. With stummel and stem reconnected, I apply several coats of carnauba wax to the Large Billiard stummel of this Kaywoodie Flame/Super Grain. I use a cotton cloth buffing wheel mounted on the Dremel at the same speed (2) and methodically apply the carnauba using the sheen reflection on the surface to guide my application. After applying carnauba, I change to a clean cotton cloth buffing wheel and go over the surface again to bring out the shine and more fully blend the wax. Finally, I hand buff the pipe with a microfiber cloth to raise the shine more.

While we don’t know with 100% certainty whether this Kaywoodie #11 Large Billiard is a Flame Grain or a Super Grain, I believe the grain is a cut above the norm looking at its quality. It has a beautiful flow of grains and is quite attractive. The Large Billiard fills the hand well with an interesting, tapered Fancy Stem, that probably came later and is not original with the older #11 stummel. I’m happy to provide this Kaywoodie to add to Jenny gift trove as she goes back to the US. Jen’s purchase benefits the Daughters of Bulgaria, our work here in Bulgaria with women and girls sexually exploited and trafficked. For more information about this work, take a look at The Pipe Steward. Thanks for joining me!