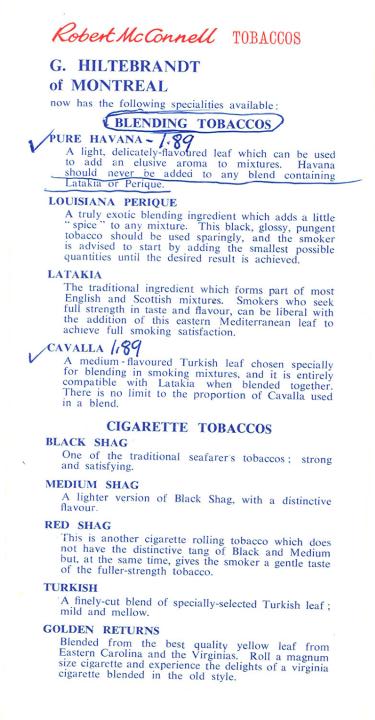

Blog by Steve Laug

This document came to me in the lot I picked up on the weekend. I am pretty sure that it came with Arthur Leonard’s Catalogue as it was folded inside that document. It would have been given out to customers who purchased a meerschaum pipe from their shop. It gives a brief history of meerschaum and some simple instructions for obtaining “the utmost pleasure and value” from your meerschaum. I found it a quick and enjoyable read so I thought I would pass it on to you all.