Blog by Steve Laug

I decided to take some time to reflect on my slide into pipe repair work. I figured it would be good to process the slide a bit and try to wrestle with my reticence. I have been reluctant to take on pipe repairs for other people because I really like doing the work as a hobby and I don’t really want to deal with all the potential people issues. I find it relaxing to move at my own pace and when I feel like doing the work. To add the desires and wishes of another person with their own expectations and times lines to the mix was something that I avoided for the longest time by just repairing pipes for close friends or pipe club members when I felt like it. I just did not want to ruin a perfectly good hobby and put myself at the mercy of others who exacted such a variety of forms of torture and suffering on briar and meerschaum. I wanted to be able to sit at my work table with some nice music playing, no pressure sip some coffee or a beer and just putter away. Working that way there were no deadlines or phone calls checking up on the status of a pipe. There was just the predictable ability of pipework to de-stress me. With my job I actually am never finished; each day marches on and the work is never done. With pipework I can often finish working on one or two pipes in an evening and even more on a weekend if I choose to do so. I have the immediate satisfaction of not only finishing something but bringing a worn and tired old pipe back to life – hence the name rebornpipes. Probably the beginning of the downward slide into pipe repair can be associated with the start of my blog. A little over three years ago I started the rebornpipe blog as an online storage site for the documentation I had done over the years of learning the art of pipe refurbishing. I have been on Smokers Forums for many years and about that time the server was hacked and all of the posts and archived material that I had written there on pipes and repairs disappeared into cyberspace. Fortunately I had saved copies of every post with pictures included on my hard drive. But to add insult to injury the next thing that happened was that my hard drive crashed. I took it to the shop and they were able to rescue my files including the posts. That was enough for me. I found the WordPress site and signed up for the free version of the blog. I put everything on the web and breathed a sigh of relief. Now I have the blog plus I backed it up on DVDs and have them in storage and I keep the current years’ work on my new hard drive. I am convinced that one can never be prepared enough!

Probably the beginning of the downward slide into pipe repair can be associated with the start of my blog. A little over three years ago I started the rebornpipe blog as an online storage site for the documentation I had done over the years of learning the art of pipe refurbishing. I have been on Smokers Forums for many years and about that time the server was hacked and all of the posts and archived material that I had written there on pipes and repairs disappeared into cyberspace. Fortunately I had saved copies of every post with pictures included on my hard drive. But to add insult to injury the next thing that happened was that my hard drive crashed. I took it to the shop and they were able to rescue my files including the posts. That was enough for me. I found the WordPress site and signed up for the free version of the blog. I put everything on the web and breathed a sigh of relief. Now I have the blog plus I backed it up on DVDs and have them in storage and I keep the current years’ work on my new hard drive. I am convinced that one can never be prepared enough!

Over the years the blog has grown to include more than me – there are now many folks who have joined me in posting their work. I bought the domain name and upgraded the storage space and capacity of the sight. It did not take too long before I began to get emails from folks who wanted advice on how to repair their pipes or wanted to send them to me for a repair. In those early days I generally did the work for barter. A tin of tobacco, a box of pipe cleaners or even pipes were often the form of payment. All of these were ways I tried to keep from crossing the line and make my hobby into work. I still had an aversion to that and wanted to keep the line very clear.

Well the bartering took a turn – more of a slow and steady slippage into doing the work for others. Looking back I can see how it happened and when it took a turn. It seems like friends of friends wanted a new stem or a repair or a tenon replacement. There was no end in sight so I sought yet another way to keep the hobby just a hobby. I still did not want to step into the doing repairs for a fee. I did a bit of research to see what others charged to do what I was doing. My thinking at that point was truly to set a price and discourage the knocks on the door, the emails and the phone calls. However, it did not do that. Slowly but surely the stream increased. I still did some of the repairs in exchange for a tin of tobacco or something else that would be worth bartering. In my head I kept trying to at least postpone the inevitable day that would come when I would have to charge.

But the slippage into doing repairs for others continued and soon the postie was delivering boxes from all over the world for repairs. Sometimes I wonder what he thinks when he rings the bell and hands me yet another small box that says pipe for repair. I could still rationalize to myself that I was just helping friends I had met online in the various pipe forums or through the blog. But my rationalization was more a form of denial as the repairs kept coming. My wife and daughters soon raised the question that I had sensed was coming, “When are you going to come up with a price list for your repairs? You should get some compensation other than more pipes and tobacco for the work you are doing.” I tried to ignore them for as long as I could but one day I sat down and figured out a price list for what I do and designed a business card to match.

I should have figured out that the line was crossed with these two creations – a price list and a business card. The first iteration of the card only said Used and Estate Pipes Bought and Sold so I was still able to live in the wonderful world of denial. But even that soon gave way as with the next iteration of the card I added the word Repaired between Pipes and Bought.

I should have figured out that the line was crossed with these two creations – a price list and a business card. The first iteration of the card only said Used and Estate Pipes Bought and Sold so I was still able to live in the wonderful world of denial. But even that soon gave way as with the next iteration of the card I added the word Repaired between Pipes and Bought.

The question is clear for me, “Did this signify the beginning of the end for my hobby – at least at some level?”. I continue to work on pipes I find and the ones my brother supplies me with as a hobbyist. The trouble is that I now have to fit them in between the ones that I am fixing for others. I cling tenaciously to the hobby aspect of refurbishing and refuse to let go of it! However, no matter how hard I tried the slippage became a full out free fall not long ago.

I know the precise moment that it happened. I can tell you the date but that really does not matter. I do know that when it happened it was a dark rainy Vancouver evening. After work I took my daughter to an eye specialist for an appointment. When I dropped her off I remembered that there was a cigar/pipe shop just down the hill from the clinic. So instead of paying a garage parking fee or feeding a meter I drove down the hillside to shop and parked in their lot. My thinking was I could park there for free and do a bit of shopping at the same time. It could be a win win for me – no meters or parking fees and I could pick up refurbishing supplies. I needed some pipe cleaners and I wanted to see what pipes the shop had available.

I had not been there for a long time so I was looking forward to checking it out. I had heard that they had a good selection of pipes and tobaccos. It had originally been just a cigar shop with nothing pipe related so this would be interesting. I parked in their lot and went inside. I greeted the two women who were running the shop and went into the pipe area. They had indeed made a lot of changes and carried some beautiful pipes. I was looking at the Peterson pipes in the display case when one of the women asked if I would like a coffee. I accepted her offer and was soon chatting with her about the pipes and tobacco they carried. As I we talked I asked her for different items and began to build my purchase pile. These included two packages and an additional six bundles of pipe cleaners and a tin of Escudo. She asked me what I needed that many pipe cleaners for so I told her that I worked on estate pipes. I even went out of my way to make it clear that restoring and repairing old pipes was a hobby that I really enjoyed.

That was where things got interesting. She wanted to know what kind of restoration work I did so I summarized what I did. I told her about my blog and suggested she check it out to see what kind of work I did. Up to this point I was pretty oblivious to where this was going. We were just having a conversation so I did not think too much about it. She asked for an email and a link for the blog so I gave them to her. You might think I was a little dense at this point and you are probably right in your assumption. When I am in a pipe shop I am pretty focused on pipes and tobaccos and not thinking about much else. I went through the various display cases and enjoyed the Dunhills, Chacoms, Butz Choquins, Brighams and several baskets of inexpensive pipes and cobs. Time was flying by while I waited to pick up my daughter.

Finally, I made my way to the cash register to pay the bill and collect my purchases. They ladies asked me if I had a price list of the work I do. I laughed and said yes I did. She then told me that the pipe repairman that they referred people to had retired. He lived in Toronto and was no longer working on pipes. They were in need of a new repairman. Then came the question – “Would I be willing to have them refer people to me with their repairs?” Unthinkingly, truly I did not think too much about it, I said sure. Well the slippage was over and I was free falling into repair work. I did not think much about it and went to pick up my daughter, quite oblivious to what would transpire.

It was not long before I began to get phone calls asking if I would repair a stem, a broken tenon, a damaged finish or a dent in a bowl. People began to drop off pipes at my door for me to repair. I think this is more than my family was expecting. Not too long ago my wife asked me when our home had become a pipe shop… fortunately she was laughing but I got the point. But what could I do, I was caught in the free fall and was doing repairs. I have met some interesting people in the last few months of this adventure. I had no idea the number of pipe smokers in Vancouver. I know a few from the pipe club here but the ones stopping by for repairs are people I have never met before of a variety of ages. It is great to see that our hobby is alive and well even in the anti- smoking climate of Vancouver.

I will see where this aspect of pipe refurbishing and repair takes me. But one thing I know is that I still have a huge box of pipes of my own to refurbish so the hobby will continue. I am just going to have to learn to pace myself so I can still enjoy my hobby while fixing other people’s pipes.

When I got it to the work table I took my usual pre-work photos. They were probably not necessary but I am working on keeping the habit so that I do not forget to document the work I am doing on pipe restoration.

When I got it to the work table I took my usual pre-work photos. They were probably not necessary but I am working on keeping the habit so that I do not forget to document the work I am doing on pipe restoration.

I worked on the rim of the pipe with saliva and cotton pads and a 1500 grit micromesh sanding pad. I was able to remove the build up on the rim. The damage on the inner edge at the front is very visible.

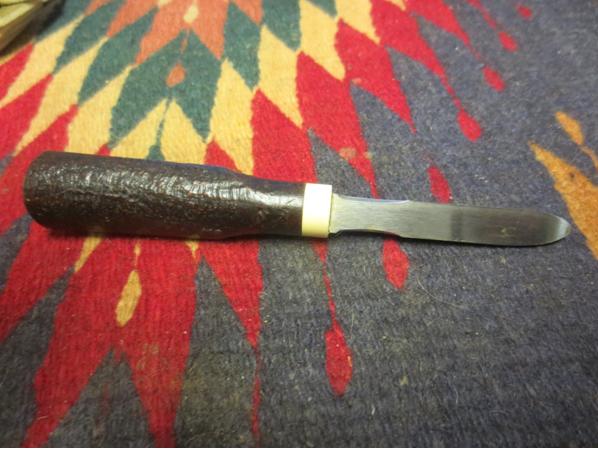

I worked on the rim of the pipe with saliva and cotton pads and a 1500 grit micromesh sanding pad. I was able to remove the build up on the rim. The damage on the inner edge at the front is very visible. I lightly topped the bowl with micromesh pads. I then used my new Savinelli Pipe Knife to ream the bowl and clean out the buildup.

I lightly topped the bowl with micromesh pads. I then used my new Savinelli Pipe Knife to ream the bowl and clean out the buildup. I worked on the inside of the rim edge with a folded piece of 220 grit sandpaper and beveled edge inward.

I worked on the inside of the rim edge with a folded piece of 220 grit sandpaper and beveled edge inward. Even though the stain on the bowl was a dark oxblood colour it also had some dark brown overtones. I used a dark brown stain pen to touch up the rim top and edges. I buffed the rim with Blue Diamond to blend the stain into the rest of the briar.

Even though the stain on the bowl was a dark oxblood colour it also had some dark brown overtones. I used a dark brown stain pen to touch up the rim top and edges. I buffed the rim with Blue Diamond to blend the stain into the rest of the briar. I sanded the stem with 220 grit sandpaper to remove the oxidation and also the slight pitting on the surface of the vulcanite.

I sanded the stem with 220 grit sandpaper to remove the oxidation and also the slight pitting on the surface of the vulcanite.  I cleaned out the stem with alcohol and pipe cleaners to remove the tars and oils. I also cleaned out the shank and mortise with alcohol, pipe cleaners and cotton swabs. I was surprised to see that what came out was the red stain. It appears that the pipe may well have been dipped in stain. It took quite a few cotton swabs to remove the stain.

I cleaned out the stem with alcohol and pipe cleaners to remove the tars and oils. I also cleaned out the shank and mortise with alcohol, pipe cleaners and cotton swabs. I was surprised to see that what came out was the red stain. It appears that the pipe may well have been dipped in stain. It took quite a few cotton swabs to remove the stain.

I wet sanded the stem with 1500-2400 micromesh sanding pads to smooth out the pitting on the surface and to remove the oxidation. I rubbed it down with Obsidian Oil and then dry sanded it with 3200-4000 grit pads and gave it another coat of oil. I continued to sand it with 6000-12000 grit pads and gave it a final coat of oil. I let it dry.

I wet sanded the stem with 1500-2400 micromesh sanding pads to smooth out the pitting on the surface and to remove the oxidation. I rubbed it down with Obsidian Oil and then dry sanded it with 3200-4000 grit pads and gave it another coat of oil. I continued to sand it with 6000-12000 grit pads and gave it a final coat of oil. I let it dry.

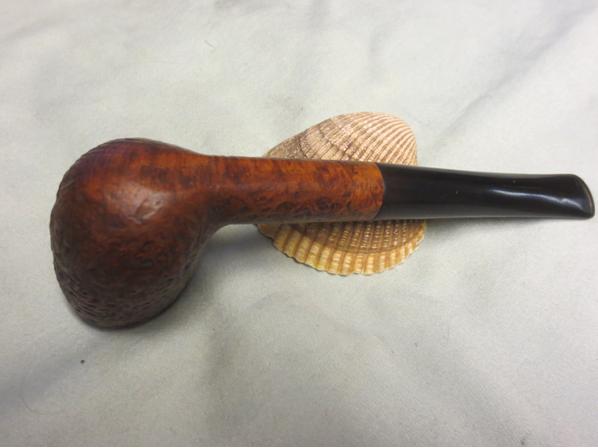

I buffed the pipe with Blue Diamond on the buffing wheel and then gave it multiple coats of carnauba wax. I buffed it with a clean buffing pad and then by hand with a microfibre cloth to raise the shine. The finished pipe is shown in the photos below. It is a beauty with a long stem – almost a Bing Crosby style pipe. The grain is beautiful and it was great to have an easy pipe to work on for once. Thanks for looking.

I buffed the pipe with Blue Diamond on the buffing wheel and then gave it multiple coats of carnauba wax. I buffed it with a clean buffing pad and then by hand with a microfibre cloth to raise the shine. The finished pipe is shown in the photos below. It is a beauty with a long stem – almost a Bing Crosby style pipe. The grain is beautiful and it was great to have an easy pipe to work on for once. Thanks for looking.