Blog by Steve Laug

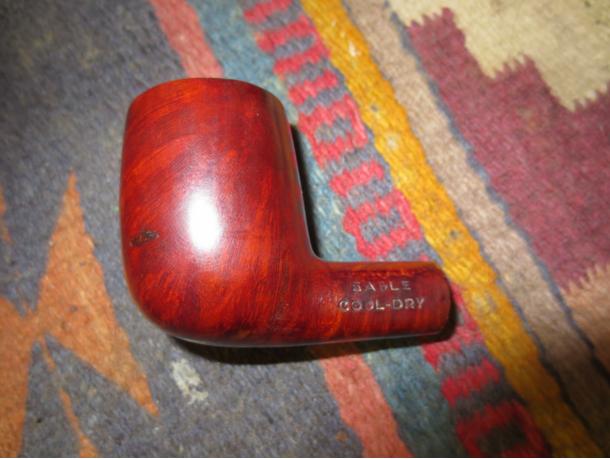

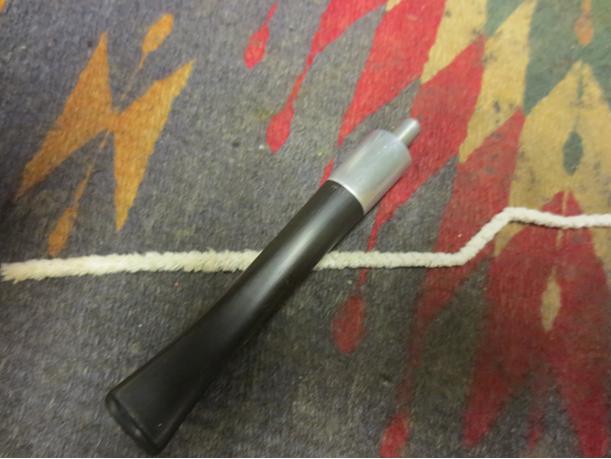

The pipe was another gift pipe sent to me by Pam. It is in decent shape. The stem is oxidized and has some tooth marks on the top and bottom side of the stem near the button. The tooth mark is like a vertical slit on the top and bottom side about ½ inch up the stem from the button. There is also a small tooth dent near the button. The metal part of the stem and tenon were integrated into the stem rather than in the shank of the pipe. The finish on the pipe was shiny and showed that the lacquer or varnish that had been used was peeling in spots on the front of the bowl. The stamping was deep and readable. There were quite a few fills on the bottom of the bowl. The largest was on the bottom front edge of the bowl. It had shrunken and was a large pit that ran across the front of the bowl. The bowl was heavily caked and the buildup on the beveled rim was hard and chipped looking. There were some nicks on the outer edges of the rim from when the bowl had been tapped out. The shank was not too dirty and the mortise appeared to be lined with a white tube of some sort. The Eagle Cool-Dry has some unique plumbing in terms of system pipes. It is different from any of the other pipes like this in my collection. The rest of the ones that externally look like this one, the Keyser Hygienic and the Millard Perfect Pipe are actually very different in terms of design. They have a metal insert at the end of the shank that acts as a condenser area with a tube extending from the airway into the condensation chamber. The stem also has a metal tube insert and no tenon but is a military mount stem that inserts into the chamber. The two tubes either meet in the chamber or sit in the chamber. The Eagle is very different in terms of design from the other two mentioned above. The shank is lined with either clay or meerschaum – hard to tell by just looking. My tendency is to assume it is clay. The porous tube is inserted into the shank forming the mortise of the pipe and extending to the end of the shank (see photo below). The metal tenon integrated into the vulcanite stem sits snuggly into the lined mortise. Once I clean it up I may be more certain what the material that makes up the mortise lining.

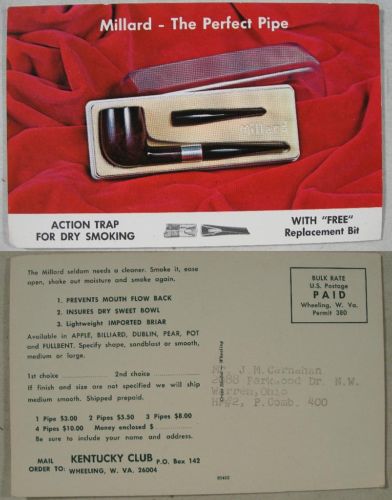

The Eagle Cool-Dry has some unique plumbing in terms of system pipes. It is different from any of the other pipes like this in my collection. The rest of the ones that externally look like this one, the Keyser Hygienic and the Millard Perfect Pipe are actually very different in terms of design. They have a metal insert at the end of the shank that acts as a condenser area with a tube extending from the airway into the condensation chamber. The stem also has a metal tube insert and no tenon but is a military mount stem that inserts into the chamber. The two tubes either meet in the chamber or sit in the chamber. The Eagle is very different in terms of design from the other two mentioned above. The shank is lined with either clay or meerschaum – hard to tell by just looking. My tendency is to assume it is clay. The porous tube is inserted into the shank forming the mortise of the pipe and extending to the end of the shank (see photo below). The metal tenon integrated into the vulcanite stem sits snuggly into the lined mortise. Once I clean it up I may be more certain what the material that makes up the mortise lining. As I worked on cleaning up the pipe I took a little time to see if I could ferret out any information on the brand and the manufacturer of the pipe. I looked for Cool-Dry pipes and found a metal Falcon like pipe that uses the same threaded bowls as Dr. Grabow Vikings. I looked for Eagle Pipes and found a clay pipe manufacturer in Montreal, Quebec in the late 1890s but nothing on a briar pipe maker of that name. I searched for patent information on the internals of the pipe under both the Eagle and the Cool-Dry name and found nothing specific on the system in this pipe. The one thing I did find was that the pipe was made by the Hudson Universal Pipe Co. who also made the brands Excelsior, Harrington Park, and Hilex. This information came out through some notes I found while Googling the brand.

As I worked on cleaning up the pipe I took a little time to see if I could ferret out any information on the brand and the manufacturer of the pipe. I looked for Cool-Dry pipes and found a metal Falcon like pipe that uses the same threaded bowls as Dr. Grabow Vikings. I looked for Eagle Pipes and found a clay pipe manufacturer in Montreal, Quebec in the late 1890s but nothing on a briar pipe maker of that name. I searched for patent information on the internals of the pipe under both the Eagle and the Cool-Dry name and found nothing specific on the system in this pipe. The one thing I did find was that the pipe was made by the Hudson Universal Pipe Co. who also made the brands Excelsior, Harrington Park, and Hilex. This information came out through some notes I found while Googling the brand.

Having that information in hand I looked for the pipe on the Pipephil Stampings and Logos website and interestingly found the following picture and short information. The brief notes under the picture confirm that Hudson Universal Pipe Co. was one of the makers of the pipe. The pipe I received has the same stamping as the one pictured below. The one I have does not have the stem logo but rather is stamped ITALIA on the underside of the stem next to the metal portion of the stem.

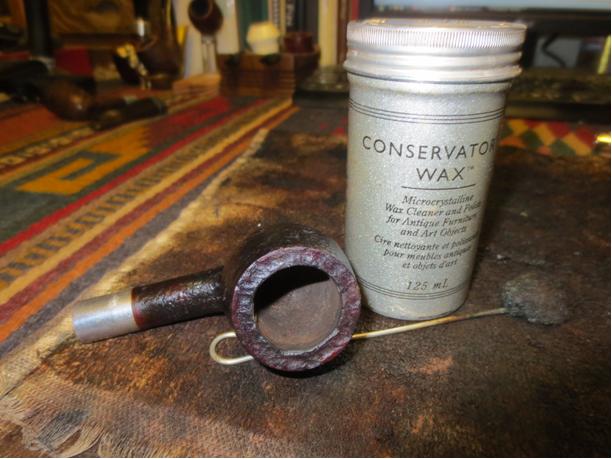

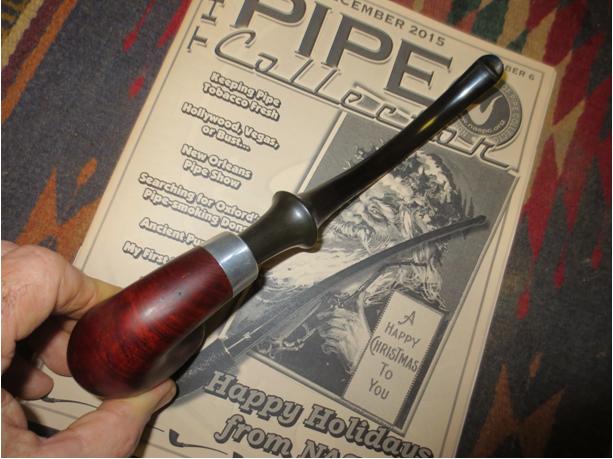

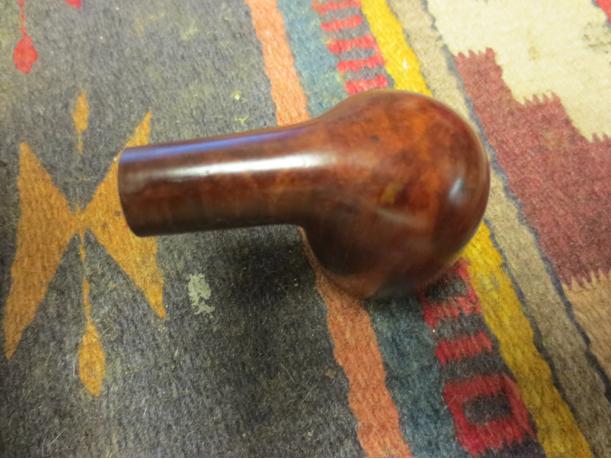

When I brought the pipe to my work table I took the following photos to give an idea of the condition it was in when I started. I have spoken of the finish and the general worn condition of the bowl. The rim and cake issues have also been mentioned. The photos show the oxidized stem and aluminum. The bowl has an attractive shape and there is something about the old pipe that drew me to it.

When I brought the pipe to my work table I took the following photos to give an idea of the condition it was in when I started. I have spoken of the finish and the general worn condition of the bowl. The rim and cake issues have also been mentioned. The photos show the oxidized stem and aluminum. The bowl has an attractive shape and there is something about the old pipe that drew me to it.

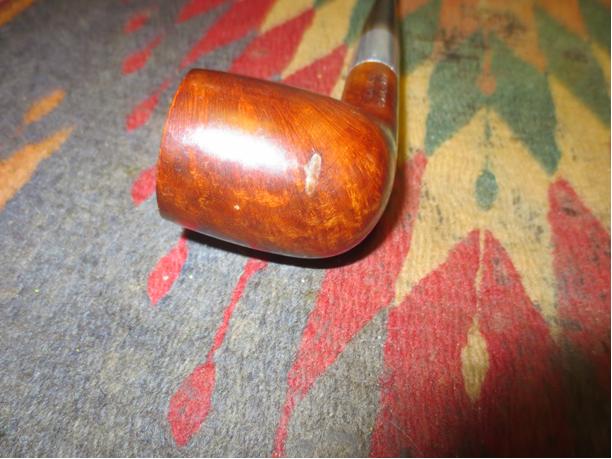

The next two photos are close up shots. The first shows the large shrunken fill on the bottom front part of the bowl. The second shows the thickness of the build up on the rim and the cake in the bowl.

The next two photos are close up shots. The first shows the large shrunken fill on the bottom front part of the bowl. The second shows the thickness of the build up on the rim and the cake in the bowl.

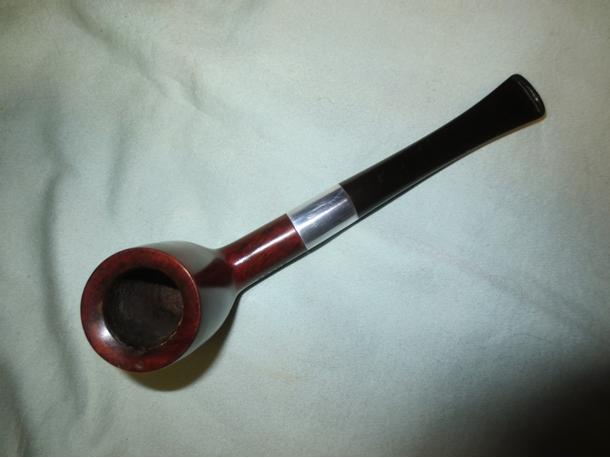

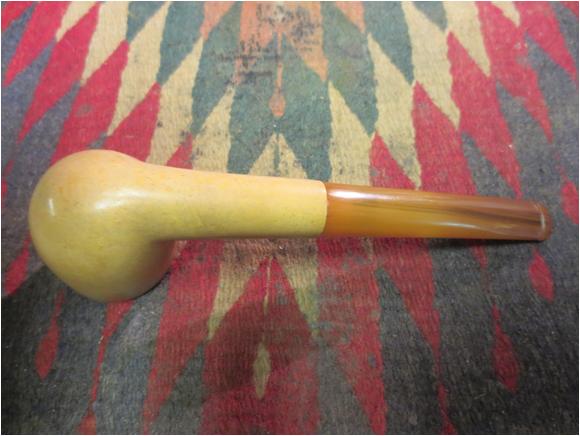

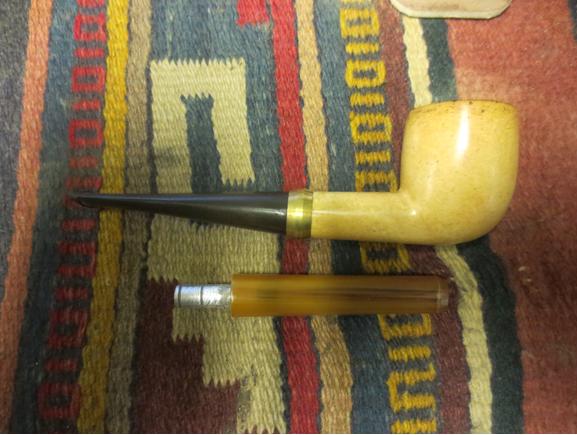

I took the pipe apart to show the nature of the tenon and stem apparatus.

I took the pipe apart to show the nature of the tenon and stem apparatus. I sanded the stem with 220 grit sandpaper to remove the oxidation on the stem and to prepare it for the repairs that needed to be done to the tooth marks on both sides of the stem. I sanded it and removed much of the oxidation and minimized the tooth chatter. I then scrubbed the stem with alcohol to remove the dust and debris in the tooth marks. I filled them with a bubble of clear super glue – both the two spots next to the button (1 on top and 1 on the underside) and the two vertical cuts or marks (one on each side). I set the stem aside to let the glue cure.

I sanded the stem with 220 grit sandpaper to remove the oxidation on the stem and to prepare it for the repairs that needed to be done to the tooth marks on both sides of the stem. I sanded it and removed much of the oxidation and minimized the tooth chatter. I then scrubbed the stem with alcohol to remove the dust and debris in the tooth marks. I filled them with a bubble of clear super glue – both the two spots next to the button (1 on top and 1 on the underside) and the two vertical cuts or marks (one on each side). I set the stem aside to let the glue cure.

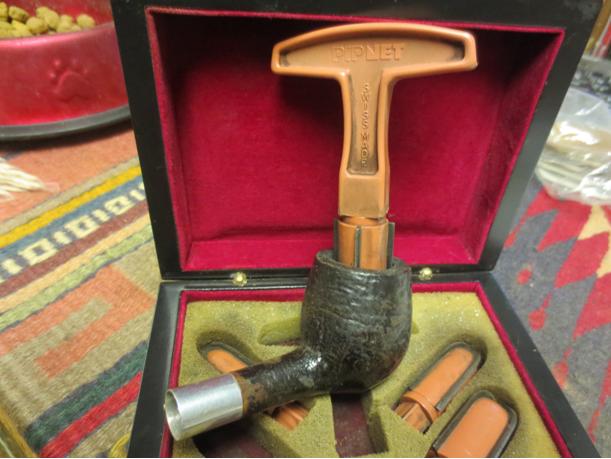

While the glue dried I worked on the bowl. I sanded the top of the rim with 220 grit sandpaper to remove the cake that had built up on that surface. I would need to continue to reshape the rim. I reamed it back to bare wood with a PipNet reamer.

While the glue dried I worked on the bowl. I sanded the top of the rim with 220 grit sandpaper to remove the cake that had built up on that surface. I would need to continue to reshape the rim. I reamed it back to bare wood with a PipNet reamer.

I continued to sand the rim and also sanded the inside edge of the rim with the 220 grit sandpaper.

I continued to sand the rim and also sanded the inside edge of the rim with the 220 grit sandpaper. I scrubbed the bowl with acetone on a cotton pad to remove the varnish coat and the grime that collected on the briar through the years.

I scrubbed the bowl with acetone on a cotton pad to remove the varnish coat and the grime that collected on the briar through the years.

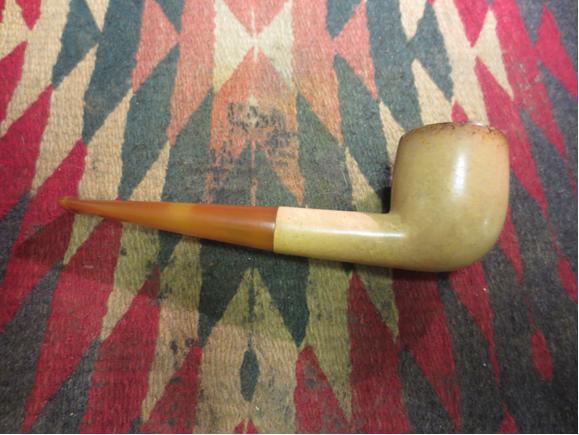

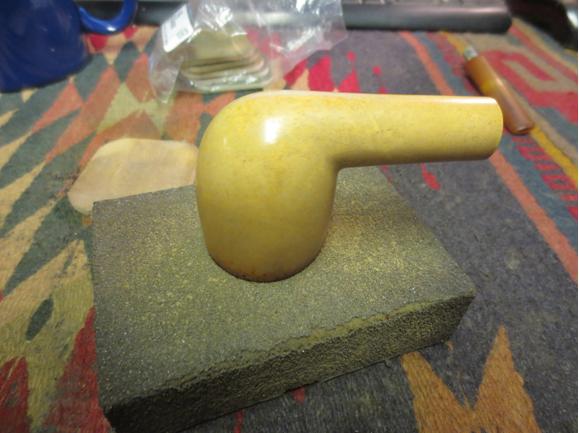

The next photo shows the clay/meerschaum insert in the shank that lined the mortise on the pipe. I cleaned it with cotton swabs, pipe cleaners and alcohol.

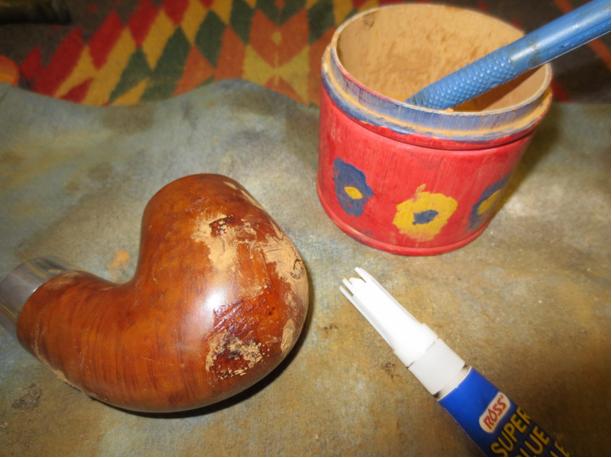

The next photo shows the clay/meerschaum insert in the shank that lined the mortise on the pipe. I cleaned it with cotton swabs, pipe cleaners and alcohol. I picked out the large fill on the front of the bowl with a dental pick until the sandpit was clear of the white putty. I wiped the bowl down with alcohol on a cotton swab to clean out any remaining debris. I used the dental pick to press briar dust into the sandpit and packed it in. I dripped a couple of drops of glue into the dust. Unfortunately the glue ran down the face of the bowl. I am using a new kind of glue and it is very thin and dries slowly. I sanded the surface of the bowl to remove the heavy overdone patch until it was smooth with the surface of the bowl. I then added a little more briar dust to the patch and used the tip of the pick to put some more glue on the repair.

I picked out the large fill on the front of the bowl with a dental pick until the sandpit was clear of the white putty. I wiped the bowl down with alcohol on a cotton swab to clean out any remaining debris. I used the dental pick to press briar dust into the sandpit and packed it in. I dripped a couple of drops of glue into the dust. Unfortunately the glue ran down the face of the bowl. I am using a new kind of glue and it is very thin and dries slowly. I sanded the surface of the bowl to remove the heavy overdone patch until it was smooth with the surface of the bowl. I then added a little more briar dust to the patch and used the tip of the pick to put some more glue on the repair.

When the glue dried I sanded the patch until it was smooth. I sanded the entire bowl with a medium and fine grit sanding sponge to remove the scratches. I wet sanded the bowl with 400 grit wet dry sandpaper and then with 1500-2400 grit micromesh sanding pads. I wiped the bowl down with alcohol and cotton pads to remove the sanding dust in preparation for restaining the pipe.

When the glue dried I sanded the patch until it was smooth. I sanded the entire bowl with a medium and fine grit sanding sponge to remove the scratches. I wet sanded the bowl with 400 grit wet dry sandpaper and then with 1500-2400 grit micromesh sanding pads. I wiped the bowl down with alcohol and cotton pads to remove the sanding dust in preparation for restaining the pipe.

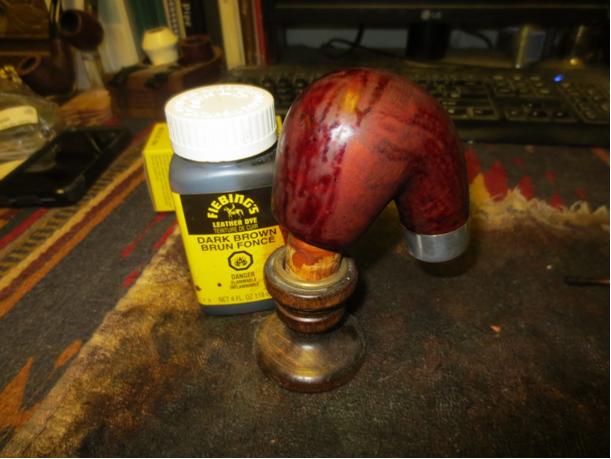

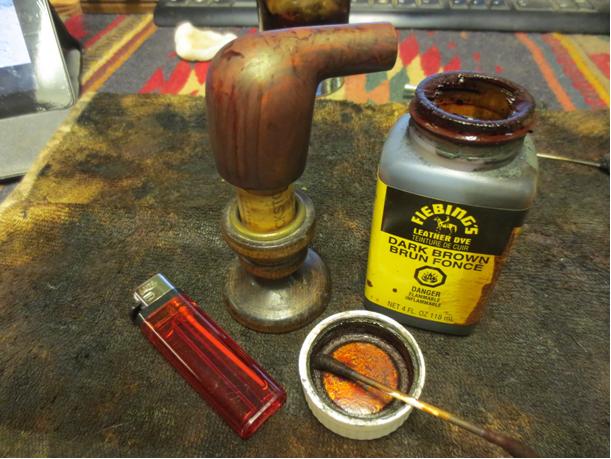

I gave the bowl a coat of dark brown aniline stain and flamed it with a lighter. I gave the pipe several more coats of stain and flamed each one.

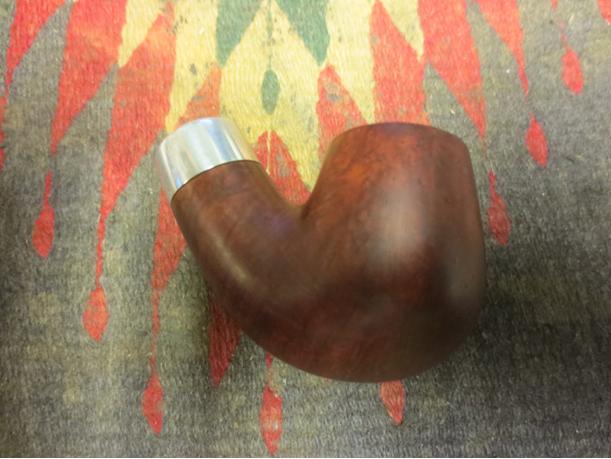

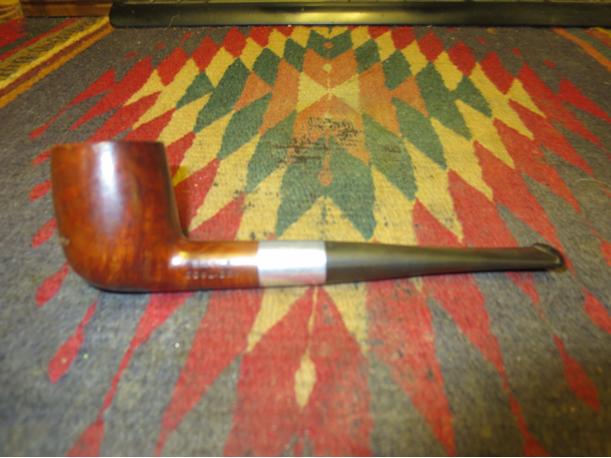

I gave the bowl a coat of dark brown aniline stain and flamed it with a lighter. I gave the pipe several more coats of stain and flamed each one. When the stain had dried I hand buffed it with a cloth and then gave it a light buff on the wheel with White Diamond. The first two side view photos of the bowl show it with a red tint that really is not as prevalent as it appears. The photo of the bottom of the bowl is more accurate in terms of the colour of the pipe.

When the stain had dried I hand buffed it with a cloth and then gave it a light buff on the wheel with White Diamond. The first two side view photos of the bowl show it with a red tint that really is not as prevalent as it appears. The photo of the bottom of the bowl is more accurate in terms of the colour of the pipe.

I sanded the repaired stem with 220 grit sandpaper to blend the repair into the surface of the stem. I sanded it with a medium and a fine grit sanding sponge to remove the scratches in the surface of the stem.

I sanded the repaired stem with 220 grit sandpaper to blend the repair into the surface of the stem. I sanded it with a medium and a fine grit sanding sponge to remove the scratches in the surface of the stem.

The stem was quite clean on the inside so it took only one pipe cleaner to take out the sanding dust that had collected inside.

The stem was quite clean on the inside so it took only one pipe cleaner to take out the sanding dust that had collected inside. I wet sanded the stem with 1500-2400 grit micromesh sanding pads and then rubbed it down with Obsidian Oil. I dry sanded with 3200-4000 grit pads and then gave it another coat of oil. I finished sanding it with 6000-12000 grit pads. I gave it a final coat of Obsidian Oil and let it dry.

I wet sanded the stem with 1500-2400 grit micromesh sanding pads and then rubbed it down with Obsidian Oil. I dry sanded with 3200-4000 grit pads and then gave it another coat of oil. I finished sanding it with 6000-12000 grit pads. I gave it a final coat of Obsidian Oil and let it dry.

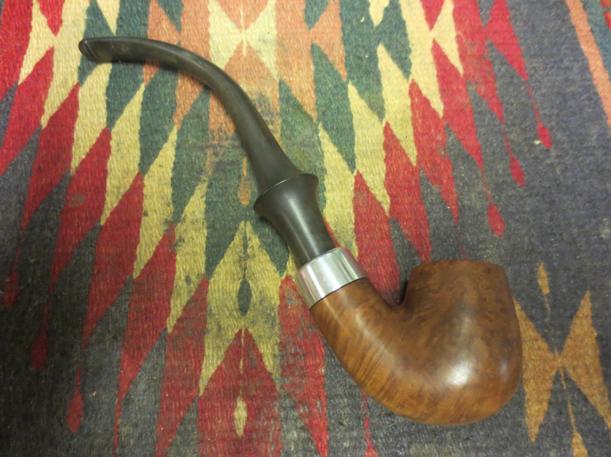

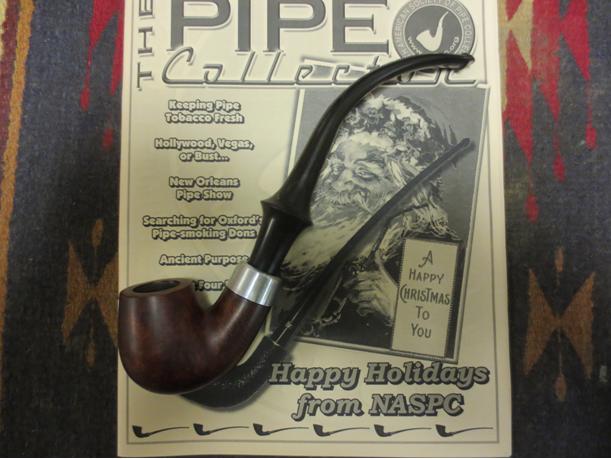

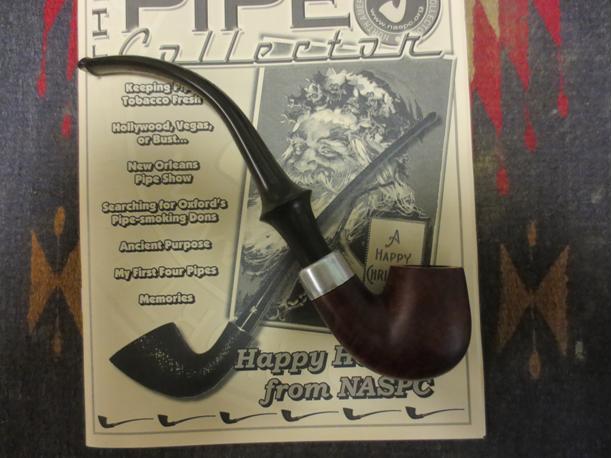

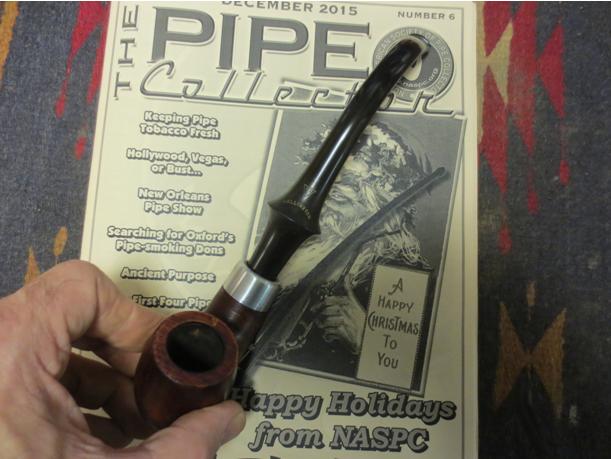

I buffed the pipe and stem on the wheel with Blue Diamond. I gave the aluminum a light buff so as not to darken the buffing pad and carry the metallic colour onto the vulcanite or the briar. I gave the bowl and stem multiple coats of carnauba wax and then buffed the pipe with a clean flannel buff. I finished by buffing it by hand with a microfibre cloth. The finished pipe is shown in the photos below. The glow of the briar and the vulcanite are really set off by the burnished aluminum portion of the stem. It is truly a beautiful pipe. Thanks for the pipe Pam it is a keeper. Thanks also to each of you who are reading this blog.

I buffed the pipe and stem on the wheel with Blue Diamond. I gave the aluminum a light buff so as not to darken the buffing pad and carry the metallic colour onto the vulcanite or the briar. I gave the bowl and stem multiple coats of carnauba wax and then buffed the pipe with a clean flannel buff. I finished by buffing it by hand with a microfibre cloth. The finished pipe is shown in the photos below. The glow of the briar and the vulcanite are really set off by the burnished aluminum portion of the stem. It is truly a beautiful pipe. Thanks for the pipe Pam it is a keeper. Thanks also to each of you who are reading this blog.