Blog by Steve Laug

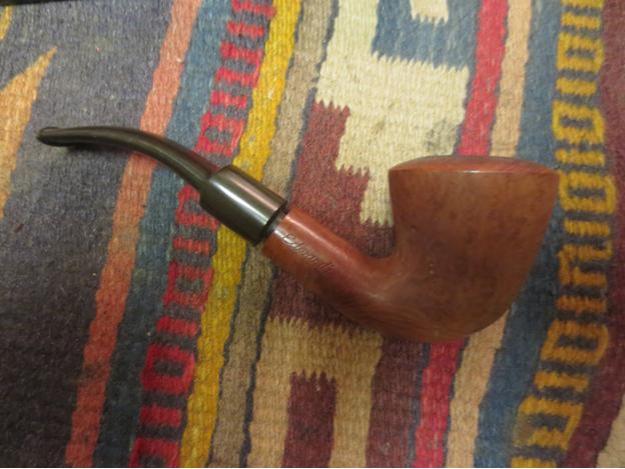

The second Edward’s pipe from the box I received to clean up and sell to support Smokers was a beautiful smaller sized apple with an acrylic/Lucite stem. It is stamped Edwards in script on the right side of the shank and European Collection on the left side. There is no shape number on this pipe. The finish was dirty, the rim had less lava overflow than others that came with this collection but it was present. The bowl had a thick crumbly cake. All of these pipes tended to have stickiness to the cake that makes me think that the pipes were used for aromatics. The shank was dirty with tars and oils. The stem is black acrylic with dark green swirls throughout that are accentuated in the light. It is a bit thick which leads me to believe that the pipe came from the 70’s or 80’s era. It is a saddle stem with an integral tenon turned from the Lucite. It was dull from the oils and disuse. It would be interesting to see the colours once it was shined up.

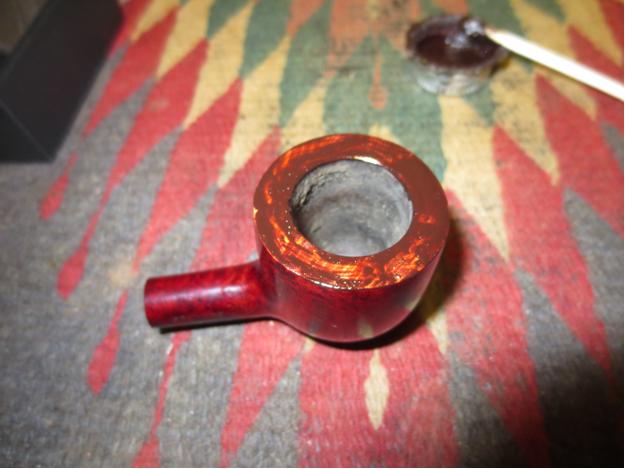

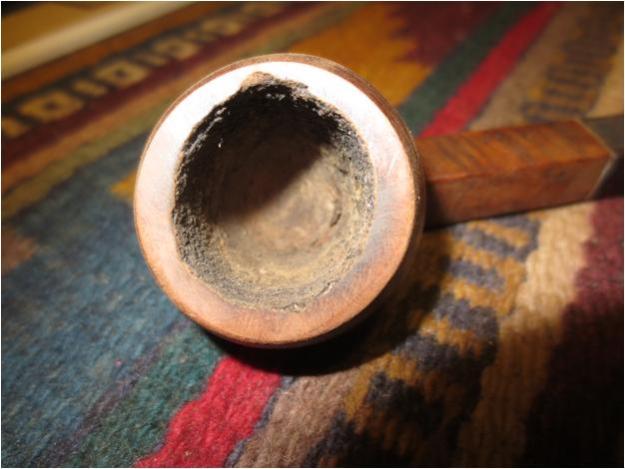

I took a close-up photo of the bowl to show the cake and the state of the rim. Fortunately the rim had no damage on the outer or inner edge.

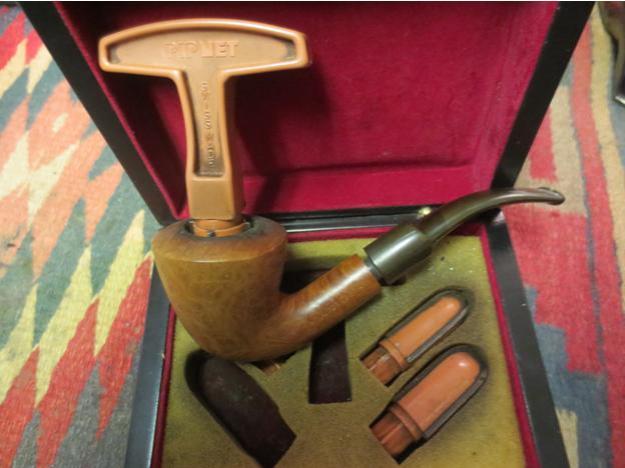

I took a close-up photo of the bowl to show the cake and the state of the rim. Fortunately the rim had no damage on the outer or inner edge. I reamed the bowl with the PipNet pipe reamer and took the cake back to bare wood. Whatever the previous tobacco was the cake was soft and crumbly.

I reamed the bowl with the PipNet pipe reamer and took the cake back to bare wood. Whatever the previous tobacco was the cake was soft and crumbly.

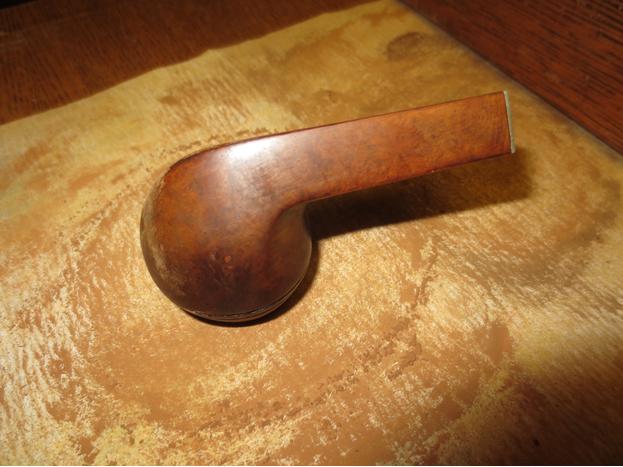

I dampened the rim and scrubbed it with 0000 steel wool to remove the lava that was on the top edges. It worked really well and the rim was clean in no time at all. I wiped down the bowl with alcohol on a cotton pad to remove the grime and oil that was in the finish. It took off all of the grim and left me with some beautiful mixed grain around the bowl.

I dampened the rim and scrubbed it with 0000 steel wool to remove the lava that was on the top edges. It worked really well and the rim was clean in no time at all. I wiped down the bowl with alcohol on a cotton pad to remove the grime and oil that was in the finish. It took off all of the grim and left me with some beautiful mixed grain around the bowl.

I scrubbed out the interior of the bowl and the shank with pipe cleaners, cotton swabs and alcohol to remove the tar and oil. I did the same with the stem and the chamfered tenon end.

I scrubbed out the interior of the bowl and the shank with pipe cleaners, cotton swabs and alcohol to remove the tar and oil. I did the same with the stem and the chamfered tenon end.

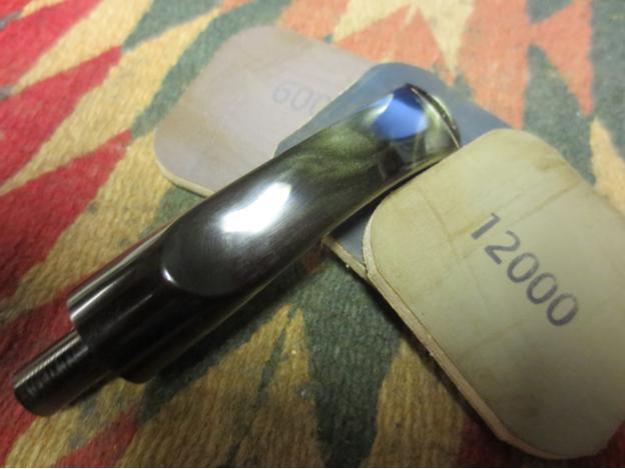

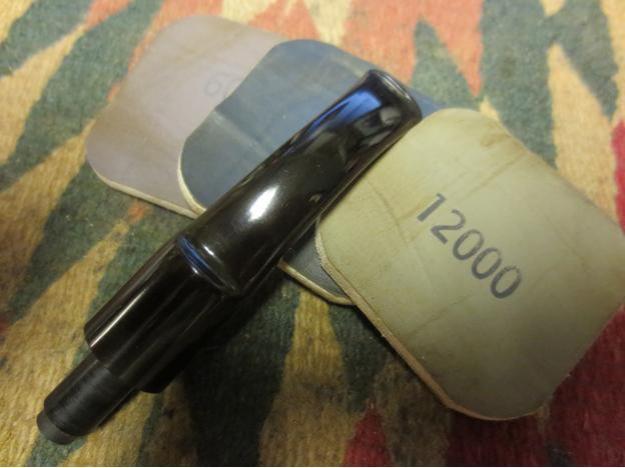

With the interior clean I turned my attention to the acrylic/Lucite stem. It had some light tooth chatter on the top and underside but was in pretty decent shape. The finish was dull and no longer smooth to the touch. I worked on it with micromesh sanding pads – wet sanding with 1500-2400 grit pads and dry sanding with 3200-12000 grit pads. I buffed it with Tripoli and White Diamond after I finished with the 4000 grit pad and then finished with the last three pads. As I polished it with the pads you could begin to see the colours come through the stem. It is a beautiful piece of Lucite.

With the interior clean I turned my attention to the acrylic/Lucite stem. It had some light tooth chatter on the top and underside but was in pretty decent shape. The finish was dull and no longer smooth to the touch. I worked on it with micromesh sanding pads – wet sanding with 1500-2400 grit pads and dry sanding with 3200-12000 grit pads. I buffed it with Tripoli and White Diamond after I finished with the 4000 grit pad and then finished with the last three pads. As I polished it with the pads you could begin to see the colours come through the stem. It is a beautiful piece of Lucite.

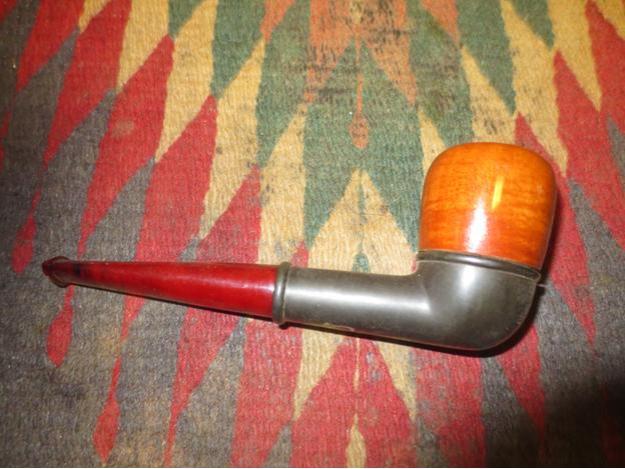

I buffed the bowl and the stem with Blue Diamond Plastic polish on the wheel and was amazed at the shine. I then gave the bowl and stem several coats of carnauba wax to protect it and give it a shine. I buffed it with a clean flannel buff and then hand buffed it with a mircrofibre cloth to raise depth to the shine. The finished pipe is shown in the photos below. I have to tell you that so far I really like the two Edward’s pipes that I have cleaned up out of this lot. They seem to be ringing all of my bells. It will be hard to part with either of them 😉

I buffed the bowl and the stem with Blue Diamond Plastic polish on the wheel and was amazed at the shine. I then gave the bowl and stem several coats of carnauba wax to protect it and give it a shine. I buffed it with a clean flannel buff and then hand buffed it with a mircrofibre cloth to raise depth to the shine. The finished pipe is shown in the photos below. I have to tell you that so far I really like the two Edward’s pipes that I have cleaned up out of this lot. They seem to be ringing all of my bells. It will be hard to part with either of them 😉