Blog by Steve Laug

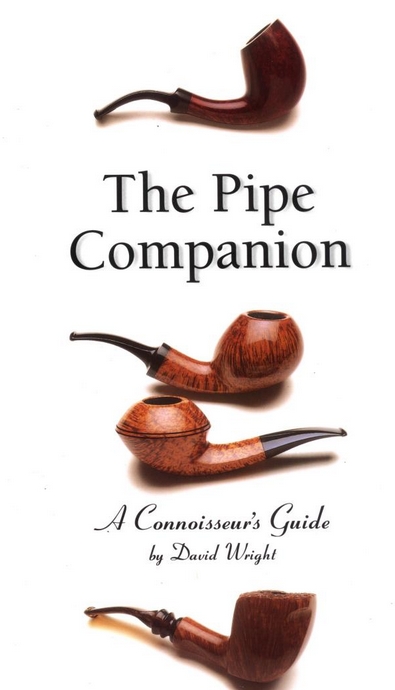

Several things about this book caught my attention when I first saw it. The first of course was the magnificent photography that graces the pages. It is literally packed with more than 125 full colour plates of pipes. The age of some of the pipes made me read the fly-leaf of the cover to know more about the author. That is when the second thing caught my attention, The Pipe Companion was written by David Wright who is the Curator of the Museum of Tobacco Art & History in Nashville, Tennessee, USA. What was interesting about that was the wealth of tobacciana that was available to the author at his work place. I was already hooked before I even read any of the text.

Several things about this book caught my attention when I first saw it. The first of course was the magnificent photography that graces the pages. It is literally packed with more than 125 full colour plates of pipes. The age of some of the pipes made me read the fly-leaf of the cover to know more about the author. That is when the second thing caught my attention, The Pipe Companion was written by David Wright who is the Curator of the Museum of Tobacco Art & History in Nashville, Tennessee, USA. What was interesting about that was the wealth of tobacciana that was available to the author at his work place. I was already hooked before I even read any of the text.

When I did read the fly-leaf on the cover it only solidified my commitment to purchase the book. I quote from there:

“Smoking a pipe is a refined, relaxing ritual. More than a tool for reflection, a well-crafted pipe is a work of art to be admired and appreciated. Whether made of clay, briar, or meerschaum, every pipe’s personality and history is evident I the beauty of its bowl and the style of its stem.”

“Profiling more than 50 master carvers from around the world and their elegant, yet functional creations, The Pipe Companion is the essential guide to the world of pipes. Within these pages you’ll explore the exquisite artistry of pipe making and enjoy a behind-the-scenes tour of carving styles and manufacturing techniques. You’ll also learn about the history of the pipe – from its North American origins to its spread throughout Europe and the Middle East to the wide variety of classical and freehand styles popular today (2000). Finally you’ll discover modern pipe-smoking customs and practices, as well as learn how to select, smoke, and care for your pipes.”

“Perfect for both pipe enthusiasts and anyone with a penchant for the occasional puff, The Pipe Companion provides practical advice along with a wealth of information. So lean back, fire up your pipe, and enjoy.”

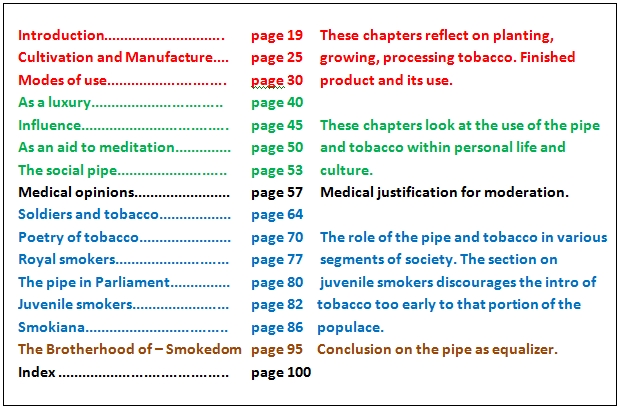

As with previous reviews I have written I include the table of contents to give an idea of how the author proceeds to do what is promised in the quotations from the preface or in this case the fly-leaf of the book’s cover. It is arranged in three parts with subsections underneath each part. It concludes with a glossary, a suggested reading list, pipe makers contact information and then ends with notes. PART 1: A Brief History of the Pipe – this first section of the book uniquely presents the standard pipe history that has been repeated in a variety of descriptive ways since Alfred Dunhill’s Pipe Book. However, what makes this presentation unique among the others is the beautiful photographs of the pipes from the early periods of history. He looks at the origins of the pipe from Native American pipes to those developed later in Europe when tobacco was brought there.

PART 1: A Brief History of the Pipe – this first section of the book uniquely presents the standard pipe history that has been repeated in a variety of descriptive ways since Alfred Dunhill’s Pipe Book. However, what makes this presentation unique among the others is the beautiful photographs of the pipes from the early periods of history. He looks at the origins of the pipe from Native American pipes to those developed later in Europe when tobacco was brought there.

After giving a very brief description of the origins with photos the author turns to the different types of material that have been used for making pipes. Again this section is graced with beautiful photographs illustrating the pipes made of each material. There are paragraphs on Clay Pipes, Wood Pipes, Porcelain Pipes, Meerschaum Pipes, and Briar Pipes. This section ends with an inserted article on Pipe Production. The interest in artisans who made these pipes sets the stage for the later PART THREE which looks at Pipe Makers.

The author’s style is engaging and enjoyable to read. You are carried forward through the chapter as he unfolds the history, interjecting stories and incidents among the photos of the pipes that illustrate his points. It is well written and flowing in style.

PART 2: The Art of Pipe Making – the second section covers pipe making from the perspective of one person shops to medium-sized factories. Again this PART 2 sets the stage for PART 3 on Pipe Makers. It does this with reference to the fact that before looking at the variety of pipe makers that it is important to understand how block meerschaum and briar are carved from their natural state into functional and artistic pipes.

The first chapter is on the materials that pipes are made from. The first section in this chapter is on meerschaum. It looks at the history of meerschaum and how it is mined and then refined and carved into pipes. There are pictures in the section that show raw meerschaum and ornate figural and design pipes carved from meer.

This is followed by a section on briar. There again the author looks at the agriculture of briar and where it grows and how it is harvested. Then the section looks at the seasoning/curing of the briar and finally how the blocks are cut and then carved into pipes.

The next section covers carving in all of its aspects. There are beautiful photos of figural pipes, carving and then finally of bending the stems that were used. Even machine-made pipes are discussed. It is interesting to note that the author says that even machine-made pipes involve a lot of hand work – sanding, shaping, finishing etc. are all done by hand.

The second chapter describes how to select a pipe. The author likens buying a pipe to buying a car. He discusses the materials that go into making a pipe, the finish and compares machine-made to handmade pipes and closes the chapter by discussing the features of a pipe. He states that the most important feature is free air passage from the bowl to your mouth – mechanics.

The third chapter discusses the how to of smoking a pipe. Truly this section should be called breaking in a new pipe and interestingly the author gives a sub-title part way through the text where he gives it that title. He discusses bowl coatings, various methods of loading a pipe including the Frank method with a brief segue into choice of tobacco. Then he moves to talking about lighting the pipe, tamping the tobacco and concludes with after smoking care and cleaning of the pipe.

PART 2 is a well written concise exposition of the pipe – materials, selection and smoking. It is written in an engaging way but always with the awareness of what is ahead in PART 3 of the book. There is a building excitement in the chapters about the various pipe makers that will be discussed ahead.

PART 3: The Pipe Makers Directory – The remainder, and by far the largest part of the book is the present one. The author has arranged his list of hand-picked pipe makers by country for ease of reference. Quoting from Wright’s introduction to this part of the book:

“As you examine the different carvers around the world and their unique interpretations, you’ll notice similarities and schools of art. The oldest briar school, for example, is centered in Saint-Claude, France. Italy has two distinct schools of carving, while the other Scandinavian countries have a look all their own. Then, there are the United States and Japan. The variety of styles and techniques in the United States reflect America as the proverbial melting pot. In Japan, styling can by very Japanese or exhibit a combination of Japanese and Danish features.” Page 57

“Modern briar and meerschaum pipe styles can be divided into two broad categories: classic and freehand. The classic style has its origins in early French and English pipes. The proportions of the bowl and the stem: length, height, and diameter are standardized in these pipes. Many of the names of classic pipe shapes and styles were chosen many generations ago and reflect the shape or appearance of the pipe… Freehand was a term coined for the “wild” or “organic” designs of Danish pipes that first appeared in the late 1950s. Freehand implies that the pipe carved at the whim of the carver. A truer definition is that the pipe design is governed by the grain of the wood. No two freehand pipes are carved alike, nor do they conform to any one style.” Page 58

Following the short introduction, from which the two quotes above are taken, the author proceeds to move through the various countries he has chosen. In each country he has chosen pipe makers to highlight and includes photographs of their work. This catalogue of pipe makers is the highlight of the book to me and a section I turn to repeatedly. I will list each country as the author has organized them and then give a list of the pipe makers he covers in each one. I don’t know what your thoughts will be but I was surprised by the listings and found there were several I had not heard of previously.

Canada: J. Calich (p.59-61), Julius Vesz (p.62-63).

Corsica: L.J. Georges (p.64-66).

Denmark: Bang’s Pibemageri (p.68-69), Jess Chonowitsch (p.70-72), Lars Ivarsson (p.72-74), Jorn (p.74-75), Anne Julie (p.75-77), W.O. Larsen (p.77-79), Nording (p.79-80), Stanwell (p.81).

France: Butz-Choquin (p.82-83).

Germany: Holger Frickert (p.84-86), Karl-Heinz Joura (p.86-88), Manuel Shaabi (p.88-90).

Great Britain: Ashton (p.91-94), Castleford (p.94-95), Dunhill (p.95-98), Ferndown (p. 98-99).

Ireland: Peterson (p.100-101).

Italy: Ardor (p.103-104), Paolo Becker and Becker & Musico (p.104-106), Brebbia (p.106-108), Castello (p.108-110), Il Ceppo (p.110-111), Mastro de Paja (p.111-113), Radice (p.113-115), Savinelli (p.115-118), Ser Jacopo (p.118-119).

Japan: Shizuo Arita (p. 120-121), Jun’ichiro Higuchi (p.121-122), Tsuge Pipe Company (p.123-124).

Spain: Joan Saladich y Garriga (p.123-127).

Sweden: Bo Nordh (p.128-130).

Turkey: Ismet Bekler (p.132), Yunas Ege (p.133), Sevket Gezer (p.134), Huseyin and Mustafa Sekircioglu (p.133-134), Salim Sener (p.134), Sadik Yanik (p.135).

United States: E. Andrew, Briars (p.136-138), Alfred Baier (p.138-140), Boswell’s Pipe & Tobacco (p.140-142), J.T. & D. Cooke (p.142-144), Cristom (p.144-147), Jody Davis Princeton Pipes (p.147-149), Dr. Grabow (p.149-151), Fairchild Pipes (p.151-153), David Jones Briar Pipes (p.153-155), Kaywoodie (p.155-157), Kirsten Pipe Company, Inc. (p.157-159), Sam Learned (p.159-161), Lucille Ledone (p.161-162), Andrew Marks (p.163-165), Mr. Groum Pipes (p.165-167), Clarence Mickles (p.167-168), Elliott Nachwalter Pipestudio (p.168-170), Denny Souers (p.170-172), Trever Talbert (p.173-174), Mark Tinsky American Smoking Pipe Company (p.175-176) Von Erck’s Pipes & Repairs (p.176-178), Roy Roger Webb (p.178-180), Steve Weiner (p.181-182), Tim West (p.182-186), Randy Wiley (p.186-187)

From the above information it is obvious that the largest portion of the pipe makers included is from the United States. I am assuming that this is because of the author’s location. However, within each section there is a concise biographical note on the pipe maker and a description of the style and where they fit within the classic/freehand division that introduced PART 3. The photos in this section are absolutely stunning and give a good idea of the style, quality and craftsmanship of the makers. I will continue to use this book as a reference to the works of the makers covered and as a wish book of pipes I want to add to the collection.

The book ends with some sections that could easily be skipped to the detriment of the reader. The Glossary gives excellent definitions of the terminology of pipe making. These definitions are concise and helpful. The Suggested Reading bibliography is a great resource and one that I use as a checklist of published materials on pipes and tobaccos – both books and periodicals. The Pipe Makers Contact Information is worth a look as well if you want to contact any of the above makers for a commission or just write them a thank you note for a great pipe you are smoking. The book ends with Notes that really are endnotes for the chapters in the book giving bibliographical notes for information used from other references.

I can heartily recommend The Pipe Companion – a Connoisseur’s Guide by David Wright to every pipe collector and collector of books and information on pipes. It is a resource that is well written, well illustrated and unusually thorough in the kind of information that is resourced in the book. It is an ongoing pleasure to read repeatedly or to just thumb through and enjoy the pipe photography that graces the pages from the beginning to the end. If you have not picked this one up you really owe it to yourself to get a copy before it too goes out of print.