Blog by Steve Laug

I picked this old pipe up on EBay for a very cheap price. In fact I think the postage was more than the pipe. I had read on the forums that John Bessai carved some great smoking pipes.

Pipedia has this information http://pipedia.org/index.php?title=Bessai

John Bessai was a long time pipemaker, repairman and tobacco shop owner who operated his pipe shop at the “Old Arcade” in Cleveland, Ohio. The shop was opened in approximately 1898. It was a small 2-room shop where he hand-crafted his own pipes in the back room and could work when customers were not there. Like so many other shop made brand, John Bessai’s limited production was quickly acquired by regular customers and thus his craftsmanship remained little known outside of Ohio and the Midwest. While his name is known by pipe collectors in the Midwest, his work is seldom seen elsewhere! He died before 1969. Nevertheless, John Bessai left behind a small number of classic shaped pipes; all were made on-site. They are praised worthy of collecting and reflecting skills well beyond most American pipe makers. John Bessai’s logo “JB” appeared as one letter as the “back” of the “J” and the “back” of the “B” share a single line. The logo was stamped on the stem and on the left side of the shank. His son Herb Bessai took over the business and also continued making pipes. He closed the shop in about 1978.

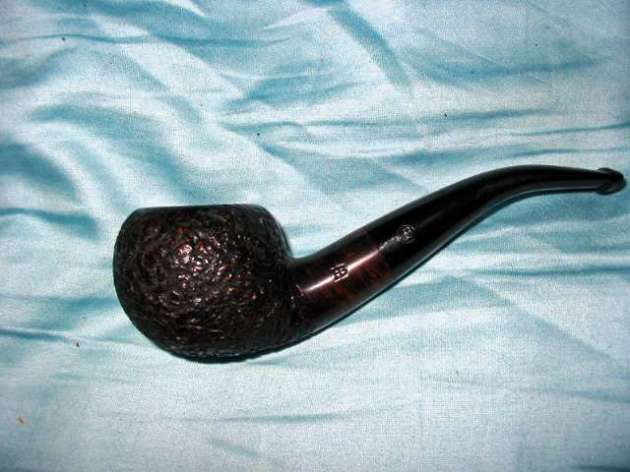

I was excited to have one of his pipes and looked forward to its arrival here in Canada. When it came and I opened the package I loved the shape and the feel of the pipe, but the large fills really bugged me. I cleaned up the pipe and gave it a smoke to see if I would even keep it. It smoked incredibly well and the draw was effortless. It was comfortable and lightweight so it seemed like one that I would keep. But what to do with the fills that covered the right side and the front of the bowl puzzled me. I wanted to keep the pipe clearly a Bessai pipe. I did not want to destroy what he had carved but I wanted to do something to deal with the fills.

So I decided to rusticate it with a leather-like rustication and then give it a contrast stain on it give it an interesting look. I used my rustication tool (the pipe and nails that I have written about in another post on the blog) to cut into the finish and rusticate the surface of the bowl. Once the bowl was rusticated to the place I liked I took it to the buffer and buffed off the rough spots and made the overall surface smooth to the touch. I then stained it with a coat of black aniline stain and flamed it to set the stain. Once it was dry I took it to the buffer and removed the black stain on the high spots with a Tripoli buffing pad. I then took it back to the desk and gave it a coat of medium brown aniline stain and flamed it. I let it dry and then buffed it with White Diamond. I then buffed the whole pipe with White Diamond to polish the stem and bowl and gave it several coats of carnauba wax. I used a light touch on the bowl as I did not want to fill the grooves with wax.