by Steve Laug

The next pipe is on the table is an interesting looking smooth volcano shaped pipe with a vulcanite saddle stem. Jeff and I purchased it on 08/28/2024 from Antique Store in Astoria, Oregon, USA. The pipe is well shaped and has nice grain around the bowl. It has a flat thin rim top and a rounded heel on the bowl. The pipe is stamped on the left side of the shank and reads Richmond [over] London Made. On the right side it is stamped with the shape number 190 [over] Made in England. There was grime and dust ground into the smooth finish of the bowl and shank. The bowl was heavily caked with lava on the rim top and edges. The inside edge looks like it may actually be undamaged under the lava coat. The outer edge looks very good. The vulcanite saddle stem was oxidized, calcified and had tooth chatter and marks on the top and underside near the button and on the button edge. There was no logo or stamping on the stem at all. The pipe showed a lot of promise but it was very dirty. Jeff took some photos of the pipe before he started his cleanup work.

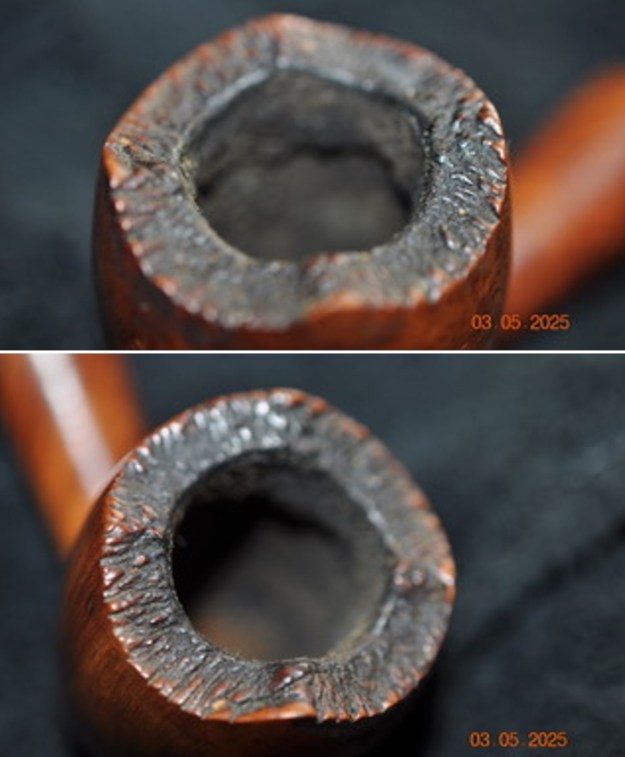

He took photos of the rim top and bowl to give a clear picture of the thickness of the cake and tobacco debris as well as the inner edge of the rim. He also took photos of the top and underside of the stem. The photos show the overall condition of the stem.

He took photos of the rim top and bowl to give a clear picture of the thickness of the cake and tobacco debris as well as the inner edge of the rim. He also took photos of the top and underside of the stem. The photos show the overall condition of the stem.

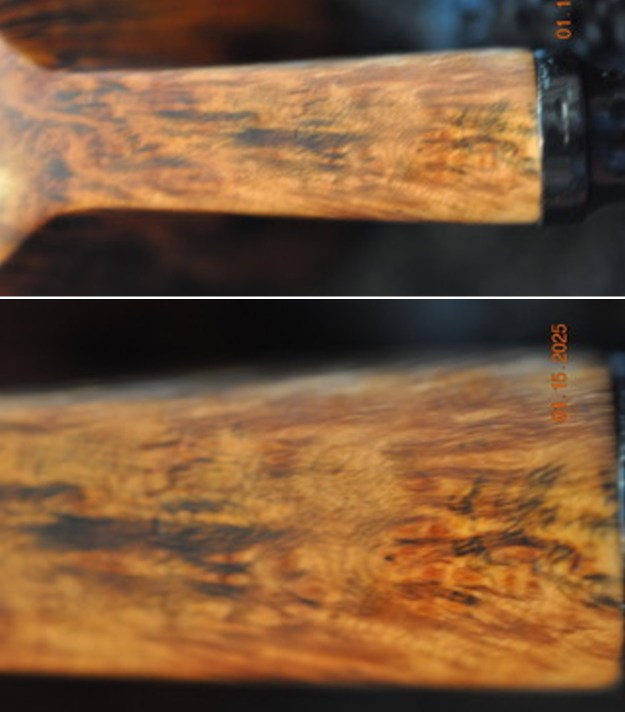

Jeff took photos of the sides and heel of the bowl to give a picture of what the briar looked like. It truly has some nice grain around the bowl and shank.

Jeff took photos of the sides and heel of the bowl to give a picture of what the briar looked like. It truly has some nice grain around the bowl and shank.

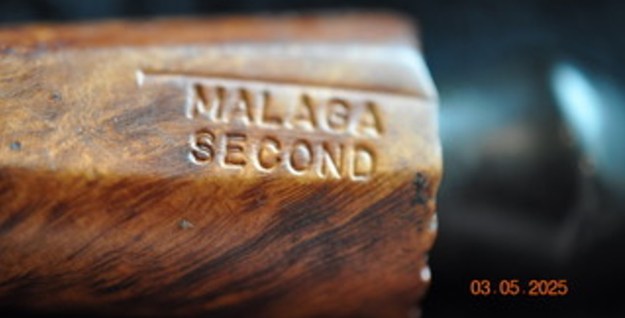

The stamping on the underside of the shank is clear and readable and read as noted above. Jeff took several photos to capture the stamping on the underside of the shank.

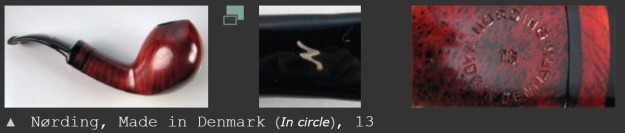

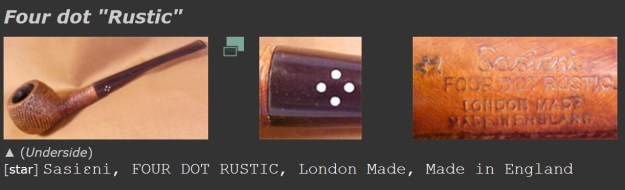

The stamping on the underside of the shank is clear and readable and read as noted above. Jeff took several photos to capture the stamping on the underside of the shank. The shape and conformation of this pipe reminded me of a Sasieni Four Dot Ruff Root Richmond Volcano I had worked on in the past. Here is a link to that pipe and I think you can see the similarity (https://rebornpipes.com/2020/10/04/restoring-a-sasieni-four-dot-ruff-root-richmond-volcano/). The curves of the bowl and shank match quite well as do the angles of the walls of the bowl. I need to do a bit more work but I think there is a potential Sasieni connection with this one.

The shape and conformation of this pipe reminded me of a Sasieni Four Dot Ruff Root Richmond Volcano I had worked on in the past. Here is a link to that pipe and I think you can see the similarity (https://rebornpipes.com/2020/10/04/restoring-a-sasieni-four-dot-ruff-root-richmond-volcano/). The curves of the bowl and shank match quite well as do the angles of the walls of the bowl. I need to do a bit more work but I think there is a potential Sasieni connection with this one.

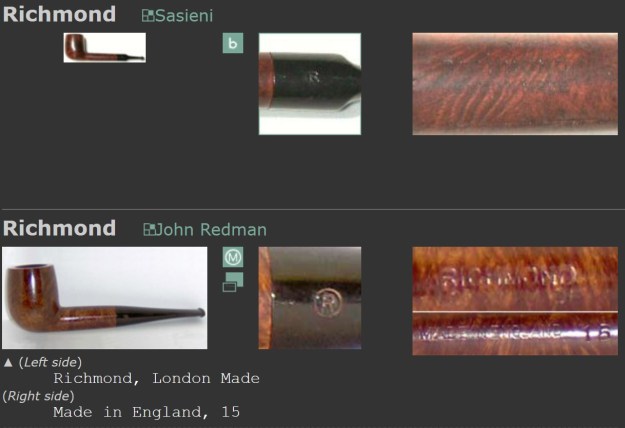

I turned to Pipephil (http://www.pipephil.eu/logos/en/logo-r4.html) and found a listing for Richmond pipes – actually two of them. The first links the brand to Sasieni and the second links it to John Redmond. The stamping on both is similar however the Richmond stamp and the Made in England stamp is virtually identical to the John Redman. Pipedia confirmed that the Richmond brand is a Sasieni sub-brand or second. Here is the link for that information (https://pipedia.org/wiki/British_Pipe_Brands_%26_Makers_R_-_T). Given the information on Pipephil I lean toward the pipe being a John Redmond made pipe.

Pipedia confirmed that the Richmond brand is a Sasieni sub-brand or second. Here is the link for that information (https://pipedia.org/wiki/British_Pipe_Brands_%26_Makers_R_-_T). Given the information on Pipephil I lean toward the pipe being a John Redmond made pipe.

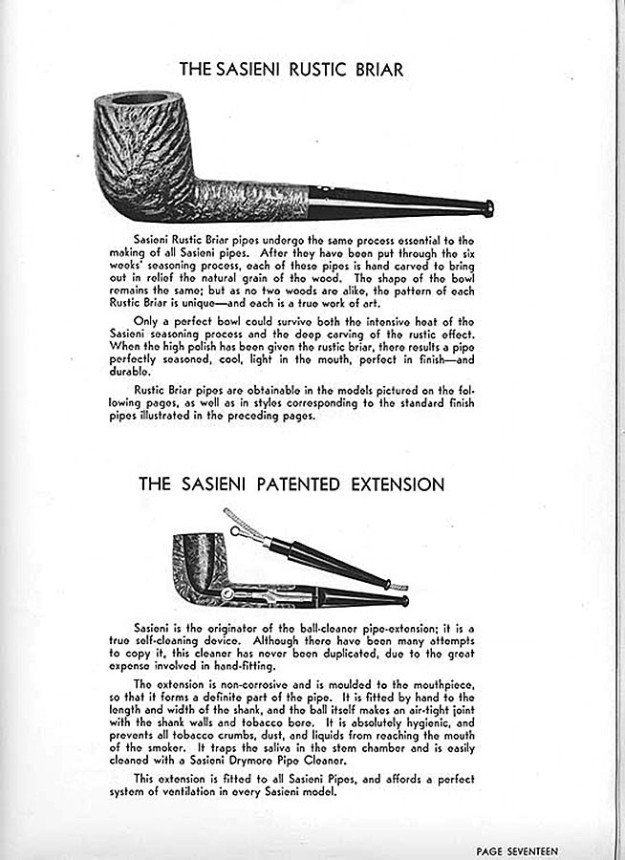

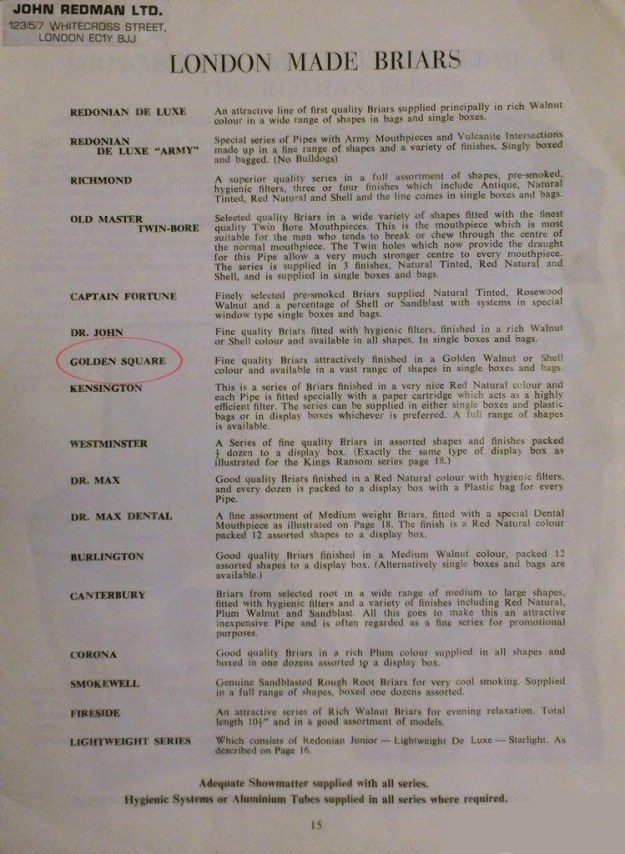

In googling the shape and brand further a link took me to the blog and to a post I had made on a John Redman Leaflet (https://rebornpipes.com/2020/02/04/john-redman-leaflet/). The third pipe down on the London Made Briar list (stamped on the pipe in hand) is the Richmond.

The description says that the Richmond is a superior quality series in a full assortment of shapes, pre-smoked, hygienic filters, three or four finishes which include Antique, Natural Tinted, Red Natural and Shell and the line comes in single boxes and bags.  I think that confirms that it is indeed a John Redman Pipe with a Red Natural Finish. Now it was time to work on the pipe itself.

I think that confirms that it is indeed a John Redman Pipe with a Red Natural Finish. Now it was time to work on the pipe itself.

Jeff had cleaned up the pipe with his usual penchant for thoroughness. He reamed the pipe with a PipNet pipe reamer and removed the rest of it with a Savinelli Fitsall Pipe Knife. He scrubbed the bowl with undiluted Murphy’s Oil Soap with a tooth brush. He rinsed it under running warm water to remove the soap and grime. He cleaned out the inside of the shank and the airway in the stem with alcohol, cotton swabs, shank brushes and pipe cleaners. He soaked the stem in a Briarville’s Pipe Stem Deoxidizer bath and rinsed it off with warm water. I took photos of the pipe before I started my part of the restoration work. It looked very good with just a slight tinge of remaining oxidation on the stem.

The rim top cleaned up really well. The rim top, inner and outer edge of the bowl are in excellent condition. The stem surface looked very good with a few tooth marks and chatter on both sides near the button. There was also some remaining oxidation.

The rim top cleaned up really well. The rim top, inner and outer edge of the bowl are in excellent condition. The stem surface looked very good with a few tooth marks and chatter on both sides near the button. There was also some remaining oxidation.  The stamping on the shank sides is faint in spots, double stamped but is nonetheless readable. It is stamped as noted above. I removed the stem and took a photo of the pipe to give a sense of the whole. The taper stem is nice and the photo gives a sense of what the pipe looks like.

The stamping on the shank sides is faint in spots, double stamped but is nonetheless readable. It is stamped as noted above. I removed the stem and took a photo of the pipe to give a sense of the whole. The taper stem is nice and the photo gives a sense of what the pipe looks like.

The pipe is was in such good shape that I started my work on it by sanding the bowl with 320-3500 grit 2 x 2 inch sanding pads. I wiped the bowl down after each sanding pad with a damp cloth to remove the sanding debris. It began to take on a rich shine.

The pipe is was in such good shape that I started my work on it by sanding the bowl with 320-3500 grit 2 x 2 inch sanding pads. I wiped the bowl down after each sanding pad with a damp cloth to remove the sanding debris. It began to take on a rich shine.

I polished the briar with micromesh sanding pads – dry sanding with 1500-12000 grit pads. I wiped the bowl down after each pad with a damp cloth to remove the sanding dust. By the end of the process the pipe bowl looked very good.

I polished the briar with micromesh sanding pads – dry sanding with 1500-12000 grit pads. I wiped the bowl down after each pad with a damp cloth to remove the sanding dust. By the end of the process the pipe bowl looked very good.

I worked some Before & After Restoration Balm into the surface of the briar with my fingertips on the smooth. The product works to clean, enliven and protect the briar. I let the balm sit for 15 minutes and then buffed with a cotton cloth to raise the shine. The photos show the bowl at this point in the restoration process.

I worked some Before & After Restoration Balm into the surface of the briar with my fingertips on the smooth. The product works to clean, enliven and protect the briar. I let the balm sit for 15 minutes and then buffed with a cotton cloth to raise the shine. The photos show the bowl at this point in the restoration process.

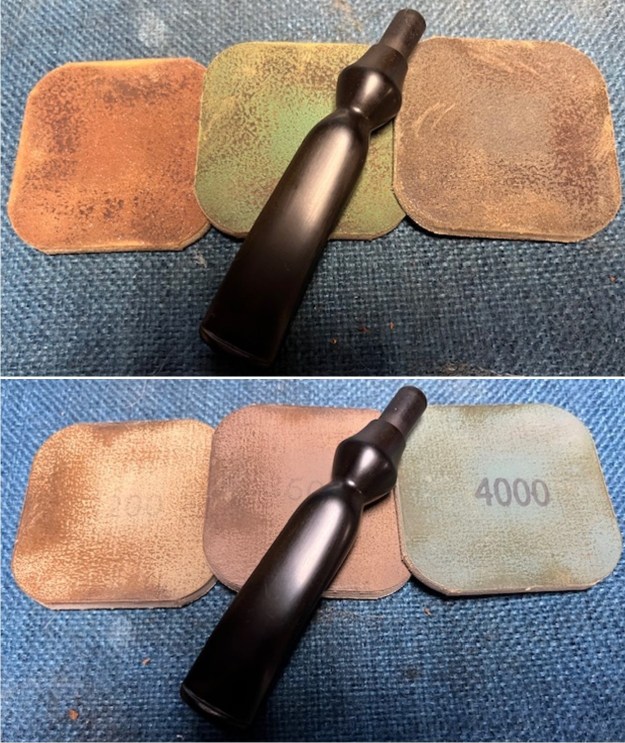

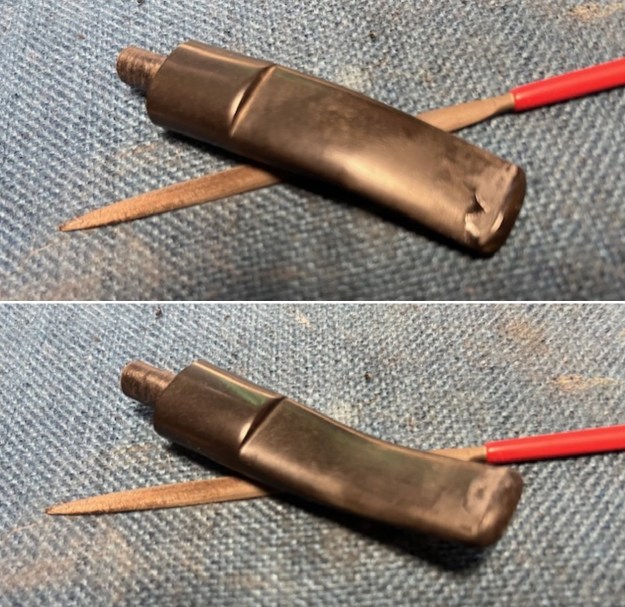

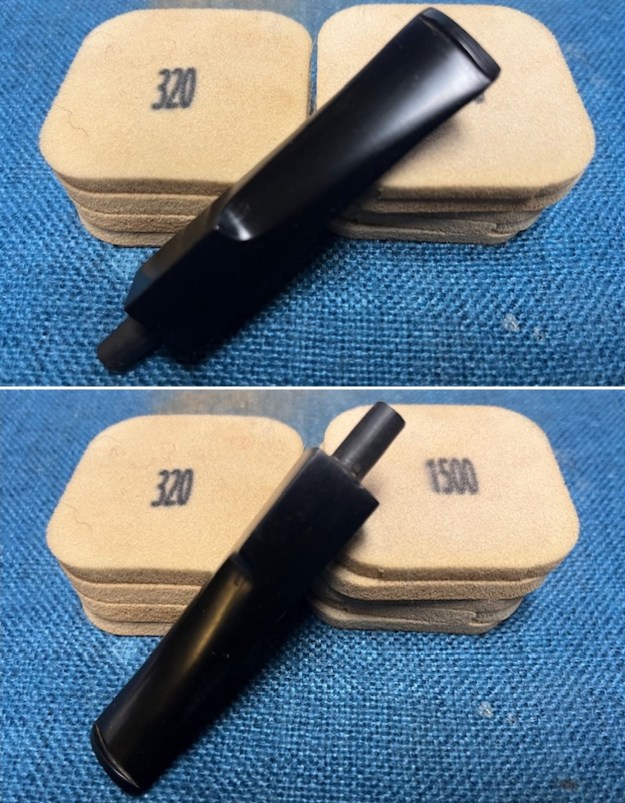

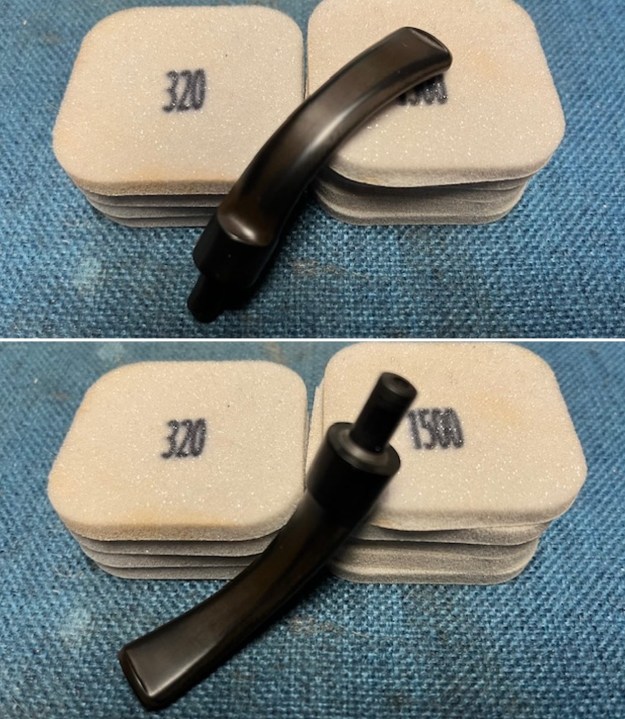

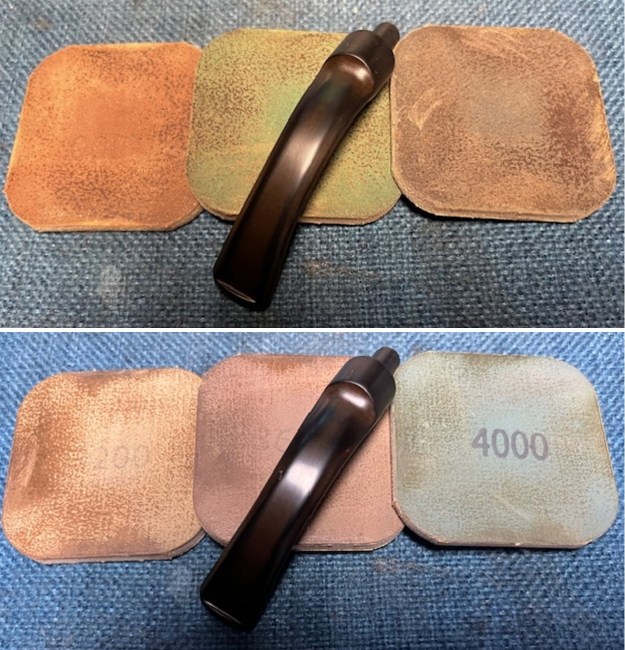

I set the bowl aside and turned my attention to the vulcanite stem. I sanded the stem with 320-3500 grit sanding pads to remove the tooth marks and chatter against the button edge. I wiped the stem down between pads with an Obsidian Oil cloth to remove the sanding debris from the stem.

I set the bowl aside and turned my attention to the vulcanite stem. I sanded the stem with 320-3500 grit sanding pads to remove the tooth marks and chatter against the button edge. I wiped the stem down between pads with an Obsidian Oil cloth to remove the sanding debris from the stem. I polished the stem with micromesh sanding pads – dry sanding with 1500-12000 grit sanding pads. I wiped it down after each sanding pad with Obsidian Oil. I polished it with Before & After Pipe Stem Polish – both Fine and Extra Fine.

I polished the stem with micromesh sanding pads – dry sanding with 1500-12000 grit sanding pads. I wiped it down after each sanding pad with Obsidian Oil. I polished it with Before & After Pipe Stem Polish – both Fine and Extra Fine.

This smooth, nicely grained Richmond Volcano is a great looking pipe now that it has been restored. The rich finish gives the shape an elegant look. The flow of the bowl and stem are well done make for a great hand feel. I put the stem back on the bowl and carefully buffed the pipe with Blue Diamond on the buffing wheel using a light touch on the briar. I gave the bowl and the stem multiple coats of carnauba wax on the buffing wheel. I buffed the entire pipe with a clean buffing pad. I hand buffed the pipe with a microfiber cloth to deepen the shine. The finished John Redmond London Made Richmond Volcano fits nicely in the hand and feels great. Give the finished pipe a look in the photos below. The dimensions of the pipe are Length: 5 inches, Height: 1 ¾ inches, Outside diameter of the bowl: 1 ¼ inches, Chamber diameter: 7/8 of an inch. The weight of the pipe is 45 grams/1.59 ounces. It is a great looking and light weight pipe. I will be putting it on the rebornpipes store shortly. If you are interested in adding this pipe to your collection send me a message or an email. Thanks for reading this blog and my reflections on the pipe while I worked on it. There are many more to come!

This smooth, nicely grained Richmond Volcano is a great looking pipe now that it has been restored. The rich finish gives the shape an elegant look. The flow of the bowl and stem are well done make for a great hand feel. I put the stem back on the bowl and carefully buffed the pipe with Blue Diamond on the buffing wheel using a light touch on the briar. I gave the bowl and the stem multiple coats of carnauba wax on the buffing wheel. I buffed the entire pipe with a clean buffing pad. I hand buffed the pipe with a microfiber cloth to deepen the shine. The finished John Redmond London Made Richmond Volcano fits nicely in the hand and feels great. Give the finished pipe a look in the photos below. The dimensions of the pipe are Length: 5 inches, Height: 1 ¾ inches, Outside diameter of the bowl: 1 ¼ inches, Chamber diameter: 7/8 of an inch. The weight of the pipe is 45 grams/1.59 ounces. It is a great looking and light weight pipe. I will be putting it on the rebornpipes store shortly. If you are interested in adding this pipe to your collection send me a message or an email. Thanks for reading this blog and my reflections on the pipe while I worked on it. There are many more to come!