Blog by Steve Laug

The next pipe that I chose to work on is a bit of a mystery pipe that Jeff and I picked up but have no real memory of when or where. It is a sandblast volcano pipe that has a flat bottom making it a sitter. The pipe was coated in a heavy coat of varnish that made it shiny and a mess. There was a chip on rear outer edge of the bowl. It was stamped on the underside of the shank and reads CHA…[over] Bruyere. The finish was dirty and tired but had a great sandblast with grain that. The bowl had a moderate cake inside and a lava overflow and darkening on the back rim edge and top. The vulcanite stem was oxidized and had light tooth chatter and marks on the stem near the button on both sides. It had a white circle C stamp on the left side of the stem. It had a great shape to it and the blast was well done. Jeff took photos of the pipe before his cleanup.  He took photos of the rim top to show the condition of the top and edges of the bowl. The cake in the bowl, the lava on the back side of the rim top and the wear on the outer edges are visible. The stem had light tooth marks and chatter on both sides ahead of the button.

He took photos of the rim top to show the condition of the top and edges of the bowl. The cake in the bowl, the lava on the back side of the rim top and the wear on the outer edges are visible. The stem had light tooth marks and chatter on both sides ahead of the button.

Jeff took the stem off the pipe and took some photos of the stinger apparatus in the tenon and the look of the shank end and mortise.

Jeff took the stem off the pipe and took some photos of the stinger apparatus in the tenon and the look of the shank end and mortise. He took photos of the sides and heel of the bowl to show the sandblast around the bowl and the condition of the pipe. It is a very unique looking pipe. You can also see the peeling and chipping varnish coat on the bowl sides.

He took photos of the sides and heel of the bowl to show the sandblast around the bowl and the condition of the pipe. It is a very unique looking pipe. You can also see the peeling and chipping varnish coat on the bowl sides.

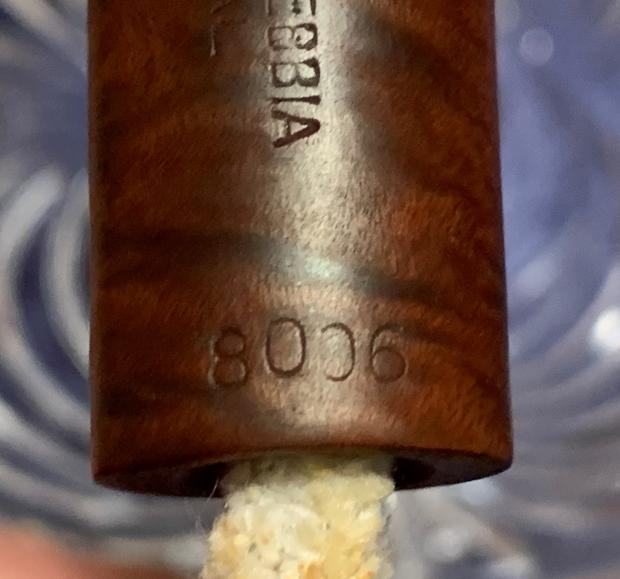

He took photos of the stamping on the underside of the shank and also of the Circle C stamp on the left side of the saddle stem. It is clear and readable as noted above.

He took photos of the stamping on the underside of the shank and also of the Circle C stamp on the left side of the saddle stem. It is clear and readable as noted above. I turned first to Pipephil’s site to have a look at what was listed there in terms of pipes with stamping starting with a CHA… I wanted to see if I could decipher the mystery of the brand on this pipe. I scrolled through the list of pipes beginning with those three letters to see if any stood out as possible candidates. There were so many options and nothing stood out. Then it dawned on me that there was also a circle C stamp on the left side of the saddle stem. Perhaps with those two pieces in place I could connect the dots and find the brand. Then it was clear that I was dealing with a CHATAM Pipe. I did a screen capture of the section and have included it below (http://pipephil.eu/logos/en/logo-c4.html).

I turned first to Pipephil’s site to have a look at what was listed there in terms of pipes with stamping starting with a CHA… I wanted to see if I could decipher the mystery of the brand on this pipe. I scrolled through the list of pipes beginning with those three letters to see if any stood out as possible candidates. There were so many options and nothing stood out. Then it dawned on me that there was also a circle C stamp on the left side of the saddle stem. Perhaps with those two pieces in place I could connect the dots and find the brand. Then it was clear that I was dealing with a CHATAM Pipe. I did a screen capture of the section and have included it below (http://pipephil.eu/logos/en/logo-c4.html).  I turned to Pipedia to see what I could learn. There was nothing that I could find listed there so I was limited to the information on Pipephil’s site.

I turned to Pipedia to see what I could learn. There was nothing that I could find listed there so I was limited to the information on Pipephil’s site.

I knew that I was dealing with a Chatham pipe. It was stamped Chatham Bruyere on the underside of the shank. The Circle C stamp on the left side of the saddle was also the piece that gave me the link to the brand. Knowing that I had the background I needed for the brand and it was time to work on the pipe itself.

As usual Jeff had done an cleanup on the pipe. He reamed the bowl with a PipNet pipe reamer and followed up with a Savinelli Fitsall pipe knife to remove the cake. He scrubbed out the mortise and the airway in the shank and the stem with alcohol, cotton swabs and pipe cleaners. He scrubbed the exterior of the bowl, rim, shank and stem with a tooth brush and acetone to cut through the varnish coat on the finish. Once it was cleaned off the finish he scrubbed the bowl with a tooth brush and Murphy’s Oil Soap to remove the remaining grime on the finish of the bowl. He rinsed it under running water. One of the benefits of this scrub is that it also tends to lift some of the scratches and nicks in the surface of the briar. He dried it off with a soft cloth. He cleaned the internals and externals of the stem with alcohol, pipe cleaners and cotton swabs. He soaked the stem in Briarville’s Pipe Stem Deoxidizer and rinsed it off with warm water and cleaned out the airway in the stem with alcohol. When I received it the pipe looked very good.

I took a photo of the rim top and stem to show the condition. The rim top and the inner edge of the bowl were in good condition. There were some nicks on the back outer edge of the bowl but otherwise it looked good. The stem was vulcanite and there were some tooth marks and chatter on both sides ahead of the button.

I took a photo of the rim top and stem to show the condition. The rim top and the inner edge of the bowl were in good condition. There were some nicks on the back outer edge of the bowl but otherwise it looked good. The stem was vulcanite and there were some tooth marks and chatter on both sides ahead of the button. The stamping on the pipe is well hidden in the sandblast of the pipe. If you look at the photo below carefully you will see the stamping as noted above.

The stamping on the pipe is well hidden in the sandblast of the pipe. If you look at the photo below carefully you will see the stamping as noted above.  I removed the stem from the shank and took a photo of the pipe to give a sense of the whole. The first photo shows the stinger in the tenon and the second shows the stinger removed.

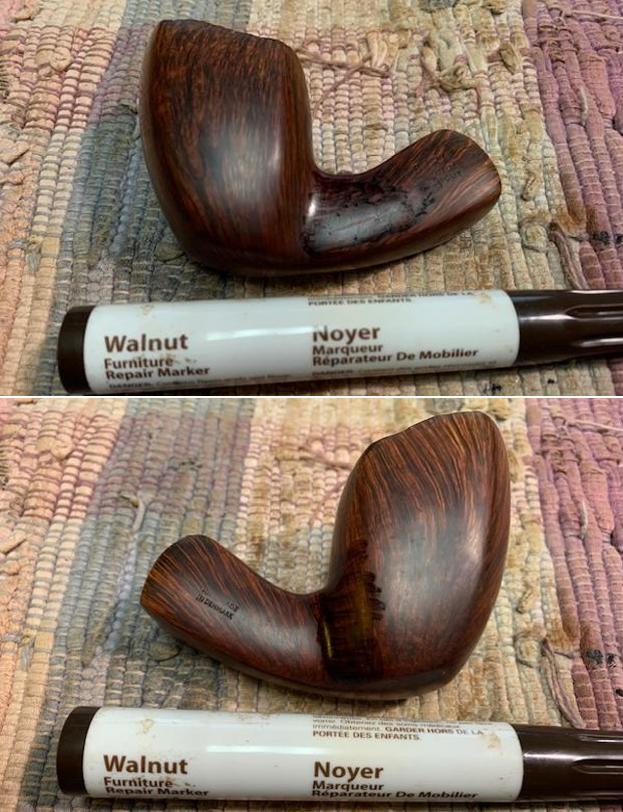

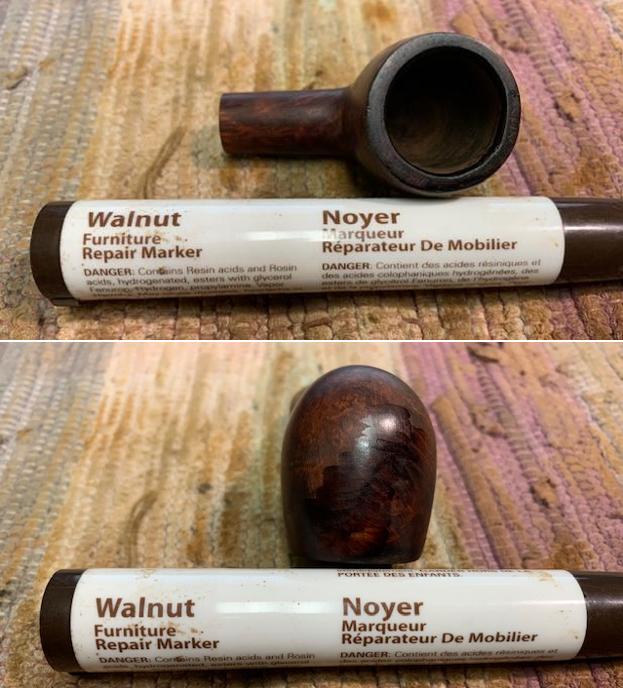

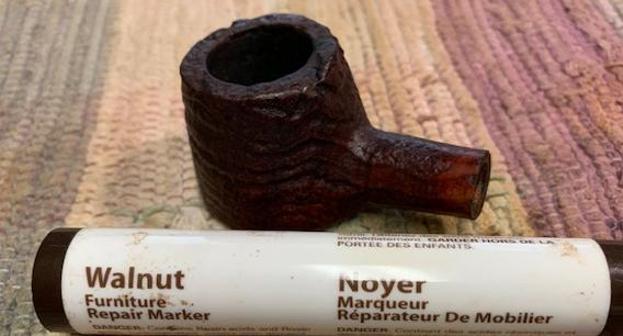

I removed the stem from the shank and took a photo of the pipe to give a sense of the whole. The first photo shows the stinger in the tenon and the second shows the stinger removed. I started working on the pipe by touching up the chipped area on the back outer edge of the rim top. The chipped area was not large and it could be blended in well with the surrounding sandblast. I stained it with a walnut stain pen and it looked good.

I started working on the pipe by touching up the chipped area on the back outer edge of the rim top. The chipped area was not large and it could be blended in well with the surrounding sandblast. I stained it with a walnut stain pen and it looked good.  I rubbed the bowl and shank down with Before & After Restoration Balm. I worked it into the surface of the bowl sides and shank with my fingertips to clean, enliven and protect the briar. I rubbed it into the vulcanite shank extension to we what it would do. I let the balm sit for 10 minutes, then buffed with a cotton cloth to raise the shine.

I rubbed the bowl and shank down with Before & After Restoration Balm. I worked it into the surface of the bowl sides and shank with my fingertips to clean, enliven and protect the briar. I rubbed it into the vulcanite shank extension to we what it would do. I let the balm sit for 10 minutes, then buffed with a cotton cloth to raise the shine.

I studied look of the bowl and shank and it appeared to me that the shank had been sanded down as there was a swale or dip between the shank end and the end of the blast. I put the stem back on the shank and took a few photos. The gap between the shank and the stem was also uneven. The more I looked the more I knew that it would look good with a thin band and the band would take care of the swale in the sanded part and the unevenness of the shank/stem joint.

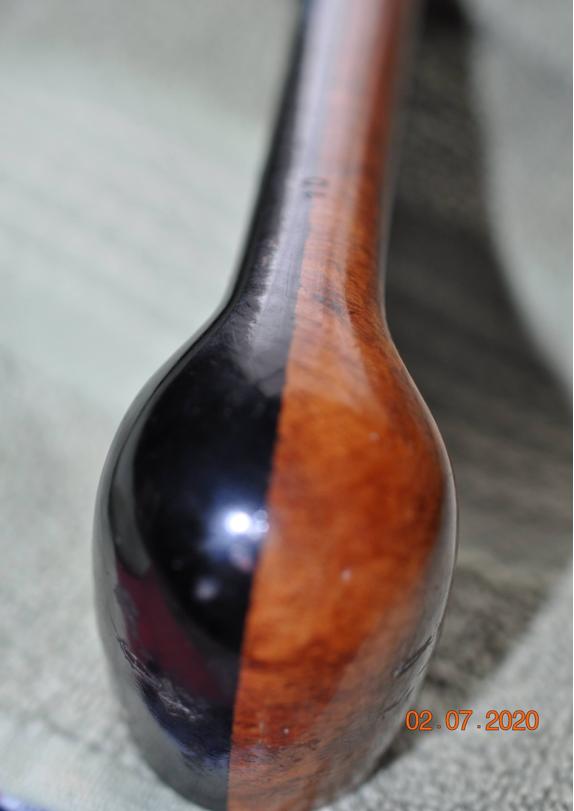

I studied look of the bowl and shank and it appeared to me that the shank had been sanded down as there was a swale or dip between the shank end and the end of the blast. I put the stem back on the shank and took a few photos. The gap between the shank and the stem was also uneven. The more I looked the more I knew that it would look good with a thin band and the band would take care of the swale in the sanded part and the unevenness of the shank/stem joint. The photos show the variation in the diameter of the shank and the poor fit of the stem. I was more convinced than ever than the band was a good option. I went through my bands and found one that was a perfect fit. It was going to be a cosmetic band rather than one to repair a cracked shank. I used a dental spatula to put a ring of all purpose glue on the shank end. I pressed the band into place and I liked the looks of it. I took photos of the looks of the banded shank.

The photos show the variation in the diameter of the shank and the poor fit of the stem. I was more convinced than ever than the band was a good option. I went through my bands and found one that was a perfect fit. It was going to be a cosmetic band rather than one to repair a cracked shank. I used a dental spatula to put a ring of all purpose glue on the shank end. I pressed the band into place and I liked the looks of it. I took photos of the looks of the banded shank.

I put the stem in place and took a photo of the new look of the pipe. I was liking what I saw as I look it over.

I put the stem in place and took a photo of the new look of the pipe. I was liking what I saw as I look it over.

I set the bowl aside and turned my attention to the stem. There was a large chip out of the stem on the right underside of the stem. I filled it in with clear CA glue and set it aside to cure. Once the repair had hardened I sanded it smooth with 220 grit sandpaper to blend it into the stem surface.

I set the bowl aside and turned my attention to the stem. There was a large chip out of the stem on the right underside of the stem. I filled it in with clear CA glue and set it aside to cure. Once the repair had hardened I sanded it smooth with 220 grit sandpaper to blend it into the stem surface. I touched up the stamp on the left side of the saddle stem with White Acrylic fingernail polish. I pressed it into the stamp with a tooth pick. Once it cured I polished off the excess with a 1500 grit micromesh pads. The stamping was too faint on the top portion of the C and the Circle to hold the acrylic but it is visible in person.

I touched up the stamp on the left side of the saddle stem with White Acrylic fingernail polish. I pressed it into the stamp with a tooth pick. Once it cured I polished off the excess with a 1500 grit micromesh pads. The stamping was too faint on the top portion of the C and the Circle to hold the acrylic but it is visible in person. I polished the stem with micromesh sanding pads – 1500-12000 grit pads. I wiped it down with Obsidian Oil after each sanding pad. I used Before & After Pipe Polish – both Fine and Extra Fine to further polish the stem. The photos below show the polished stem.

I polished the stem with micromesh sanding pads – 1500-12000 grit pads. I wiped it down with Obsidian Oil after each sanding pad. I used Before & After Pipe Polish – both Fine and Extra Fine to further polish the stem. The photos below show the polished stem.

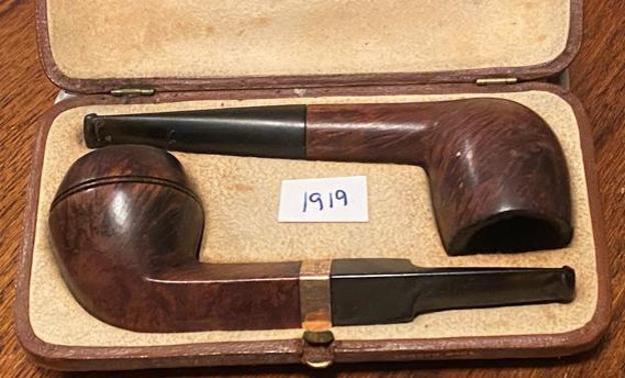

This sandblasted finish on this French Made Chatham Bruyere is beautiful. The volcano shape on the bowl and the flat bottom worked well to make it a great sitter that could be stationed next to a mug of coffee or a favourite drink while you work. The mixture of rich brown stains looked amazing and with the polishing it really came alive with buffing and waxing. I put the stem back on the shank and carefully buffed the pipe with Blue Diamond on the buffing wheel using a light touch on the briar. I gave the bowl multiple coats of Conservator’s Wax and the stem multiple coats of carnauba wax on the buffing wheel. I buffed the pipe with a clean buffing pad to raise the shine. I hand buffed the pipe with a microfiber cloth to deepen the shine. The finished Chatham Bruyere Volcano Sitter is a beauty and feels great in the hand and looks very good. Give the finished pipe a look in the photos below. The dimensions of the pipe are Length: 5 ¾ inches, Height: 1 ¼ inches, Outside diameter of the bowl: 1 ¼ inches, Chamber diameter: ¾ of an inch.The weight of the pipe is 1.20 ounces/34 grams. This pipe will soon be on the French Pipe Makers section of the rebornpipes store if you are interested in adding it to your rack. Thanks for reading this blog and my reflections on the pipe while I worked on it. There are many more to come!

This sandblasted finish on this French Made Chatham Bruyere is beautiful. The volcano shape on the bowl and the flat bottom worked well to make it a great sitter that could be stationed next to a mug of coffee or a favourite drink while you work. The mixture of rich brown stains looked amazing and with the polishing it really came alive with buffing and waxing. I put the stem back on the shank and carefully buffed the pipe with Blue Diamond on the buffing wheel using a light touch on the briar. I gave the bowl multiple coats of Conservator’s Wax and the stem multiple coats of carnauba wax on the buffing wheel. I buffed the pipe with a clean buffing pad to raise the shine. I hand buffed the pipe with a microfiber cloth to deepen the shine. The finished Chatham Bruyere Volcano Sitter is a beauty and feels great in the hand and looks very good. Give the finished pipe a look in the photos below. The dimensions of the pipe are Length: 5 ¾ inches, Height: 1 ¼ inches, Outside diameter of the bowl: 1 ¼ inches, Chamber diameter: ¾ of an inch.The weight of the pipe is 1.20 ounces/34 grams. This pipe will soon be on the French Pipe Makers section of the rebornpipes store if you are interested in adding it to your rack. Thanks for reading this blog and my reflections on the pipe while I worked on it. There are many more to come!