by Kenneth Lieblich

Next on the chopping block is a gorgeous example of a Danish freehand which I got from an older gentleman in Vancouver. I’ve had my eye on this one for a while because of its a beautiful plateau and wood grain, and I was looking forward to working on it.

This is a Consul De Luxe pipe and I am sorry to report that I have found very little on the origin of the Consul brand of pipes. There is no information to be had from the usual sources (Pipepedia, Pipephil, etc.), but Steve believes that Consul could have been made either by Preben Holm or Karl Erik – both esteemed names in Danish pipemaking. In any event, this pipe is clearly Danish, clearly well-made, and clearly a beautiful addition to anyone’s collection.

This is a Consul De Luxe pipe and I am sorry to report that I have found very little on the origin of the Consul brand of pipes. There is no information to be had from the usual sources (Pipepedia, Pipephil, etc.), but Steve believes that Consul could have been made either by Preben Holm or Karl Erik – both esteemed names in Danish pipemaking. In any event, this pipe is clearly Danish, clearly well-made, and clearly a beautiful addition to anyone’s collection.

The markings were clear enough. On the left-hand side of the shank, it said Consul [over] De Luxe [over] Special. On the right-hand side of the shank, it said Handcut. On the underside of the stummel, it read Made in Denmark. On the left side of the stem, there was a very thin, stylized capital “C”, which appeared to have been slightly worn.

The markings were clear enough. On the left-hand side of the shank, it said Consul [over] De Luxe [over] Special. On the right-hand side of the shank, it said Handcut. On the underside of the stummel, it read Made in Denmark. On the left side of the stem, there was a very thin, stylized capital “C”, which appeared to have been slightly worn.

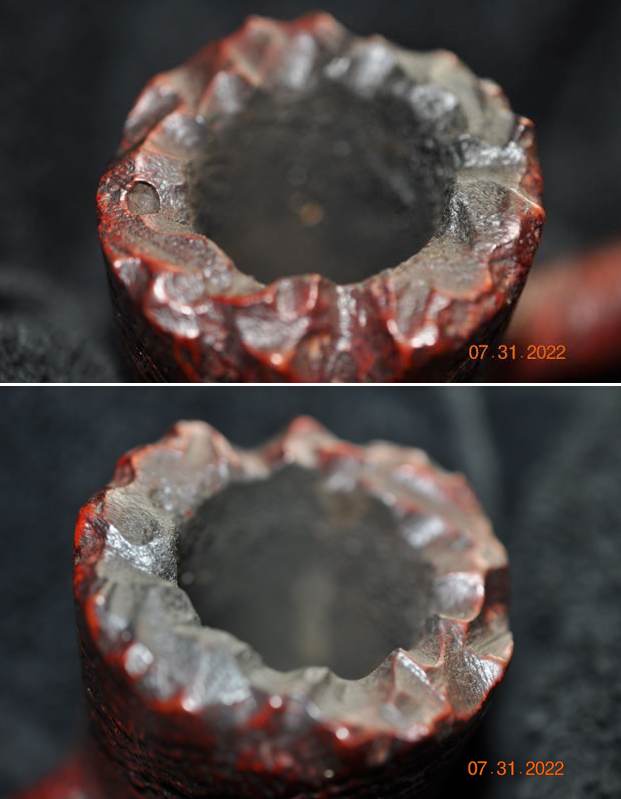

The condition was generally good, and it must have been a good smoker, because it was very well used. The stem was heavily oxidized and had some tooth marks. In addition, there was a strange residue scattered over the surface that was reminiscent of icing sugar – I have no idea what it was, but hopefully, it would come off during cleaning. The stummel was fine; there was some cake in the bowl, lava on the rim, and some dents, though no burn marks to speak of. However, the heel of the bowl was very narrow which made reaming a challenge.

The condition was generally good, and it must have been a good smoker, because it was very well used. The stem was heavily oxidized and had some tooth marks. In addition, there was a strange residue scattered over the surface that was reminiscent of icing sugar – I have no idea what it was, but hopefully, it would come off during cleaning. The stummel was fine; there was some cake in the bowl, lava on the rim, and some dents, though no burn marks to speak of. However, the heel of the bowl was very narrow which made reaming a challenge.

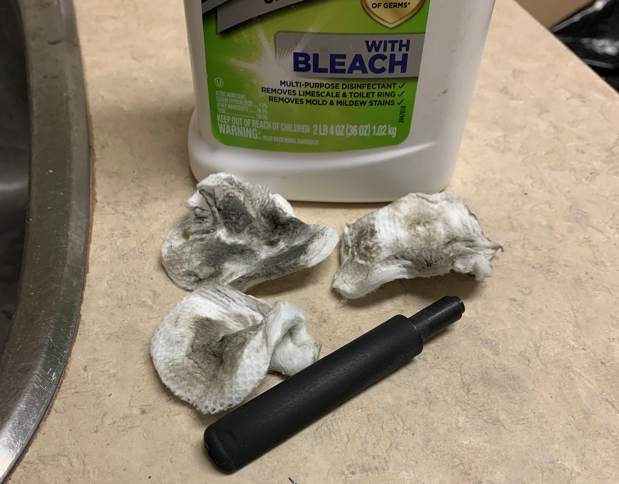

To work! The stem was so oxidized and filthy that I wiped it down with SoftScrub before soaking. Ultimately, I did send it for an overnight soak in the Pipe Stem Oxidation Remover.

To work! The stem was so oxidized and filthy that I wiped it down with SoftScrub before soaking. Ultimately, I did send it for an overnight soak in the Pipe Stem Oxidation Remover.

The following day, I cleaned the rest of the de-oxidizing mess off with alcohol, pipe cleaners, et cetera. The oxidation had migrated to the surface and would be fairly straightforward to remove. Again, I scrubbed with SoftScrub on some cotton pads to remove the leftover oxidation. Fortunately, that bizarre ‘icing-sugar’ stuff did come off without a problem.

The following day, I cleaned the rest of the de-oxidizing mess off with alcohol, pipe cleaners, et cetera. The oxidation had migrated to the surface and would be fairly straightforward to remove. Again, I scrubbed with SoftScrub on some cotton pads to remove the leftover oxidation. Fortunately, that bizarre ‘icing-sugar’ stuff did come off without a problem.  After this, I used some nail polish to restore the logo on the stem. I painted the area carefully and let it fully set before proceeding. Then, I built up the dents on the stem with black cyanoacrylate adhesive and let them fully cure.

After this, I used some nail polish to restore the logo on the stem. I painted the area carefully and let it fully set before proceeding. Then, I built up the dents on the stem with black cyanoacrylate adhesive and let them fully cure. Next, I sanded the adhesive down with 220- and 400-grit sandpapers to meld seamlessly into the stem. I then used all nine Micromesh pads (1,500 through 12,000 grit) to bring out the lovely black lustre on the stem. I also used Obsidian Pipe Stem Oil in between each pad scrubbing. As I surmised, the ‘C’ on the stem was not as robust as it had been in better days, but I managed to restore it nicely.

Next, I sanded the adhesive down with 220- and 400-grit sandpapers to meld seamlessly into the stem. I then used all nine Micromesh pads (1,500 through 12,000 grit) to bring out the lovely black lustre on the stem. I also used Obsidian Pipe Stem Oil in between each pad scrubbing. As I surmised, the ‘C’ on the stem was not as robust as it had been in better days, but I managed to restore it nicely.

Now for the stummel. Firstly, I reamed out the bowl. I used the PipNet Reamer to remove the built-up cake and followed that with 220-grit sandpaper taped to a dowel to eliminate as much as I could. I took the chamber down to bare briar, as I wanted to ensure there were no hidden flaws in the wall. Fortunately, there were none.

Now for the stummel. Firstly, I reamed out the bowl. I used the PipNet Reamer to remove the built-up cake and followed that with 220-grit sandpaper taped to a dowel to eliminate as much as I could. I took the chamber down to bare briar, as I wanted to ensure there were no hidden flaws in the wall. Fortunately, there were none.

I then proceeded to clean out the insides with Q-tips, pipe cleaners, and lemon-infused isopropyl alcohol. There was a bit of filth inside this stummel and it took some cotton to get it clean. I followed that up by cleaning the insides with some dish soap and tube brushes. I used cotton rounds and some Murphy’s Oil Soap to scrub the outside of the stummel and a toothbrush with Murphy’s on the rugged plateau of the pipe. A toothbrush gets into the grooves of the wood more easily.

I then proceeded to clean out the insides with Q-tips, pipe cleaners, and lemon-infused isopropyl alcohol. There was a bit of filth inside this stummel and it took some cotton to get it clean. I followed that up by cleaning the insides with some dish soap and tube brushes. I used cotton rounds and some Murphy’s Oil Soap to scrub the outside of the stummel and a toothbrush with Murphy’s on the rugged plateau of the pipe. A toothbrush gets into the grooves of the wood more easily.  Next, I decided to de-ghost the pipe in order to remove any lingering smells of the past. I thrust cotton balls into the bowl and the shank and saturated them with 99% isopropyl alcohol. I let the stummel sit overnight. This caused any remaining oils, tars and smells to leach out into the cotton. The bowl was nice and clean after this. You can see the before and after photos – it needed a de-ghosting!

Next, I decided to de-ghost the pipe in order to remove any lingering smells of the past. I thrust cotton balls into the bowl and the shank and saturated them with 99% isopropyl alcohol. I let the stummel sit overnight. This caused any remaining oils, tars and smells to leach out into the cotton. The bowl was nice and clean after this. You can see the before and after photos – it needed a de-ghosting!

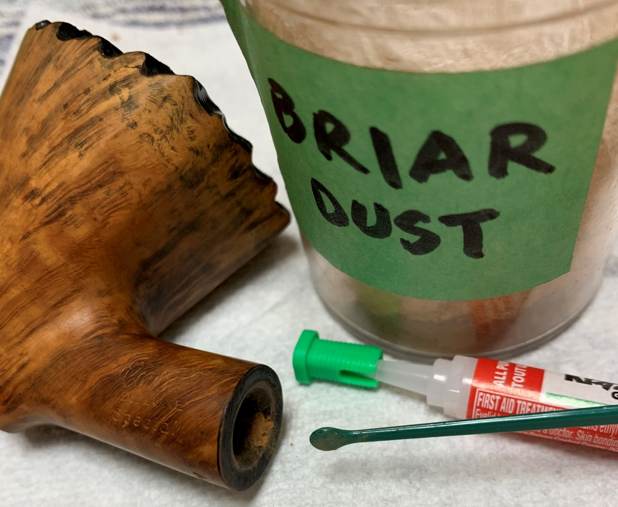

But wait! I had missed something. Inside the shank, there was a small gouge – no idea how it got there – but I felt it needed to be repaired. It’s difficult to make out, but I’ve pointed it out in the photograph. Similar to other blemishes, I filled this gouge with cyanoacrylate adhesive and briar dust. Once it had cured, I sanded it down and voilà! Problem solved.

But wait! I had missed something. Inside the shank, there was a small gouge – no idea how it got there – but I felt it needed to be repaired. It’s difficult to make out, but I’ve pointed it out in the photograph. Similar to other blemishes, I filled this gouge with cyanoacrylate adhesive and briar dust. Once it had cured, I sanded it down and voilà! Problem solved.

Finally, I used all nine Micromesh pads (1,500 through 12,000 grit) on the stummel to make it lovely and smooth. After that, a light application of Before & After Restoration Balm brought out the best in the stummel’s grain.

Finally, I used all nine Micromesh pads (1,500 through 12,000 grit) on the stummel to make it lovely and smooth. After that, a light application of Before & After Restoration Balm brought out the best in the stummel’s grain.

This is a very elegant Danish pipe. At the buffer, a dose of White Diamond and a few coats of carnauba wax were just what this pipe needed. However, on the rugged plateau, I used Clapham’s Beeswax Salad Bowl Finish, as carnauba wax will get gummed up in the crevices of the wood. I applied the beeswax finish with my fingers and used a horsehair brush to buff it.

This is a very elegant Danish pipe. At the buffer, a dose of White Diamond and a few coats of carnauba wax were just what this pipe needed. However, on the rugged plateau, I used Clapham’s Beeswax Salad Bowl Finish, as carnauba wax will get gummed up in the crevices of the wood. I applied the beeswax finish with my fingers and used a horsehair brush to buff it.

This Consul Freehand looks fantastic again and is ready to be enjoyed again by the next owner! It is a gorgeous pipe and will make a fantastic smoker. I am pleased to announce that this pipe is for sale! If you are interested in acquiring it for your collection, please have a look in the ‘Danish’ Pipe Makers Section of the rebornpipes store here on Steve’s website. You can also email me directly at kenneth@knightsofthepipe.com. The approximate dimensions of the pipe are as follows: length 5¾ in. (146 mm); height 2⅜ in. (60 mm); bowl diameter 1⅝ x 2 in. (41 x 51 mm); chamber diameter ¾ in. (19 mm). The weight of the pipe is 1⅞ oz. (56 g). I hope you enjoyed reading the story of this pipe’s restoration as much as I did restoring it. If you are interested in more of my work, please follow me here on Steve’s website or send me an email. Thank you very much for reading and, as always, I welcome and encourage your comments.

This Consul Freehand looks fantastic again and is ready to be enjoyed again by the next owner! It is a gorgeous pipe and will make a fantastic smoker. I am pleased to announce that this pipe is for sale! If you are interested in acquiring it for your collection, please have a look in the ‘Danish’ Pipe Makers Section of the rebornpipes store here on Steve’s website. You can also email me directly at kenneth@knightsofthepipe.com. The approximate dimensions of the pipe are as follows: length 5¾ in. (146 mm); height 2⅜ in. (60 mm); bowl diameter 1⅝ x 2 in. (41 x 51 mm); chamber diameter ¾ in. (19 mm). The weight of the pipe is 1⅞ oz. (56 g). I hope you enjoyed reading the story of this pipe’s restoration as much as I did restoring it. If you are interested in more of my work, please follow me here on Steve’s website or send me an email. Thank you very much for reading and, as always, I welcome and encourage your comments.