Blog by Steve Laug

In January Jeff found out about an estate sale in Pocatello, Idaho, USA. It turned out that the sale was for a fellow Jeff and I had purchased pipes from in the past, Gene. He had been the owner of Outwest Tobacco in Pocatello (long closed now) and I bought tobacco and other smoking items from him in the past. As I think about it now, it seems that I had known Gene for over 30 years Jeff and I had been to his home and enjoyed coffee and a few pipes together. I have no idea how many pipes we bought on those visits as well as to the antique shop of his daughter. I know that there were many pipes. When we heard that it was Gene’s personal collection that was for sale and that he had passed away we decided for Jeff to go to the house and have a look. He went on January 25, 2024 to scope it out as we had seen his personal collection of pipes and there were definitely some among those well smoked old warriors that would be great to pick up. Perhaps there would even be one that could join my own collection in memory of Gene.

In January Jeff found out about an estate sale in Pocatello, Idaho, USA. It turned out that the sale was for a fellow Jeff and I had purchased pipes from in the past, Gene. He had been the owner of Outwest Tobacco in Pocatello (long closed now) and I bought tobacco and other smoking items from him in the past. As I think about it now, it seems that I had known Gene for over 30 years Jeff and I had been to his home and enjoyed coffee and a few pipes together. I have no idea how many pipes we bought on those visits as well as to the antique shop of his daughter. I know that there were many pipes. When we heard that it was Gene’s personal collection that was for sale and that he had passed away we decided for Jeff to go to the house and have a look. He went on January 25, 2024 to scope it out as we had seen his personal collection of pipes and there were definitely some among those well smoked old warriors that would be great to pick up. Perhaps there would even be one that could join my own collection in memory of Gene.

Jeff went to the house and looked through the racks, pipe bags, tobacco both bulk and tinned as well as a variety of pipes. All the pipes were well smoked and needed serious cleaning. Another one of the pipes he picked up was this Savinelli Made Bings Favorite pipes with a poorly fit replacement black vulcanite taper stem. It was very dirty and was a reddish, brown coloured pipe when it started. The smooth finish around the bowl was dirty and had hand oils ground into the grooves. The bowl had a thick cake that overflowed in lava onto the rim edge and top of the bowl. The bottom of the bowl was flattened so the pipe could be set on a desktop. The stem was vulcanite that was very dirty and had the marks of a rubber Softee Bit on the end. It had become discoloured and there was a line where the debris from smoking had accumulated along the edge and under the bit protector. The good news was that there were some deep tooth marks and chatter under the calcification and grime. The rest of the stem was dirty and had lost the characteristic shine. The pipe was stamped on the left side of the shank and read Bings Favorite. On the right side of the shank it is stamped Italy. On the underside of the shank it was stamped Savinelli Product. Jeff took photos of the pipe so I could have a sense of what it looked like before he started his work on it. Jeff took photos of the stem surfaces and the bowl and rim to give a sense of condition of the pipe. You can see the thick cake in bowl and the spots of lava overflow on the edges and rim top of the bowl. It is had to know if there is any damage as the cake and lava is quite thick. The stem surface is very dirty and you can see the area on the end of the stem where the Softee Bit had protected it from chewing though there were some previous deep tooth marks covered by the dirt and debris. I am pretty sure the stem was a replacement and it did not fit the diameter of the shank properly. It was larger than the shank and would need to be fitted.

Jeff took photos of the stem surfaces and the bowl and rim to give a sense of condition of the pipe. You can see the thick cake in bowl and the spots of lava overflow on the edges and rim top of the bowl. It is had to know if there is any damage as the cake and lava is quite thick. The stem surface is very dirty and you can see the area on the end of the stem where the Softee Bit had protected it from chewing though there were some previous deep tooth marks covered by the dirt and debris. I am pretty sure the stem was a replacement and it did not fit the diameter of the shank properly. It was larger than the shank and would need to be fitted.

He also took photos of the sides of the bowl and the heel to show the interesting grain that went around the bowl. The grain is beautiful and you can see the oils and debris in the surface of the briar.

He also took photos of the sides of the bowl and the heel to show the interesting grain that went around the bowl. The grain is beautiful and you can see the oils and debris in the surface of the briar.

He took photos of the stamping on the sides of the shank. It is clear and readable on all the shank sides as noted above.

He took photos of the stamping on the sides of the shank. It is clear and readable on all the shank sides as noted above.

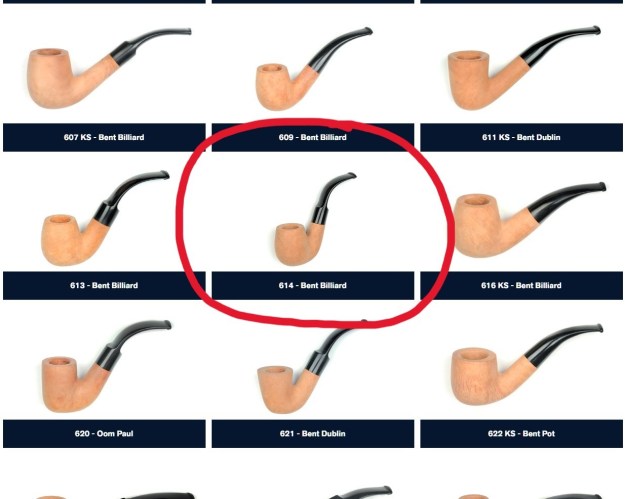

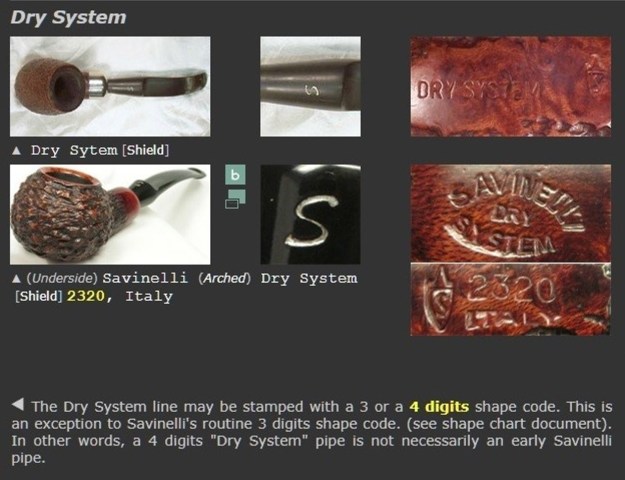

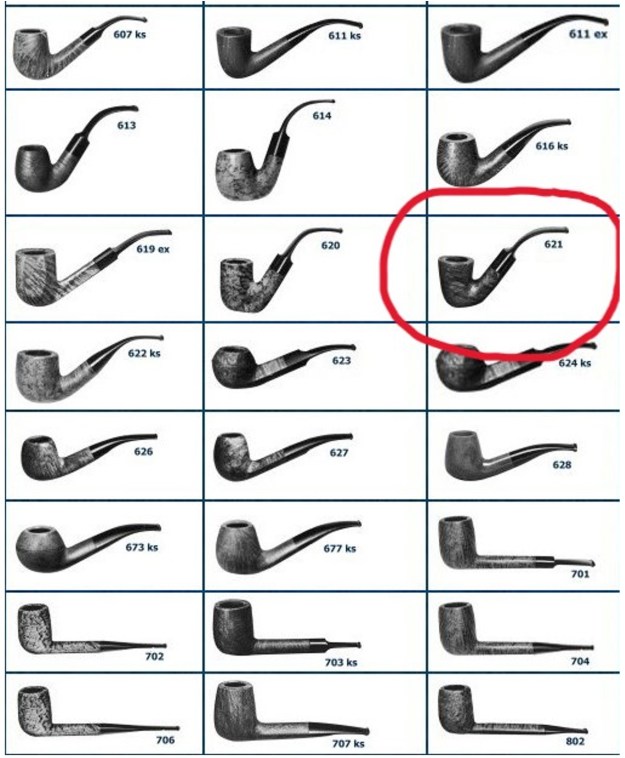

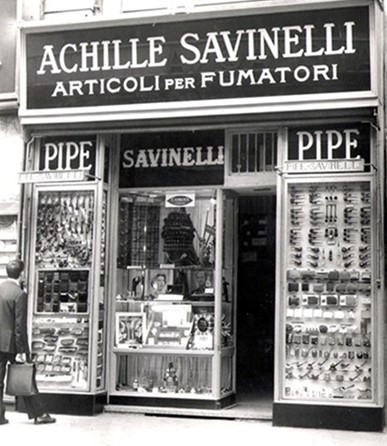

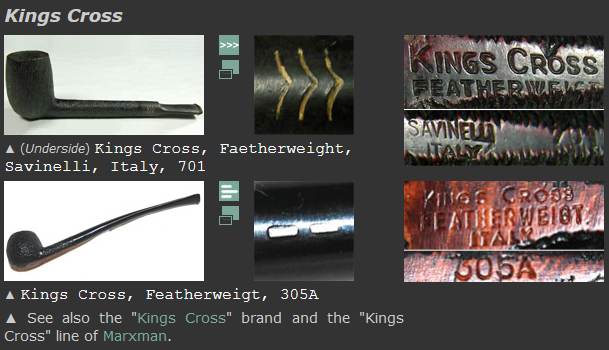

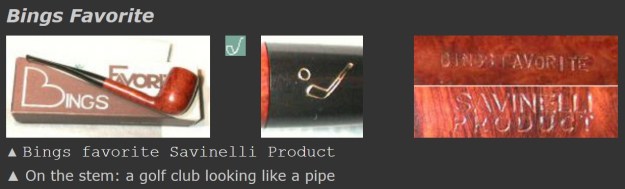

I turned to Pipephil’s site (http://www.pipephil.eu/logos/en/logo-savinelli1.html) to get a sense of the Bing’s Favorite. It is a Savinelli Product and it is listed in the Savinelli pipe section. I did a screen capture of the section and included it below. The stamping on the stem confirms that the stem I have is a replacement.

I turned to Pipephil’s site (http://www.pipephil.eu/logos/en/logo-savinelli1.html) to get a sense of the Bing’s Favorite. It is a Savinelli Product and it is listed in the Savinelli pipe section. I did a screen capture of the section and included it below. The stamping on the stem confirms that the stem I have is a replacement. I turned to Pipedia (https://pipedia.org/wiki/Savinelli) and after reading through the history I focused on a section entitled Editions in the “Favorite” line. I have included that section below.

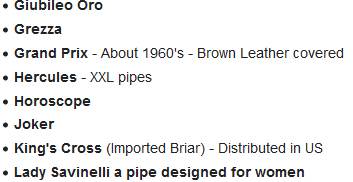

I turned to Pipedia (https://pipedia.org/wiki/Savinelli) and after reading through the history I focused on a section entitled Editions in the “Favorite” line. I have included that section below.

We are compiling a sub-list of known editions in the “Favorite” line of Savanelli pipes, starting with those in Fred Huening’s collection. If you know of others, or have additional information about this line of pipes, please add it here, or send them to sethile.pipes@gmail.com and we can add them for you:

- Bing’s Favorite

- Byron’s Favorite

- Clark’s Favorite

- Ginger’s Favorite

- Achille’s Favorite (apparently, I, II, and III)

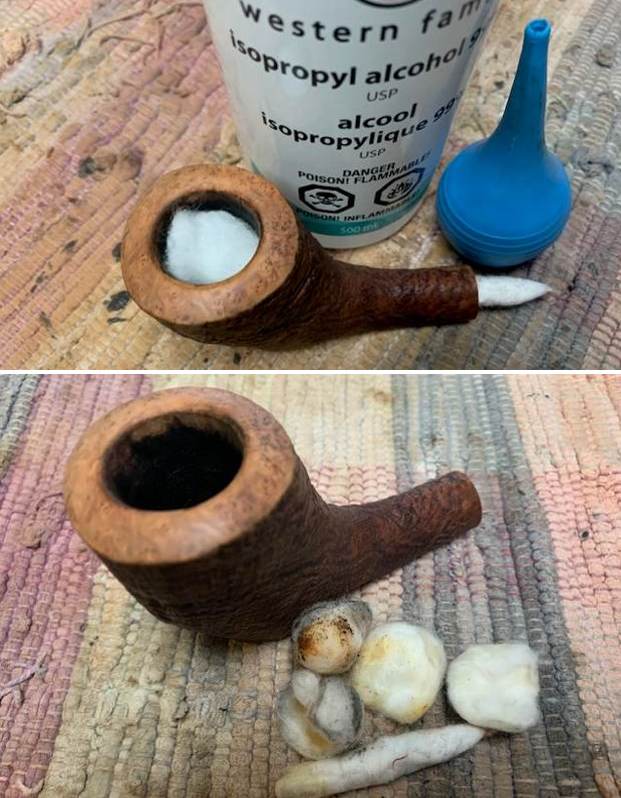

Now it was my turn to work on the pipe. Jeff had done an amazing cleanup of the pipe. He reamed the cake with a PipNet reamer and cleaned up that with a Savinelli Fitsall Pipe Knife. He scrubbed the internals of the bowl and stem with alcohol, cotton swabs and pipe cleaners. He scrubbed the externals with undiluted Murphy’s Oil Soap and rinsed the bowl off with running water. He soaked the stem in Briarville’s Pipe stem Deoxidizer and once it had soaked, rinsed it off with warm water to remove the residual solution. He dried it off and rubbed it down to remove any oxidation that was still on the stem. The pipe looked very good when I received it.

I took a photo of the rim top to show the condition. You can see the clean bowl. The bowl is in excellent condition and is clean. The rim top and the front inner edge was in great condition. The stem came out looking clean. There were definitely deep tooth marks and chatter on both sides.

I took a photo of the rim top to show the condition. You can see the clean bowl. The bowl is in excellent condition and is clean. The rim top and the front inner edge was in great condition. The stem came out looking clean. There were definitely deep tooth marks and chatter on both sides.  I took photos of the stamping on the shank. It is faint but still very readable. I removed the stem from the shank and took a photo of the pipe parts to show what I was working with.

I took photos of the stamping on the shank. It is faint but still very readable. I removed the stem from the shank and took a photo of the pipe parts to show what I was working with.

The pipe had cleaned up so well that I turned to polish the briar with micromesh sanding pads. I dry sanded it with 1500-12000 grit sanding pads and wiped the bowl down after each pad with a damp cloth. By the final pads the briar really had a shine.

The pipe had cleaned up so well that I turned to polish the briar with micromesh sanding pads. I dry sanded it with 1500-12000 grit sanding pads and wiped the bowl down after each pad with a damp cloth. By the final pads the briar really had a shine.

I rubbed the briar down with Before & After Restoration Balm. I worked it into the briar with my fingertips. The product works to clean, enliven and preserve the briar. I let it sit for 10 minutes then I buffed it with a cotton cloth to deepen the shine. The briar really comes alive with the balm.

I rubbed the briar down with Before & After Restoration Balm. I worked it into the briar with my fingertips. The product works to clean, enliven and preserve the briar. I let it sit for 10 minutes then I buffed it with a cotton cloth to deepen the shine. The briar really comes alive with the balm.

I set aside the bowl and turned my attention to the stem. I “painted” the stem surface with the flame of a lighter. I was able to lift the tooth marks significantly. There were still some deep marks. I filled them in with a coat of clear CA glue and spread it across the surface with a dental spatula.

I set aside the bowl and turned my attention to the stem. I “painted” the stem surface with the flame of a lighter. I was able to lift the tooth marks significantly. There were still some deep marks. I filled them in with a coat of clear CA glue and spread it across the surface with a dental spatula.

Once the repairs cured I flattened them with a small file. I started the process of blending them into the surface of the surrounding vulcanite.

Once the repairs cured I flattened them with a small file. I started the process of blending them into the surface of the surrounding vulcanite. Once I finished that work I addressed the diameter of the stem. I needed to take off the excess so that the flow between the shank and the stem were smooth. I used a flat rasp to quickly remove the excess then sanded it with 220 grit sandpaper to clean up the file marks and smooth out the surface of the stem.

Once I finished that work I addressed the diameter of the stem. I needed to take off the excess so that the flow between the shank and the stem were smooth. I used a flat rasp to quickly remove the excess then sanded it with 220 grit sandpaper to clean up the file marks and smooth out the surface of the stem.

I moved on to further smooth out the surface of the vulcanite. I sanded it smooth with 320-3500 grit sanding pads to further blend them into the surface of the stem.

I moved on to further smooth out the surface of the vulcanite. I sanded it smooth with 320-3500 grit sanding pads to further blend them into the surface of the stem. I polished the vulcanite with micromesh sanding pads – 1500-12000 grit pads. I wiped it down with Obsidian Oil after each sanding pad. I used Before & After Pipe Polish – both Fine and Extra Fine to further polish the stem. It really took on a shine and I knew that once it was buffed it would look amazing.

I polished the vulcanite with micromesh sanding pads – 1500-12000 grit pads. I wiped it down with Obsidian Oil after each sanding pad. I used Before & After Pipe Polish – both Fine and Extra Fine to further polish the stem. It really took on a shine and I knew that once it was buffed it would look amazing.

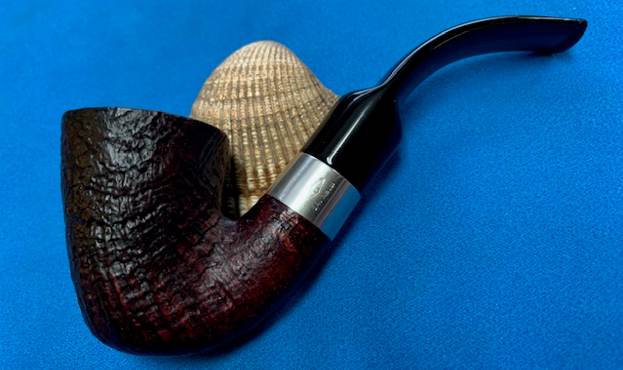

I put the stem back on the Bings Favorite ¼ Bent Vulcanite Stem Long Billiard and took it to the buffer. I worked it over with Blue Diamond to polish out the remaining small scratches. I gave the bowl and the stem several coats of carnauba wax and buffed the pipe with a clean buffing pad to raise the shine. I hand buffed it with a microfiber cloth to deepen the shine. The pipe polished up really well and the rim top looked good. I was happy with the look of the finished pipe. The photos below show what the pipe looks like after the restoration. The Bings Favorite Savinelli Product is a beautiful and unique take on a classic shape. The polished, reshaped vulcanite taper stem looks really good with the browns of the briar. The dimensions of the pipe are Length: 6 ½ inches, Height: 1 ¾ inches, Outside diameter of the bowl: 1 ¼ inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 1.23 ounces/35 grams. This is another pipe that I will be putting it on the rebornpipes store in the Italian Pipe Makers Section shortly, if you are interested in adding it to your collection. The long shank and tall bowl look and feel great in the hand. This one should be a great smoker. Thanks for walking through the restoration with me on this beauty!

I put the stem back on the Bings Favorite ¼ Bent Vulcanite Stem Long Billiard and took it to the buffer. I worked it over with Blue Diamond to polish out the remaining small scratches. I gave the bowl and the stem several coats of carnauba wax and buffed the pipe with a clean buffing pad to raise the shine. I hand buffed it with a microfiber cloth to deepen the shine. The pipe polished up really well and the rim top looked good. I was happy with the look of the finished pipe. The photos below show what the pipe looks like after the restoration. The Bings Favorite Savinelli Product is a beautiful and unique take on a classic shape. The polished, reshaped vulcanite taper stem looks really good with the browns of the briar. The dimensions of the pipe are Length: 6 ½ inches, Height: 1 ¾ inches, Outside diameter of the bowl: 1 ¼ inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 1.23 ounces/35 grams. This is another pipe that I will be putting it on the rebornpipes store in the Italian Pipe Makers Section shortly, if you are interested in adding it to your collection. The long shank and tall bowl look and feel great in the hand. This one should be a great smoker. Thanks for walking through the restoration with me on this beauty!